Protective coating for inhibiting platinum bushing from being oxidized and volatilized, and manufacturing method and application thereof

A protective coating, oxidative volatilization technology, used in alkali metal silicate coatings, coatings, manufacturing tools, etc., can solve problems such as volatilization cannot be well protected, bushings cannot heal themselves, and platinum bushings cannot be protected. , to achieve the effect of enhancing air tightness and chemical stability, perfect matching of expansion coefficient, and short cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

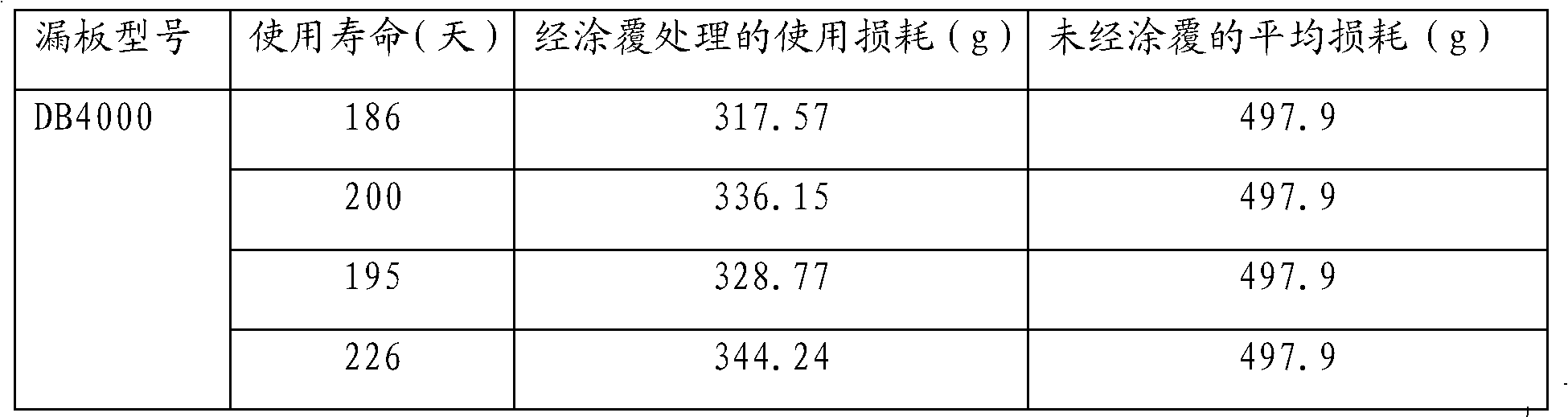

Examples

Embodiment 1

[0038] The making of embodiment 1 coating

[0039] A protective coating, the main raw materials of which are: 200g of silicon oxide, 450g of aluminum oxide, 50g of sodium silicate, 250g of sodium tetraborate, and 5g of thermoplastic phenolic resin as a binder.

[0040] The production process of the protective coating includes the following processes:

[0041] ①. Mix the main raw material components according to the ratio, and grind until all of them pass through the 200-mesh sieve;

[0042] 2. Add thermoplastic phenolic resin powder and water accounting for about 40% of the total weight to the ground material in step 1, stir and mix evenly, wherein the thermoplastic phenolic resin powder can all pass through a 200-mesh sieve;

[0043] ③. Heating step ② Mix the material until it reaches a temperature of about 120°C and keep stirring until it becomes viscous.

Embodiment 2

[0044] The making of embodiment 2 coating

[0045] A protective coating, the main raw materials of which are: 500g of silicon oxide, 200g of aluminum oxide, 150g of sodium silicate, 100g of sodium tetraborate, and 10g of thermoplastic phenolic resin.

[0046] The manufacturing process of this protective paint is the same as embodiment 1.

Embodiment 3

[0047] The making of embodiment 3 coating

[0048] A protective coating, the main raw materials of which are: 400g of silicon oxide, 350g of aluminum oxide, 80g of sodium silicate, 160g of sodium tetraborate, and 8g of thermoplastic phenolic resin.

[0049] The manufacturing process of this protective paint is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com