Self-repairing low-modulus high-strength waterborne polyurethane and preparation method thereof

A water-based polyurethane self-healing technology, applied in the field of water-based polyurethane, can solve problems affecting safety and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

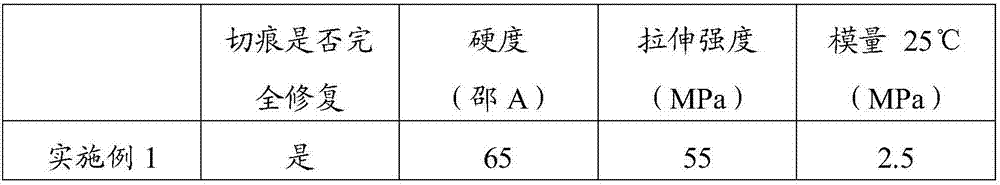

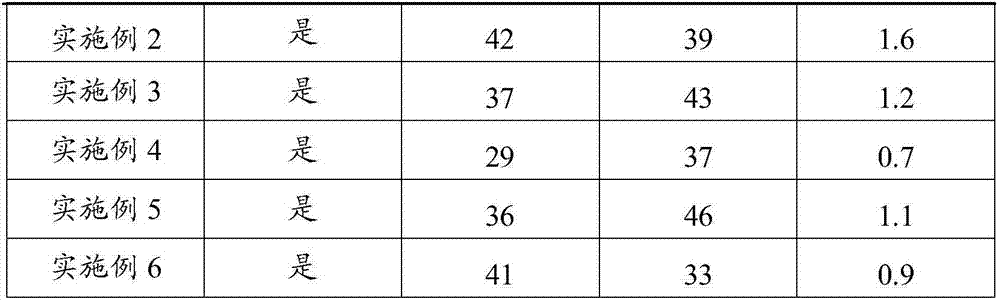

Examples

preparation example Construction

[0022] The present invention provides a kind of preparation method of self-healing low-modulus high-strength waterborne polyurethane, comprising the following steps:

[0023] a) React macromolecular diol I, macromolecular polyol II and diisocyanate at 90-100°C for 2-4 hours to obtain polyurethane prepolymer a 1 ; Macromolecular diol I is the polyester diol obtained by esterification of disulfide and adipate;

[0024] B) to the polyurethane prepolymer a that step a) obtains 1 Add small molecule chain extender, hydrophilic chain extender I, solvent, catalyst, and react at 60-80°C for 4-7 hours to obtain water-based polyurethane prepolymer a 2 ;

[0025] c) to the aqueous polyurethane prepolymer a that step b) obtains 2 Add solvent and hydrophilic chain extender II to the mixture, and react at 50-60°C for 0.5-1h to obtain water-based polyurethane prepolymer a 3 ;

[0026] d) to the water-based polyurethane prepolymer a obtained in step c) 3 Add solvent in the medium, add sa...

Embodiment 1

[0051] a) The macromolecular diol I with a relative molecular weight of 1000, polytetrahydrofuran diol and isophorone diisocyanate with a relative molecular weight of 2000 were reacted at 90° C. for 4 hours to obtain polyurethane prepolymer a 1 ; Macromolecular diol I is the polyester diol obtained by esterification of 2-hydroxyethyl disulfide and adipate;

[0052] B) to the polyurethane prepolymer a that step a) obtains 1 Add 1,2-propanediol, dimethylolpropionic acid, acetone, and stannous octoate to the mixture, and react at 60°C for 7 hours to obtain water-based polyurethane prepolymer a 2 ;

[0053] c) to the aqueous polyurethane prepolymer a that step b) obtains 2 Add acetone and sodium ethylenediamine sulfonate to the mixture, and react at 50°C for 1 hour to obtain the water-based polyurethane prepolymer a 3 ;

[0054] d) to the water-based polyurethane prepolymer a obtained in step c) 3 Add methyl ethyl ketone, add N, N dimethylethanolamine under high-speed shearin...

Embodiment 2

[0058] a) React macromolecular diol I with a relative molecular weight of 2000, polytetrahydrofuran diol with a relative molecular weight of 3000, and 4,4'-dicyclohexylmethane diisocyanate at 100°C for 2 hours to obtain polyurethane prepolymer a 1 ; Macromolecular diol I is the polyester diol obtained by esterification of 2-hydroxyethyl disulfide and adipate;

[0059] B) to the polyurethane prepolymer a that step a) obtains 1 Add 2-methyl-1,3-propanediol, dimethylolbutyric acid, butanone, n-butyltin dilaurate, and react at 80°C for 4 hours to obtain water-based polyurethane prepolymer a 2 ;

[0060] c) to the aqueous polyurethane prepolymer a that step b) obtains 2 Add acetone and sodium ethylenediamine sulfonate to the mixture, and react at 60°C for 0.5h to obtain the water-based polyurethane prepolymer a 3 ;

[0061] d) to the water-based polyurethane prepolymer a obtained in step c) 3 Add acetone, add sodium hydroxide under high-speed shearing, stir for 1 minute, add w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com