Magnetically-induced heating self-repairing thermoplastic nanocomposite material

A self-healing, thermoplastic polymer technology, applied in the field of thermoplastic polymer products, thermoplastic polymer products self-healing, can solve the problems of material properties that need to be improved, and achieve the effect of improving the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

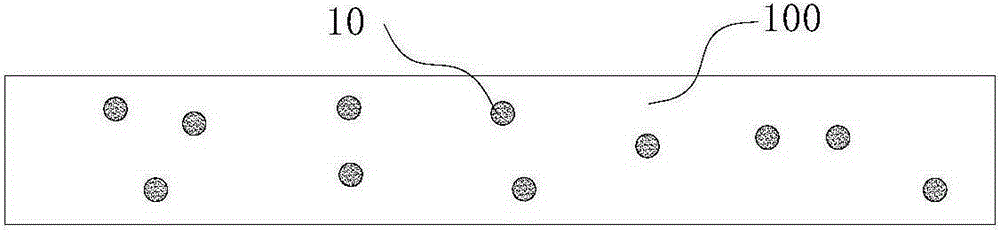

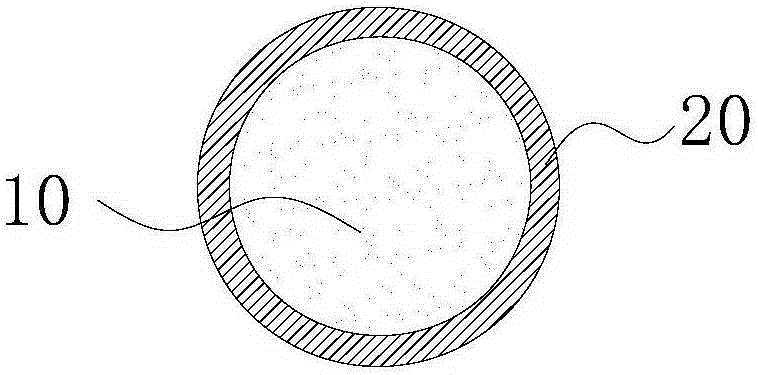

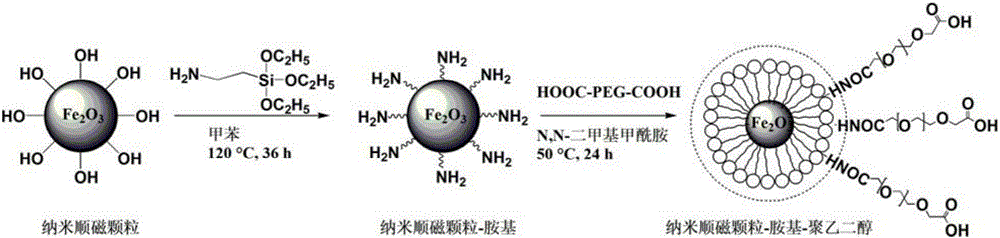

[0026] The following describes in detail the embodiments of the present invention, examples of which are illustrated in the accompanying drawings. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention and should not be construed as limiting the present invention.

[0027] The present invention is achieved based on the following findings of the inventors:

[0028] In recent years, polymer-based composite materials with self-healing function are difficult to meet the requirements of material life, durability, anti-intrusion and other properties and capabilities in various fields of engineering, so they cannot be widely used. The inventors have found through in-depth research that this is because most of the above polymers are formed on the basis of polymer materials with reversible chemical bonds. For example, using hydrogen bonds, reversible covalent bonds (such as Diels-Alder reaction), ion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com