Light oil polluted unsaturated zone soil in-situ remediation apparatus and method thereof

An in-situ remediation and contaminated soil technology, applied in the restoration of contaminated soil, etc., can solve the problems of complex ground treatment system and excessive remediation function of light oil-contaminated soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

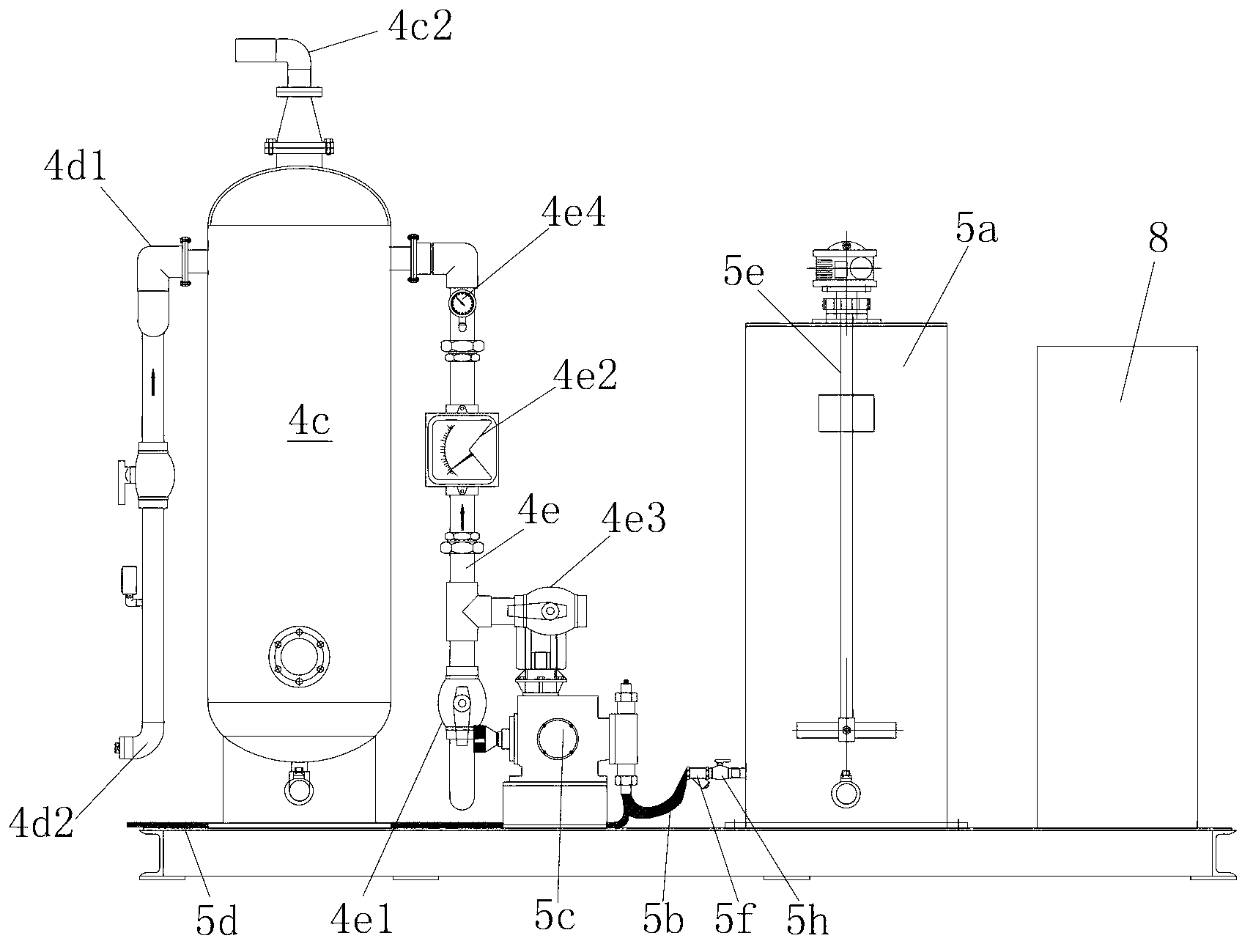

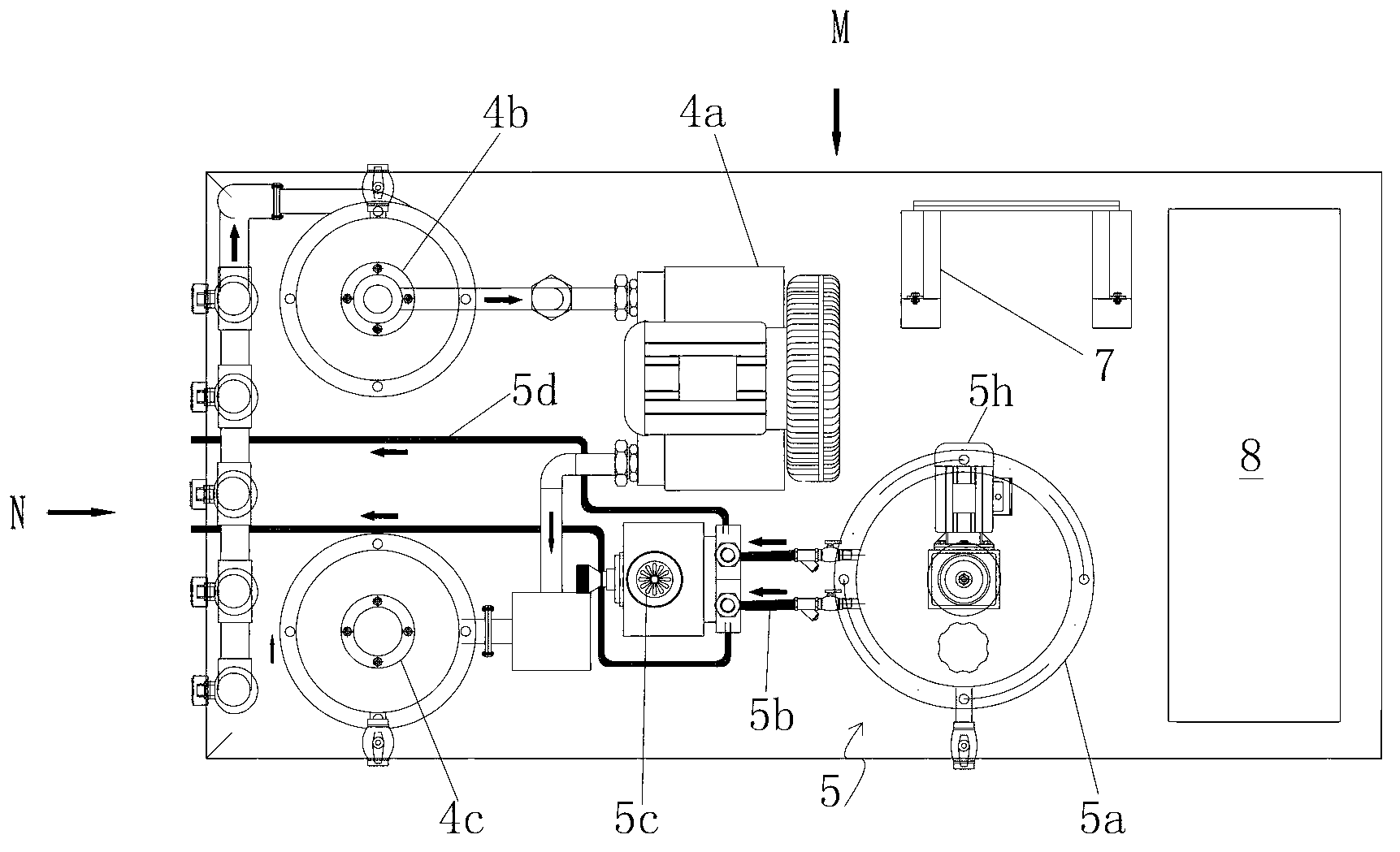

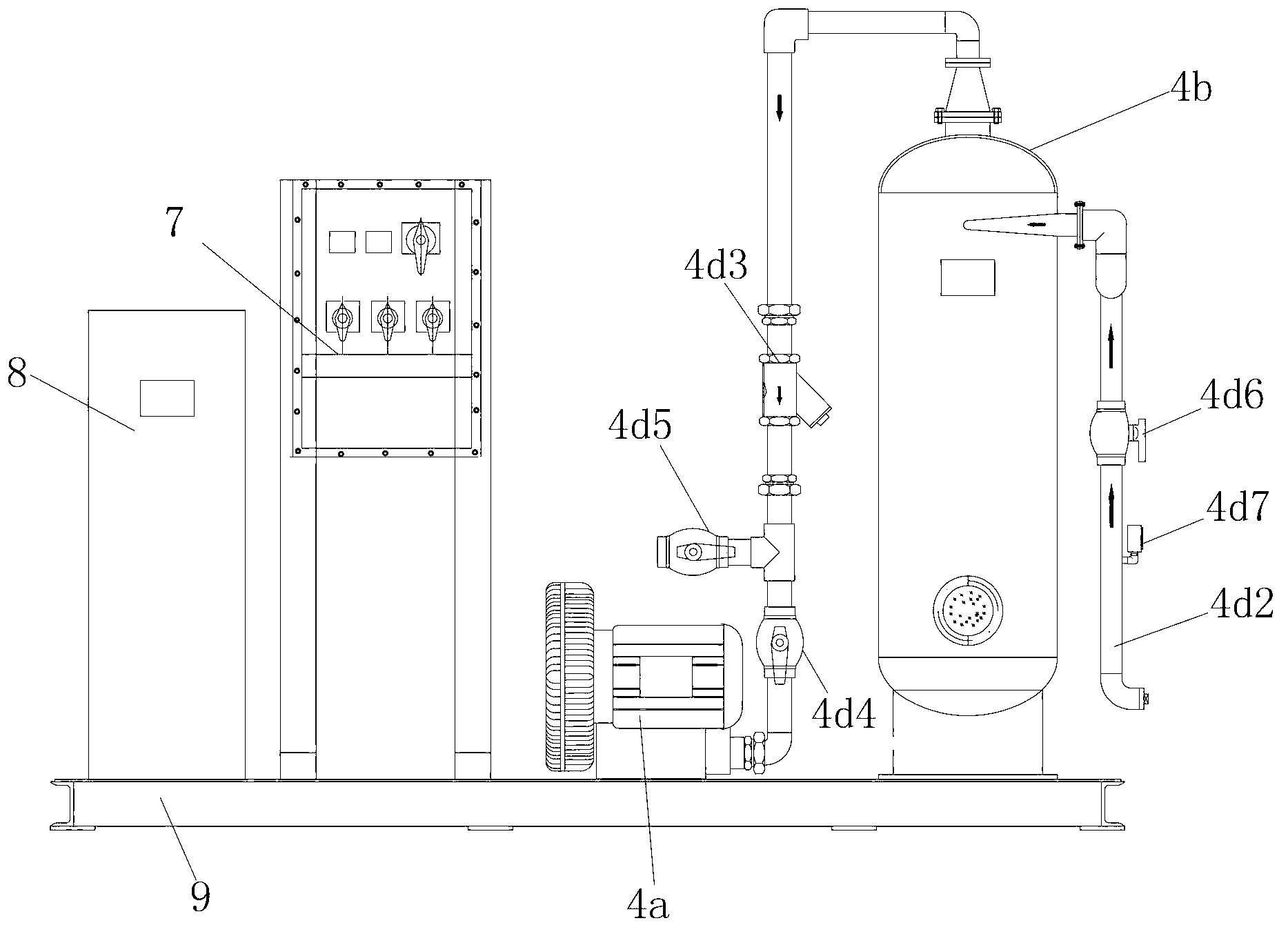

[0041] Such as Figure 1 to Figure 4 As shown, the embodiment of the present invention proposes an in-situ remediation device for light oil-contaminated soil, which includes a well group system, a soil suction system and a microbial remediation system. The well group system includes a suction well and a liquid injection well, the suction well 1 has a suction well head, and the liquid injection well 2 has a liquid injection well head, and the suction well head and the liquid injection well head are both 3 for the multifunctional well head. The soil suction system 4 includes a vortex vacuum pump 4a, an oil-gas separator 4b and an oil-gas adsorber 4c, the oil-gas separator 4b has a separation inlet pipe 4b1 and a separation air outlet pipe 4b2, and the oil-gas adsorber 4c has an adsorption inlet pipe 4c1 and adsorption air outlet pipe 4c2, the separated air inlet pipe 4b1 is connected to the suction well head through the suction pipe group 4d, the separated air outlet pipe 4b2 i...

Embodiment approach 2

[0067] A method for in-situ remediation of light oil-contaminated soil, said method comprising the steps of:

[0068] A. According to the on-site geological conditions of light oil-polluted soil, the distribution range and depth of pollutants, install the well group system, and determine the location and quantity of the suction well 1 and the injection well 2;

[0069] B. Operation of the soil suction system 4: turn on the vortex vacuum pump 4a, and the oil and gas in the soil, driven by negative pressure, enter the suction pipe group 4d through the suction well head; enter the suction pipe group 4d through the suction pipe group 4d After the oil and gas separator 4b removes moisture and soil particles, it enters the vortex vacuum pump 4a and turns to a positive pressure, and then enters the oil and gas adsorber 4c through the oil and gas delivery pipe 4e for purification and then discharges it into the atmosphere;

[0070] C. The operation of the microbial repair system 5: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com