Remediation equipment for non-volatile organic polluted soil

A polluted soil, non-volatile technology, applied in the restoration of polluted soil and other directions, can solve the problems of low treatment efficiency, low heat utilization rate, high energy consumption, and achieve the goal of improving heat utilization rate, improving heat energy utilization rate, and reducing treatment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

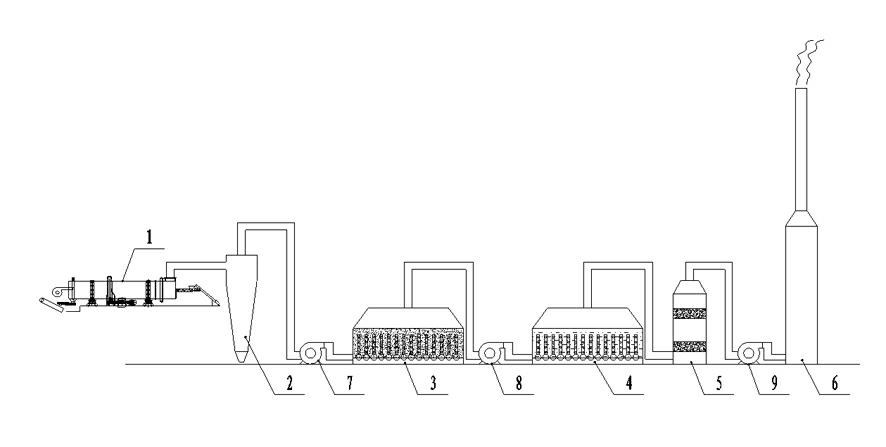

[0016] Such as figure 1 As shown, the remediation equipment of a kind of refractory organic polluted soil according to the present invention includes a rotary kiln 1, a cyclone dust collector 2, a soil pretreatment system 3, an oxidation reaction tank 4, and an activated carbon adsorption tower connected in sequence through pipelines. 5 and the chimney 6.

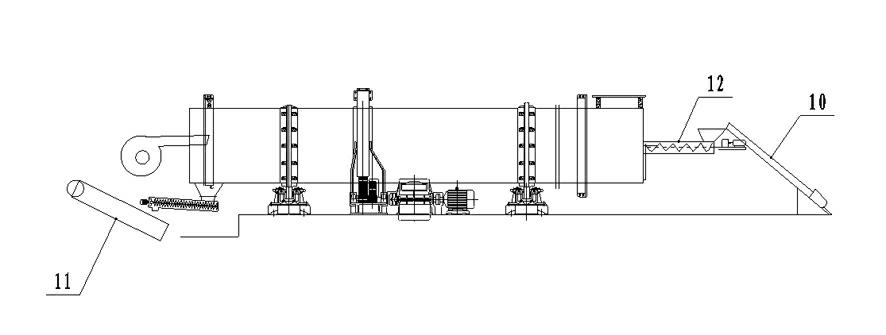

[0017] Such as figure 2 As shown, the rotary kiln 1 is a high-temperature kiln, the rotary kiln is connected with the reducer, and the reducer is connected with the frequency conversion motor. A feed screw 12 is provided between the material belt conveyors 10 . The feed screw 12 pushes the soil conveyed by the belt conveyor into the rotary kiln 1, and the speed reducer is driven to control the kiln speed by adjusting the frequency of the frequency conversion motor, so that the soil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com