Heavy metal trapping agent

A heavy metal scavenger, polymer technology, used in flocculation/sedimentation water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. and soil cannot pass the leaching experiment and other problems to achieve the effect of strengthening synergy, improving treatment effect and reducing treatment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

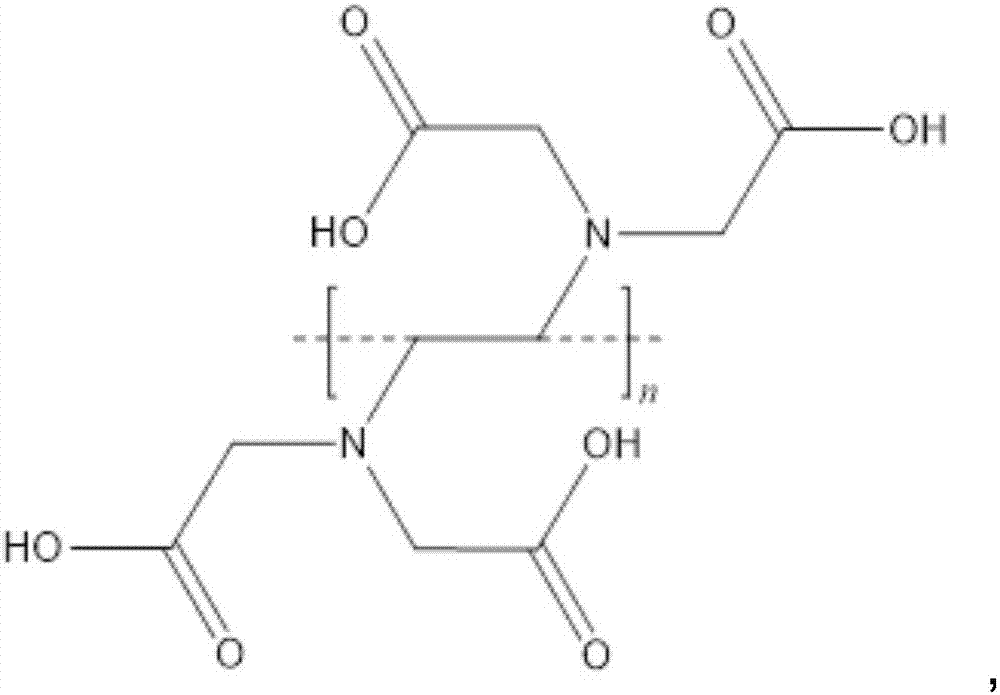

[0029] The heavy metal scavenger of this example is mainly composed of polymers containing polyethylenediaminetetraacetic acid units. The content of polyethylenediaminetetraacetic acid units is 80% to 100% of the polymer in terms of mass percentage. The structural formula of the acetic acid unit is as follows:

[0030]

[0031] In the formula, n is 10-100; it is a polymer of small molecules; it can be a homopolymer or a copolymer.

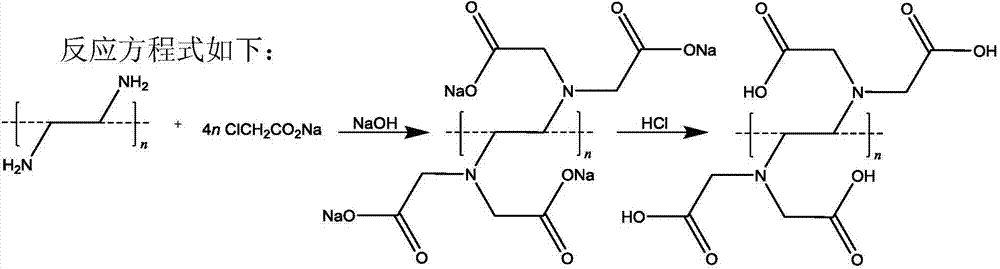

[0032] Its preparation method of the polymer containing polyethylene diamine tetraacetic acid unit is as follows:

[0033] Based on the polymer containing polyethylene diamine units, the amine group is diacetated through functional group reaction to prepare the polymer containing polyethylene diamine tetraacetic acid units.

[0034] Specifically: dissolve the polymer containing polyethylene diamine units in dilute hydrochloric acid solution, then drop excess sodium chloroacetate solution into the polymer solution containing polyethylene diamine...

Embodiment 2

[0039] The heavy metal scavenger of this example is a polymer of medium molecular weight, except that n is 100-1000, the others are the same as the first embodiment.

Embodiment 3

[0041] The heavy metal scavenger of this example is a macromolecular polymer, n is 1000~10000, and the specific preparation method is:

[0042] Dissolve the polymer containing polyethylene diamine units in water, then add sodium hydroxide that is 2 to 5 times the molar number of amino groups in the polymer containing polyethylene diamine units, stir and mix, then heat up to 65 to 95 degrees Celsius, Then slowly add excess hydroxyacetonitrile solution under stirring, after the addition, raise the temperature to 100-120 degrees Celsius, and keep it warm for 0.5-2 hours; after the reaction, add an appropriate amount of hydrogen peroxide solution to remove the remaining hydroxyacetonitrile, and then add activated carbon for decolorization; Acidify the decolorized reaction solution with hydrochloric acid to precipitate a white solid, filter, wash with water, and dry to obtain a polymer containing polyethylenediaminetetraacetic acid units.

[0043] The reaction equation is as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com