Hole-sealing, hydraulic-fracturing and gas-extraction integrated construction device and construction method thereof

A technology of gas drainage and hydraulic fracturing, which is applied in the direction of gas discharge, mining fluid, safety devices, etc., and can solve problems such as complex, unsuitable for fast sealing, improving sealing effect, and bulky

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

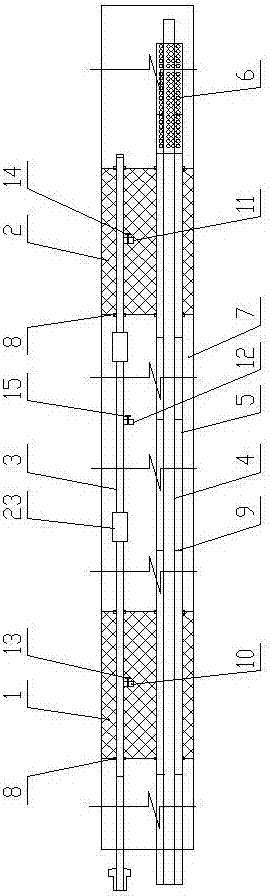

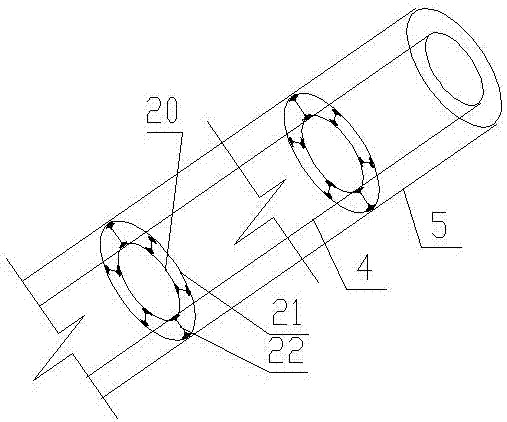

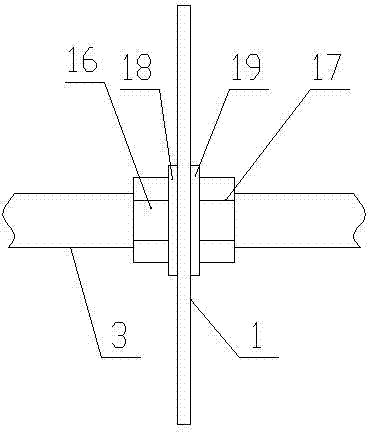

[0022] Such as figure 1 , figure 2 and image 3 As shown, the integrated construction device for hole sealing, hydraulic fracturing and gas drainage of the present invention includes a first bag 1, a second bag 2, a grouting pipe 3, a hydraulic fracturing pipe 4, and a gas drainage pipe 5 And the flower tube 6, assuming that the axial direction of the borehole 7 from the hole to the bottom of the hole is from left to right, the first pouch 1 is arranged in the borehole 7 and is located near the orifice, and the second pouch 2 is set In the borehole 7 and near the bottom of the hole, the grouting pipe 3 and the gas extraction pipe 5 pass through the first bag 1 and the second bag 2 from left to right and then extend into the bottom of the hole. 6. The left end is fixedly connected with the right end of the gas extraction pipe 5 coaxially. The outer circles of the grouting pipe 3 and the gas extraction pipe 5 are both provided with a sealing assembly with the same structure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com