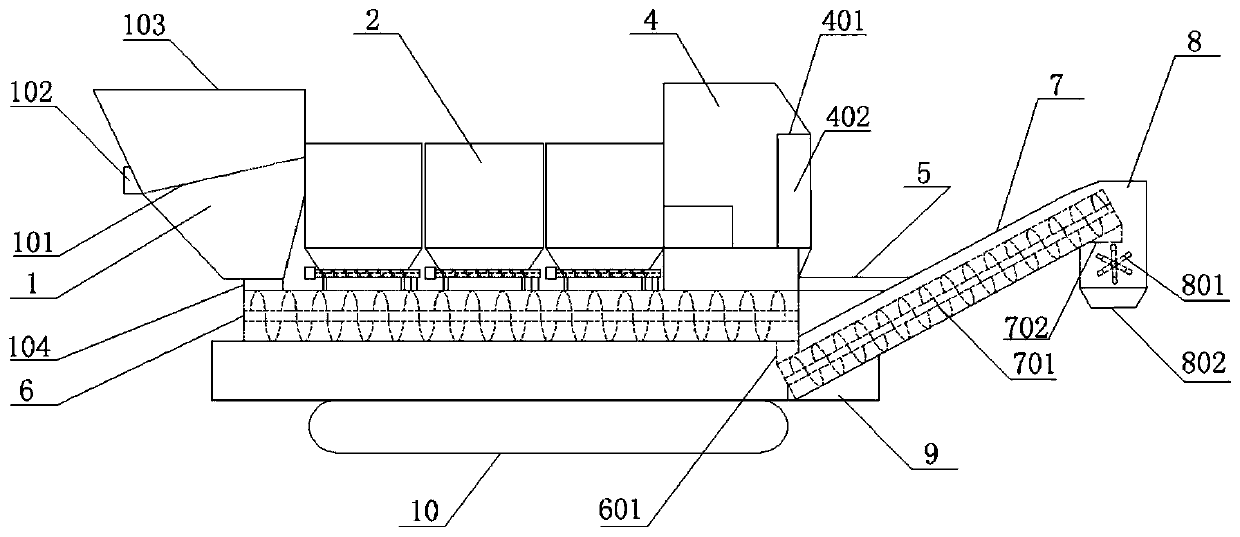

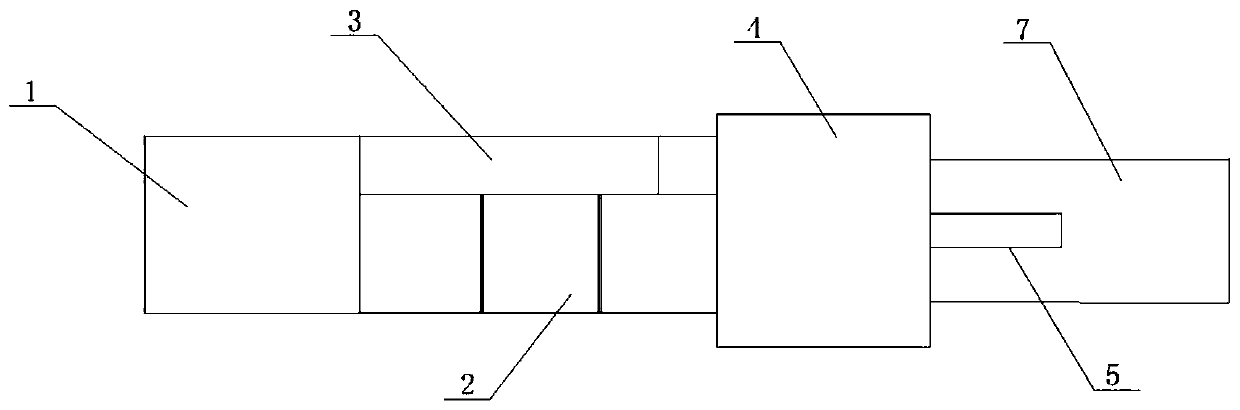

Intelligent integrated soil remediation device and method

A soil remediation and equipment technology, which is applied in the field of contaminated soil remediation, can solve the problems of inability to add remediation materials in steps, reduce the remediation effect of the remediation materials, and have a low degree of intelligence, and achieve good rigidity, good driving performance, and improved mixing. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

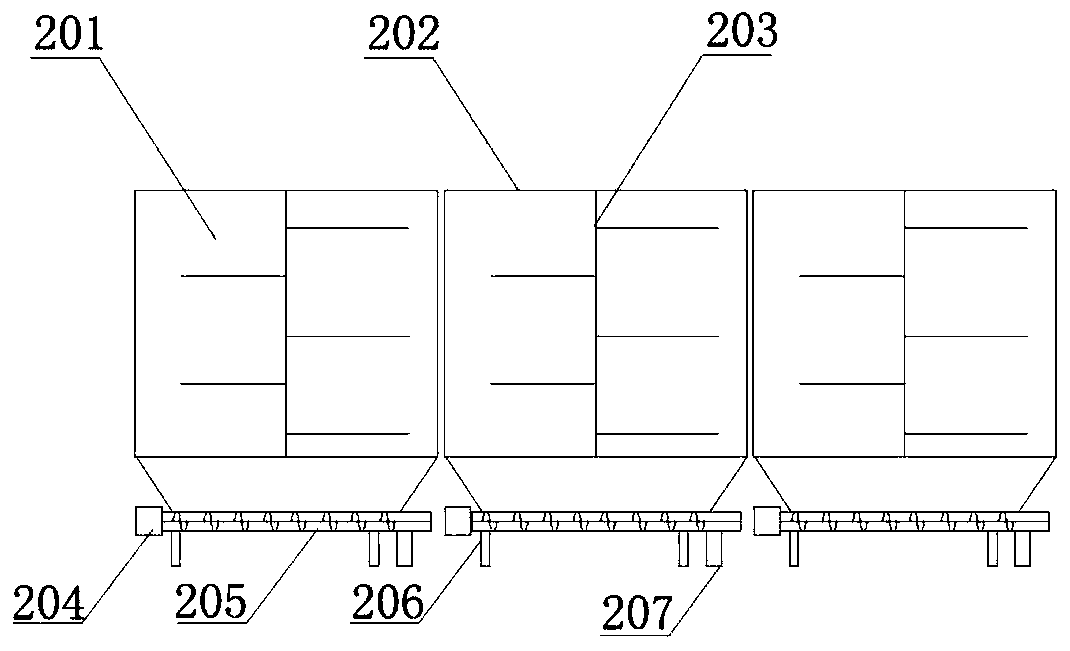

[0055] In a heavy metal polluted site, the main pollutants in the soil are arsenic, cadmium, zinc, and lead, and the toxic leaching concentrations (according to the "Solid Waste Leaching Toxic Leaching Method Sulfuric Acid Nitric Acid Method" (HJ / T 299-2007)) respectively reached 34.10mg / L , 0.52mg / L, 27.65mg / L and 1.24mg / L, the soil pH is 4.6, and the water content is 21%. This soil adopts equipment and method described in the present invention to repair, and selects 2 kinds of solid repair materials (ferrous sulfate and lime), and the dosage of 3 repair material addition units in the equipment is successively 2.5kg / min (lime ), 5kg / min (ferrous sulfate) and 0kg / min; the liquid dosing system is filled with water, and the dosage of the liquid dosing system is set to 10kg / min; the output particle size of the crushing and screening device is set to 10mm, and the mixing The running speed of the uniform stirring system is 1m / min. Sampling and monitoring of the repaired soil after...

Embodiment 2

[0059]In a heavy metal polluted site, the main pollutants in the soil are arsenic, cadmium, zinc, and lead, and the toxic leaching concentrations (according to the "Solid Waste Leaching Toxic Leaching Method Sulfuric Acid Nitric Acid Method" (HJ / T 299-2007)) respectively reached 34.10mg / L , 0.52mg / L, 27.65mg / L and 1.24mg / L, the soil pH is 4.6, and the water content is 21%. This soil adopts equipment and method described in the present invention to repair, selects 3 kinds of solid restoration materials (magnesium chloride, ferric chloride and lime), and the dosage of 3 restoration materials adding units is set to be 1.5kg / min successively (magnesium chloride ), 0.45kg / min (ferric chloride) and 1.05kg / min (lime); the liquid dosing system is filled with water, and the dosage of the liquid dosing system is set to 8kg / min; the output of the crushing and screening device is set The particle size is 5mm, and the running speed of the mixing and stirring system is 0.8m / min. Sampling a...

Embodiment 3

[0063] In a heavy metal polluted site, the main pollutants in the soil are chromium (hexavalent), cadmium, and lead, and the toxic leaching concentrations (according to the "Solid Waste Leaching Toxic Leaching Method Sulfuric Acid Nitric Acid Method" (HJ / T 299-2007)) respectively reached 2.72mg / L, 1.23 mg / L, 1.04mg / L, the soil pH is 7.8, and the moisture content is 15%. This soil adopts equipment and method described in the present invention to repair, selects 1 kind of solid repairing material (ferrous sulfate), and 1 kind of liquid repairing material (calcium polysulfide), respectively sets the dosage of repairing material dosing unit as 1.8kg / min (ferrous sulfate), 0kg / min and 0kg / min, the dosage of the liquid dosing system is 2kg / min (calcium polysulfide); set the output particle size of the crushing and screening device to 10mm, mix well The operating speed of the stirring system was 1 m / min. Sampling and monitoring the repaired soil after 10 days of maintenance, and me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com