Packaging assembly

a technology of packaging and assembly, applied in the direction of packaging, closure caps, transportation and packaging, etc., can solve the problems of inability to meet user requirements, inability to meet the needs of users, and inability to absorb liquid detergent, etc., to prevent accumulating and drying, low variation of cap opening torque, and precise dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0074]The Examples herein are meant to exemplify the present invention but are not used to limit or otherwise define the scope of the present invention. Examples 1A-1B are packaging assemblies according to the present invention, Examples 3A-3D are liquid laundry detergent composition examples according to the present invention, and Examples 2A-2B are comparative examples of certain packaging assemblies in the art. FIG. 7 illustrates the transition pieces of Comparative Examples 2A and 2B and Examples 1B and 1A in sequence (from left to right).

examples 1a-1b

Packaging Assemblies of the Present Invention

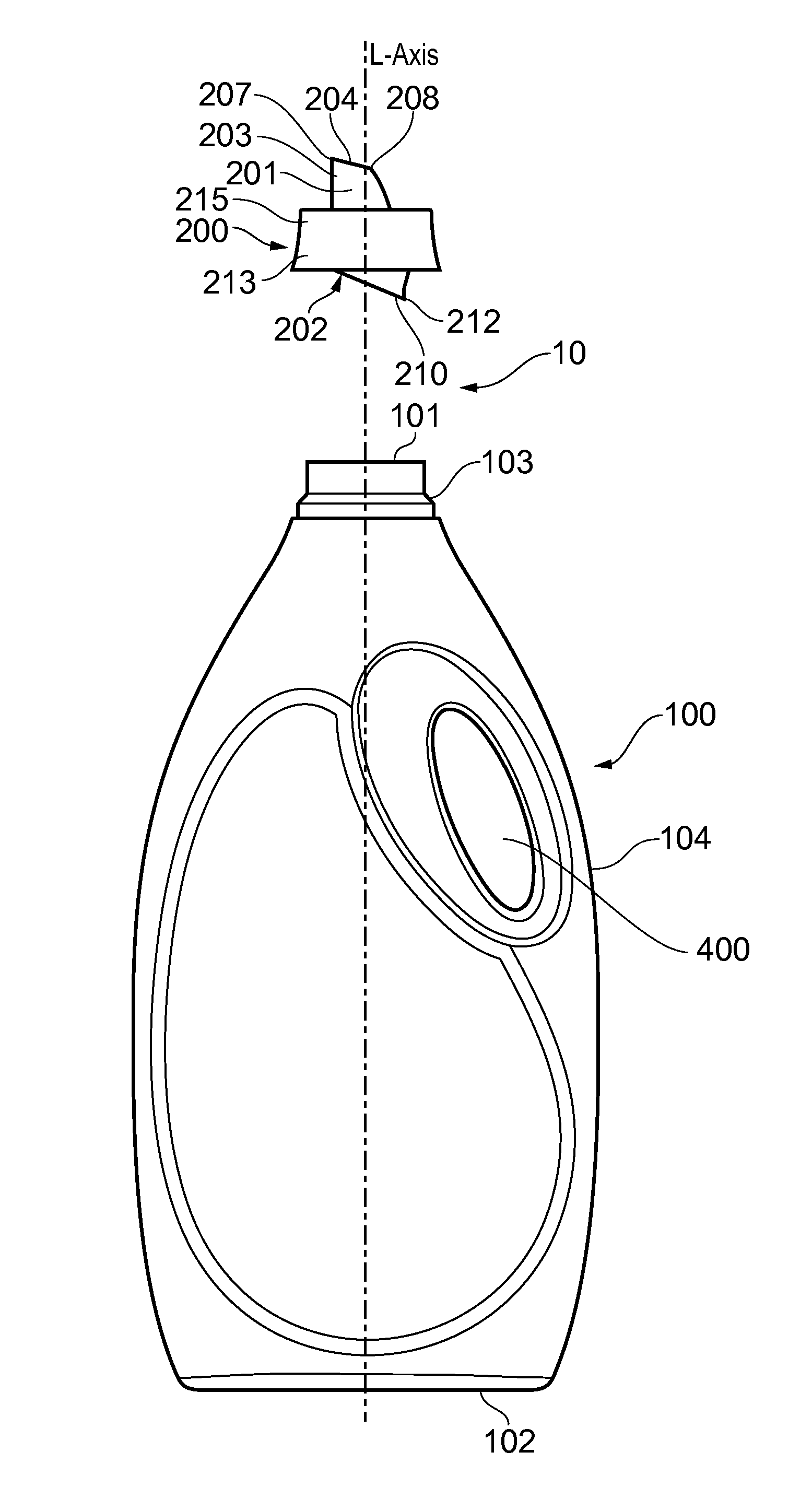

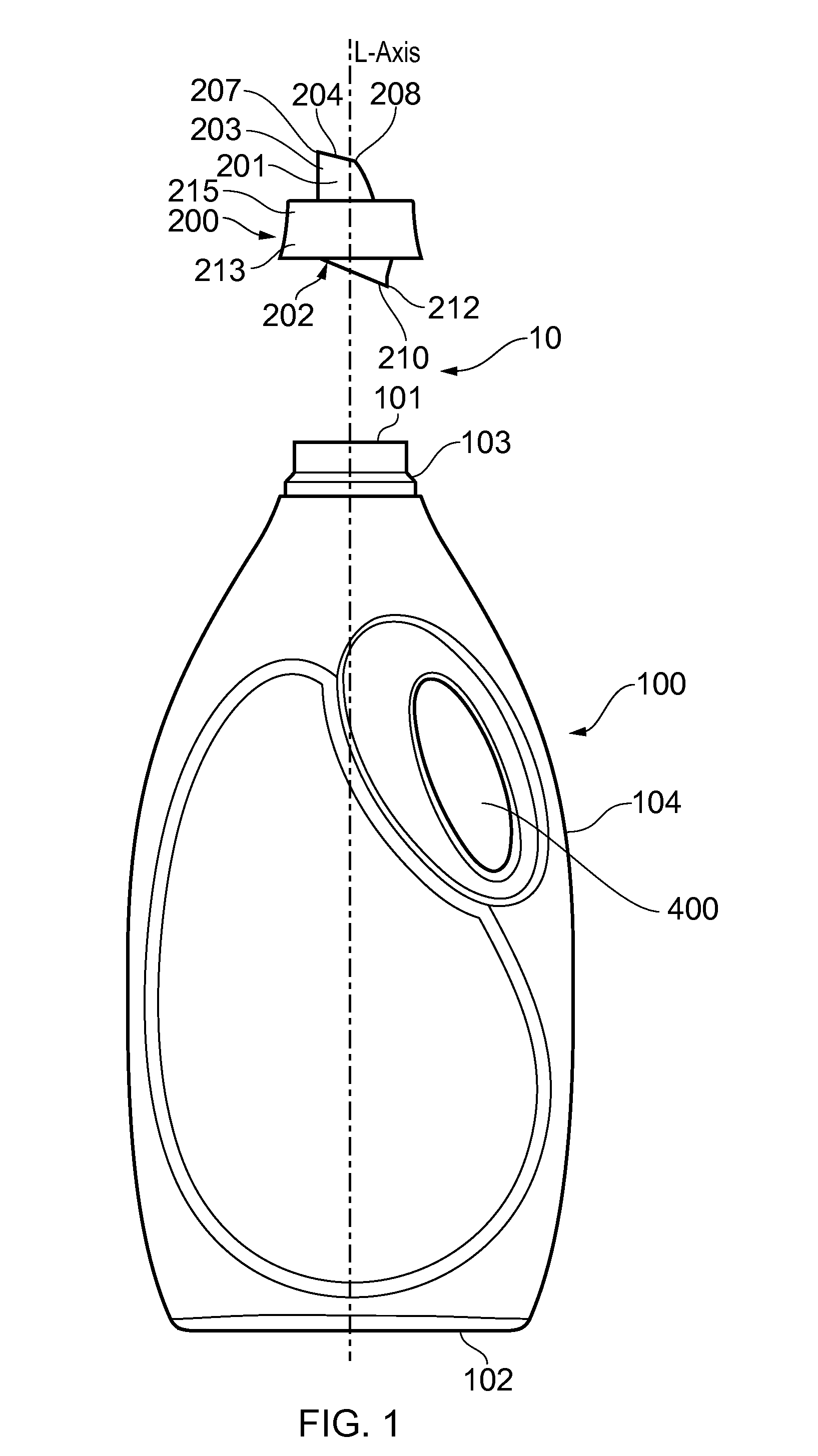

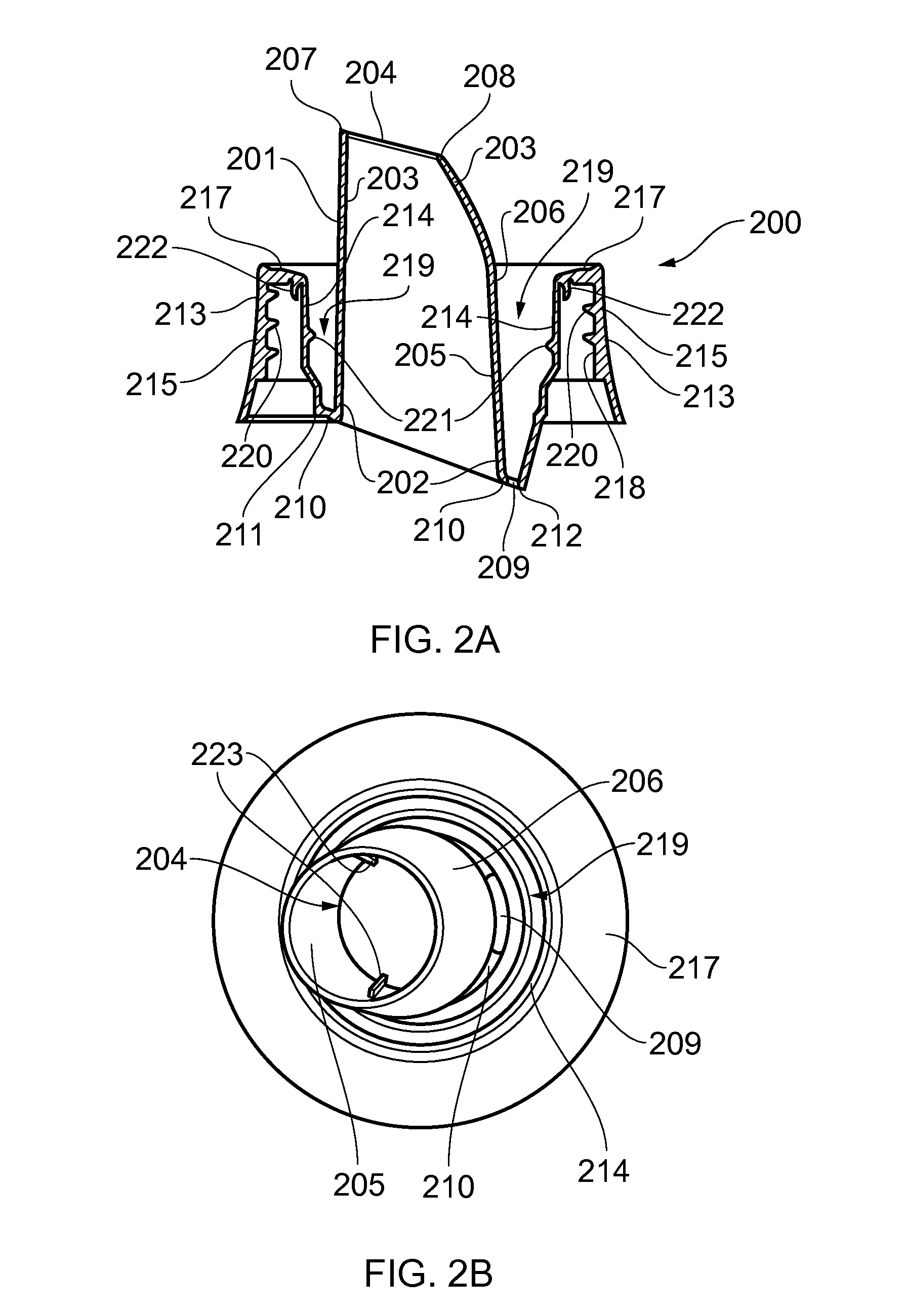

[0075]Example 1A is the packaging assembly as shown in FIG. 6. Specifically, the container of Example 1A has an internal volume of 2000 mL, and the cap of Example 1A has an internal volume of 80 mL. The transition piece as used in Example 1A is exactly the same as the one shown in FIGS. 2A, 2B, and 2C. The spout opening of the transition piece has a cross-sectional area of about 177 mm2, and the vent has a cross-sectional area of about 30 mm2. The spout has a length of about 55 mm measured from its base end to the spout opening along the longitudinal axis.

[0076]The packaging assembly of Example 1B comprises the same container and cap as Example 1A, but has a slightly different transition piece. The 3rd transition piece (from left) as illustrated in FIG. 7 is the one used for Example 1B. This transition piece has a circumferentially integral spout opening and 5 tiny vents arranged side-by-side. The spout opening therein has a cross-section...

example 3

Formulations of Liquid Laundry Detergent Compositions

[0079]The following liquid laundry detergent compositions shown in Table 1 are made comprising the listed ingredients in the listed proportions (weight %).

TABLE 13A3B3C3DC12-14AE1-3S138.3106C11-13LAS35.56.56Neodol ®25-7 a1.41.21.44.2C6-C15 dimethyl amine oxide0000.5Citric acid021.71.2Boric acid021.91.9C12-C18 fatty acid1.51.21.31Na-DTPA b0.060.20.40.21,2 propanediol01.22.52Calcium chloride000.060.03Sodium cumene sulphonate0000.2Silicone emulsion00.00250.00250.0025Monoethanolamine0.07000.096Sodium polyacrylate1.4000NaOHUp to pH 8Up to pH 8Up to pH 8Up to pH 8Brightener00.060.060.06Protease000.450Amylase000.080Dye00.0020.0020.002Perfume oil00.60.60.6Hydrogenated castor oil0000.12WaterAdd to 100Add to 100Add to 100Add to 100a Neodol ®25-7 is C12-C15 alcohol ethoxylated with an average of 7 moles of ethylene oxide as a nonionic surfactant, available from Shellb penta sodium salt diethylene triamine penta acetic acid as a chelant

[0080]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com