Metal contaminated soil remediation device

A technology of polluted soil and soil, which is applied in the field of contaminated soil remediation and management, can solve the problems of insufficient soil remediation and inability to ensure full contact of soil, and achieve the effect of ensuring the effect of remediation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

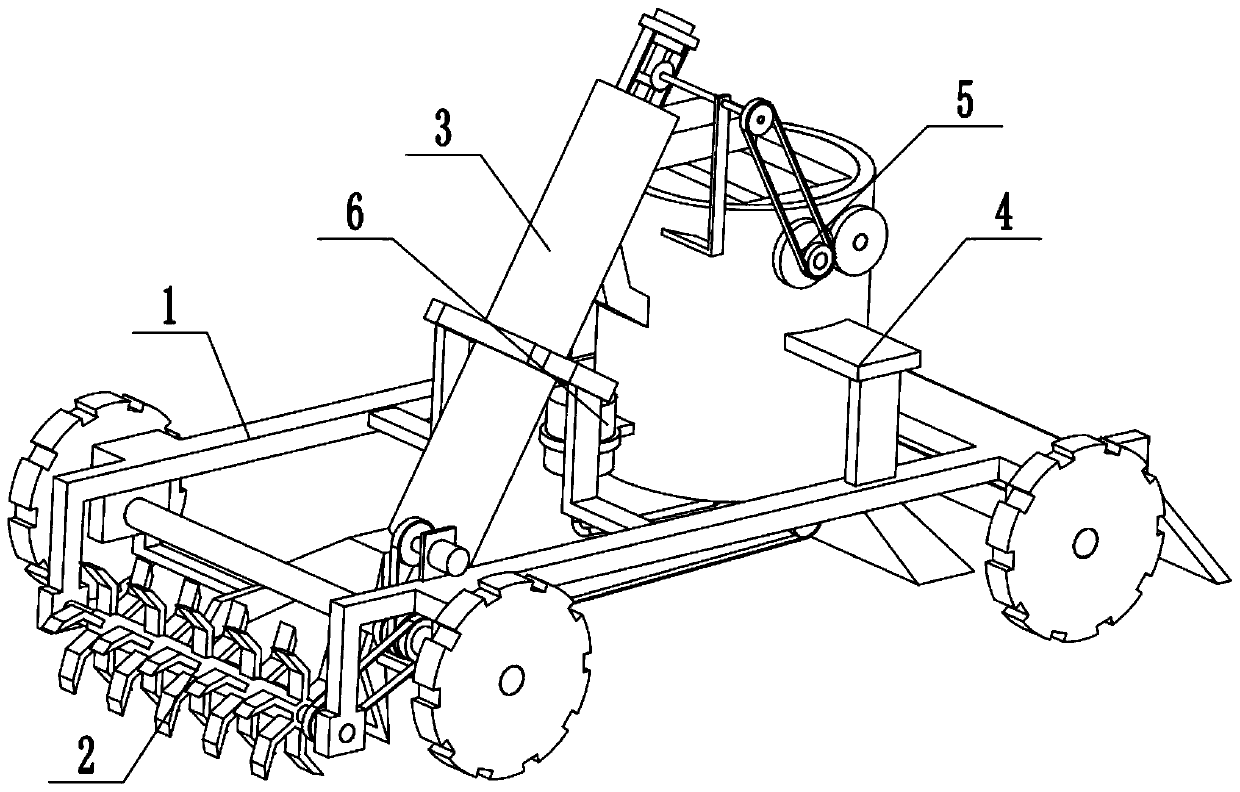

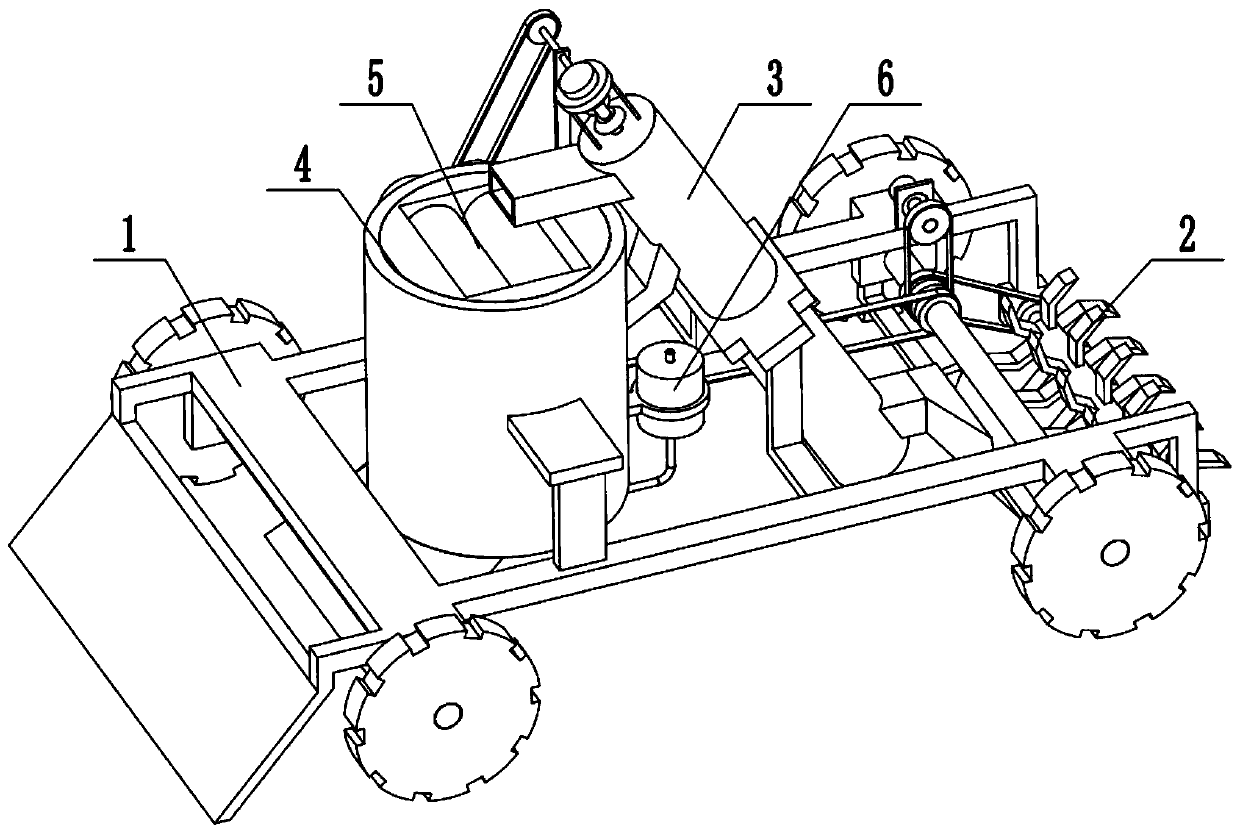

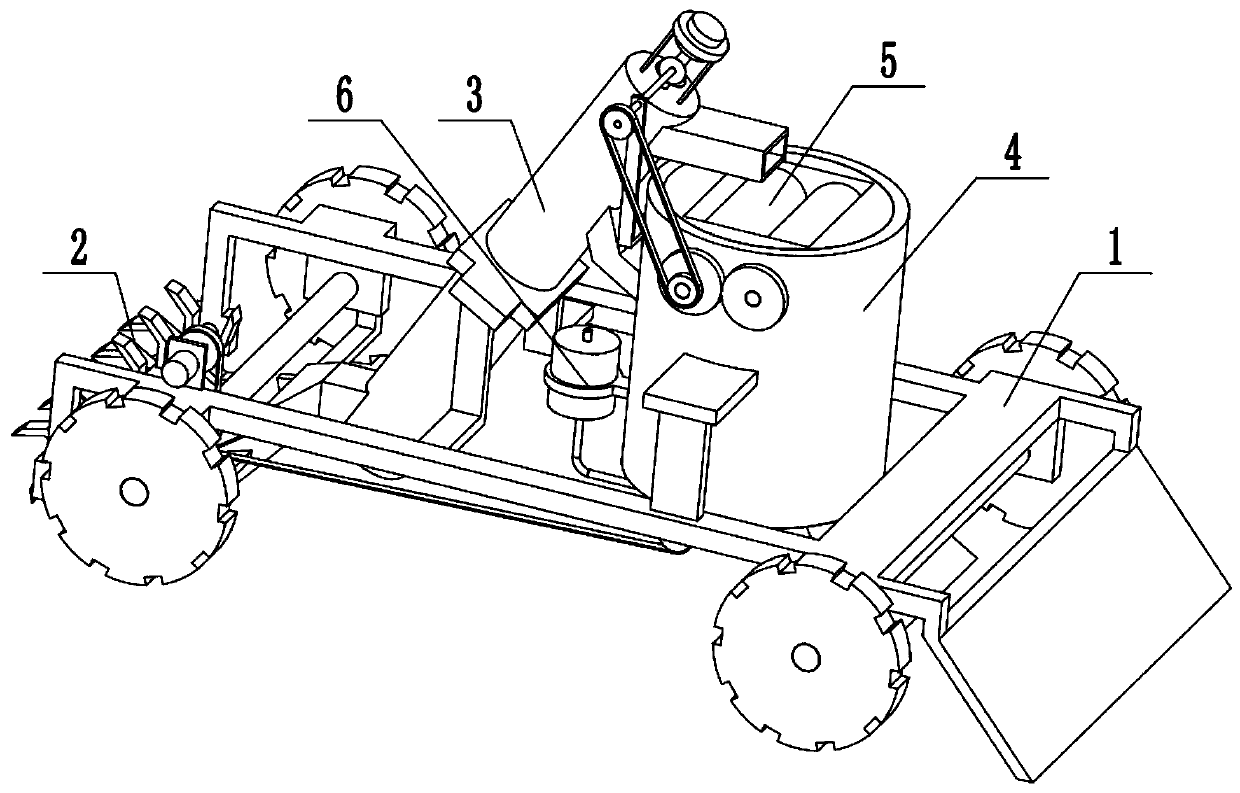

[0034] Combine below Figure 1-14 Describe this embodiment, a metal-contaminated soil remediation device, including a movable chassis 1, a soil plowing part 2, a soil collection and transportation mechanism 3, a soil spray cylinder assembly 4, a soil block crushing mechanism 5, and a soil spray mechanism 6, The soil plowing part 2 is arranged on one end of the movable underframe 1, the soil plowing part 2 is connected with the movable underframe 1 in transmission, the soil collecting and conveying mechanism 3 is arranged on the movable underframe 1, and one end of the soil collecting and conveying mechanism 3 Located on one side of the soil plowing part 2, the other end of the soil collection and conveying mechanism 3 is located above the soil spray cylinder assembly 4, the soil spray cylinder assembly 4 is located at the other end of the movable chassis 1, and the soil block crushing mechanism 5 is provided Above the soil spraying cylinder assembly 4, the soil block crushing ...

specific Embodiment approach 2

[0036] Combine below Figure 1-14 To illustrate this embodiment, the movable underframe 1 includes a wheel frame 1-1, a first wheel shaft 1-2, a second wheel shaft 1-3, a roller 1-4, a travel drive motor 1-5, a first pulley 1- 6. The second pulley 1-7, the third pulley 1-8, the fourth pulley 1-9, the support frame 1-10 and the scraping plate 1-11; the first axle 1-2 and the second axle 1-3 rotate respectively Connected to the left and right ends of the wheel frame 1-1, the two ends of the first wheel shaft 1-2 and the second wheel shaft 1-3 are respectively fixedly connected to a roller 1-4, and the walking drive motor 1-5 is fixedly connected to the wheel by the motor frame. On the left side of the frame 1-1, the output shaft of the travel drive motor 1-5 is fixedly connected to the first pulley 1-6, and the first pulley 1-6 is connected to the second pulley 1-7 through a belt transmission, and the second pulley 1- 7. The third pulley 1-8 and the fourth pulley 1-9 are all fi...

specific Embodiment approach 3

[0038] Combine below Figure 1-14 Illustrate this embodiment, described soil loosening part 2 comprises turning plate rotating shaft 2-1, turning loose plate 2-2, the 5th belt pulley 2-3 and axle frame plate 2-4; Connect a plurality of loosening plates 2-2, the fifth belt pulley 2-3 is fixedly connected on the turning shaft 2-1, and the two ends of the turning shaft 2-1 are respectively rotated to connect a shaft frame plate 2-4, two shafts The frame plates 2-4 are all fixedly connected to the left side of the wheel frame 1-1, and the fourth pulley 1-9 is connected with the fifth pulley 2-3 through belt transmission. The fourth pulley 1-9 drives the fifth pulley 2-3 to rotate counterclockwise, the fifth pulley 2-3 drives the turning shaft 2-1 to rotate counterclockwise, and the turning shaft 2-1 drives a plurality of loosening plates 2 on it -2 rotates counterclockwise, and a plurality of loosening plates 2-2 rotate around the axis of the turning shaft 2-1 to suddenly loosen....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com