Beam crane and its downward bent beam repairing method

A technology of beam crane and repair method, applied in the directions of load hanging elements, transportation and packaging, support structure, etc., can solve the problems of complex structure of the tensioner, difficulty in manufacturing, reduced camber on the main beam, etc., and achieve repair Long-lasting effect, small increase in repair weight, significant enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

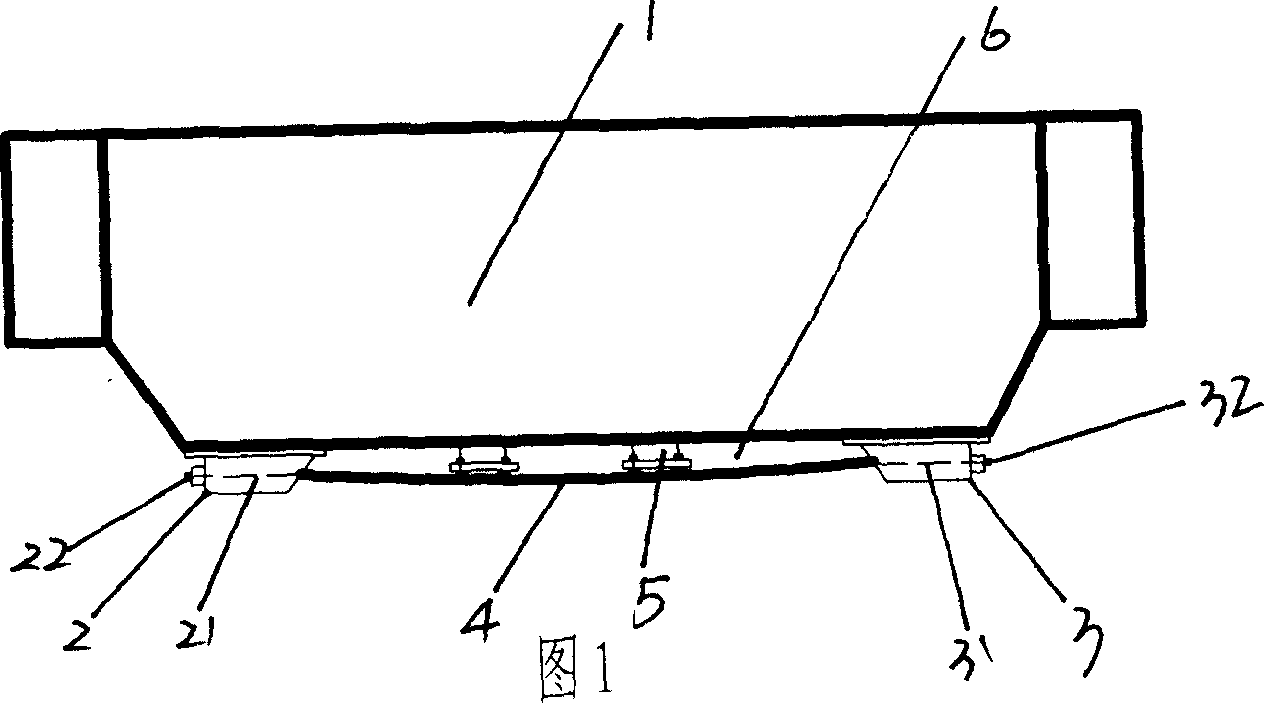

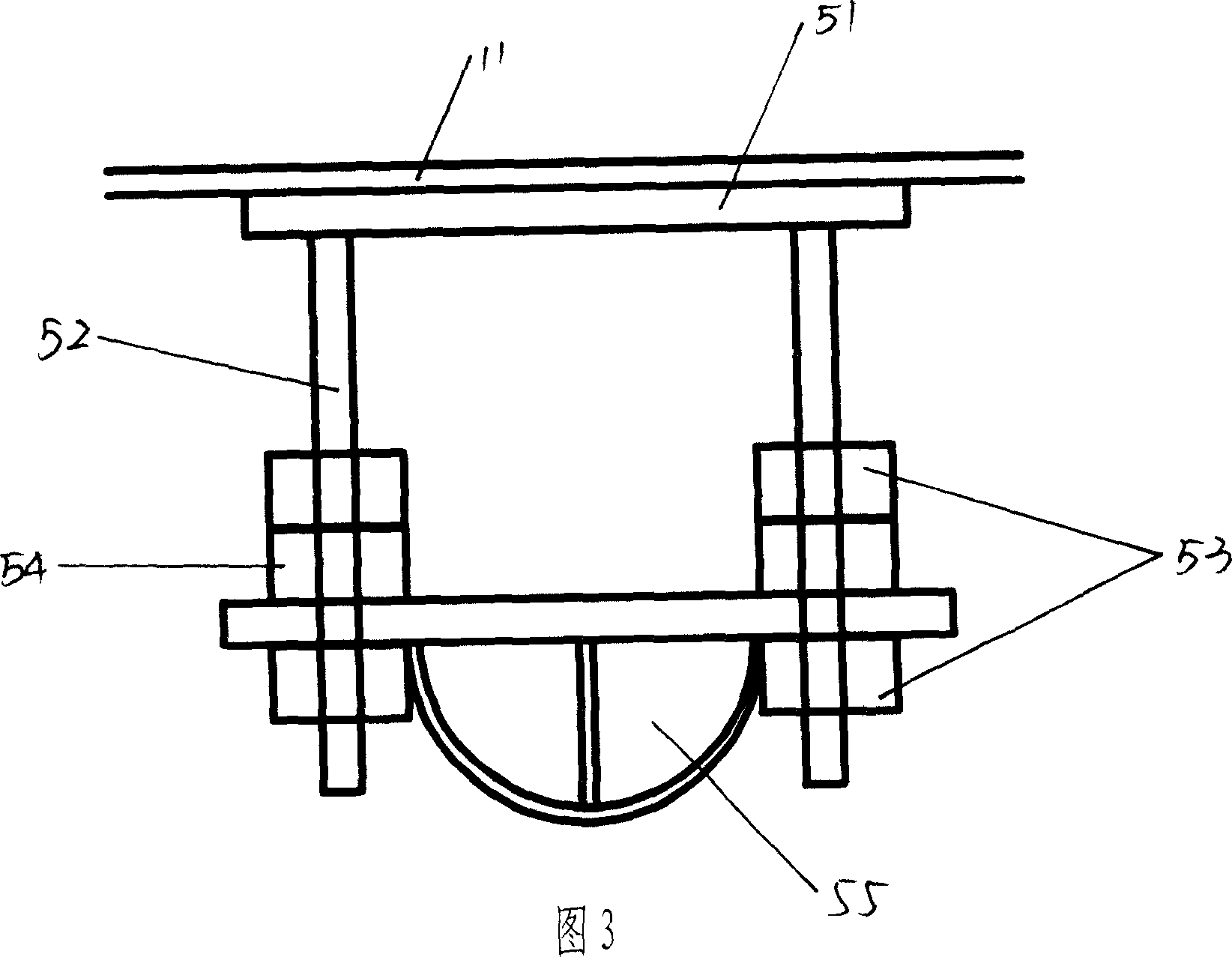

[0032] Referring to Fig. 1-6, the method for repairing the deflection of the main girder of the girder crane of the present invention comprises the following steps:

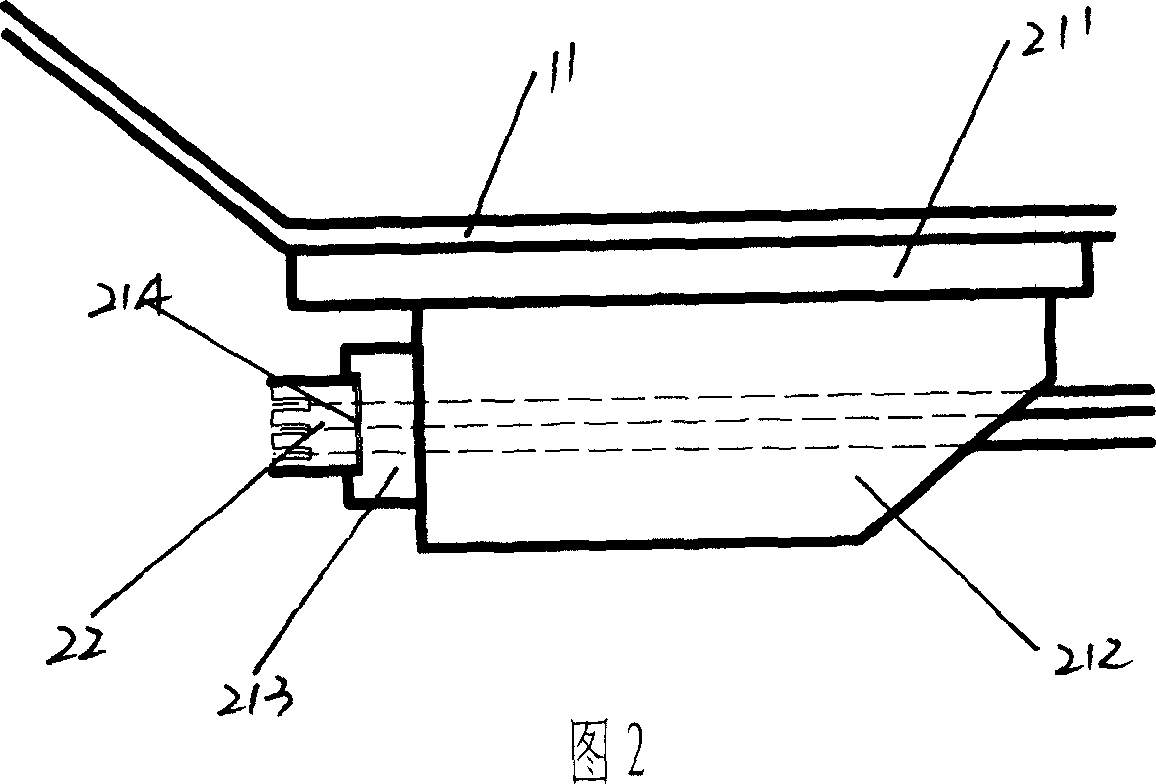

[0033] a. Fix the tension end support 21 and the fixed end support 31 at both ends of the lower cover plate 11 of the main beam 1 of the crane respectively, and the tension end support 21 and the fixed end support 31 are fixed on the lower cover plate of the main beam 1 The reinforcing plate 211 under 11 is composed of two ribs 212 fixed to the reinforcing plate 211 parallel to and perpendicular to the main beam 1, and a beam 213 fixed at one end of the two ribs;

[0034] b. Penetrate the prestressed steel strand 4 into the tension anchor 22 and the fixed anchor 32 respectively placed on the outside of the tension end support 21 and the fixed end support 31, and anchor the fixed end 3 so that the tension anchor 22 is pressed against On the outside of the tension end support 21, the outer side of the crossbeam 213...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com