Rail member

A component and fence technology, which is applied in the field of railing skeleton and fence components, can solve the problems of affecting the appearance and use, corrosion resistance, low strength, etc., and achieve the effects of not being easy to collapse, improving shock absorption, and improving bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

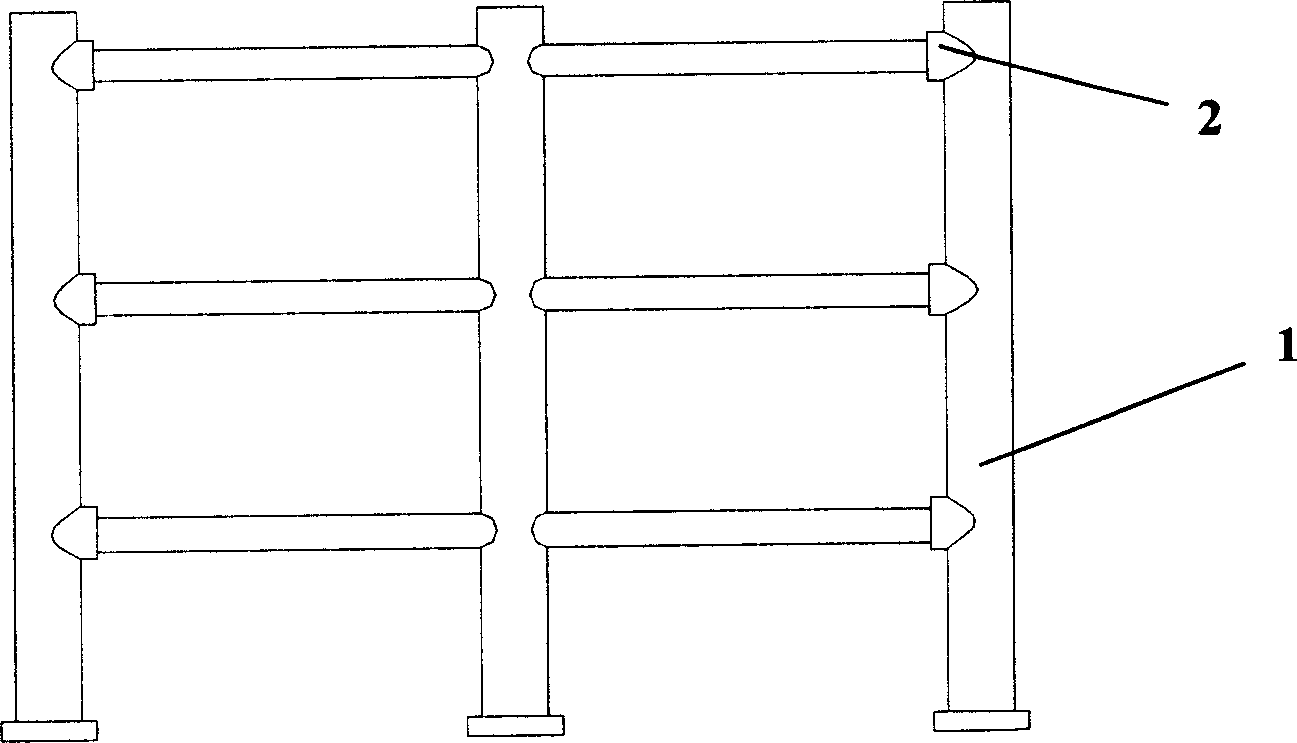

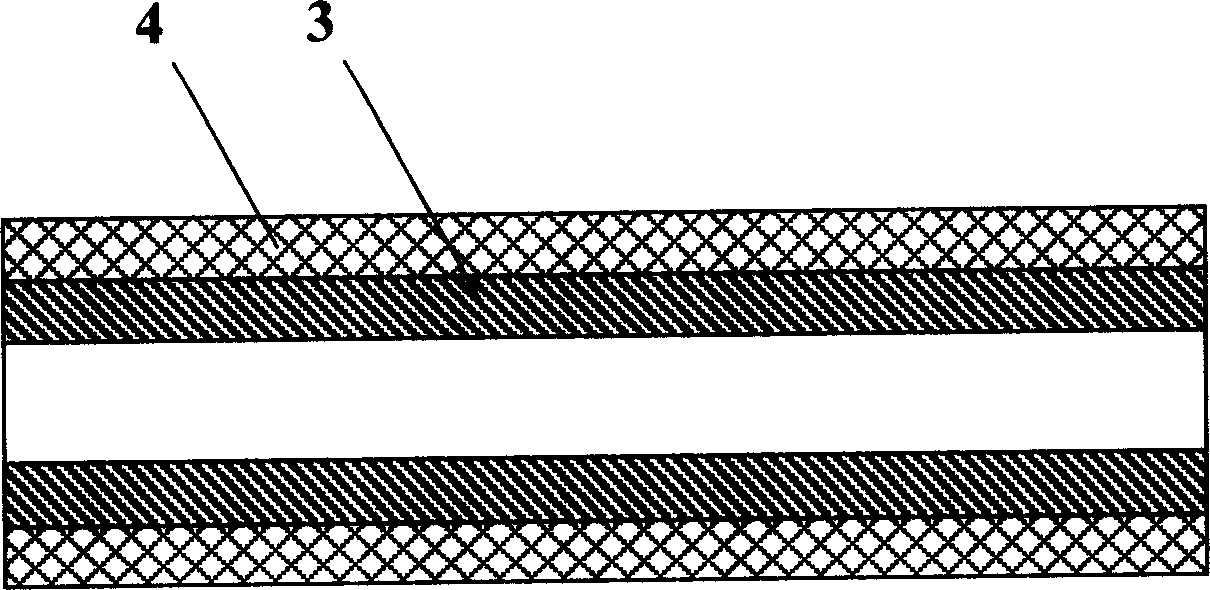

[0011] Such as figure 1 and figure 2 As shown, a fence member of the present invention is composed of at least three tubular connectors 1, wherein any one of the tubular connectors 1 is made of a stainless steel pipe body 4, and any one Reinforced fiber plastic pipe body 3 is all arranged in described stainless steel pipe body 4, and the diameter of described reinforced fiber plastic pipe body 3 matches with the diameter of described stainless steel pipe body 4, and described stainless steel pipe body 4 and The reinforced fiber plastic pipe body 3 is fixedly connected, and the tubular connectors 1 are fixedly connected.

[0012] Further, the radial section of the tubular connector 1 is circular, or rectangular, or square, or has a special-shaped section.

[0013] Further, the stainless steel pipe bodies are connected by setting thin-walled stainless steel joints 2 .

[0014] Furthermore, the thin-walled stainless steel joint 2 is connected to the tubular connector through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com