High-rigidity semitrailer axle body

A semi-trailer axle and high-rigidity technology, applied in axles, wheels, vehicle parts, etc., can solve the problems of insufficient rigidity of lightweight axle shafts, achieve the effects of improving rigidity, easy processing and production, and ensuring versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

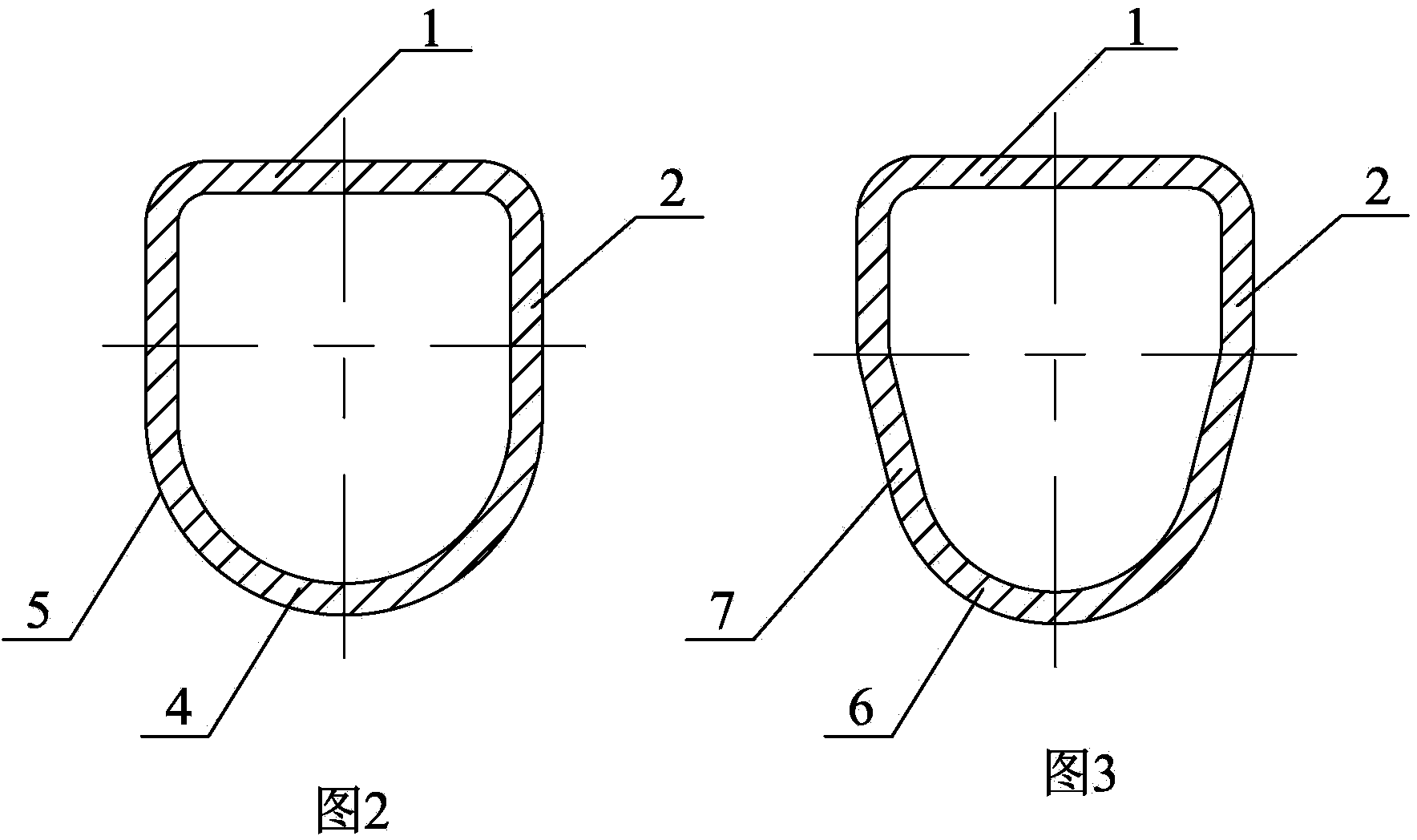

[0022] Such as figure 2 The axle body of the high-rigidity semi-trailer shown, the axle body includes the leaf spring seat assembly plane 1, the vertical surface 2 adjacent to the leaf spring seat assembly plane 1 and the lower plane 3 opposite to the leaf spring seat assembly plane 1, and the vertical plane The lower half of 2 and the lower plane 3 form a U-shaped structure. The U-shaped structure includes a first bottom arc 4 and a connecting arc 5 , the first bottom arc 4 is connected to the vertical surface 2 through the connecting arc 5 . The center of the first bottom arc 4 depends on the configuration of the rolls of the cold extrusion plant. The first bottom arc 4 and the vertical surface 2 are connected and transitioned through the connecting arc 5 , and are formed freely during the gradual change process of the workpiece.

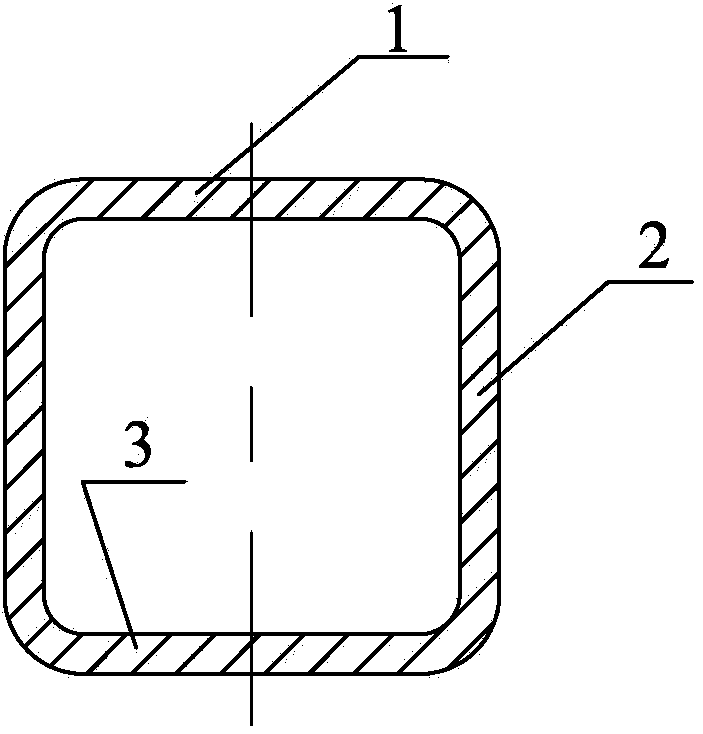

[0023] figure 1 and figure 2 The wall thickness in both is 12mm, figure 1 The flexural section modulus is 256347.47, figure 2 The flexur...

Embodiment 2

[0025] Such as image 3 In the shown high-rigidity semi-trailer axle body, the lower half of the vertical plane 2 and the lower plane form a U-shaped structure. The unusual U-shaped structure includes a second bottom arc 6 and a connecting tangent 7 , and the second bottom arc 6 is connected to the vertical surface 2 through the connecting tangent 7 . The connecting tangent line 7 is trumpet-shaped.

[0026] Such as figure 1 and image 3 The wall thickness is 12mm, figure 1 The flexural section modulus is 256347.47, image 3 The flexural section modulus is 291810.25, an increase of 13.83%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com