Method for manufacturing nano-composite tower capable of resisting strong breeze whose speed is greater than 60 m/s

A nano-composite, manufacturing method technology, applied in towers, buildings, building types, etc., can solve the problems of loss and loss in Hainan, and achieve the effect of improving mechanical properties and enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

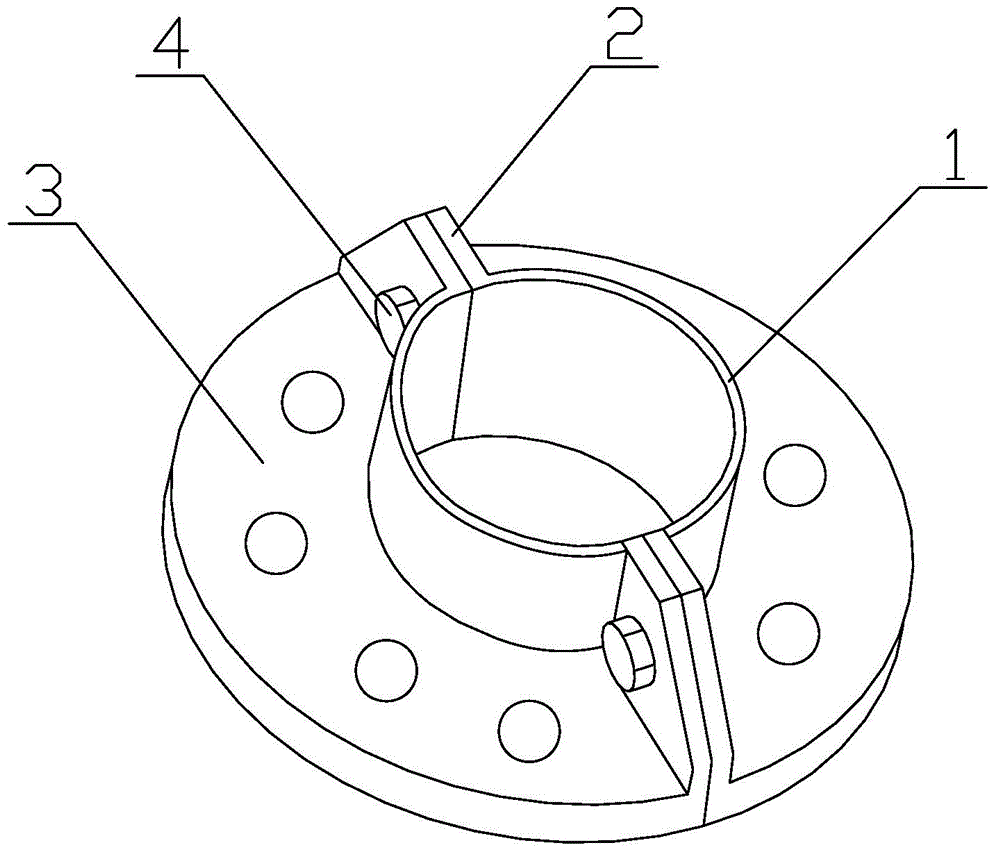

Image

Examples

Embodiment 1

[0033] Manufacturing method of composite tower against strong wind:

[0034] Step 1. Preparation of composite materials:

[0035] Step 101, to the nano-SiO dispersed through the mechanical vibration method 2 Add reinforcing material and silane coupling agent to the mixture, stir evenly to obtain mixed powder, add the mixed powder into epoxy resin and stir evenly to obtain impregnating liquid; the reinforcing material is micron-sized silicon micropowder, and the quality of reinforcing material is 16% of the mass of epoxy resin, nano-SiO before dispersion treatment 2 The mass of the epoxy resin is 5% of the mass of the epoxy resin, and the mass of the silane coupling agent is the nano-SiO before dispersion treatment 2 5% of the mass; the silane coupling agent is KH-550 silane coupling agent;

[0036] Step 102, immersing the glass fibers in the immersion solution described in step 101 to obtain a composite material; the volume percentage of glass fibers in the composite materi...

Embodiment 2

[0043] This embodiment is the same as Embodiment 1, except that the reinforcing material is silicon carbide whisker, aluminum oxide whisker, silicon nitride whisker, aluminum silicate whisker, aluminum borate whisker and magnesium oxide crystal One or more of the whiskers.

Embodiment 3

[0045] Manufacturing method of composite tower against strong wind:

[0046] Step 1. Preparation of composite materials:

[0047] Step 101, to the nano-Al dispersed through the ultrasonic vibration method 2 o 3 Add reinforcing material and silane coupling agent to the mixture, stir evenly to obtain mixed powder, add the mixed powder into epoxy resin and stir evenly to obtain impregnating liquid; the reinforcing material is silicon carbide whisker, and the quality of reinforcing material is 15% of the mass of epoxy resin, nano-Al before dispersion treatment 2 o 3 The quality of the epoxy resin is 3%, and the quality of the silane coupling agent is the nanometer Al before dispersion treatment 2 o 3 4% of the mass; the silane coupling agent is KH-550 silane coupling agent;

[0048] Step 102, immersing the glass fibers in the immersion solution described in step 101 to obtain a composite material; the volume percentage of glass fibers in the composite material is 60%;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com