Crossover

A body and aluminum alloy plate technology, applied in the field of in-line forks, can solve problems such as poor bending deformation resistance, and achieve the effects of large bending section modulus, simple and convenient adjustment, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

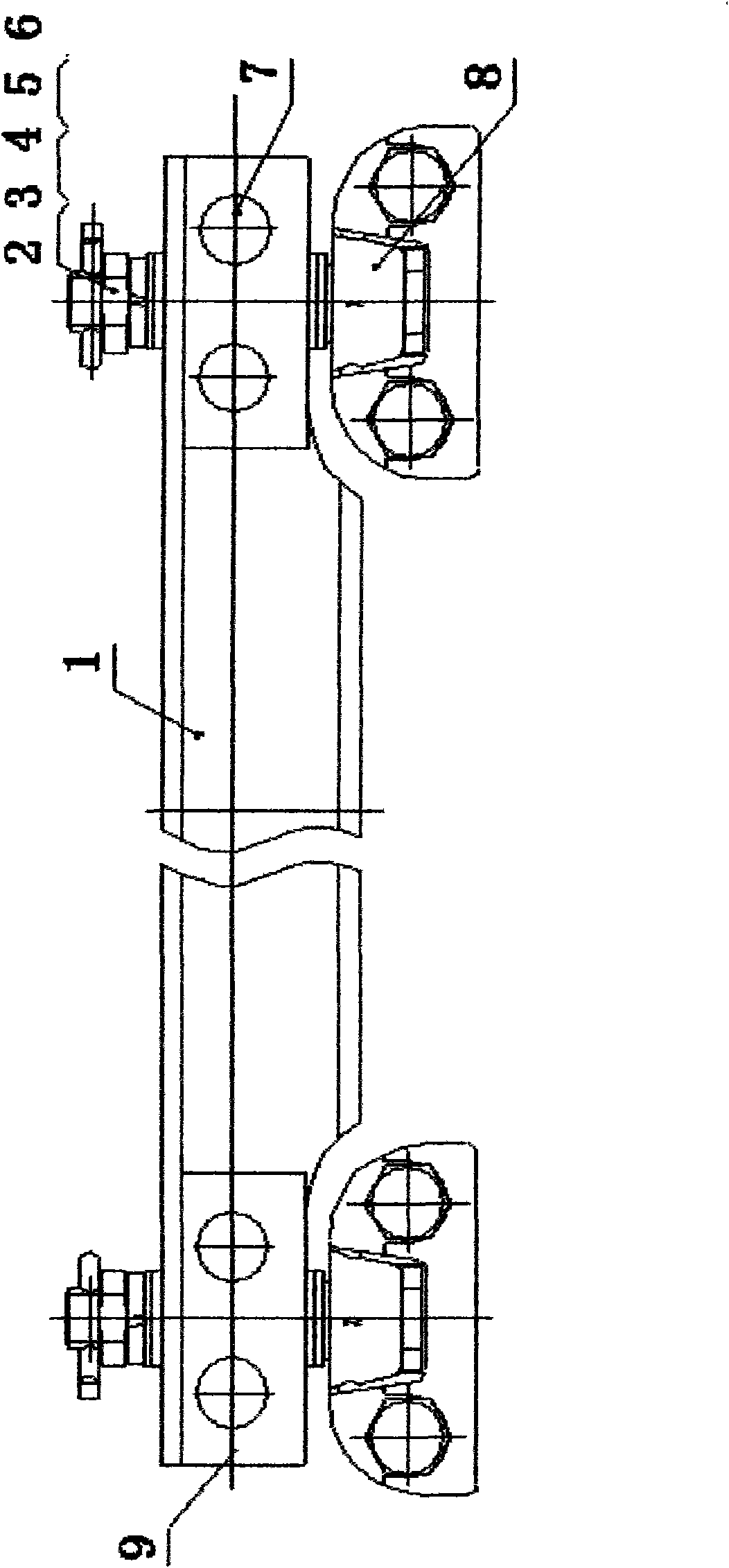

[0013] Such as figure 1 As shown, the line switch body 1 is an aluminum alloy body with a groove body, and the two ends of the aluminum alloy body are embedded in the groove-shaped body with aluminum alloy plates 9, and then two rivets 7 are used to connect the aluminum alloy body of the groove body and the aluminum alloy body. The plates 9 are riveted together. There are installation holes on the aluminum alloy plate 9 corresponding to the holes at the two ends of the switch body 1 respectively, and the distance between the holes at the two ends of the switch body 1 is 1960mm. The lag bolt 2 passes through the hole of the switch body 1, and the positioning clamp 8 and the washer 5 are installed under it, and the washer 5, the spring washer 4, the nut 3 and the cotter pin 6 are installed on the top. The positioning wire clamp 8 plays a positioning role, and the positioning wire clamp 8 is connected with the lag bolt 2 and can rotate around the lag bolt 2. The upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com