Hoisting system capable of implementing high hoisting of reach truck

A forklift and front-lifting technology, which is applied in the field of lifting system of reach-type forklift, can solve the problems of large vehicle shaking, large tilted total weight, inflexible operation, etc. The effect of improving the observation field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

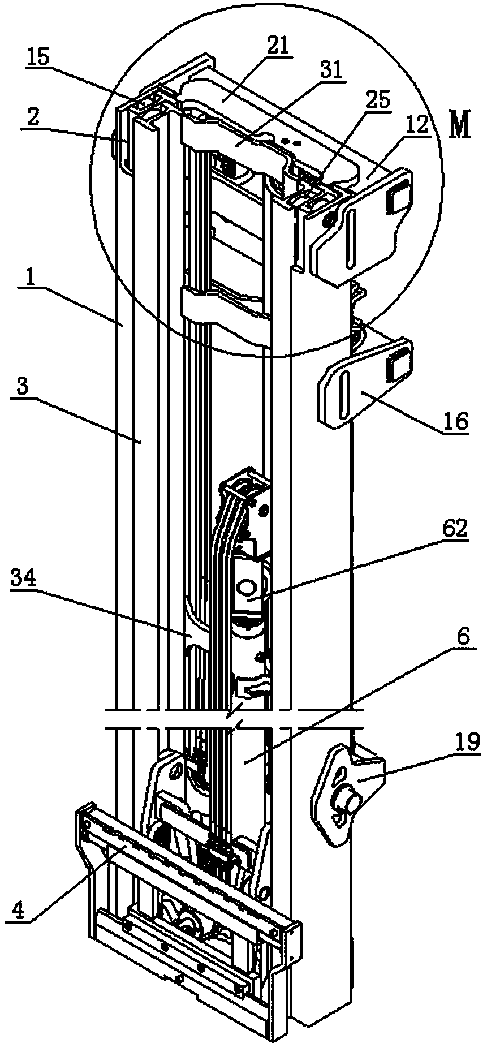

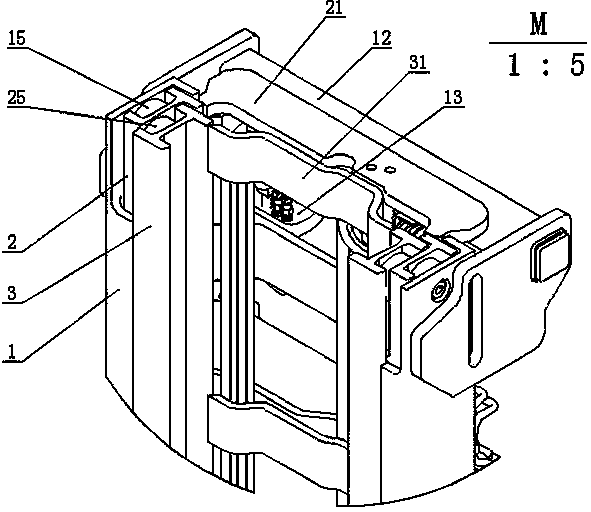

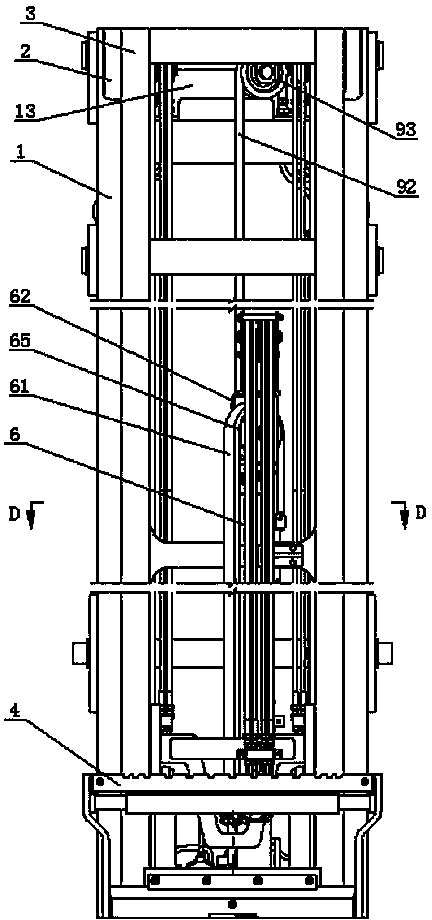

[0033] see figure 1 , figure 2 , image 3 and Figure 4 , a lifting system of a reach-type forklift that realizes high lifting includes a three-stage lifting mast, a side shifter 4, a front lifting cylinder 6, two rear lifting cylinders 7 and a hydraulic piping system 9. The three-stage hoisting mast consists of an outer mast 1, a middle mast 2 and an inner mast 3.

[0034] The front lifting oil cylinder 6 is installed in the lower part of the middle left in the inner mast 3, and the top of the front lifting oil cylinder 6 is provided with a front cylinder sprocket 65 through a rectangular frame-shaped sprocket bracket 62, and the front cylinder sprocket 65 is straddled. There is a front cylinder chain 61; the two rear lifting cylinders 7 are respectively arranged on both sides of the lower part of the outer mast 1, and are located outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com