Ball valve

A ball valve and valve body technology, applied in the direction of valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of small operating range, bending and deformation of positioning pins, affecting the opening of the ball valve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

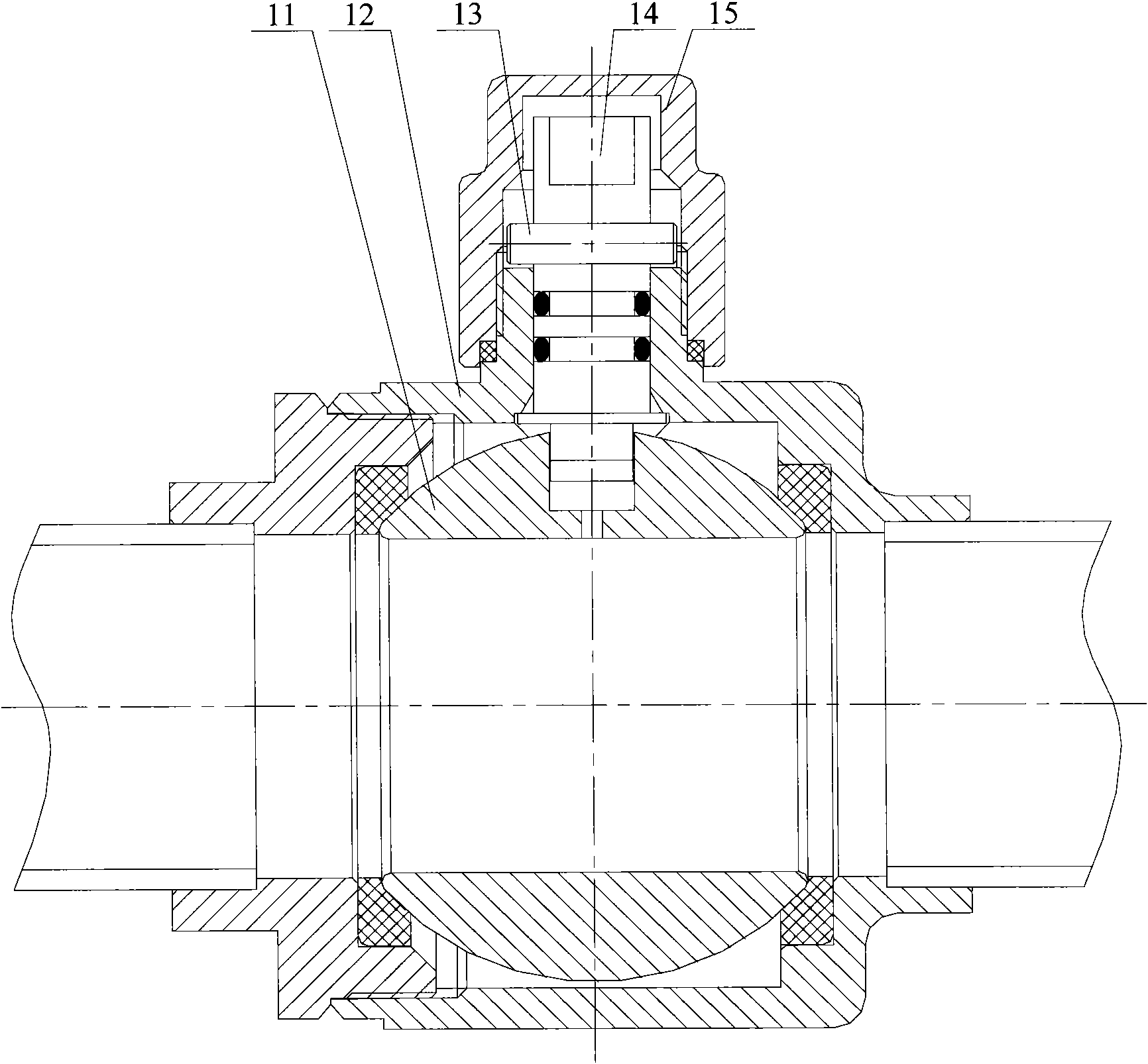

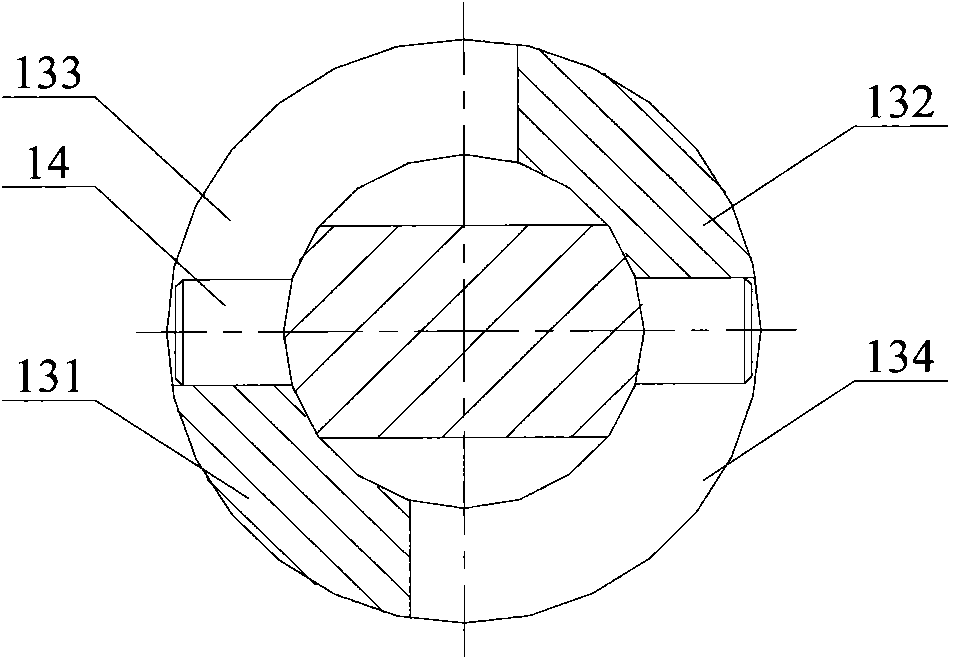

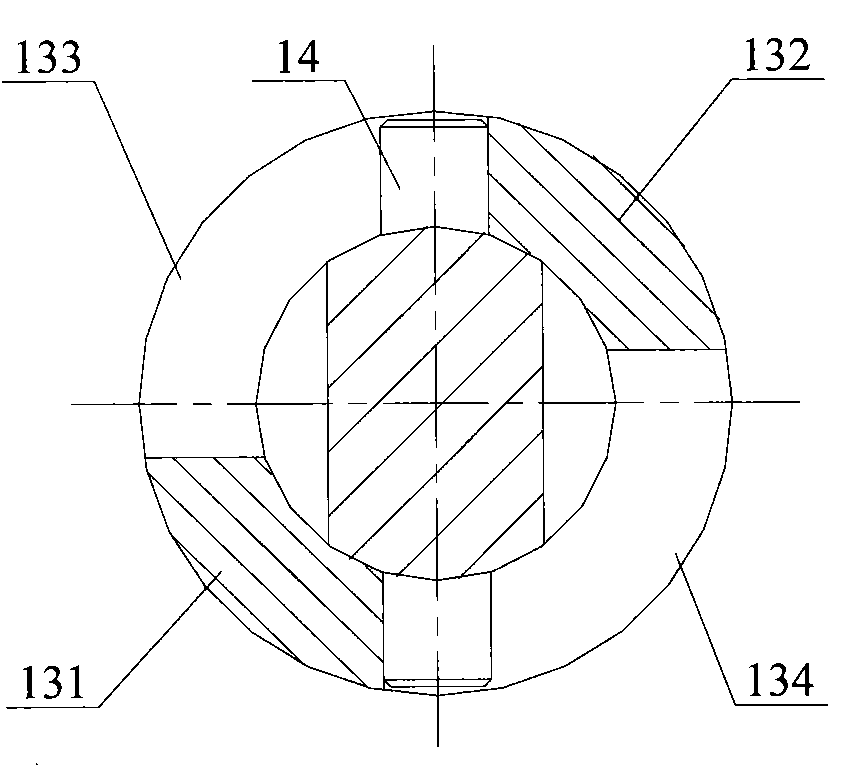

[0032] The present invention is a structural improvement design based on the existing ball valve. It includes a stop part arranged on the valve stem and a positioning boss arranged on the valve body, and the protruding part of the stop part cooperates with the positioning boss , In order to limit the fully open position and fully closed position of the ball valve; compared with the existing ball valve, the main point of the design of the present invention is that the bending section of the extension of the stop member is rectangular, and the rectangular bending section is high The width ratio h / b satisfies: 1<h / b<6 to improve the strength of the switch structure and ensure the stability of the ball valve.

[0033] The height h and width b dimensions of the rectangular bending section mentioned in this article are based on the section figure when the force analysis of the extension is carried out (see Figure 7 ) Is defined as a benchmark.

[0034] Hereinafter, this embodiment will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com