Stand structure of floor lamp

A bracket structure and floor lamp technology, applied in the parts of lighting devices, lighting devices, independent lighting devices, etc., can solve problems such as affecting the appearance and use, uneven materials, and insufficiency of corrosion, and improve the bending resistance. , Not easy to break, beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

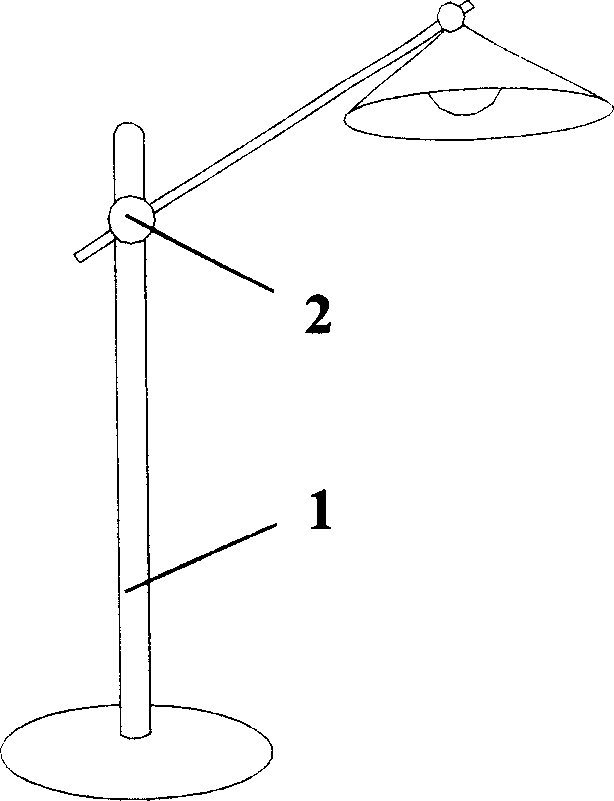

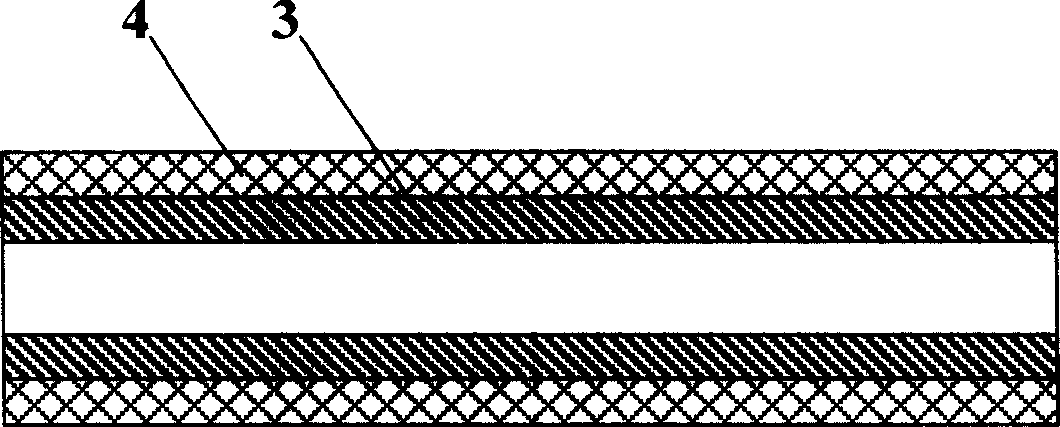

[0010] Such as figure 1 and figure 2 As shown, the bracket structure of a floor lamp of the present invention is composed of at least one tubular connector 1, wherein any one of the tubular connectors is composed of a stainless steel tube 4, and any one of the stainless steel tubes 4 Reinforced fiber plastic pipe body 3 is arranged inside, the diameter of described reinforced fiber plastic pipe body 3 is matched with the diameter of described stainless steel pipe body 4, and described stainless steel pipe body 4 and described reinforced fiber plastic pipe The bodies 3 are fixedly connected, and the tubular connectors 1 are connected through joints 2 .

[0011] Further, the radial section of the tubular connector 1 is circular, or rectangular, or square, or has a special-shaped section.

[0012] Further, the joint 2 is provided with a nut seat, and bolts are arranged in the nut seat. The bolts can adjust the tightness of the nut seat, so as to adjust the gripping force betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com