Reinforced riser pipe combined structure and construction method thereof

A water riser and composite structure technology, which is applied in the direction of drill pipe, casing, underwater drilling, etc., can solve the problems of increased operating costs and increased water riser, so as to save engineering costs, improve the overall bending resistance, improve The effect of the overall stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

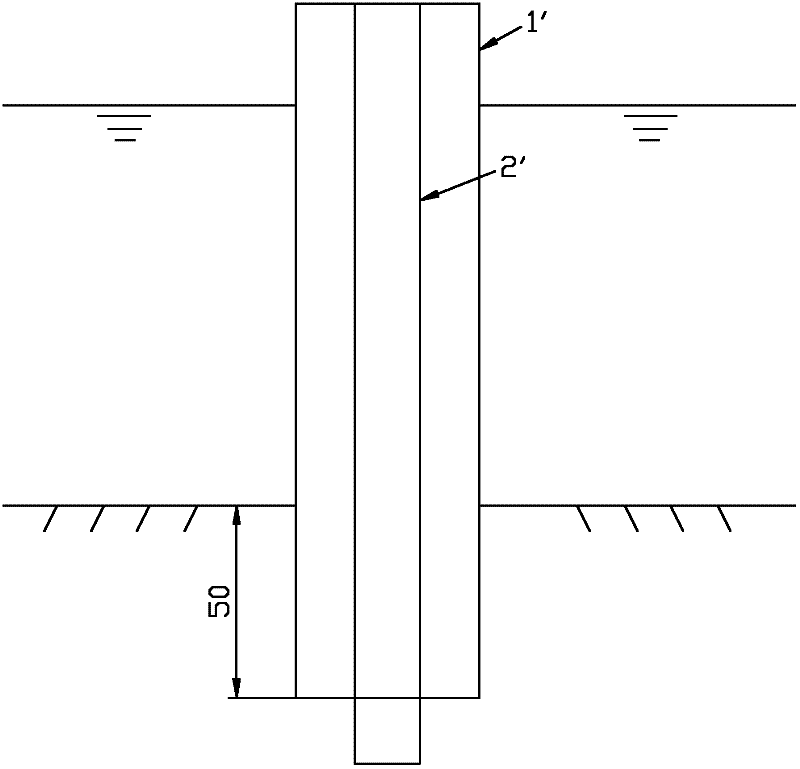

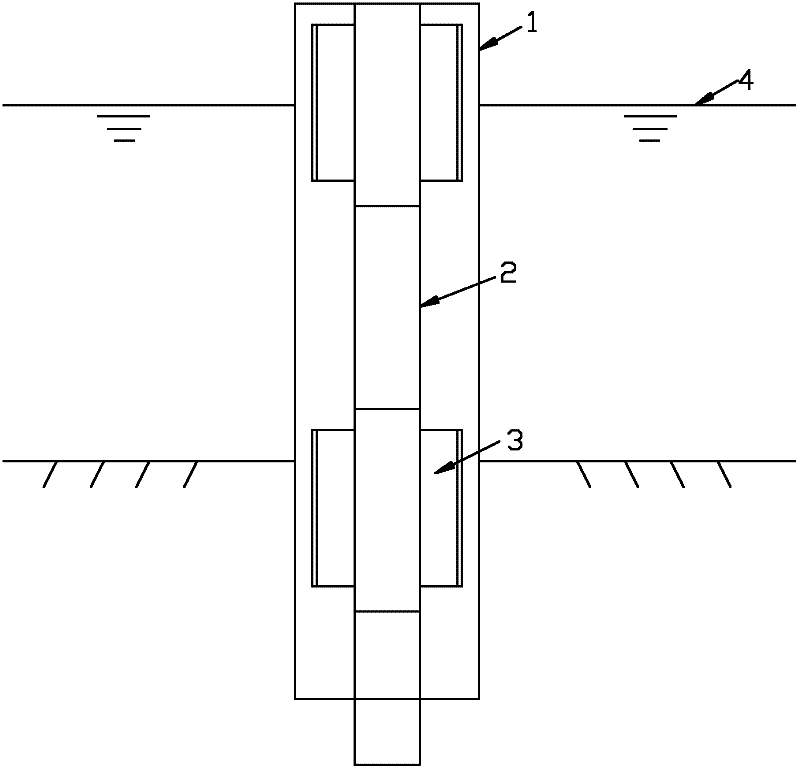

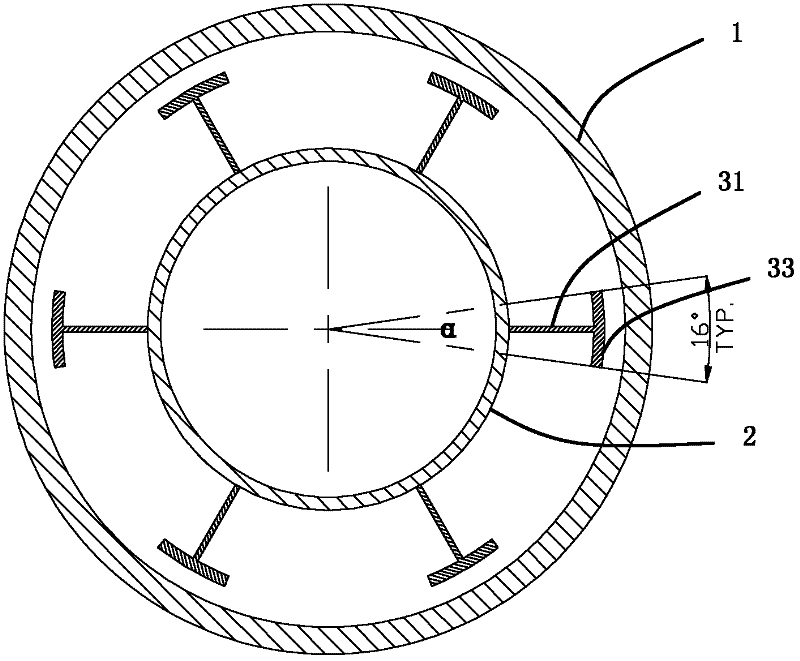

[0027] The present invention proposes a combined structure of reinforced water-resisting conduits, wherein, the combined structure of reinforced water-resisting conduits includes an inner layer casing and a water-resisting conduit, the water-resisting conduit is sleeved outside the inner layer casing, and the inner layer casing The outer surface of the pipe 2 is fixed with a reinforcing rib structure, and the annular space between the water riser and the inner casing is poured and consolidated with cement. The invention can reduce the size of the water riser while ensuring the safe construction of the drilling, while ensuring the same mechanical properties as the large size of the water riser, and greatly reducing the amount of steel used, without affecting the drilling construction period, and saving a lot engineering costs.

[0028] Preferably, the stiffener adopts a reinforced structure in the form of a T-shaped beam. In the combined structure of the reinforced water-resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com