Cu-Ni-Si-Fe alloy and preparation method and application thereof

A cu-ni-si-fe, alloy technology, applied in the direction of metal/alloy conductors, conductors, conductive materials, etc., can solve the problems of reduced yield, large casting stress, and difficult mining, etc., to improve conductivity and improve The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0095] As a preferred embodiment, in terms of mass percentage, the Cu-Ni-Si-Fe alloy includes the following components:

[0096] Ni: 1.5wt%~4.8wt%,

[0097] Co: 0wt%~0.6wt%,

[0098] Si: 0.6wt%~1.8wt%,

[0099] Fe: 0.3wt%~1.4wt%,

[0100] Mg: 0.05wt%~0.15wt%,

[0101] The balance is copper.

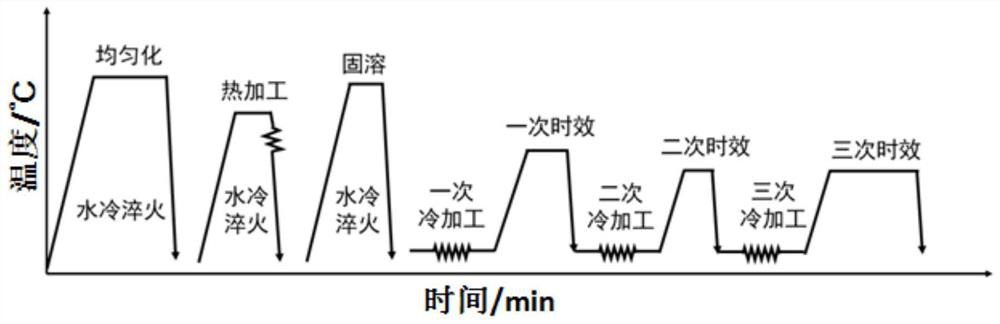

[0102] In some embodiments of the present invention, a method for preparing the above-mentioned Cu-Ni-Si-Fe alloy is provided, comprising the following steps:

[0103] S1: after the raw materials are melted according to the proportion, add a covering agent and a refining agent for smelting, casting and molding to obtain an ingot;

[0104] S2: homogenize the ingot to obtain a billet;

[0105] S3: After the billet is subjected to hot working and blanking treatment, the first water cooling treatment is performed to obtain a hot working billet;

[0106] S4: After the hot working billet is subjected to solution treatment and second water cooling treatment in a protective atmosphere, fir...

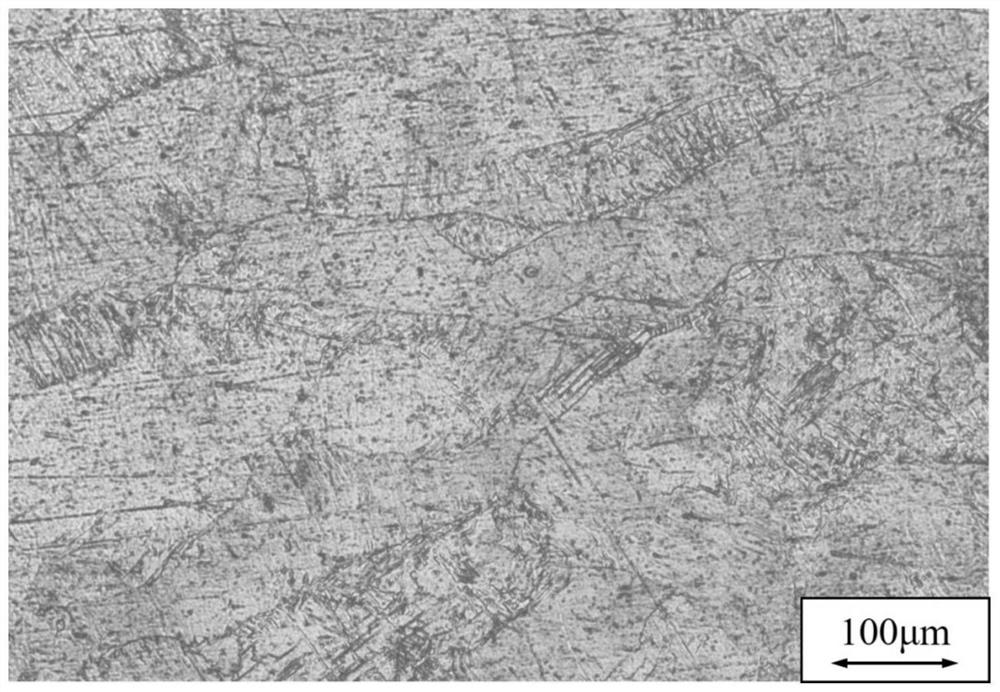

Embodiment 1

[0127] This embodiment prepares a Cu-Ni-Si-Fe alloy, specifically:

[0128] According to the composition, Ni: 4.5 wt %, Co: 0.2 wt %, Si: 1.2 wt %, Fe: 0.6 wt %, Mg: 0.1 wt %, and the balance is Cu.

[0129] Prepare materials according to the weight percentage of elemental composition, first add the copper source into the melting furnace for melting, then add the copper-silicon master alloy, nickel source, cobalt source, iron source in turn, finally add the copper-magnesium master alloy, and add the covering agent when the raw materials begin to melt and refining agent.

[0130] The mulch charcoal is baked to red heat at 500°C.

[0131] Smelting was carried out at 1300°C in the atmosphere, cast in an iron mold at 1200°C, and after cooling, it was milled by a lathe to remove surface defects.

[0132] After cooling in protective atmosphere 2%H 2 +Margin N 2 Homogenization treatment was carried out in the annealing temperature at 950 °C and the annealing time was 4 h.

[013...

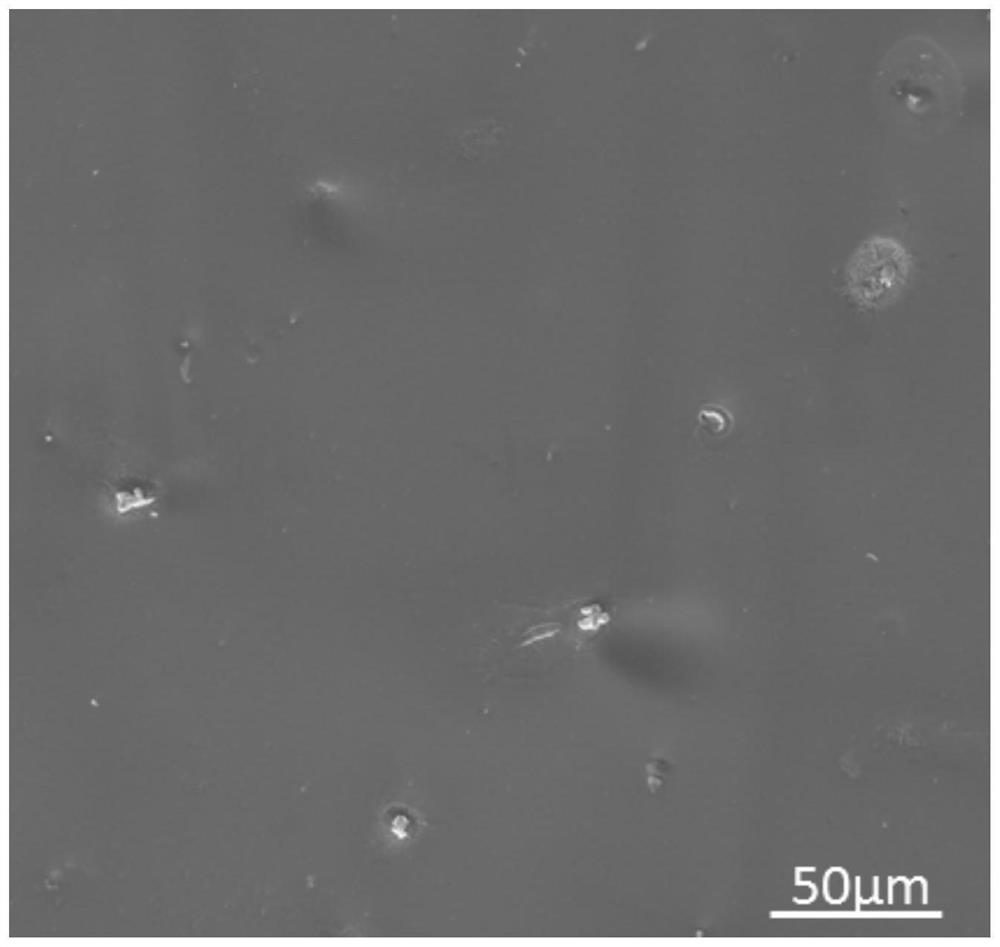

Embodiment 2

[0138] This embodiment prepares a Cu-Ni-Si-Fe alloy, specifically:

[0139] According to the composition, Ni: 4.5 wt %, Co: 0.2 wt %, Si: 1.6 wt %, Fe: 1.0 wt %, Mg: 0.1 wt %, and the balance is Cu.

[0140] Prepare materials according to the weight percentage of elemental composition, first add the copper source into the melting furnace for melting, then add the copper-silicon master alloy, nickel source, cobalt source, iron source in turn, finally add the copper-magnesium master alloy, and add the covering agent when the raw materials begin to melt And refining agent, covering agent charcoal bake at 500 ℃ to red heat.

[0141] Smelting was carried out at 1300°C in the atmosphere, cast in an iron mold at 1200°C, and after cooling, it was milled by a lathe to remove surface defects.

[0142] After cooling in a protective atmosphere of 2% H 2 +Margin N 2 and 950°C for 4 hours, followed by hot rolling with a reduction of 80%. After the hot-rolled sheet is water-cooled, it is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com