Vermicular graphite cast iron glass mold material and mold preparation method

A technology of vermicular graphite cast iron and glass molds, which is applied in the field of vermicular graphite cast iron glass mold materials and mold preparation, can solve the problems of casting stress of large materials, white holes, shrinkage cavities of rough castings, etc., to reduce the amount of matrix, reduce casting stress, The effect of increasing the degree of graphitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

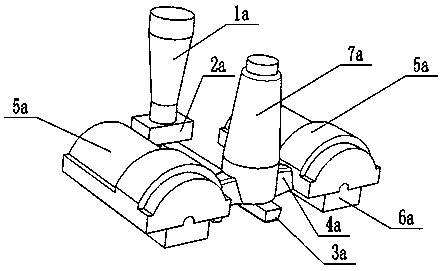

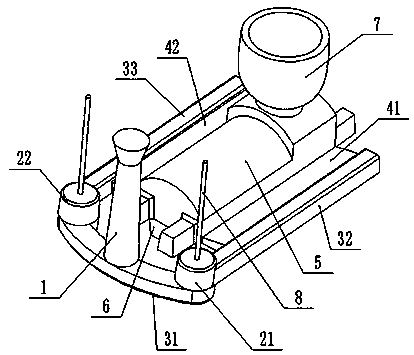

Image

Examples

Embodiment 1

[0037] The material of the vermicular graphite cast iron glass mold is composed of the following chemical elements: carbon 3.9%, silicon 1.5%, manganese 0.15%, phosphorus<0.1%, sulfur<0.03%, magnesium<0.05%, the rest is iron, and other unavoidable The impurity element; The preparation method of described vermicular graphite cast iron glass mold comprises the following steps:

[0038] A. Melting: According to the above chemical composition, add steel scrap and Q10 pig iron to the smelting furnace quantitatively, add the returned material after the scrap steel and pig iron are melted, and control the weight percentage of the returned material in the added pig iron to 30%, and the temperature of the molten iron When it reaches 1450°C, use a silicon carbon meter for process control, mainly to control the silicon content. If the silicon content is within the range, there is no need to adjust it. If it is higher than the upper limit, then add steel scrap for adjustment. Adjustment, ...

Embodiment 2

[0042] The material of the vermicular graphite cast iron glass mold is composed of the following chemical elements: carbon 4.0%, silicon 1.6%, manganese 0.2%, phosphorus<0.1%, sulfur<0.03%, magnesium<0.05%, the rest is iron, and other unavoidable The impurity element; The preparation method of described vermicular graphite cast iron glass mold comprises the following steps:

[0043] A. Melting: According to the above chemical composition, add steel scrap and Q10 pig iron to the smelting furnace quantitatively, add the returned material after the scrap steel and pig iron are melted, and control the weight percentage of the returned material in the added pig iron to 30%, and the temperature of the molten iron When it reaches 1500°C, use a silicon carbon meter for process control, mainly to control the silicon content. If the silicon content is within the range, there is no need to adjust it. If it is higher than the upper limit, add steel scrap for adjustment. If it is lower than...

Embodiment 3

[0047] The material of the vermicular graphite cast iron glass mold is composed of the following chemical elements: carbon 3.8%, silicon 1.4%, manganese 0.1%, phosphorus<0.1%, sulfur<0.03%, magnesium<0.05%, the rest is iron, and other unavoidable The impurity element; The preparation method of described vermicular graphite cast iron glass mold comprises the following steps:

[0048] A. Melting: According to the above chemical composition, add steel scrap and Q10 pig iron to the smelting furnace quantitatively, add the returned material after the scrap steel and pig iron are melted, and control the weight percentage of the returned material in the added pig iron to 30%, and the temperature of the molten iron When it reaches 1450°C, use a silicon carbon meter for process control, mainly to control the silicon content. If the silicon content is within the range, there is no need to adjust it. If it is higher than the upper limit, then add steel scrap for adjustment. Adjustment, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com