Casting apparatus for eliminating cracks of thick and large belt pulley shaft hole

A pulley shaft and crack technology, which is applied in the field of gray cast iron thick and large casting devices, can solve the problems of cross-shaped cracks in the shaft hole of castings, and achieve the effects of eliminating cracks in the shaft hole, uniform temperature distribution, and uniform cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present embodiment will be further described below in conjunction with the accompanying drawings.

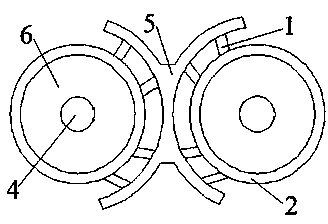

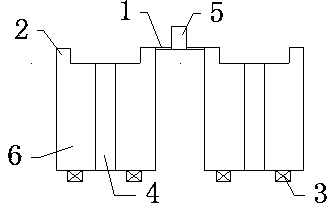

[0014] see figure 1 and figure 2 , which is a casting model of a casting device for eliminating cracks in the shaft hole of the thick and large pulley provided by the preferred embodiment of the present invention. The ingate 1 is connected with the annular runner 5, and the thick and large pulley The shaft hole 4 of the casting mold 6 is the center of the circle, and the rectangular pouring riser 2 is arranged on the outer wall of the thick pulley casting mold 6 along the outer ring thereof, and a cooling chamber is arranged on the inner bottom surface of the sand mold at the thick and large part of the pulley casting. Iron 3. At least one of the rectangular risers 2 is evenly distributed along the circumferential direction above the outer wall of the casting model, and at least one piece of the cold iron 3 is evenly arranged on the bottom surface of the middle thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com