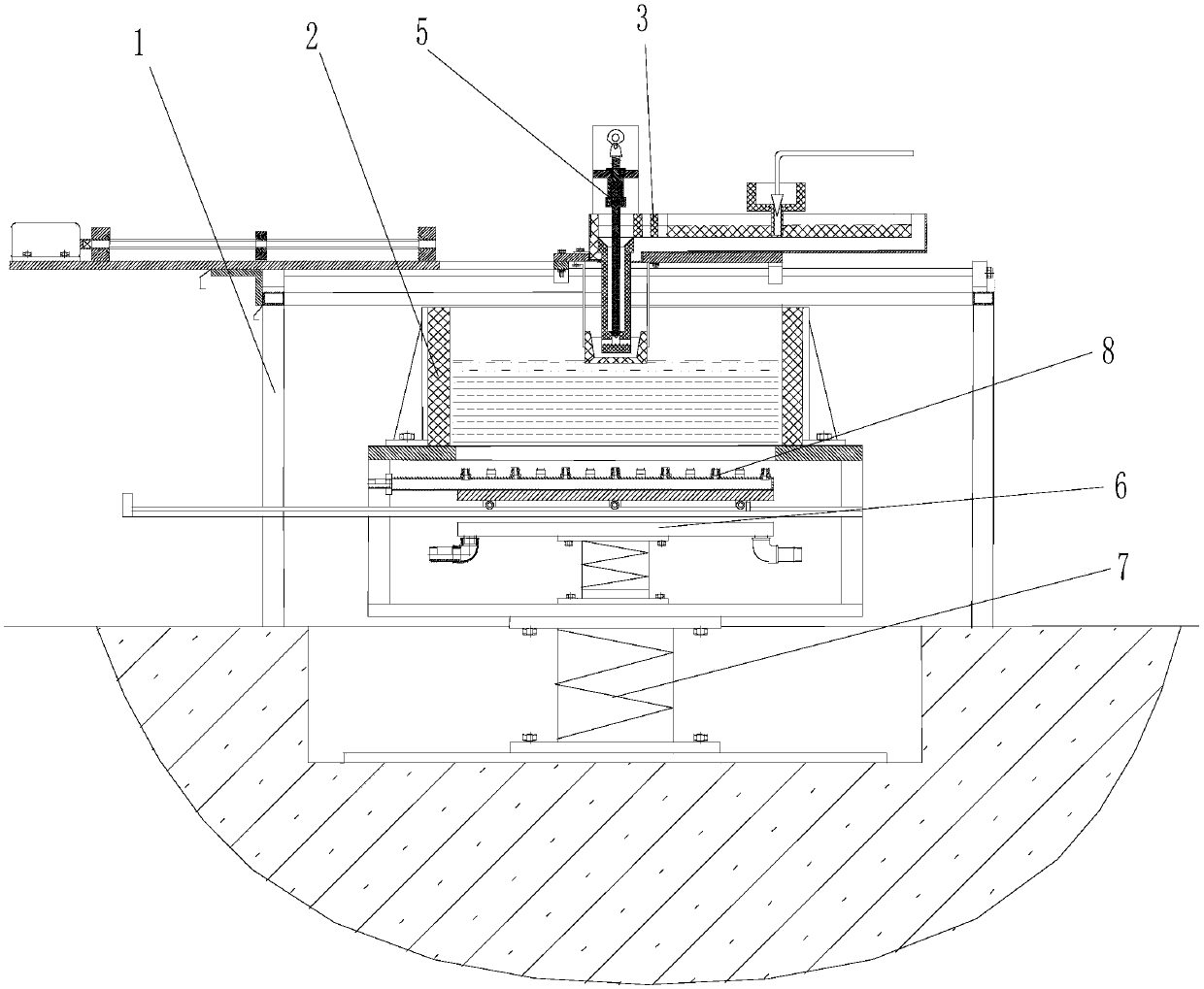

Aluminum Alloy Layered Distribution Plane Solidification Casting Device and Casting Method

A technology of aluminum alloy layer and flow distribution, applied in casting equipment, control of pouring molten metal from casting ladle, manufacturing tools, etc. effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

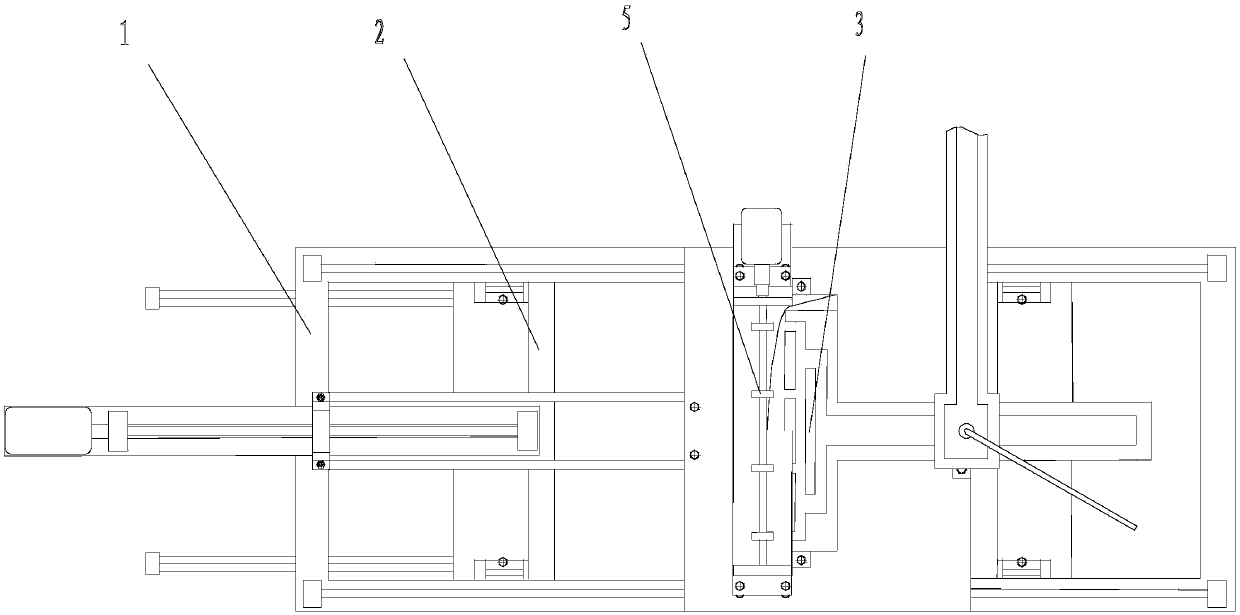

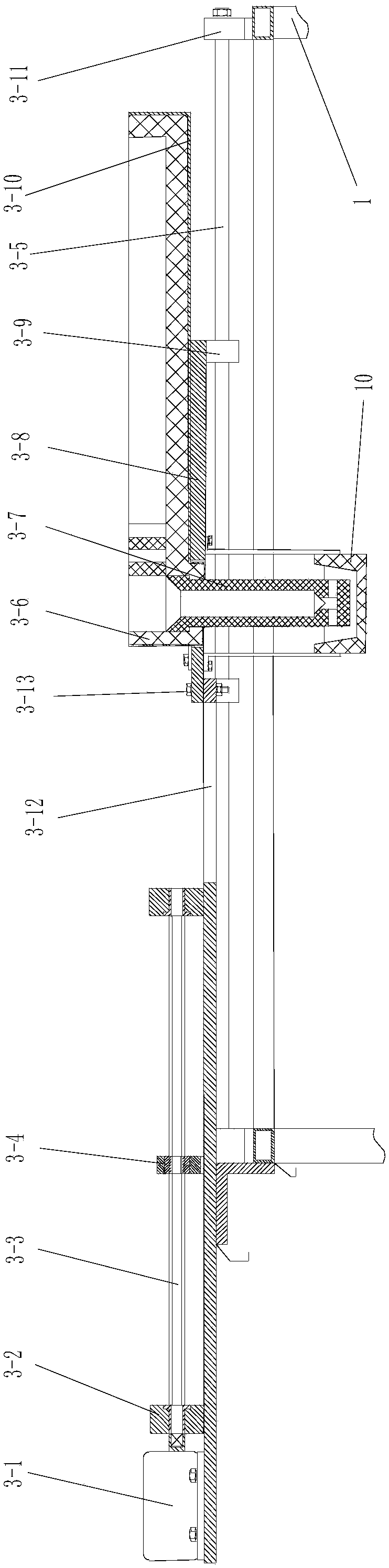

Method used

Image

Examples

Embodiment 1

[0085] The alloy is pure aluminum / 7050, the ingot size: thickness 300mm×width 600mm×length 800mm, the thickness of the 7050 alloy layer is 245mm,

[0086] Casting temperature: 720°C,

[0087] Casting speed (casting box drop speed): 60mm / min (pure aluminum), 20mm / min (7050 alloy),

[0088] Flow control method: lift the guide rod, 20mm (pure aluminum), 10mm (7050 alloy),

[0089] The running speed of translational diverter mechanism: 100mm / min (pure aluminum), 60mm / min (7050 alloy).

[0090] The cast ingot has no cracks, no cold shut on the surface, can be sawed in the cast state, and the inclusions reach A grade after ultrasonic flaw detection. The internal structure of the ingot is uniform, and the average grain size is 260 μm (see Figure 18 ). Macro segregation rate of alloying elements [(maximum value of ingot alloy element content - minimum value) / average value]: Zn is 3.1%, Mg is 5.9%, Cu is 6%, and the macroscopic composition clouds of Zn, Mg, and Cu are respectively...

Embodiment 2

[0092] The alloy is 5456 / 7055, the ingot size: thickness 300mm × width 600mm × length 800mm, the thickness of the 7055 alloy layer is 150mm,

[0093] Casting temperature: 720°C,

[0094] Casting speed (casting box drop speed): 20mm / min (7055 alloy), 15mm / min (5456 alloy),

[0095] Flow control method: lift the guide rod, 10mm (7055 alloy), 8mm (5456 alloy),

[0096] The running speed of the translational diverter mechanism: 60mm / min (7055 alloy), 60mm / min (5456 alloy).

[0097] The cast ingot has no cracks, no cold shut on the surface, can be sawed in the cast state, and the inclusions reach A grade after ultrasonic flaw detection. The internal structure of the ingot is uniform, and the average grain size is 260 μm (7055 alloy) and 250 μm (5456 alloy). The interface is clear, well bonded, free of pores and inclusions (see Figure 23 ), the alloy composition distribution in the thickness direction is shown in Figure 22 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com