Electric machine for evaporative cooling underwater equipment

A technology of evaporative cooling and cooling water, which is applied in the direction of cooling/ventilation devices, electrical components, electromechanical devices, etc., to achieve the effects of uniform and comprehensive cooling, high power density, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

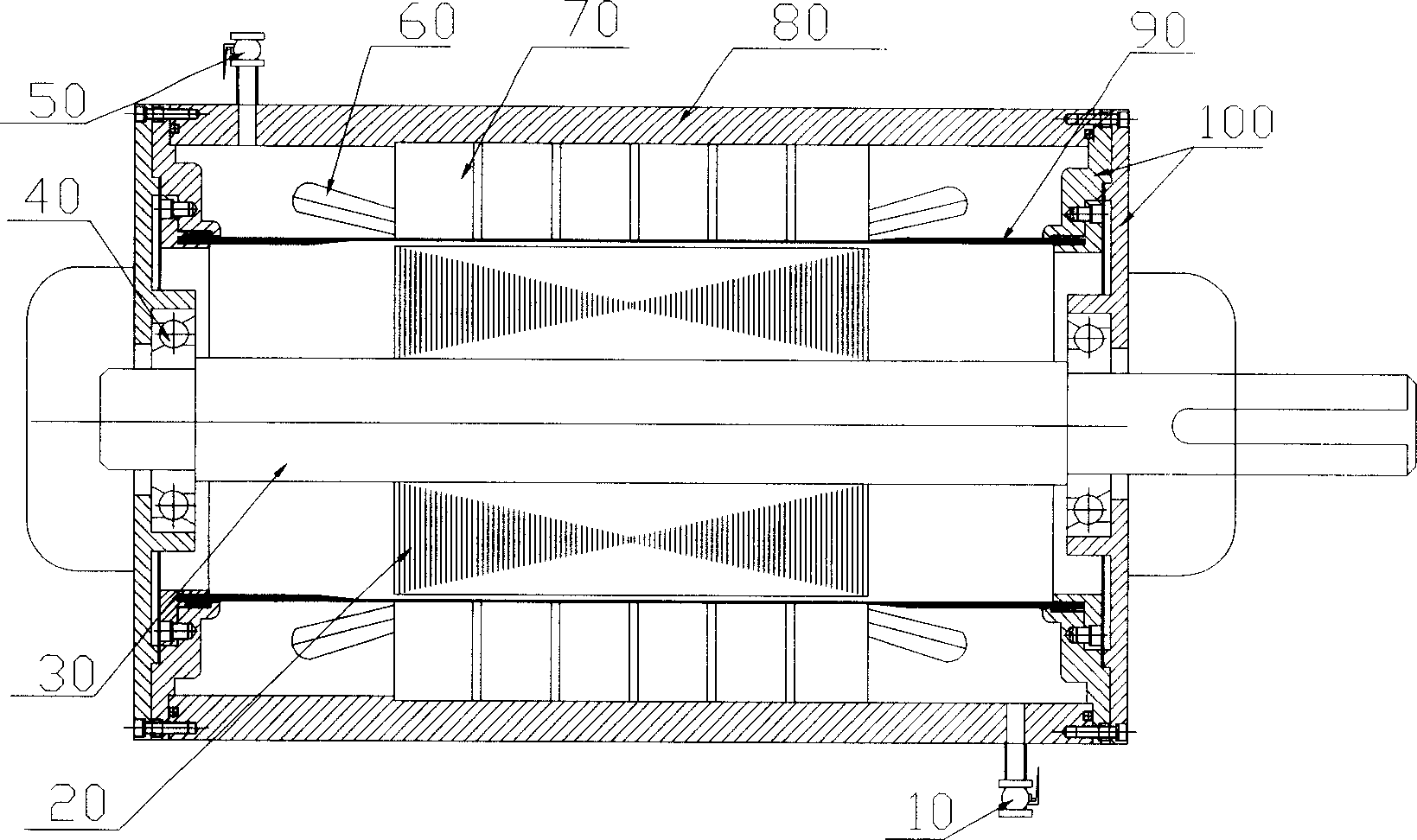

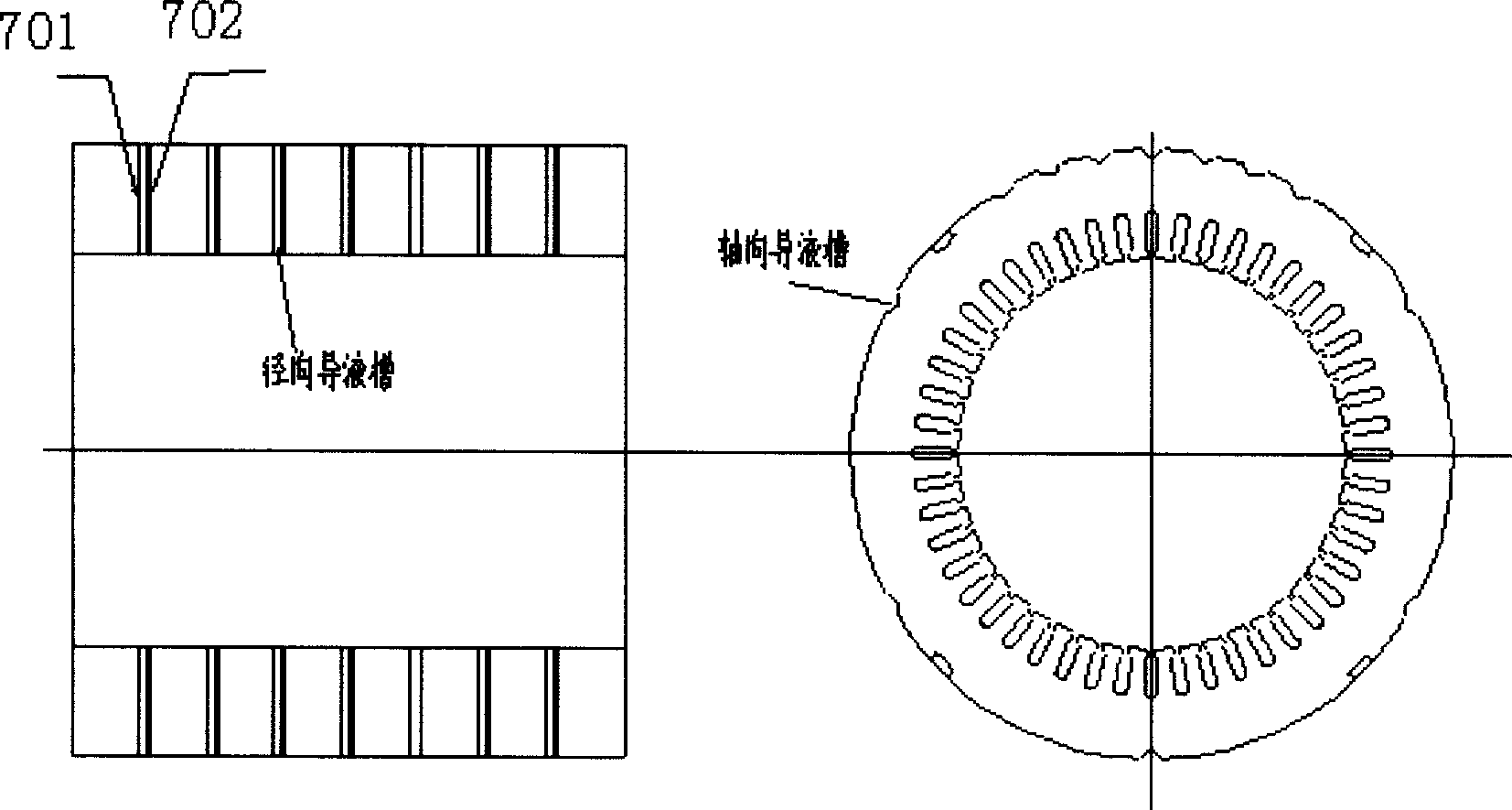

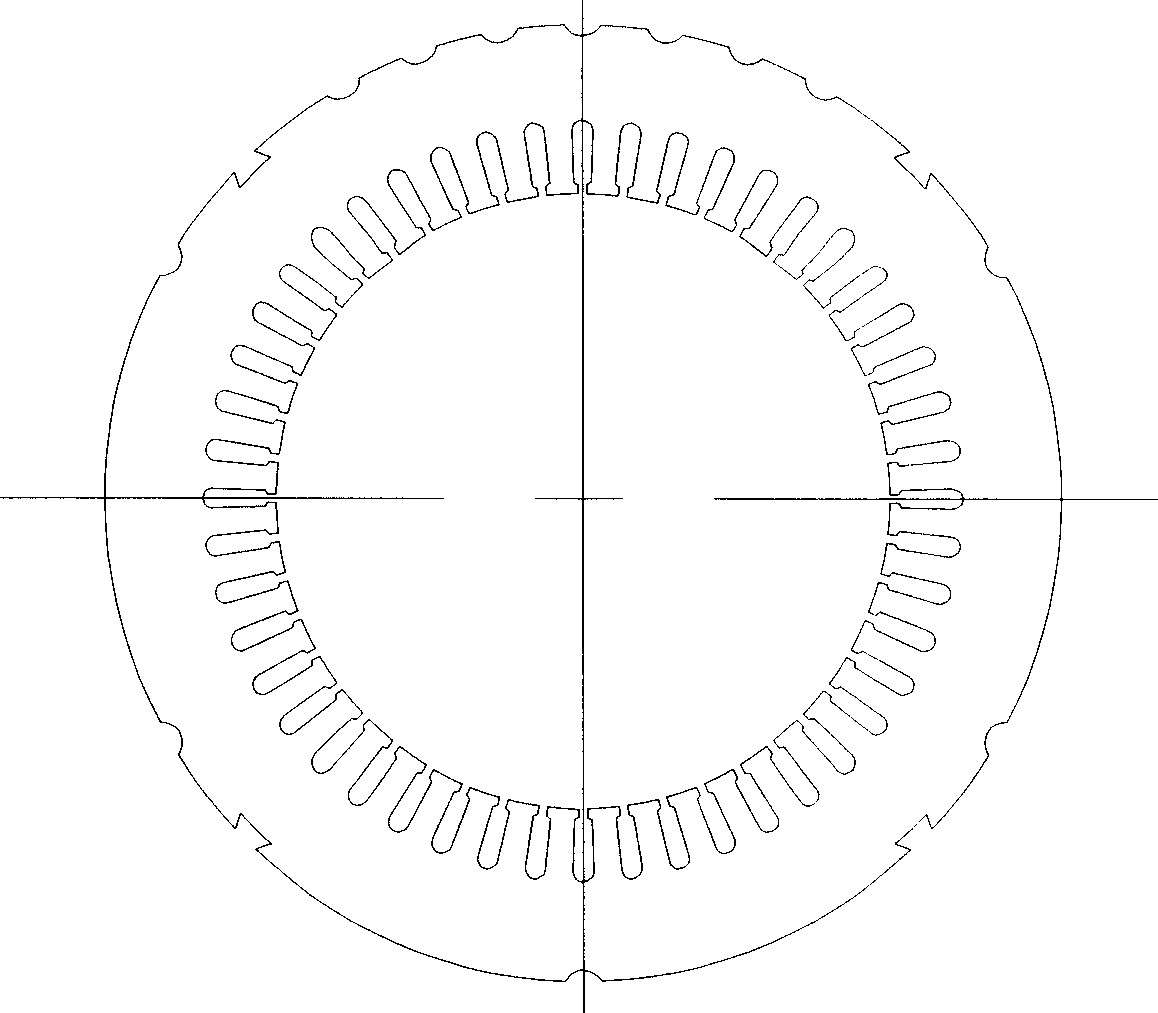

[0025] One of the specific embodiments of the present invention is as figure 1 shown. The outermost part of the motor is a motor casing, which includes a stator casing 80 and a motor end cover 100, etc. The lower right end of the stator casing 80 is provided with a cooling medium outlet 10, and the upper left end is provided with a cooling medium inlet 50; The stator core 70 is placed in the middle of the circle, the outer circle of the stator core 70 and the inner circle of the stator casing 80 are interference fit, and the stator winding 60 is embedded in the slot of the stator core 70; between the inner circle of the stator core 70 and the outer circle of the rotor 20 In the air gap of the motor, the inner sleeve 90 is installed close to the inner circle of the stator core 70, and there is a certain gap between the inner circle of the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com