Flowing boiling micro-miniature heat exchanger

A heat exchanger, micro-miniature technology, applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problems that the combination of economic benefits and heat transfer efficiency cannot be maximized, so as to improve the service life , reduce operating costs, reduce the effect of resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in conjunction with accompanying drawing:

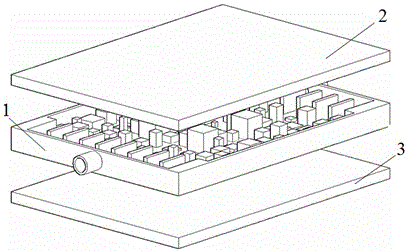

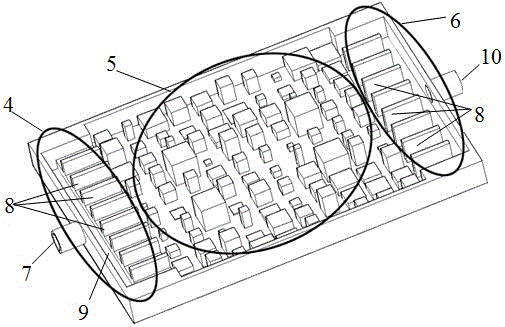

[0021] The structure of the flow boiling miniature heat exchanger proposed by the present invention is as follows: figure 1 As shown, the flow boiling miniature heat exchanger mainly includes an upper cover plate 2, a heat conducting base plate 3 and a boiling heat exchanger main body 1, and the combination of the upper cover plate 2 and the heat conducting base plate 3 forms a closed confined space. The inner surface of the thermally conductive substrate forms a layer of nanomaterials with a three-dimensional network structure through the sol-gel method. The surface water contact angle of this material is between 95° and 160°, and the hydrophobicity is extremely strong. The core of gasification, and at the same time, it will not cause a large resistance loss to the condensing medium.

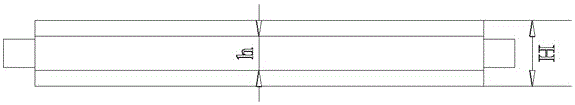

[0022] figure 2 It is the front view of the flow boiling micro heat exchanger. In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com