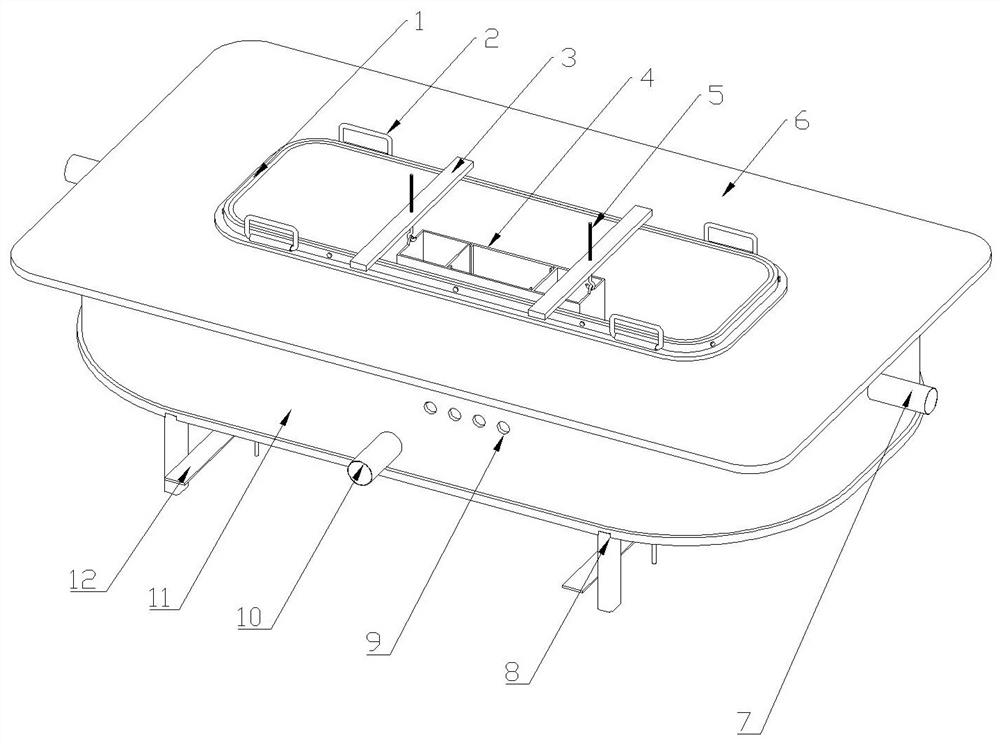

Electromagnetic semi-continuous casting device and method for alloy ingot with high casting stress

A technology for casting stress and alloy ingots, which is applied in the field of ingot casting and electromagnetic semi-continuous casting devices for alloy ingots with high casting stress. The effect of increasing growth rate, reducing casting stress and reducing ingot cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

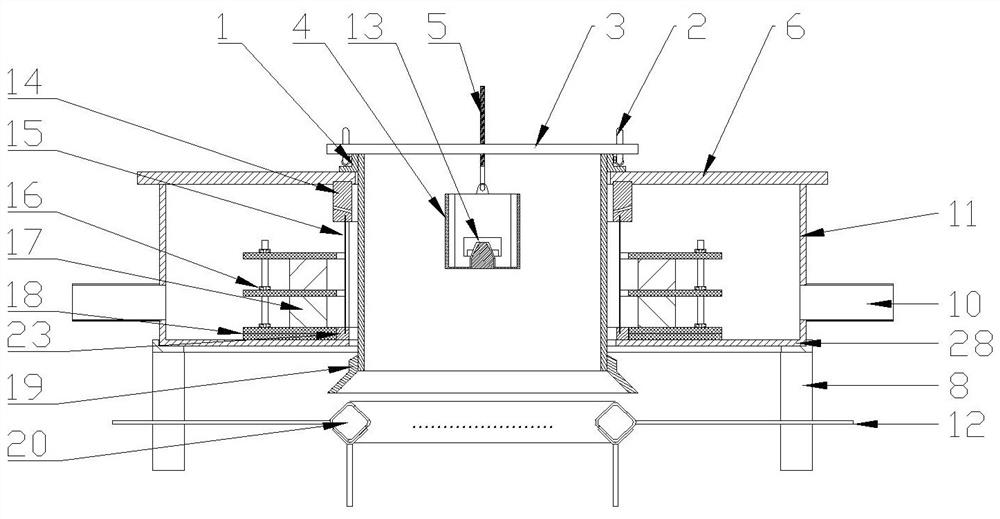

Method used

Image

Examples

Embodiment 1

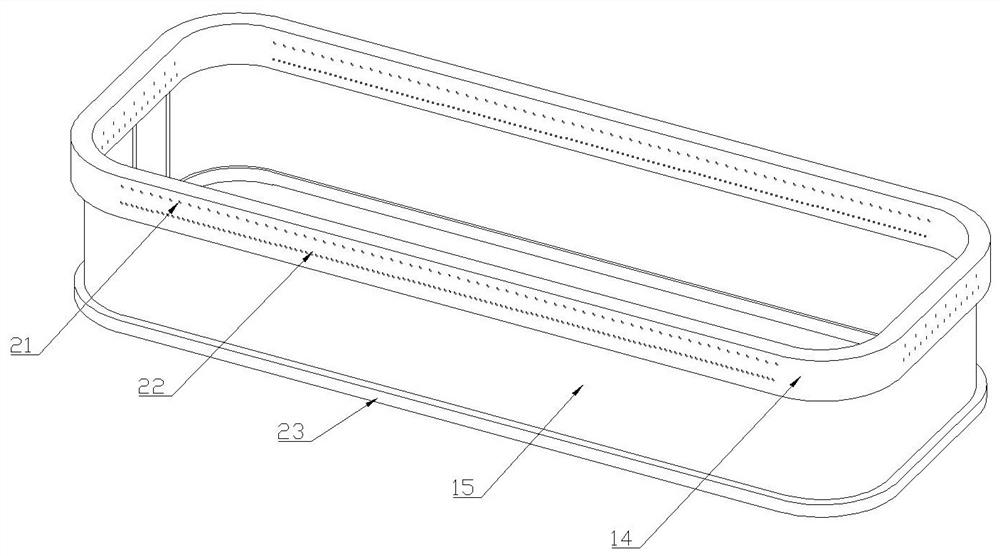

[0070] The alloy chosen for casting in this embodiment is AZ31, and its composition contains Al 2.79%, Zn 0.74%, Mn 0.31%, Si 0.012%, Fe<0.01%, and the rest is magnesium by weight percentage; The ratio is 3, and the specification is 1200×400mm.

[0071] The size of the distribution tank is selected to be 400×100×100 mm; the upper edge of the square hole 24 on the width side and the square hole 27 on the length side is 70mm away from the top surface of the inner sleeve of the crystallizer; the filter screen in the distribution tank 4 is 12 mesh, and the height of the flow control cone is 13 30mm, the distance between the two baffles 25 is 350mm, the specifications of the baffle square hole 26 and the width side square hole 24 are 80×40 mm and 60×30 mm respectively. The bottom edge and the upper edge of the square hole 27 on the length side and the square hole 24 on the width side are respectively kept flush, the distance between the bottom edge and the bottom of the shunt tank ...

Embodiment 2

[0088] Device structure and casting process flow are the same as embodiment 1, the difference is:

[0089] The casting alloy is AZ800, and the specification is 800×400mm.

[0090] The size of the shunt 4 is selected to be 350×80×100 mm, and the distance between the two baffles 25 in the shunt is 160 mm.

[0091] The height of the crystallizer inner sleeve 1 is 280mm.

[0092] There is no secondary cooling device, only through the first cooling, and the cooling water volume of the first cooling is 20m 3 / h.

[0093] The given electromagnetic field conditions are 10% duty cycle, 20Hz frequency, and 80A current.

[0094] The method is the same as in Example 1; the obtained magnesium alloy large slab product has no cracks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com