Heat treatment process for large thin-wall casting of high-strength magnesium alloy

A technology for thin-walled castings and magnesium alloys, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as scrapped castings, serious hot cracking tendency, and deformation of large-sized castings, so as to reduce casting stress, avoid cracking, avoid deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A heat treatment process for high-strength magnesium alloy large thin-walled castings specifically includes the following steps:

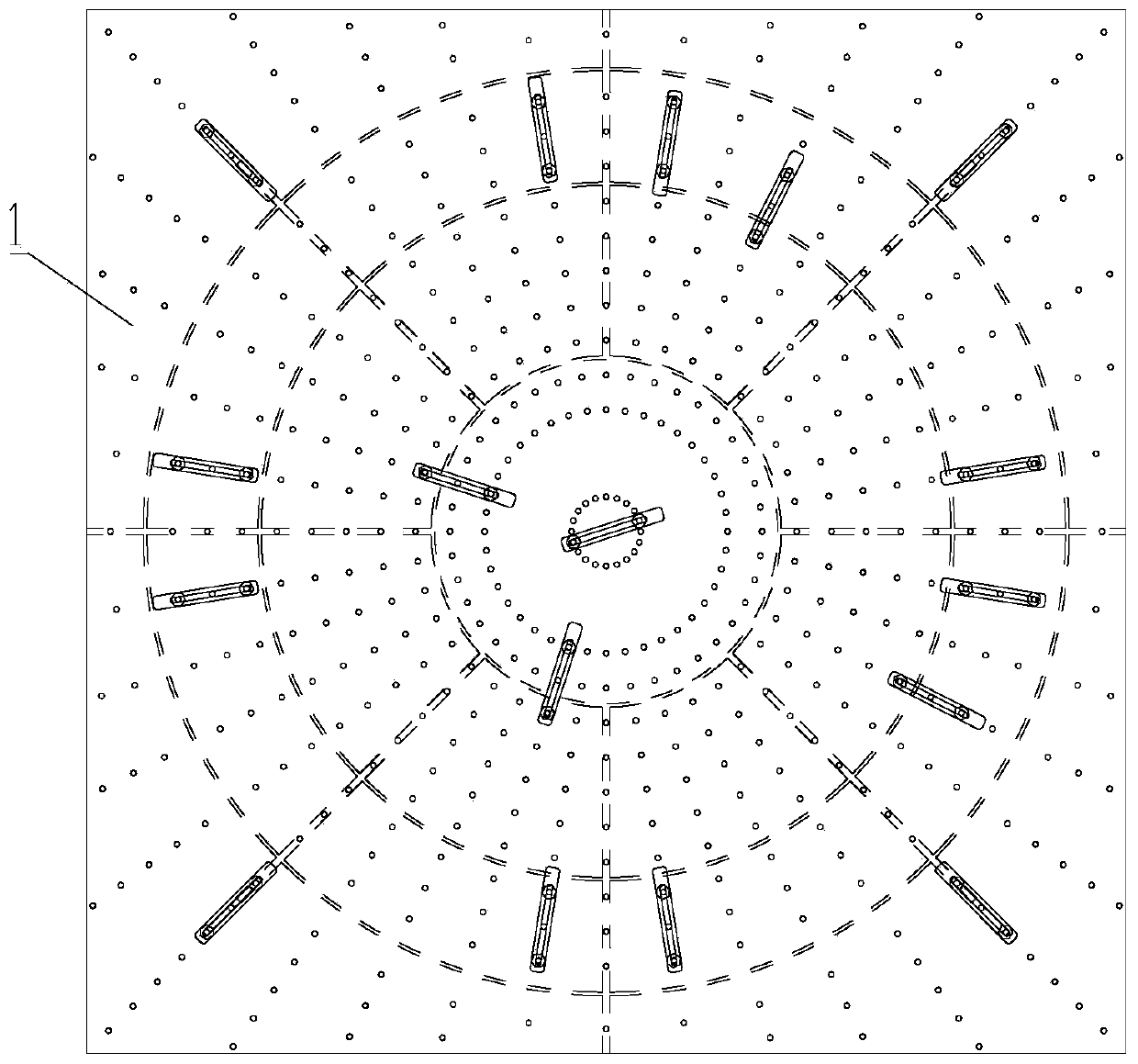

[0046] The large thin-walled castings with the size of φ1000*90 are preliminarily scribed and a datum plane is roughed out for every projected plane area not greater than 1 square meter.

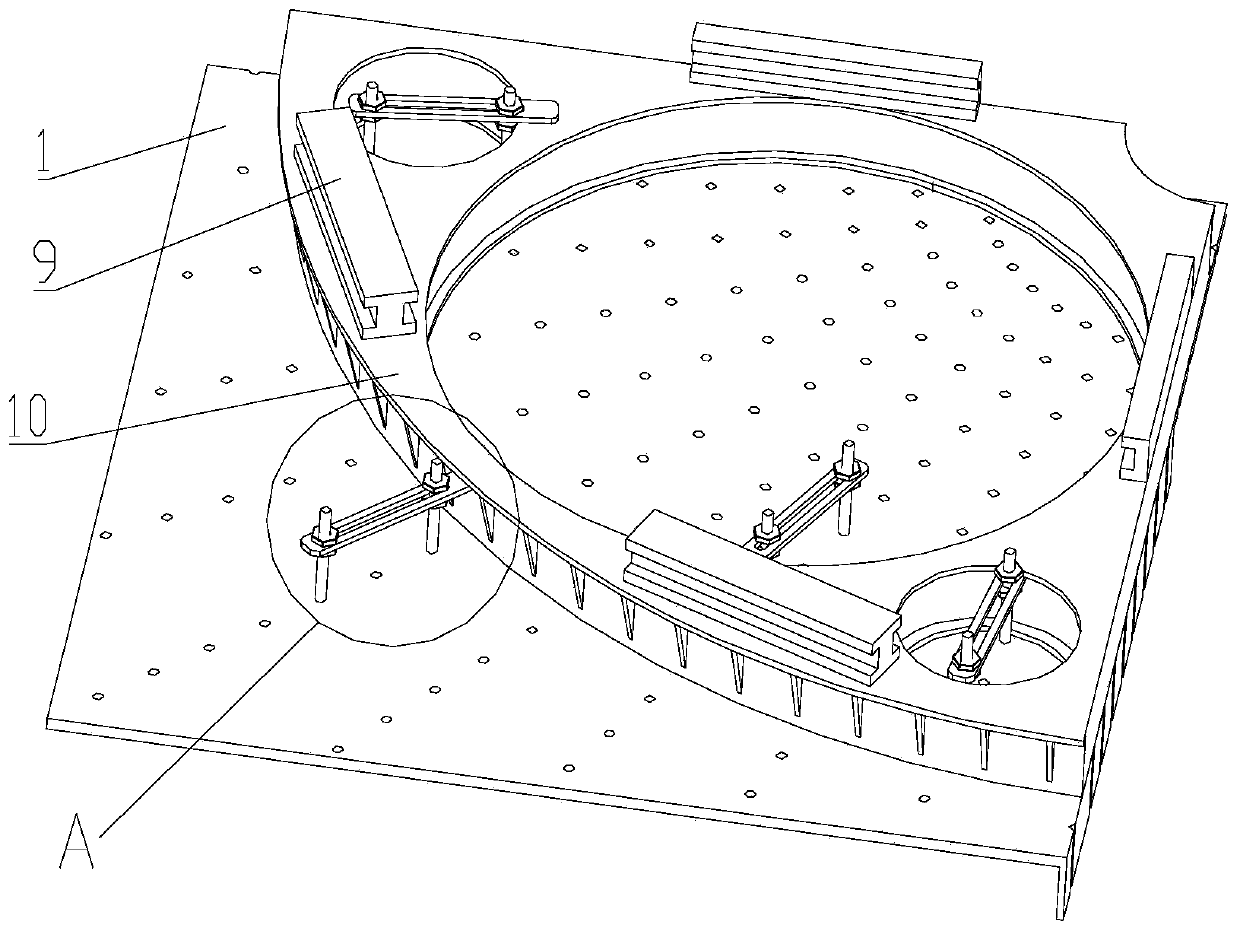

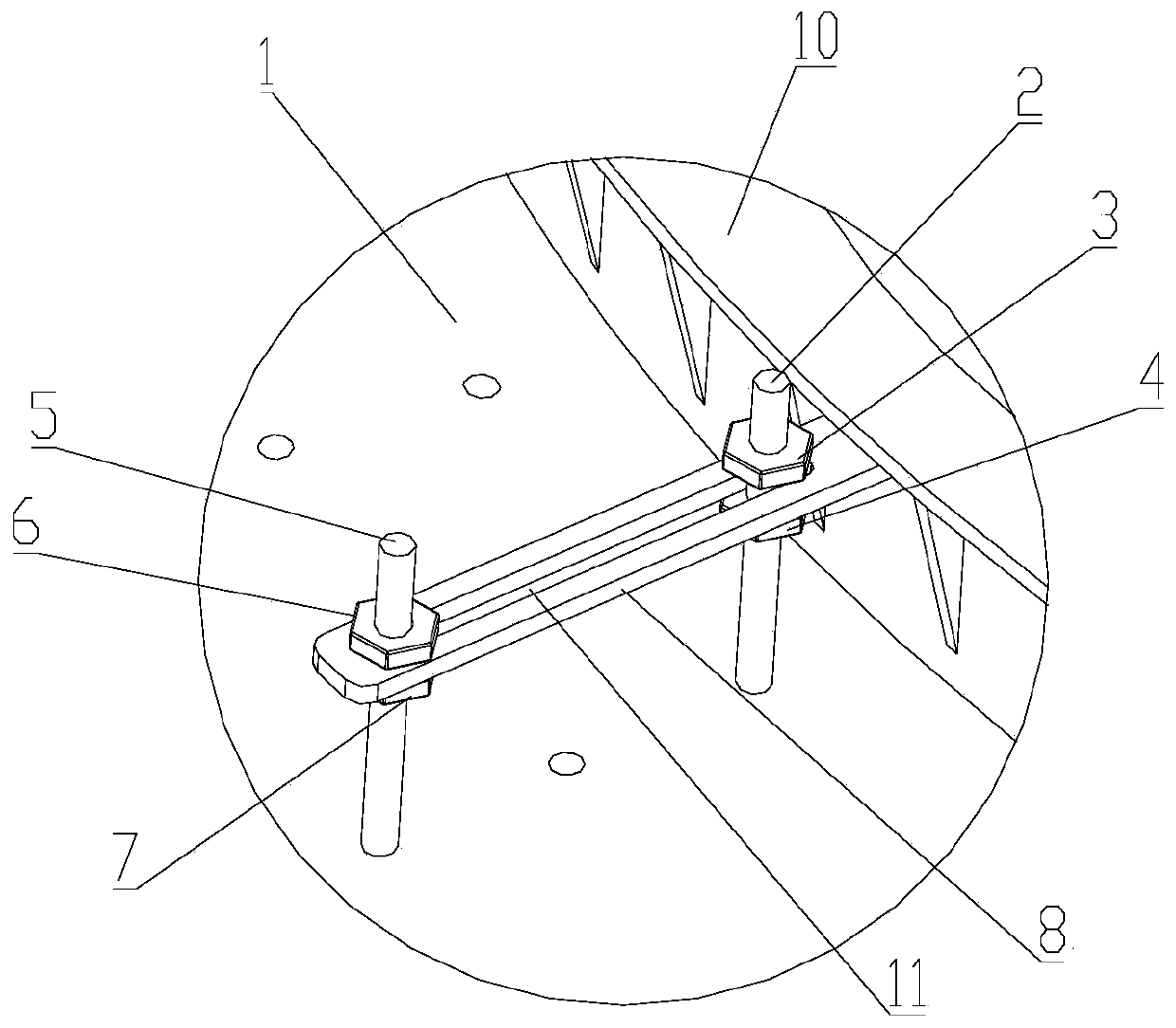

[0047] Assemble large thin-walled component castings and tooling at room temperature: Attach the castings to the high-rigidity platform A, and use the upper positioning nut on the supporting point of the supporting screw to support the high point obtained according to the scribing result, and apply force to the screw The nut at the lower part of the upper force point is screwed up, the high-rigidity pressure plate uses the principle of leverage to exert downward pressure on the high point on the casting; according to the low point obtained by the scribing result, the nut is positioned under the support point configured on the support screw For support, the uppe...

Embodiment 2

[0052] A heat treatment process for high-strength magnesium alloy large thin-walled castings specifically includes the following steps:

[0053] The large thin-walled castings with dimensions of 570*600*170 are removed from the pouring riser, initially scribed, and a datum surface is roughed out.

[0054] Assemble large thin-walled castings with high-rigidity and easy-to-heat-conducting tooling. The assembly process is the same as in Example 1. After assembly, the castings are solution-treated: first heat up to 250°C, at a rate of 20°C / min, and hold at 250°C for 2h; Then the temperature was raised to 500℃, the heating rate was 10℃ / min, and it was kept at 500℃ for 8h.

[0055] After solid solution, the castings and tooling are taken out of the furnace and forced to air cooling, the quenching air rate is 4m / s, within the temperature range of 250-350℃, the castings are quickly released from the high-rigidity platform A and transferred to another tooling at room temperature , And quickl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com