Patents

Literature

58results about How to "Lower level current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

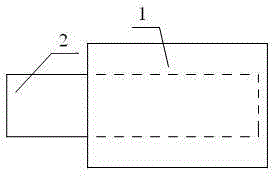

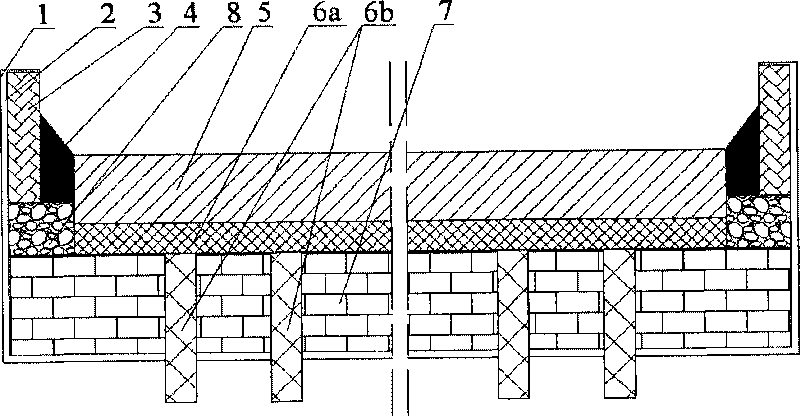

Aluminum electrolysis cell cathode structure of horizontal current in controllable regulation aluminum liquid

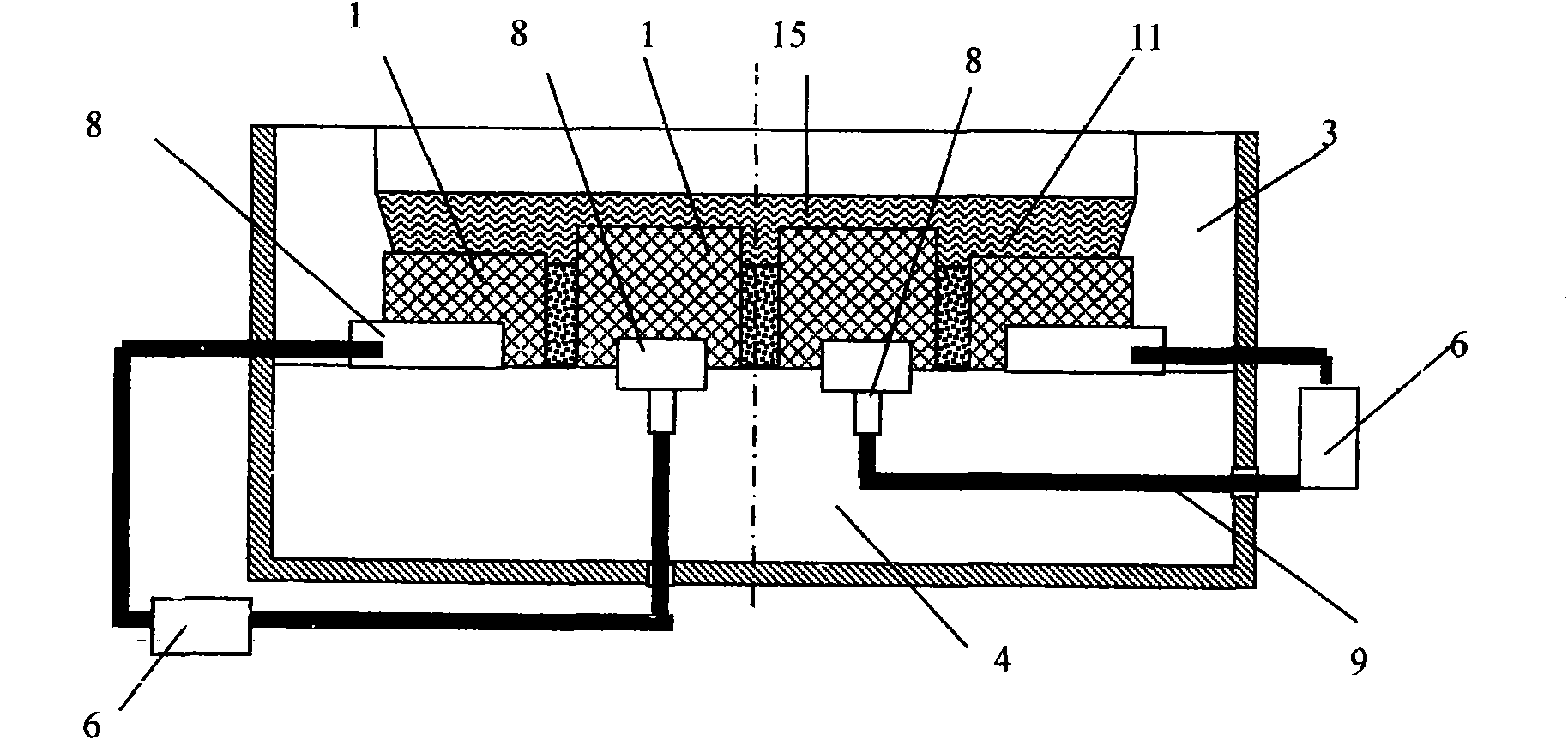

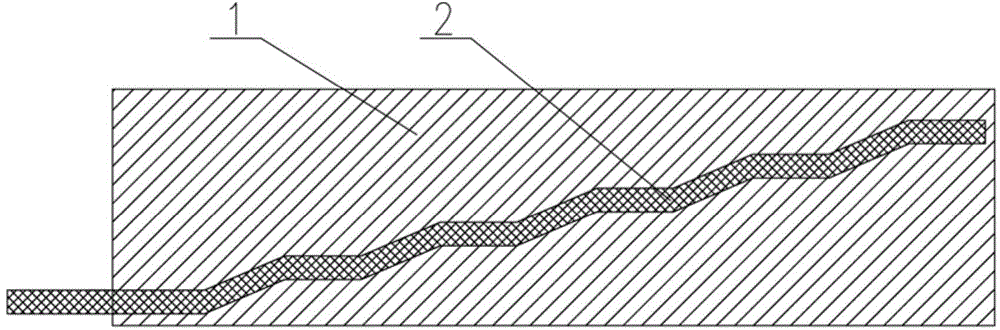

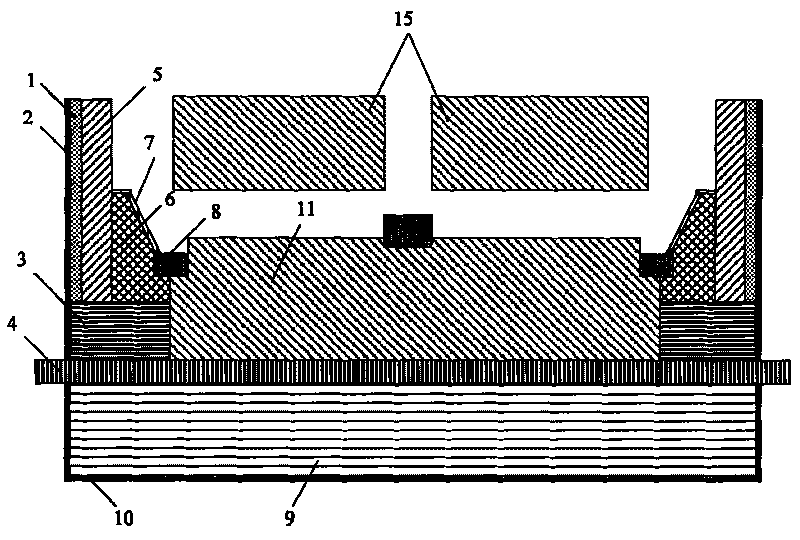

The invention discloses an aluminum electrolysis cell cathode structure of horizontal current in controllable regulation aluminum liquid. A continuously or partially bulged cathode steel bar is used or a cushion material with high electric conductivity is cushioned at the partial position between a common rectangular steel bar and a cathode carbon block, so that the distribution and the size of the horizontal current in the aluminum liquid can be readjusted by the cathode structure. Structural parameters are determined by the cathode structure according to an actual groove-type design, the horizontal current in the aluminum liquid can be obviously reduced when the cathode structure is used in an aluminum electrolysis cell, and the distribution of the horizontal current in the aluminum liquid can be optimized to prevent an area with higher horizontal current density from being superposed with an area having a larger vertical magnetic field, so that the effects of weakening the vertical fluctuation of the aluminum liquid and stabilizing the horizontal motion of a melt are achieved; therefore, electrolysis can be operated within a relatively short electrode distance, energy consumption can be reduced greatly, and the cathode structure is easy and convenient to process and is easy to realize.

Owner:CENT SOUTH UNIV +2

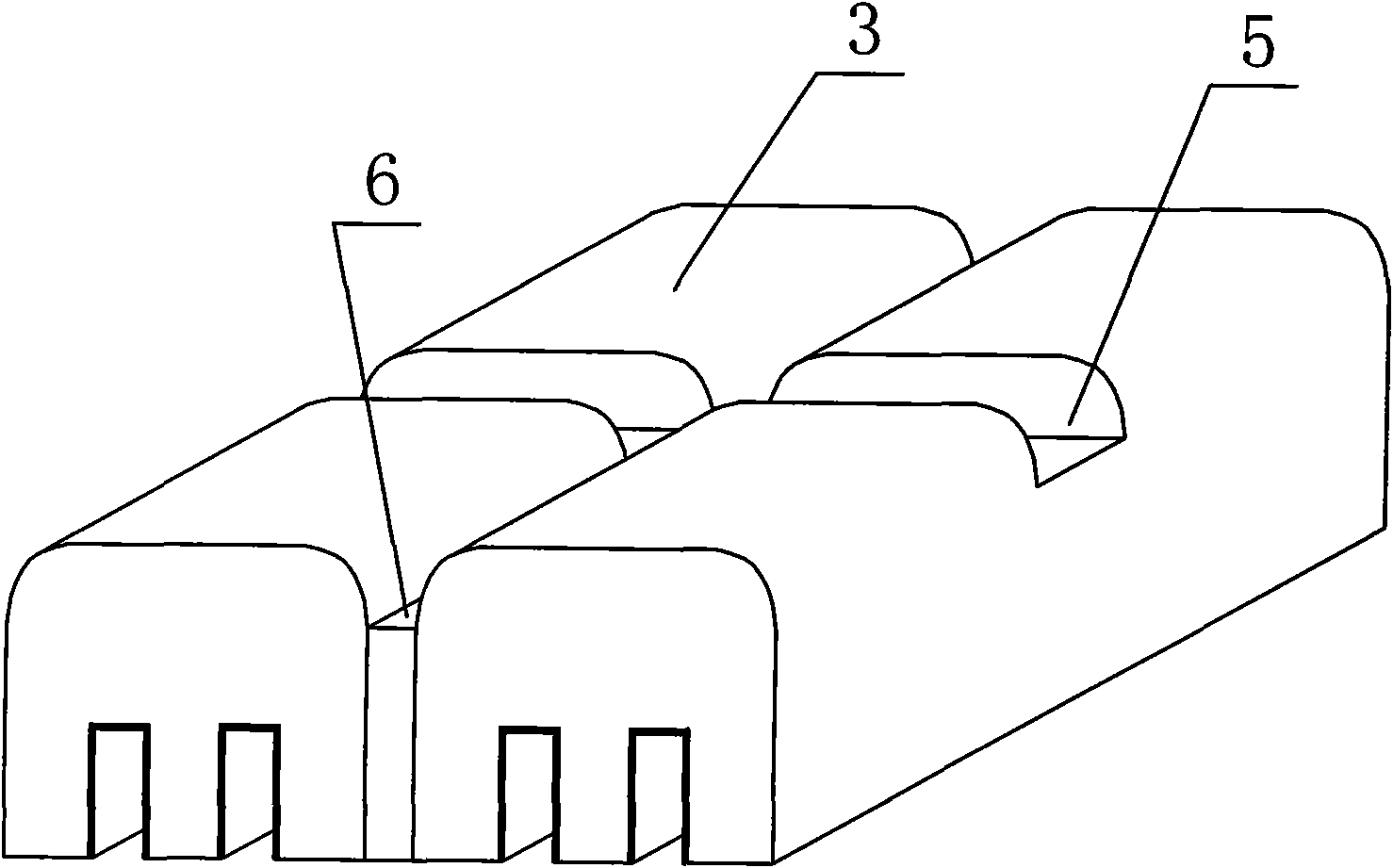

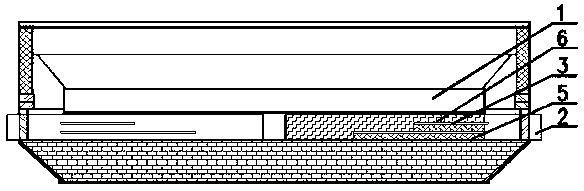

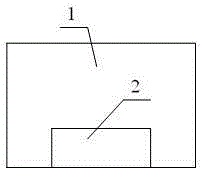

Special-shaped cathode structured aluminum electrolytic cell

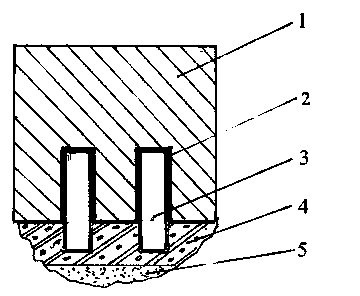

The invention relates to a special-shaped cathode structured aluminum electrolytic cell. The aluminum electrolytic cell comprises a cell shell, a fire-resistant and thermal-insulation material arranged at the bottom, an anode carbon block and a cathode carbon block, wherein the bottom of the cathode carbon block is provided with a cathode steel bar. The aluminum electrolytic cell is characterized in that: a round angle or an arc angle is formed at the upper end of the cathode carbon block lengthways; and the top of the cathode carbon block is provided with a traverse groove. The special-shaped cathode structure aluminum electrolytic cell can greatly reduce horizontal current in aluminum liquid, makes the current density of the cathode carbon block and the cathode steel bar more uniform, makes the magnetic field distribution in the cathode carbon block and the cathode steel bar more uniform, can effectively reduce the flow velocity and the fluctuation range of the aluminum liquid, and greatly prolongs the service life of the electrolytic cell.

Owner:湖南五强产业集团股份有限公司

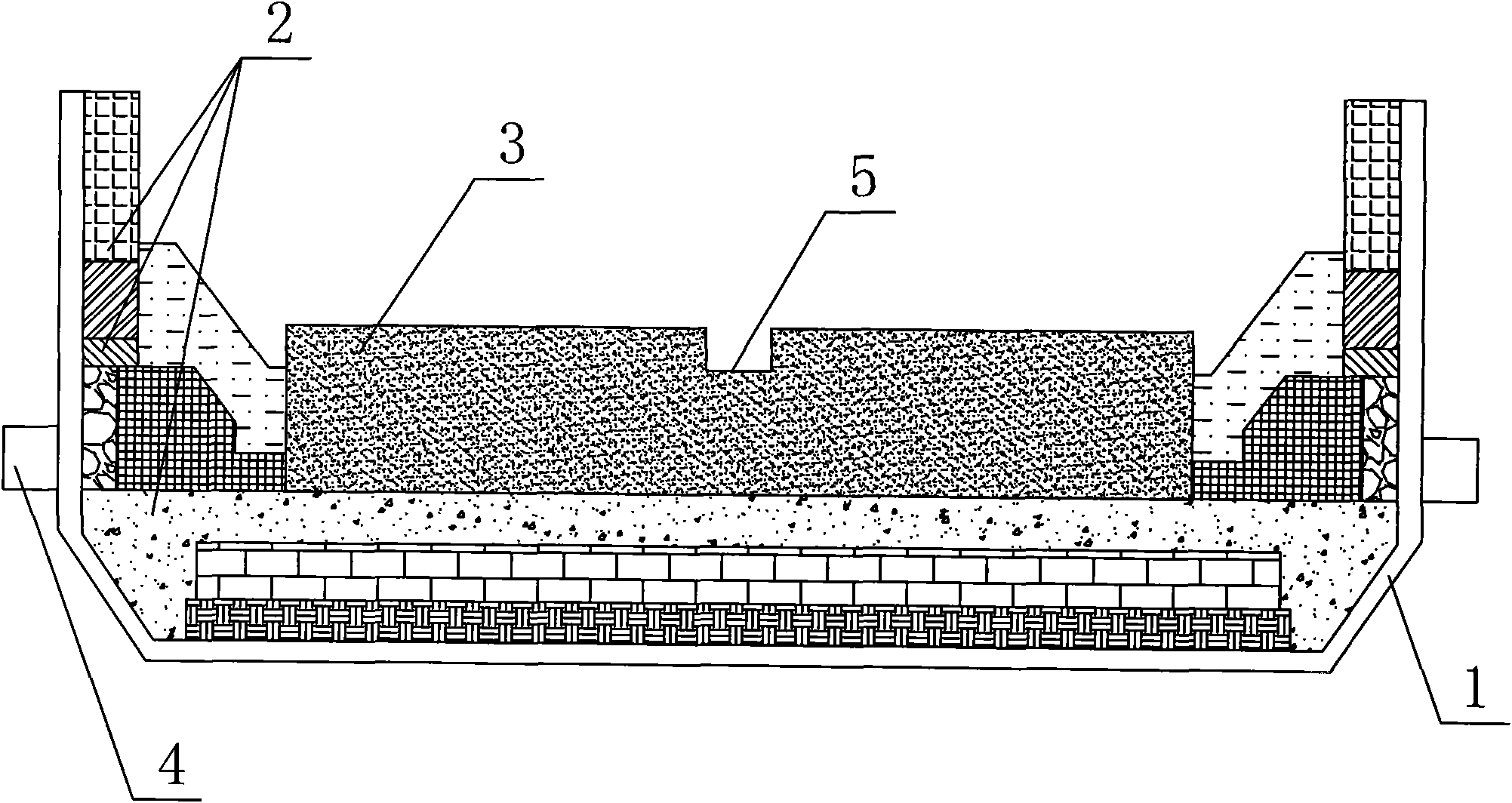

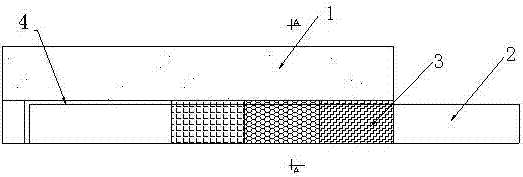

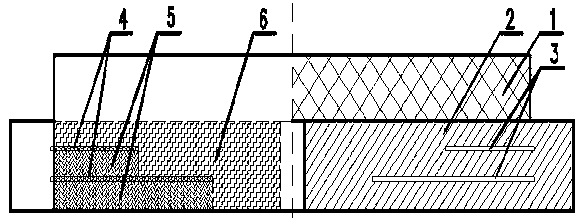

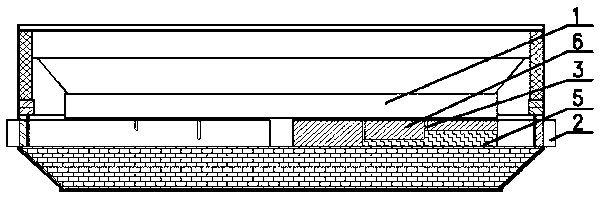

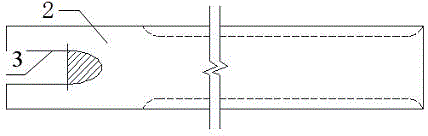

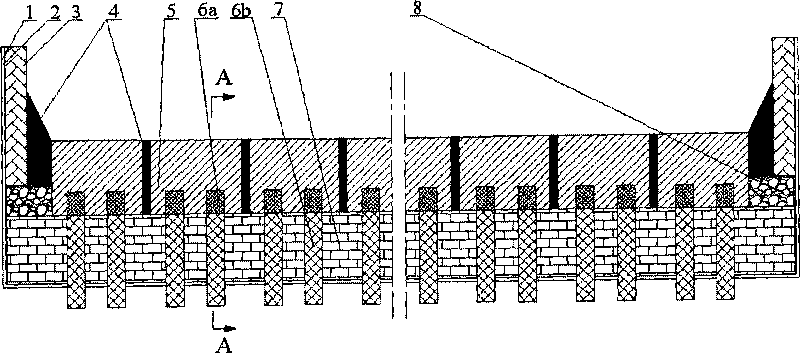

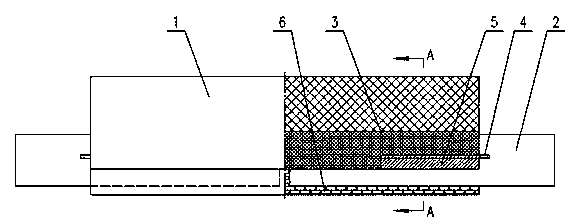

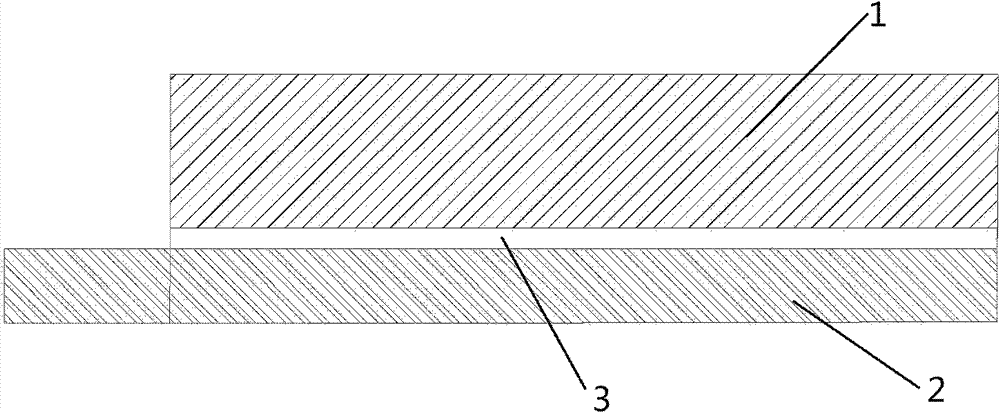

Method for reducing horizontal current in molten aluminum of aluminum electrolysis bath

ActiveCN102234820ALower level currentImprove stabilityElectrical resistance and conductanceElectrolysis

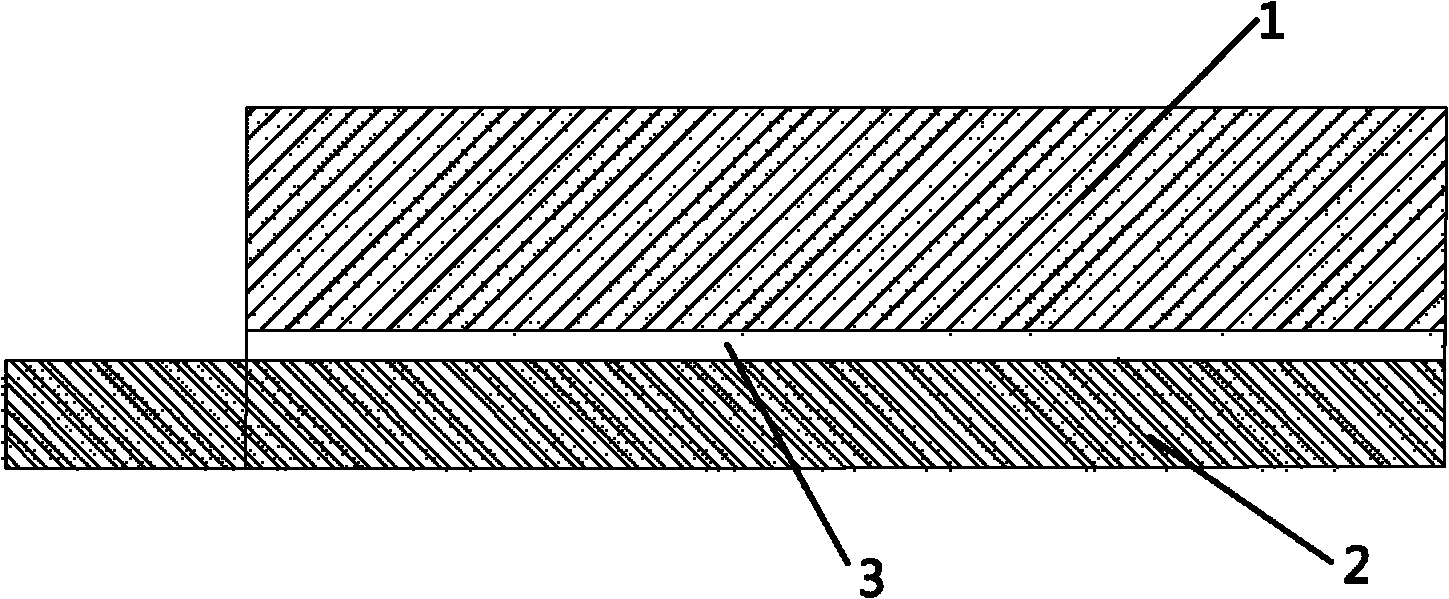

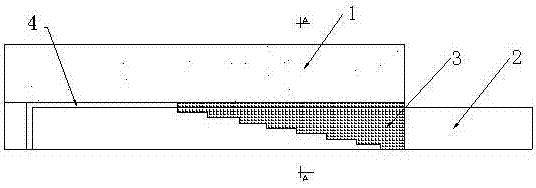

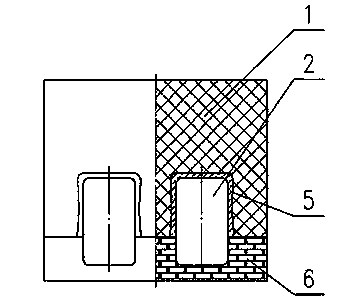

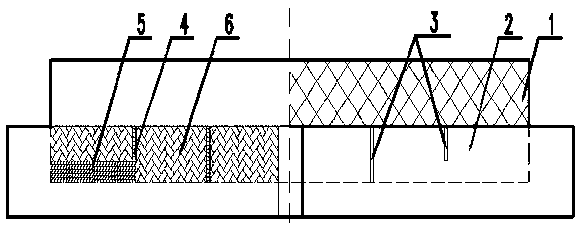

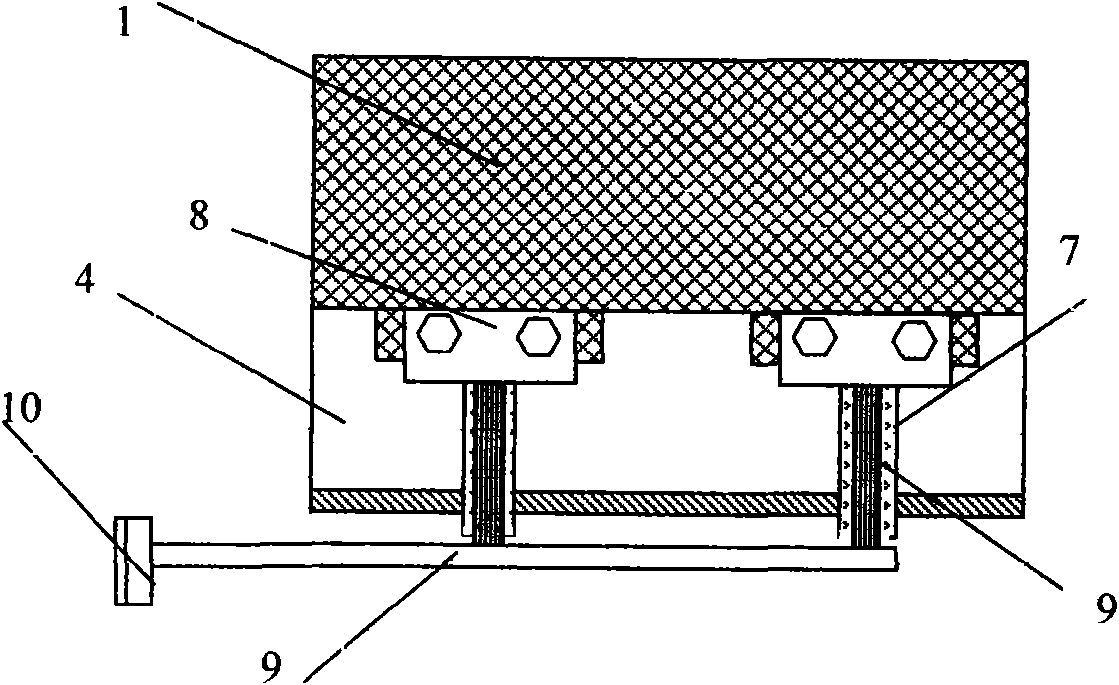

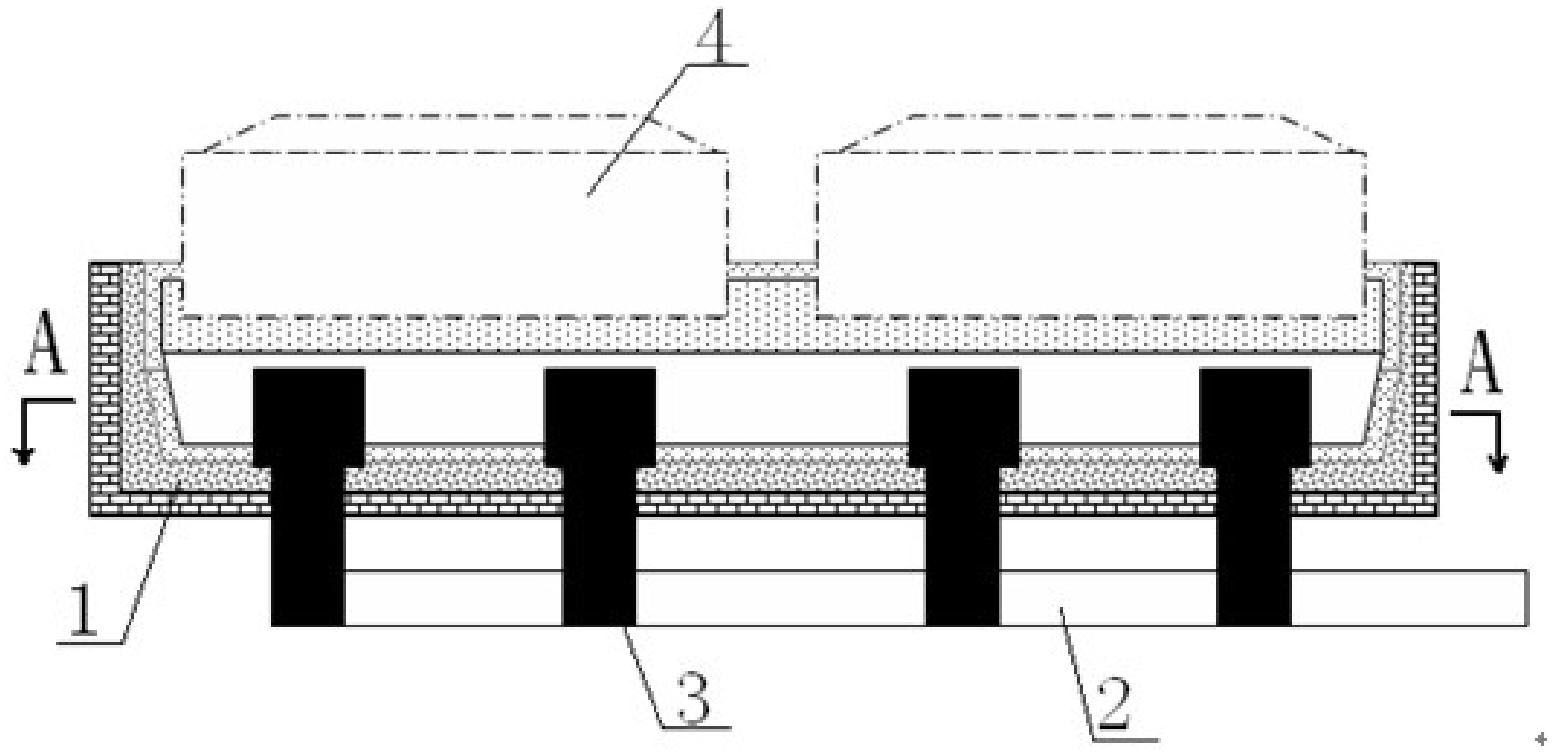

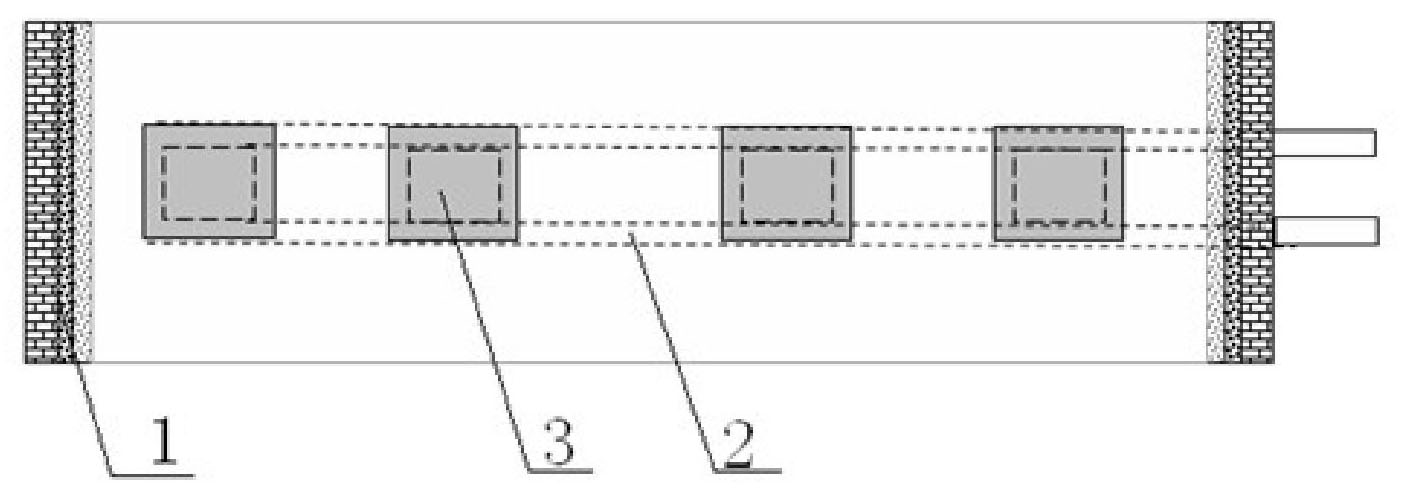

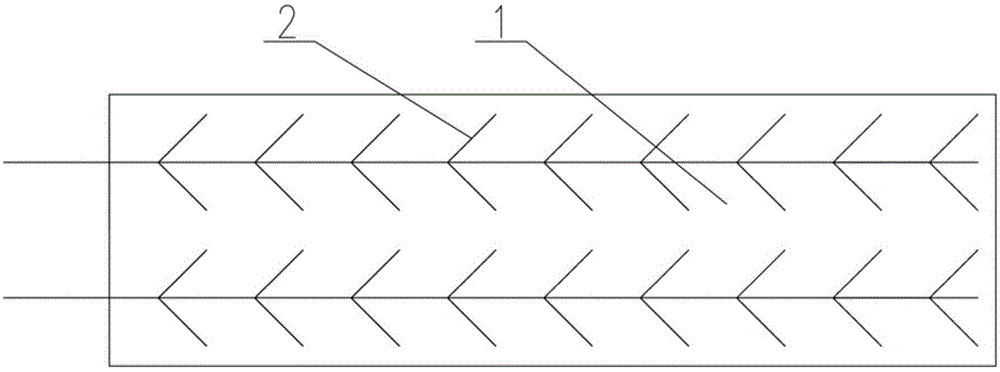

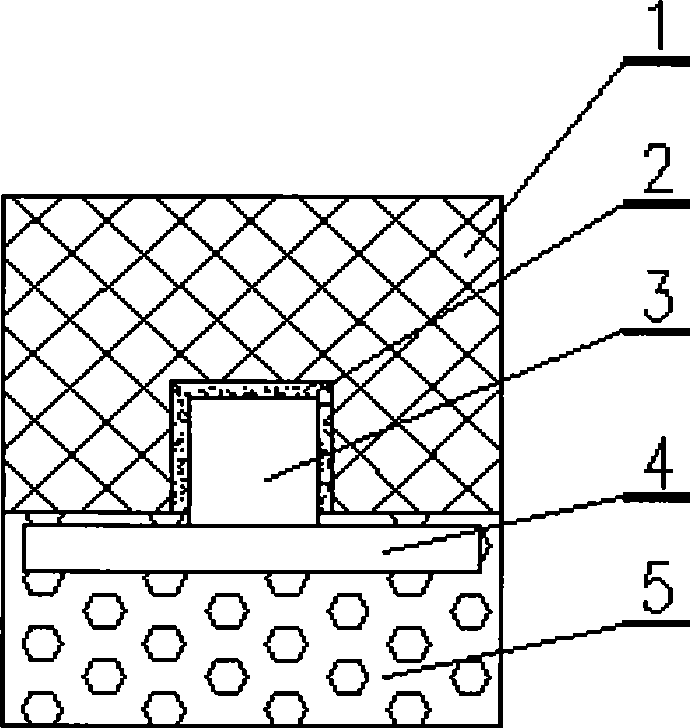

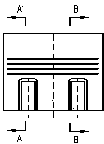

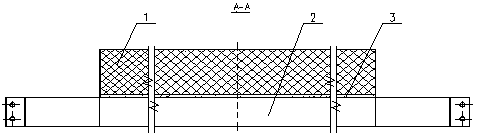

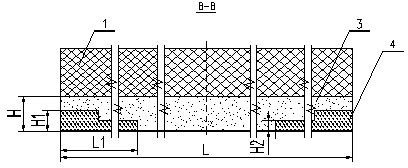

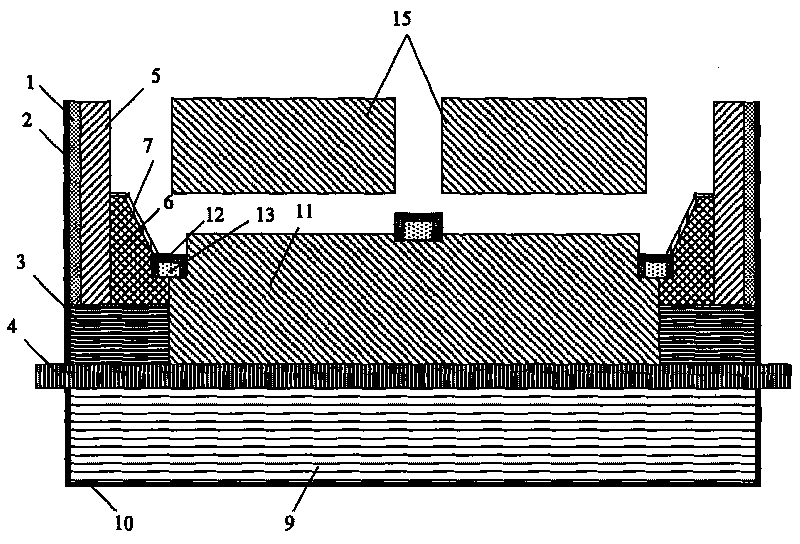

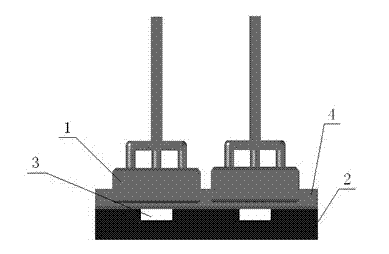

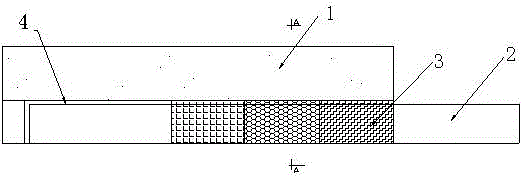

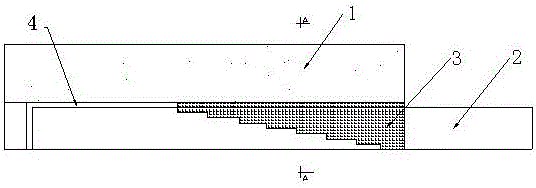

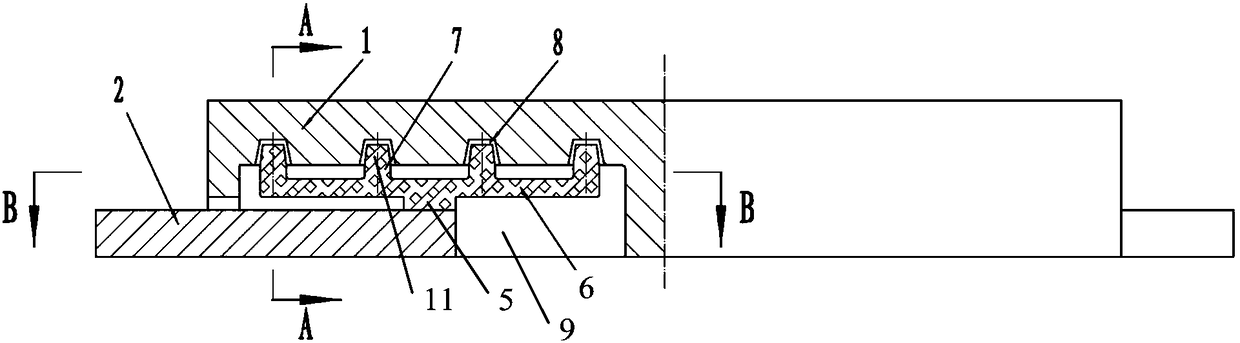

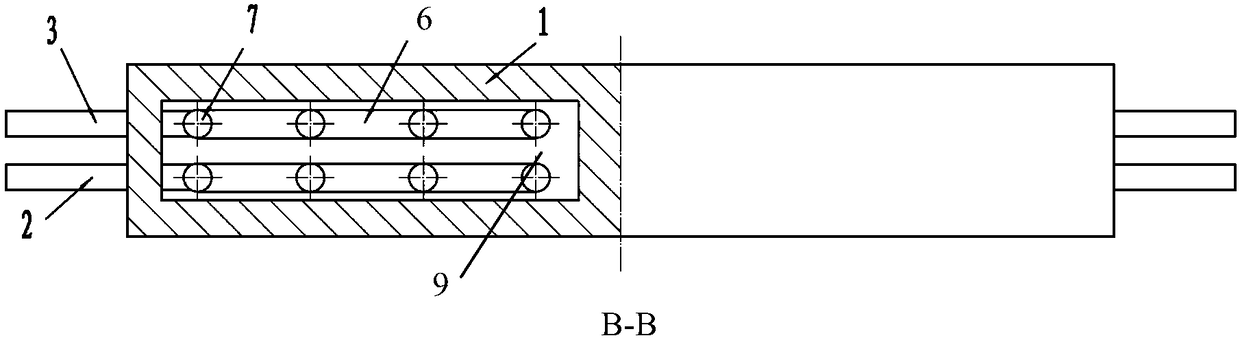

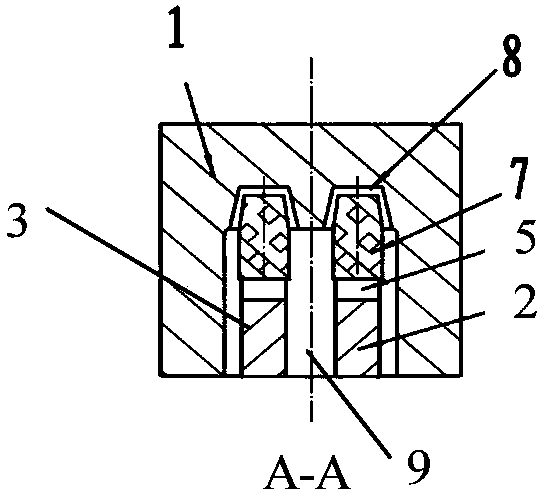

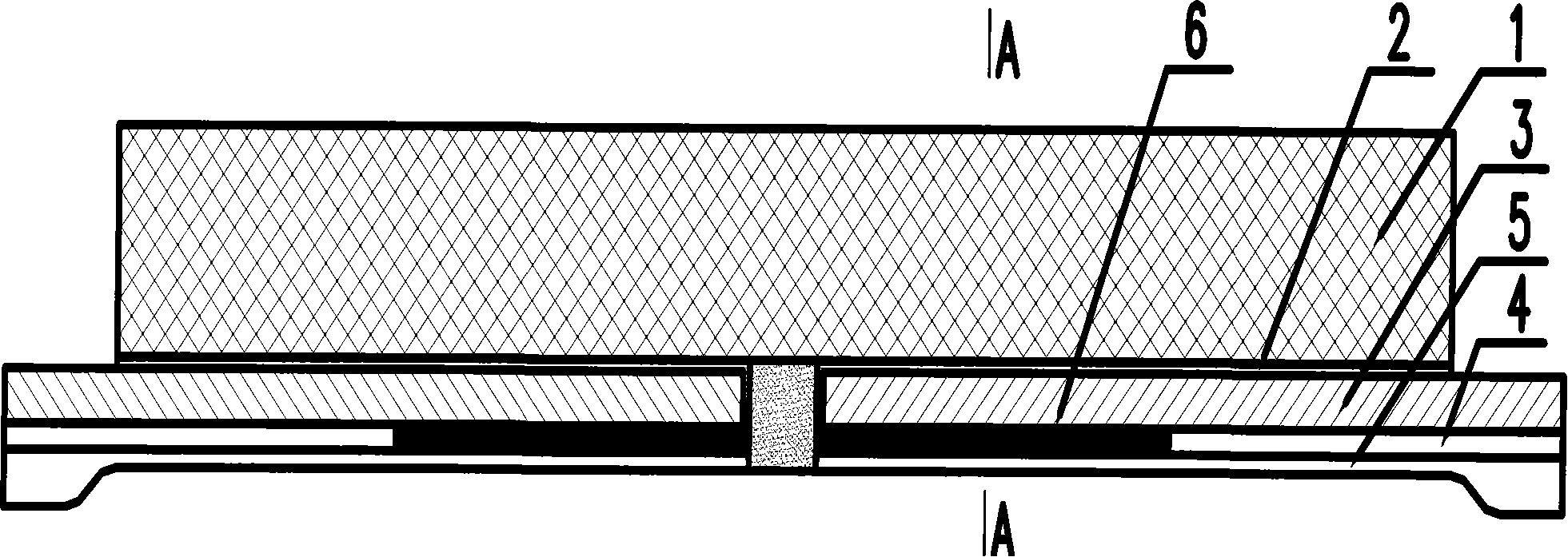

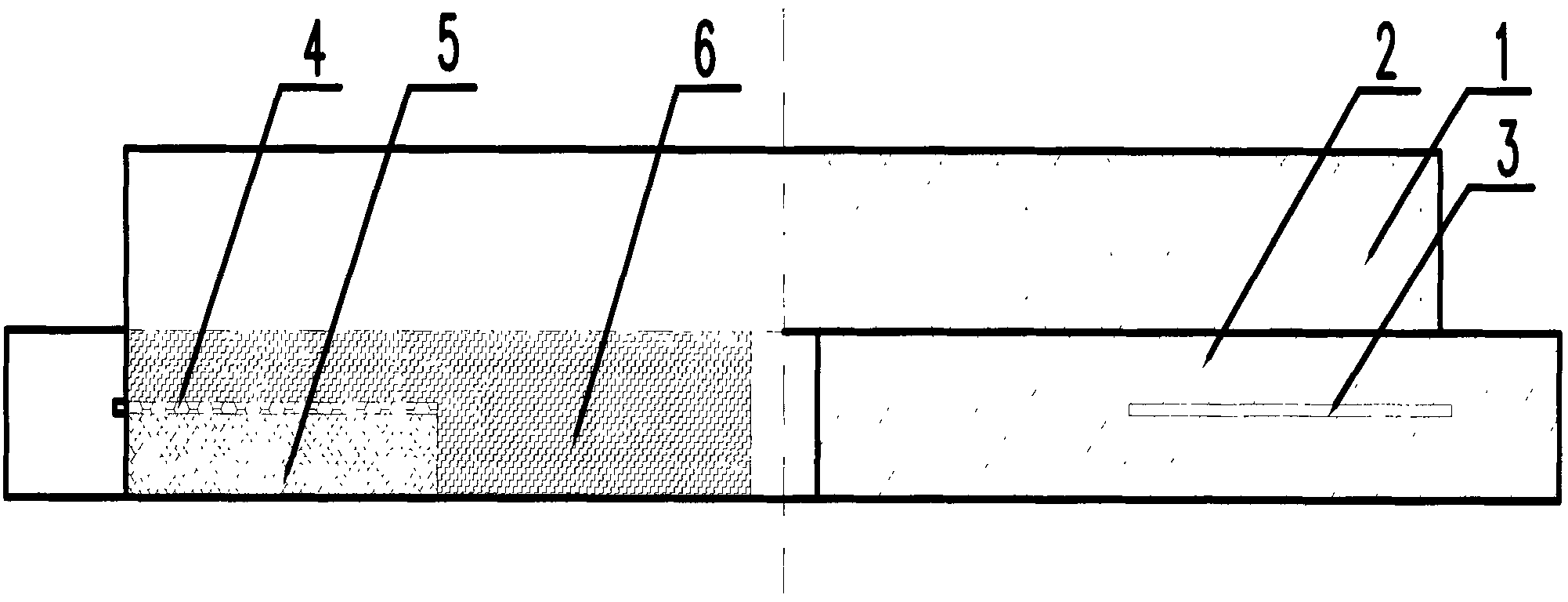

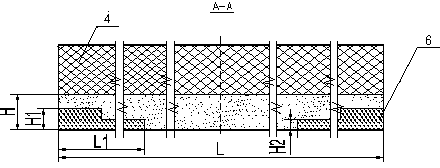

The invention relates to a method for reducing horizontal current in molten aluminum of an aluminum electrolysis bath. The method for reducing the horizontal current in the molten aluminum of the aluminum electrolysis bath is characterized in that: partial current guide material (3) is spread at a cathode carbon block (1) or a steel bar (2) or connecting material cathode paste thereof or phosphorus pig iron (4), so that the current in the molten aluminum enters the cathode carbon block relatively uniformly, passes through the steel bar and is released from the side of the electrolysis bath. In the current guide material (3), at least one material or an insulating material composition, the resistivity of which is different from that of the carbon block or the steel bar, is spread at different parts of a cathode as required and can be used for substituting partial carbon block material or steel bar material or combined together with the carbon block material or the steel bar material, and meanwhile, the width, the height or the thickness of the current guide material (3) can be gradually changed in a step shape or a gradual change form by adjusting the shape of the current guide material (3), so that the resistance distribution of the cathode is changed, the current distribution of the cathode is regulated, the horizontal current in the molten aluminum is reduced, the stability of magnetic fluid of the electrolysis bath is increased, the efficiency of the current is improved and the service life of the bath is prolonged.

Owner:中铝郑州有色金属研究院有限公司

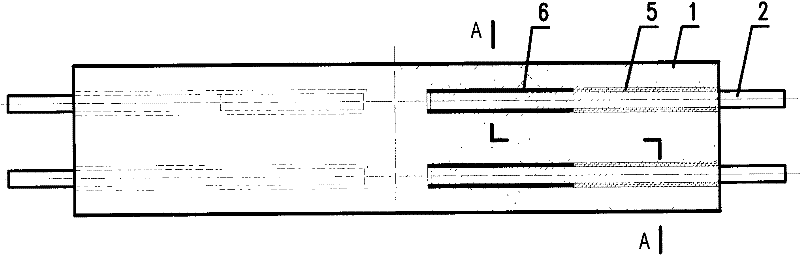

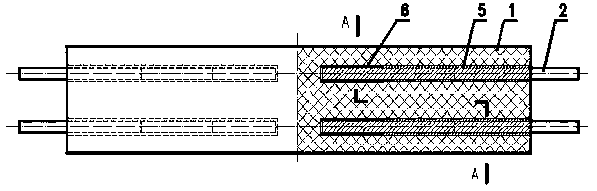

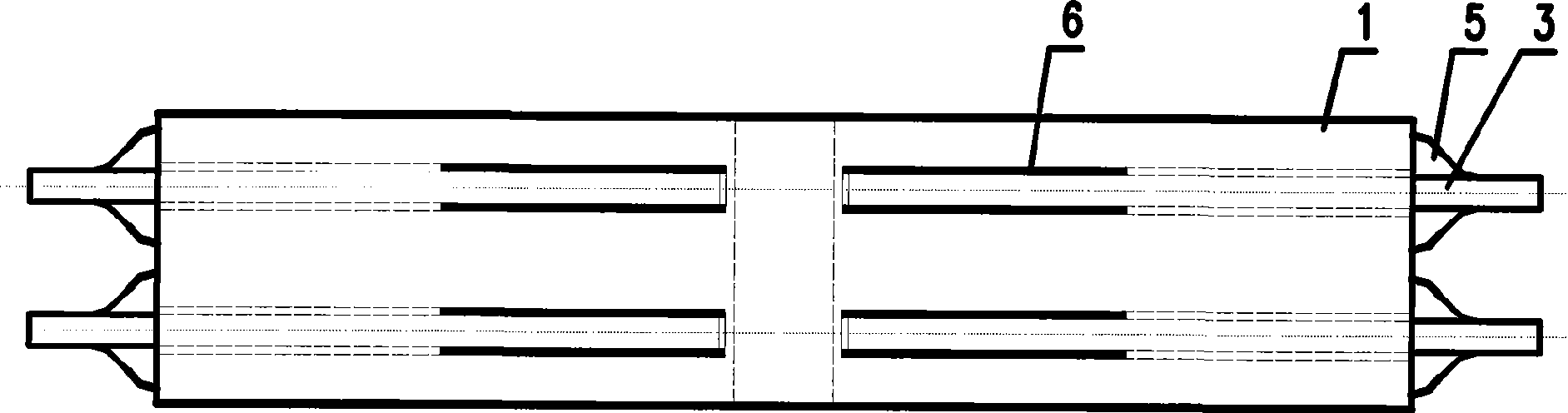

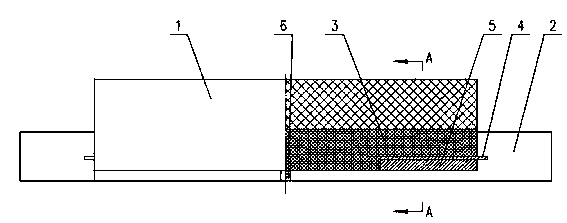

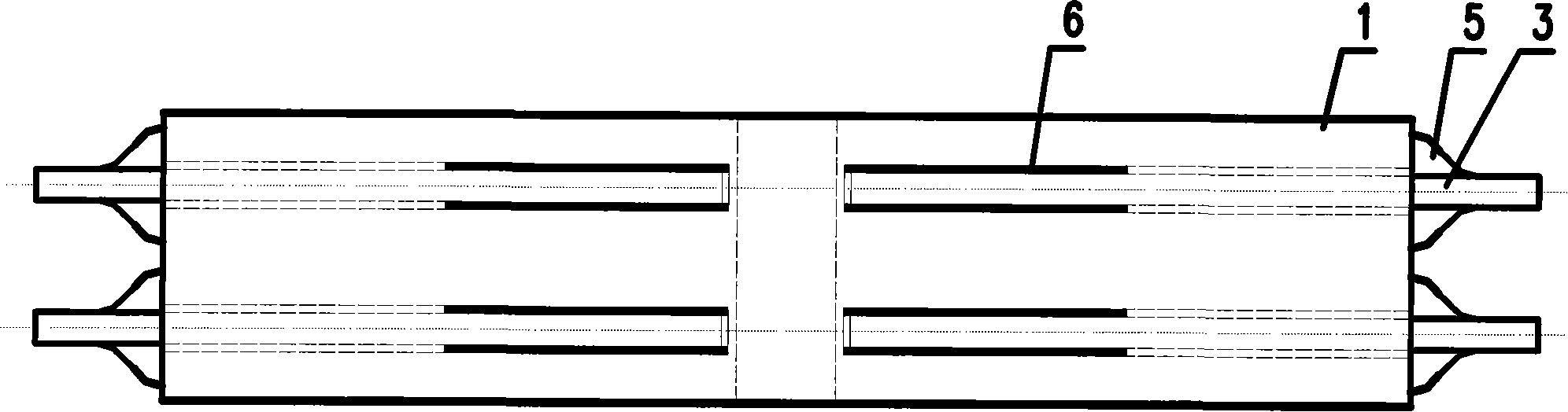

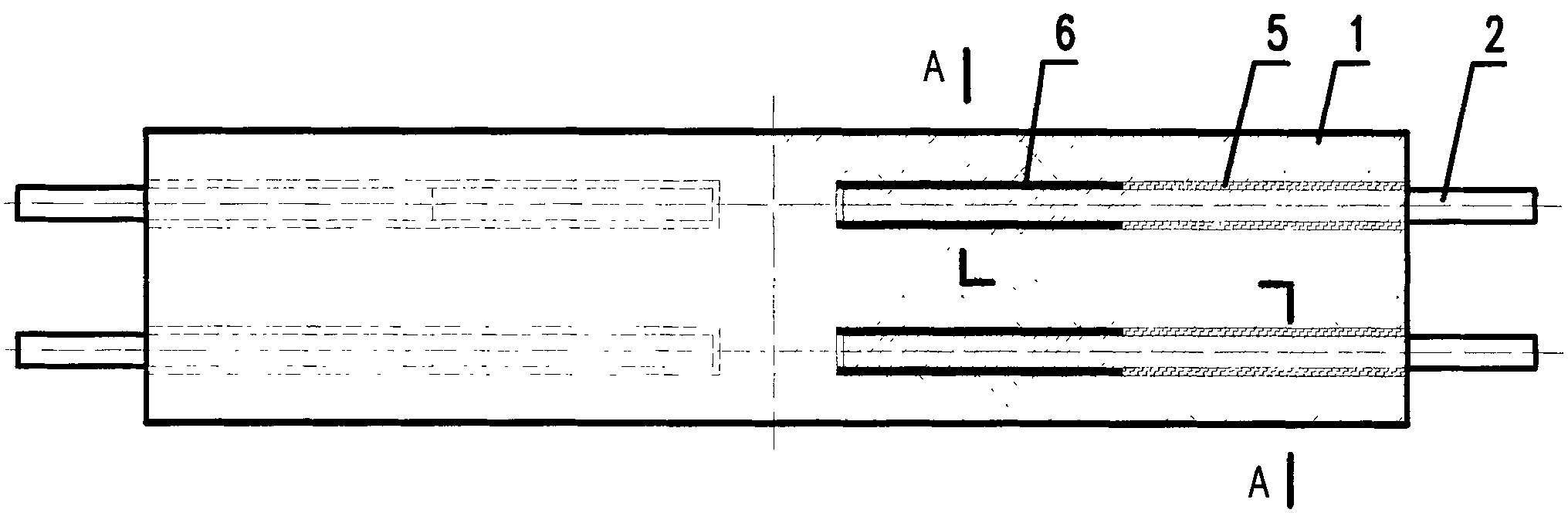

Method for greatly reducing horizontal current in aluminum liquid of aluminum electrolytic cell

ActiveCN102453927ALower level currentEvenly distributedProcess efficiency improvementSteel barEnergy consumption

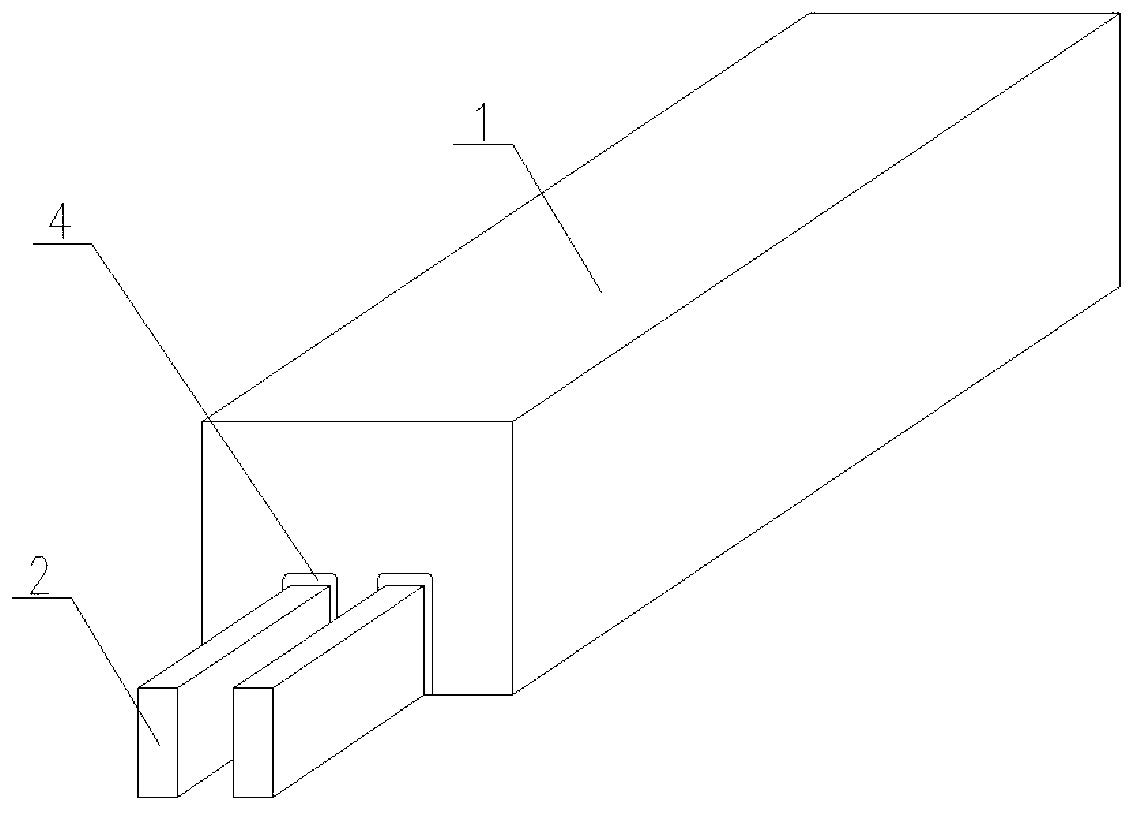

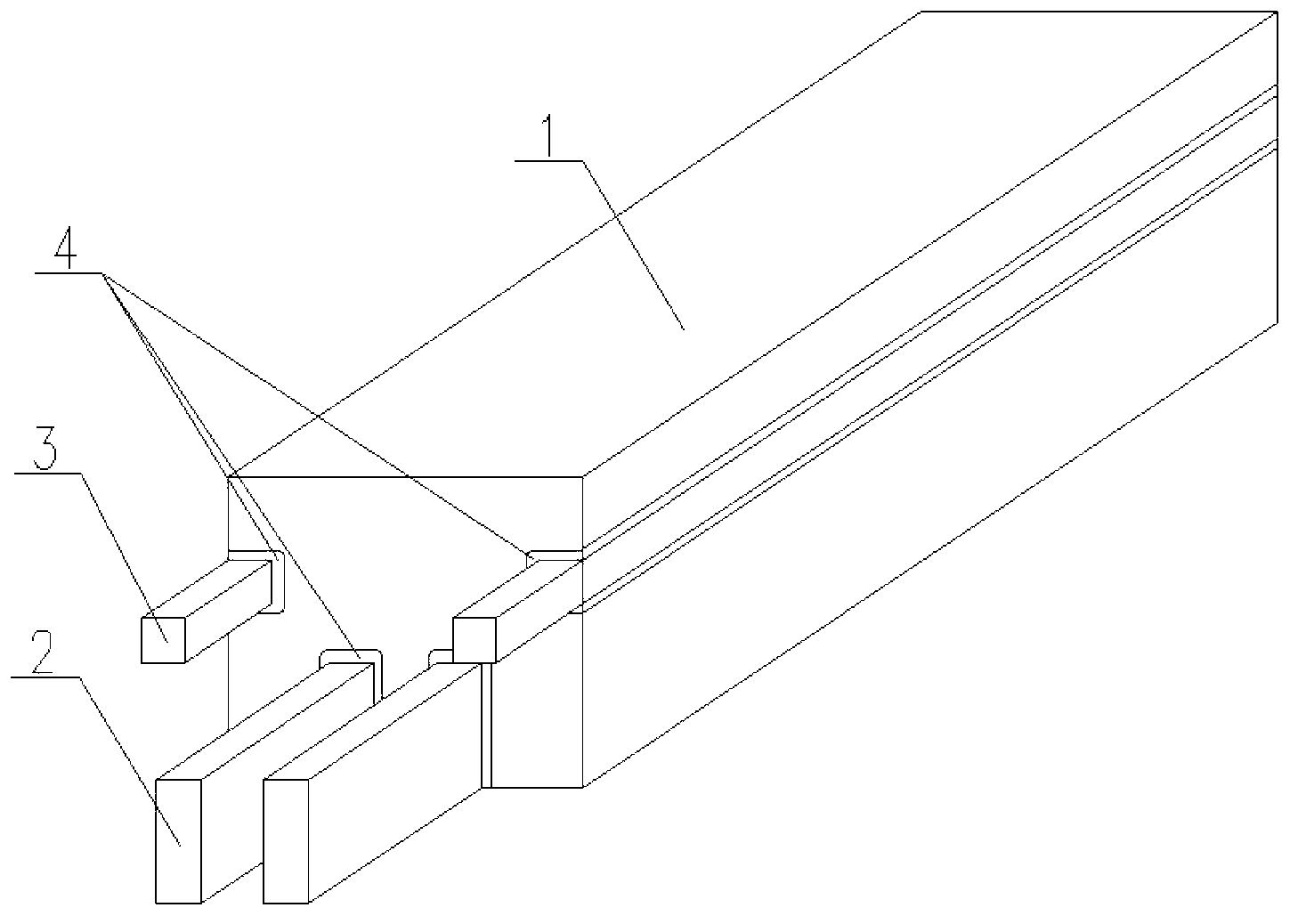

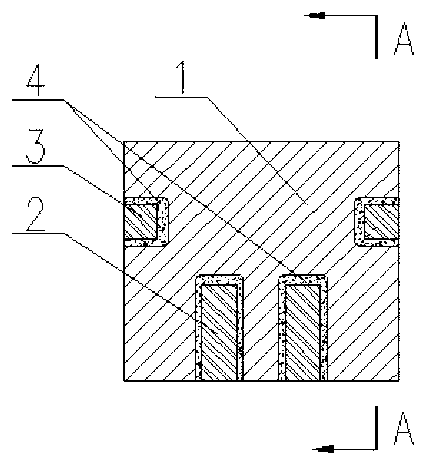

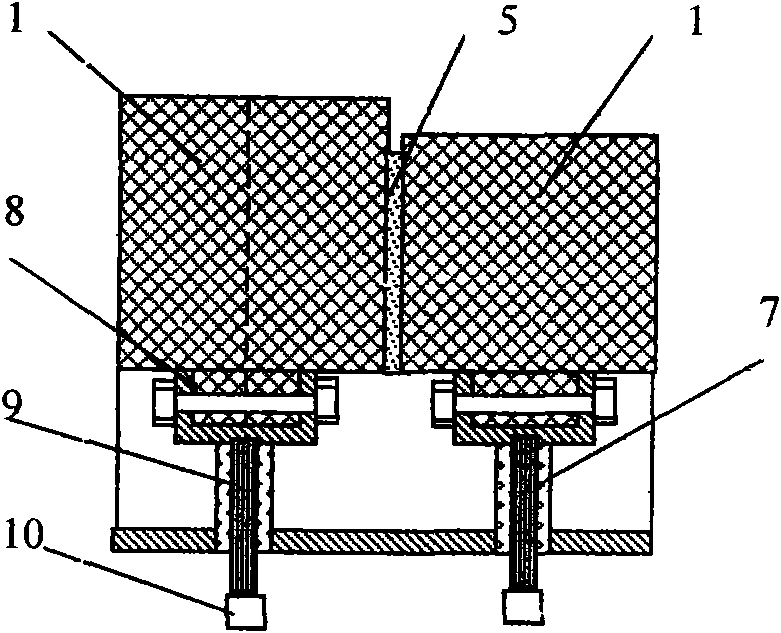

The invention discloses an aluminum cell, and particularly relates to a method for greatly reducing a horizontal current in aluminum liquid of the aluminum electrolytic cell. The method comprises the following steps of: fixedly binding or casting at least one cathode steel bar at the lower part of a cathode carbon block; dividing one section of the cathode steel bar, which is close to the end part of the cathode carbon block along the length direction, into an upper part and a lower part by a separation seam; connecting the section of the cathode steel bar, which is not divided at the middle part of the cathode carbon block, by adopting a conductor and the cathode carbon block; connecting the upper part of the cathode steel bar, which is close to the end part of the cathode carbon block, by the conductor and the cathode carbon block, and isolating the lower part of the cathode steel bar from the cathode carbon block through an insulator; filling a separation seam insulating material in the separation seam so that the upper part and the lower part of the cathode steel bar are insulated; and leading the entire body of the cathode steel bar to pass through the side part of the electrolytic cell. With the method provided by the invention, the horizontal current in the aluminum liquid is greatly reduced, the distribution of a cathode current is more uniform, the stability of the electrolytic cell is improved, the service life of the cell is prolonged, and the aluminum energy consumption per ton is effectively reduced, so that the method has obvious energy-saving effects.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Method for homogenizing current distribution in aluminum liquid in aluminum electrolytic cell

ActiveCN102758216ALower level currentAverage current distributionProcess efficiency improvementPower flowCurrent distribution

The invention discloses a cathode structure of an aluminum electrolytic cell, in particular to a method for homogenizing current distribution in aluminum liquid in the aluminum electrolytic cell. At least one cathode steel bar is bound or cast at the lower part of a cathode carbon block, and the cathode steel bar is segmented into a plurality of parts in different positions by partition joints in the length direction; cathode steel bars among the partition joints are completely connected with the cathode carbon block through electric conductors, and the rest of the cathode steel bars on the partition joints are completely insulated with the cathode carbon block through insulators; partition joint insulating material is filled in each partition joint, so that the cathode steel bars on and below the partition joints are insulated; and one end of the cathode steel bar penetrates out of the side part of the electrolytic cell. According to the method disclosed by the invention, the current distribution in the aluminum liquid in the aluminum electrolytic cell is homogenized, horizontal current in the aluminum liquid is greatly reduced, the stability of the electrolytic cell is improved, the electrolytic cell can operate with high efficiency at low polar distance, the aluminum energy consumption per ton can be effectively reduced, the energy-saving effect is significant and the service life of a cathode is simultaneously prolonged.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Cathode structure capable of saving energy and homogenizing horizontal current in molten aluminium

The invention relates to a cathode structure of an aluminium electrolysis cell and in particular relates to a cathode structure capable of saving energy and homogenizing horizontal current in molten aluminium. The cathode structure comprises a cathode carbon block and a current conducting rod, wherein the current conducting rod protrudes out of the bottom surface of the cathode carbon block and is surrounded by clad materials; an insulator is filled between the end of the cathode carbon block and the current conducting rod; other parts of the cathode carbon block are connected with a contact part of the current conducting rod by an electric connector. The cathode structure has the advantages and effects that the cathode structure has strong practicability, and not only substantially reduces the cathode drop but also substantially reduces the horizontal current in molten aluminium and improves the stability of an electrolysis cell under the condition of not changing the electricity output mode of the cathode, namely side electricity output, so that the electrolysis cell can operate efficiently and stably under the condition of short electrode distance; the cathode structure effectively reduces the energy consumption of tonnage aluminium and has an obvious energy saving effect; meanwhile, the cathode current is distributed more uniformly, thus the service life of the cell is prolonged.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Electrolytic aluminum prebaked anode anti-oxidation insulating coating and preparation method thereof

ActiveCN110964352AHigh strengthHigh purityFireproof paintsAnti-corrosive paintsMetallurgyAluminium oxides

The invention provides an electrolytic aluminum prebaked anode anti-oxidation insulating coating. The electrolytic aluminum prebaked anode anti-oxidation insulating coating comprises the following components in percentage by mass: 60%-75% of a main component, 0.01%-5% of a secondary component, 24%-34% of a nano solvent binding phase and 0.01%-5% of a coating stabilizing phase, wherein the main component comprises amorphous aluminum oxide, nano-scale rho-Al2O3, nano-scale gamma-Al2O3 and nano-scale alpha-Al2O3. The insulating coating prepared by the invention can be cured at normal temperaturefor 6-8 hours after being sprayed to an anode by a spraying machine, the anode coating can form a compact net-shaped structure at the working temperature of 500-800 DEG C, the long-term tolerable temperature is over 900 DEG C, and the physical and chemical properties are stable.

Owner:CENT SOUTH UNIV +1

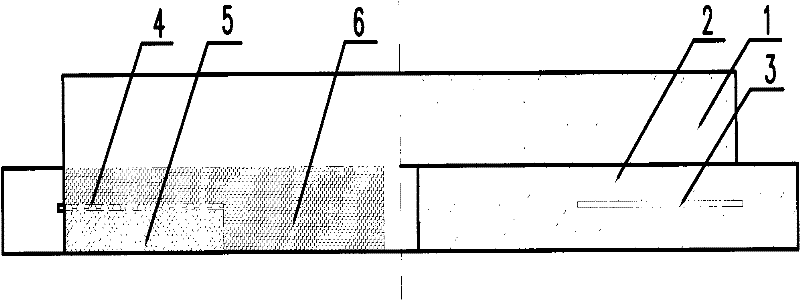

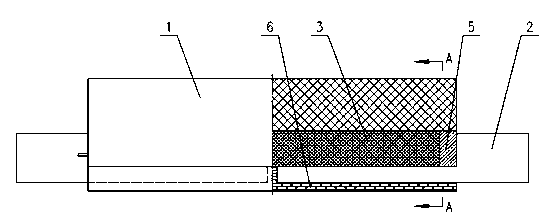

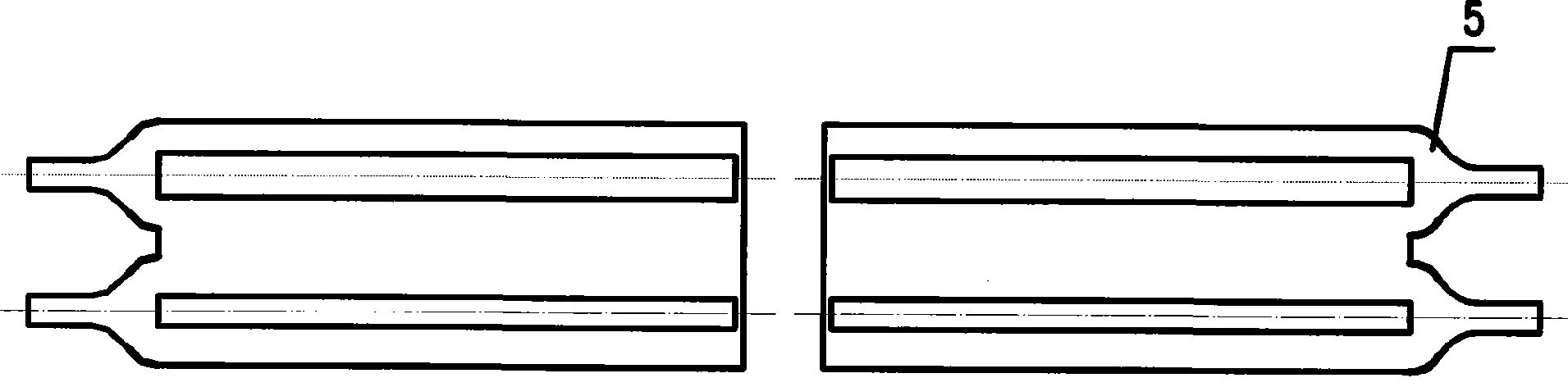

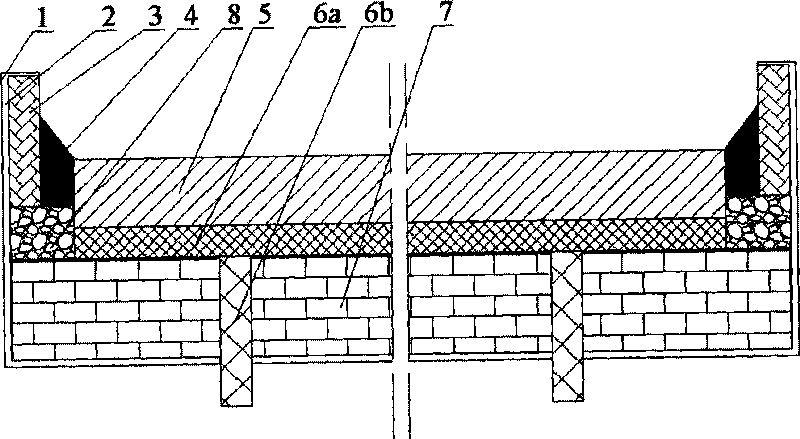

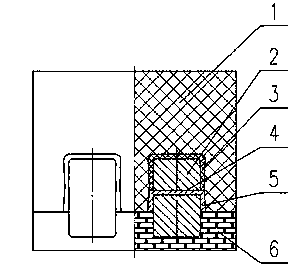

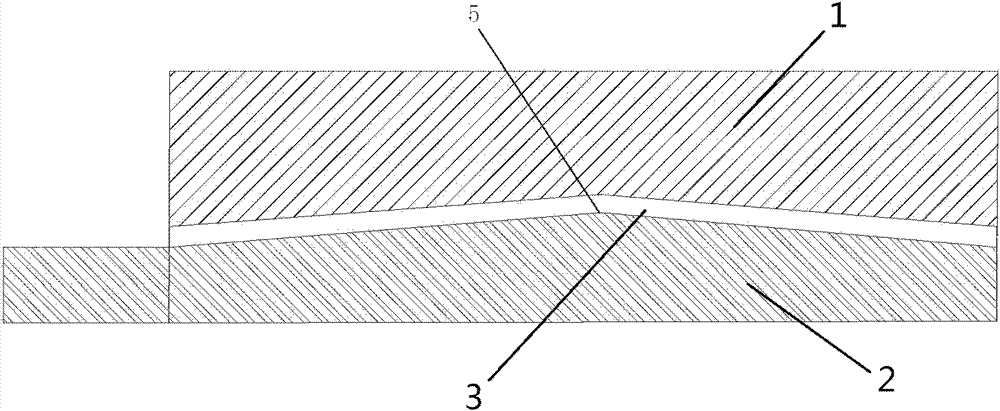

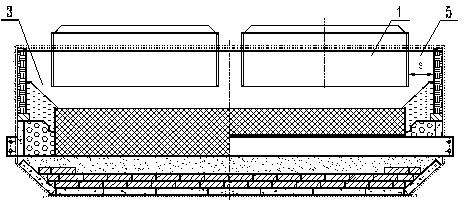

Method for reducing horizontal current in aluminum liquid of aluminum reduction cell

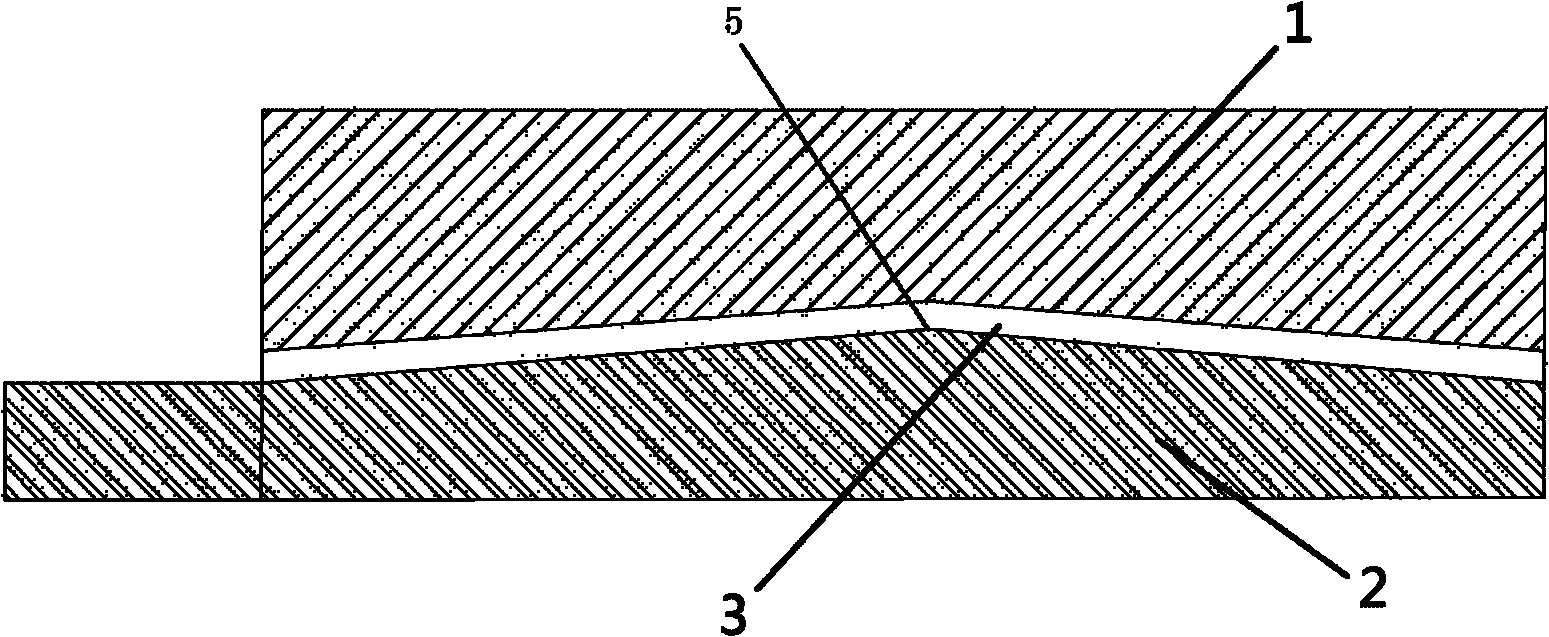

The invention discloses a Hall-Heroult electrolysis-process primary aluminum production technique and an aluminum reduction cell for implementing the industrial production method. Particularly, the invention relates to a method for reducing horizontal current in aluminum liquid of the aluminum reduction cell. The method comprises the following steps that: at least one cathode steel bar (3) is bound to or cast in the lower part of a cathode carbon block (1); at least one current-conducting plate or current-conducting bar (5) is laid on the lower part of a cathode carbon block (1); the current-conducting plate or current-conducting bar (5) is partially connected with the cathode steel bar (3) in the cathode carbon block (1); and current is led out from the side of the reduction cell through the current-conducting plate or current-conducting bar (5) and the cathode steel bar (3). The method has the advantages of remarkably reducing horizontal current in aluminum liquid under the condition of without changing the mode of leading out cathode current, ensuring more uniform distribution of the cathode current, improving the stability of the reduction cell, prolonging the life span of the cell and enabling the reduction cell to be easier to operate and manage.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE +1

Cathode structure for reducing horizontal current in molten aluminum

The invention relates to a cathode structure for reducing the horizontal current in molten aluminum. The cathode structure comprises a cathode carbon block and a cathode steel bar arranged below the cathode carbon block. The cathode structure is characterized in that the cathode steel bar is provided with a separation seam in the length direction, a separation seam insulating material is arranged in the separation seam, the region under the end of the cathode steel bar between the bottom of the cathode steel bar and the bottom of the separation seam is an insulator, and an upper portion of the cathode steel bar is connected to the cathode carbon block by an electric conductor. According to the invention, the cathode structure disclosed herein has strong practicability; without changing the electrical discharge mode of a cathode, a horizontal current in molten aluminum is reduced, the distribution of a cathode current is uniform, the stability of an electrolytic tank is improved, a service life of the electrolytic tank is prolonged, the electrolytic tank can efficiently and stably operate under the condition of a low electrode distance, consumption of each ton of aluminum is effectively reduced, and obvious energy-saving effects are obtained.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE +1

Aluminum cell side conductive cathode structure for reducing horizontal current of molten aluminum

The invention discloses an aluminum cell side conductive cathode structure for reducing a horizontal current of molten aluminum. The horizontal current in the molten aluminum can be greatly reduced through installing and using a horizontal or inclined conductive side cathode steel rod. A structure parameter of a cathode is determined according to an actual cell type design, the horizontal current in the molten aluminum can be remarkably reduced when the cathode is applied to the aluminum cell, the distribution of the horizontal current in the molten aluminum is optimized and the cathode voltage drop is reduced, thus the functions of weakening the vertical fluctuation of the molten aluminum and stabilizing the horizontal movement of the molten aluminum are achieved so that an electrolysis can be stably carried out at a low voltage, and the energy consumption is greatly reduced. The aluminum cell side conductive cathode structure is convenient and simple to process, easy to realize, low in cost and little in influence on service life of an inner linear of the cell.

Owner:CENT SOUTH UNIV

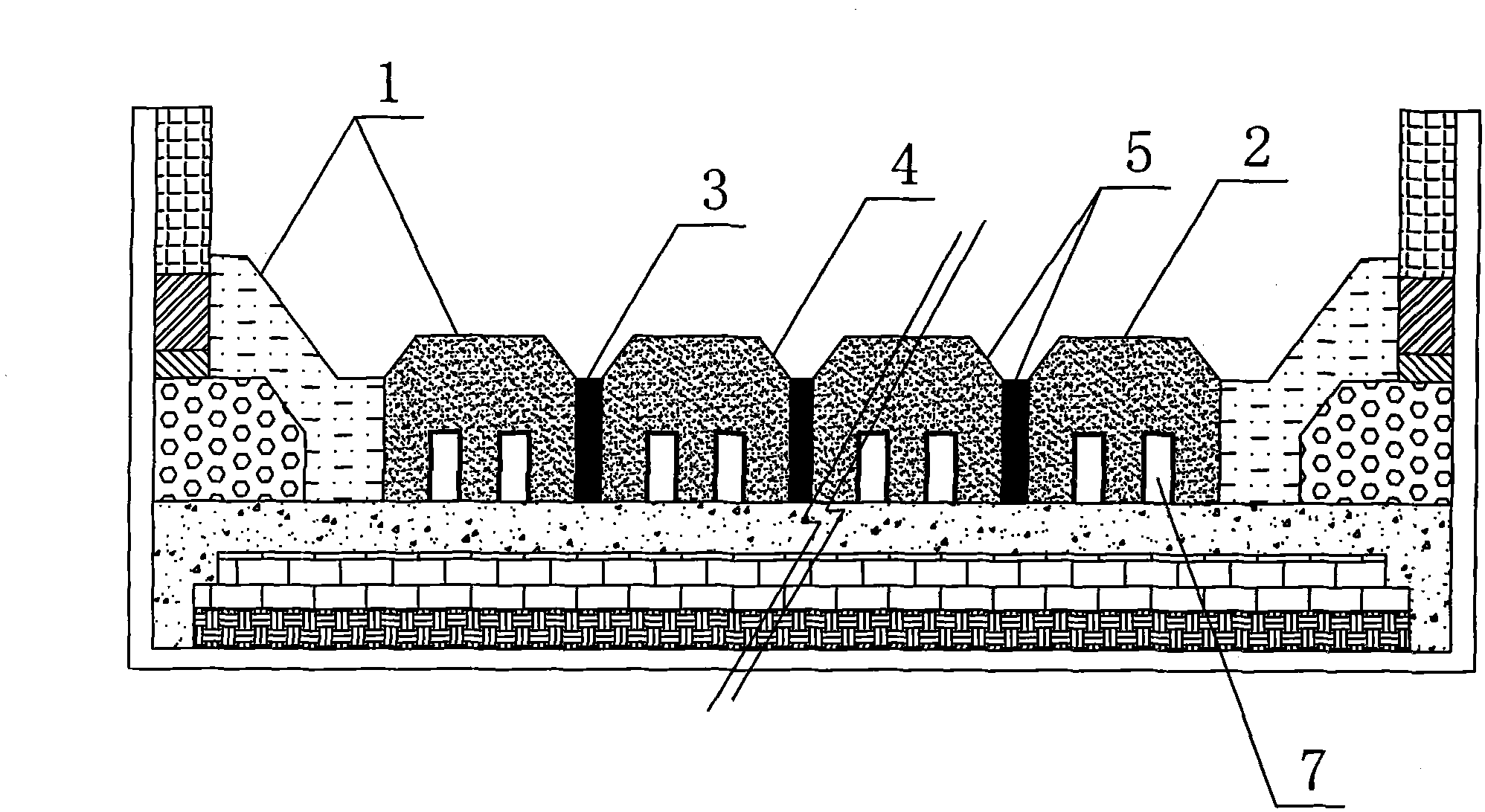

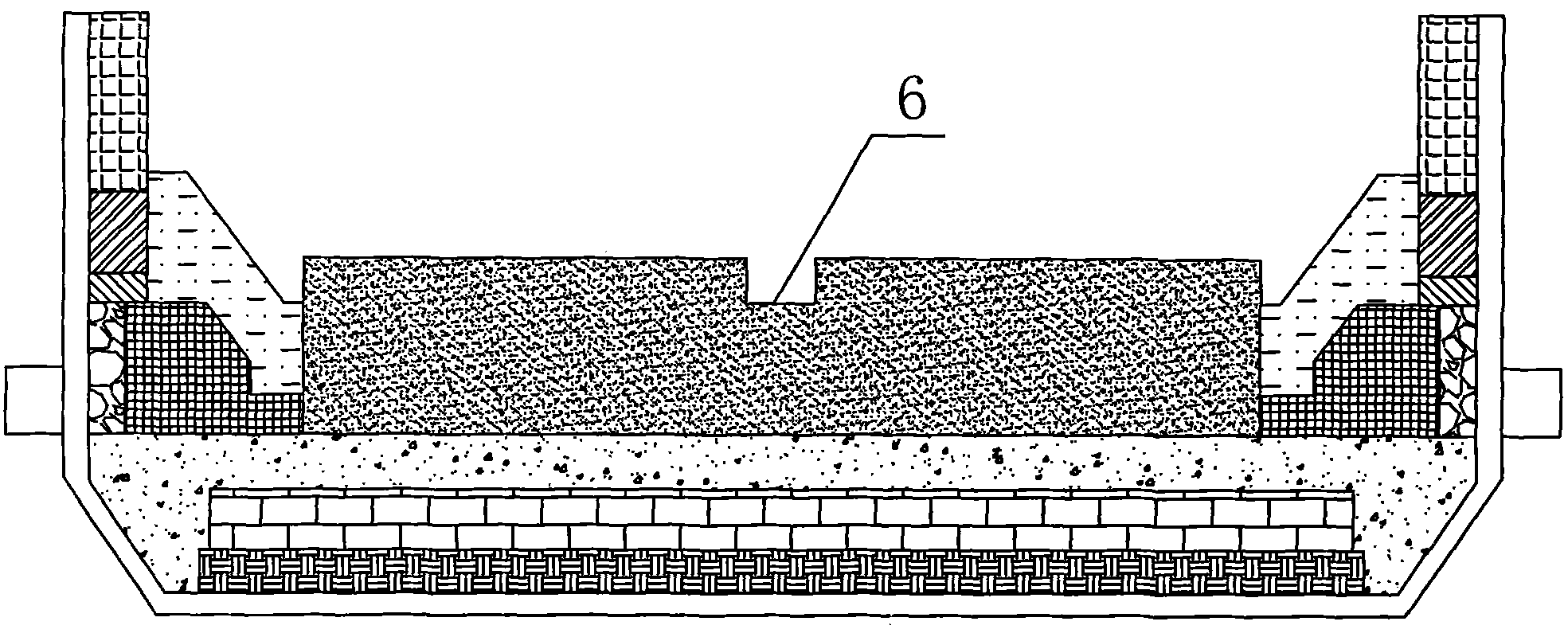

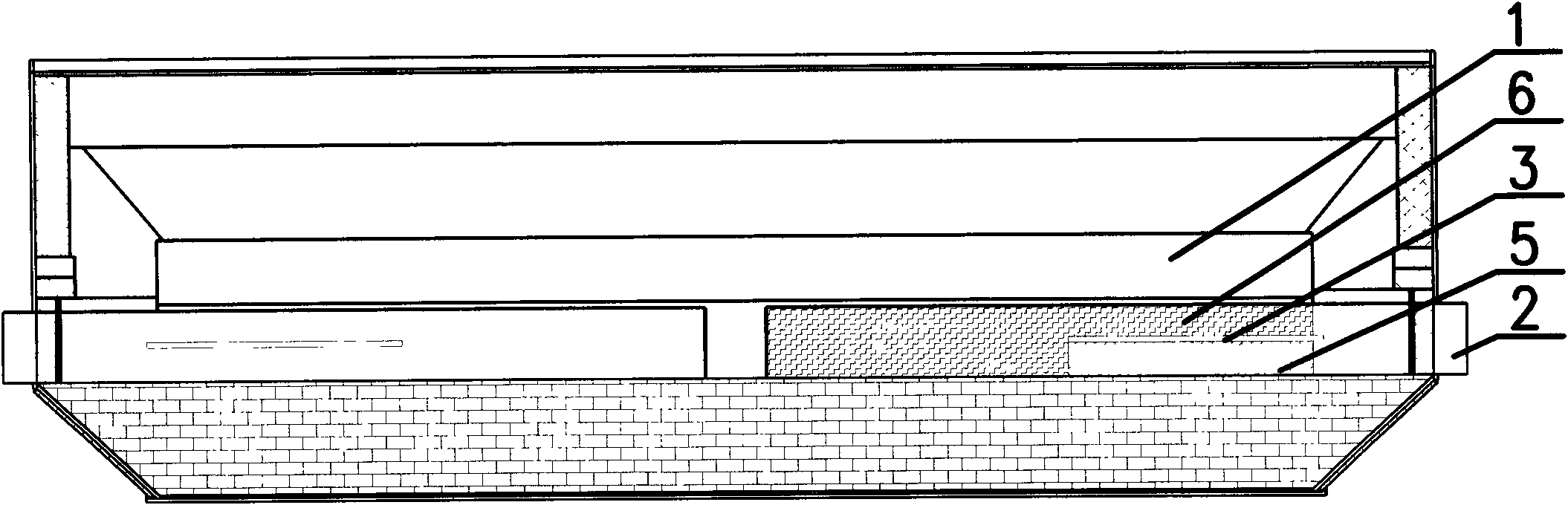

Inner lining structure of cathode molten pool for aluminum electrolytic cell

The invention relates to an inner lining structure of a cathode molten pool for an aluminum electrolytic cell, which eliminates a steel bar groove at the bottom of a cathode carbon block, a cathode steel bar and ramming paste of a steel bar and reduces the voltage drop at the groove bottom; a cathode conductive line is arranged in a heat-preservation and anti-leakage layer at the bottom of the cathode carbon block, the cathode carbon block adopts a sectional mesh point type connection conductive method, so that the vertical current distribution of the aluminum electrolytic cell is more uniform, and the horizontal current is reduced; cathode inner lining conductive carbon blocks are arranged in the furnace walls at the two opposite sides in a multidirectional and sectional arrangement manner, therefore, not only the conditions are created for the widening design of the aluminum electrolytic cell and the diversification of the cathode structure, but also a possibility for implementing the diversified structure of the cross section of the cathode carbon block is provided, and the constructive cost of the electrolytic cell is favorable for reduction; and the upper surface of the cathode inner lining adopts concave-convex design, or an aluminum liquid magnetic cyclone adjusting block is constructed, therefore, the horizontal fluctuation between the aluminum liquid and the electrolyte interface surface can be reduced, the effects of reducing the electrolytic polar distance and setting the low voltage are achieved, and the purpose of reducing the power consumption for electrolyticaluminum production is achieved.

Owner:高德金

Method for decreasing level current of electrolytic cell

InactiveCN103422121AInto the uniformSmooth connectionElectrical resistance and conductanceMetallurgy

The invention relates to a method for decreasing level current of an electrolytic cell. Electric diversion materials are laid on a cathode, a steel bar or between the cathode and the steel bar. The electric diversion materials can select different resistance values according to actual demands, and distribution of cathode carbon block resistance is adjusted, and so the current in an aluminum liquid can go into the cathode uniformly. The method is advantageous in that the resistance distribution can be changed effectively, the level current in an aluminum liquid can be decreased, the stability of the electrolytic cell can be raised, the current efficiency can be raised and the service life of the electrolytic cell can be prolonged.

Owner:TIANJIN YUDELONG ALUMINUM MFG

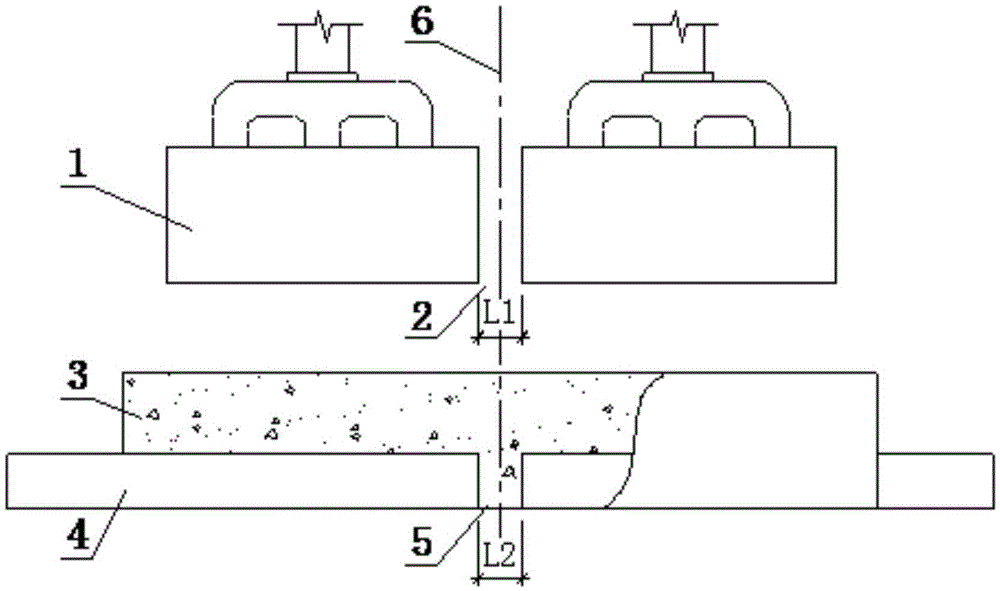

Isometric segmentation method for aluminum electrolysis cell cathode steel rods

The invention discloses an isometric segmentation method for aluminum electrolysis cell cathode steel rods. A segmentation gap between two sections of cathode carbon rods is equal to a gap between two sets of anode carbon blocks of an aluminum electrolysis cell; and the two sections of cathode steel rods are symmetrical about the center line of the cathode carbon blocks of the aluminum electrolysis cell. The method is wide in application range, is applied to the production for real measurement, reduces the production voltage fluctuation by near 50%, reduces the level current by about 30%, is more obvious in current stabilizing and energy saving effect, is convenient for segmentation technology operation, and needs no complex design and calculation.

Owner:MCC TIANGONG GROUP

Cathode for dovetail groove type aluminum electrolytic cell

The invention relates to an improvement of an aluminum electrolytic cathode set structure, in particular to an improvement of a double-dovetail-groove or multi-dovetail-groove cathode set structure for large grooves, and discloses a cathode for a dovetail groove type aluminum electrolytic cell. The cathode structurally comprises a cathode carbon block and a cathode steel rod which are bonded through combined materials. The cathode is characterized in that the number of the cathode steel rod bonded through the combined materials in the cathode carbon block is one; the distance between the cathode steel rod and the side of the cathode carbon block is 50 mm-180 mm; and the distance between the cathode steel rod and the upper portion of the cathode carbon block is 150 mm-300 mm. Compared with the prior art, the cathode has the beneficial effect of greatly lowering voltage drop of ferric carbon; the limitation for electric conduction increasing through steel rod widening is broken through; quite remarkable functions for lowering furnace bottom voltage drop, lowering the horizontal current and reducing the furnace leakage risk are achieved; and meanwhile, the structure is simple, the manufacturing and running cost is low, and the production cost of electrolytic aluminum can be effectively reduced.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

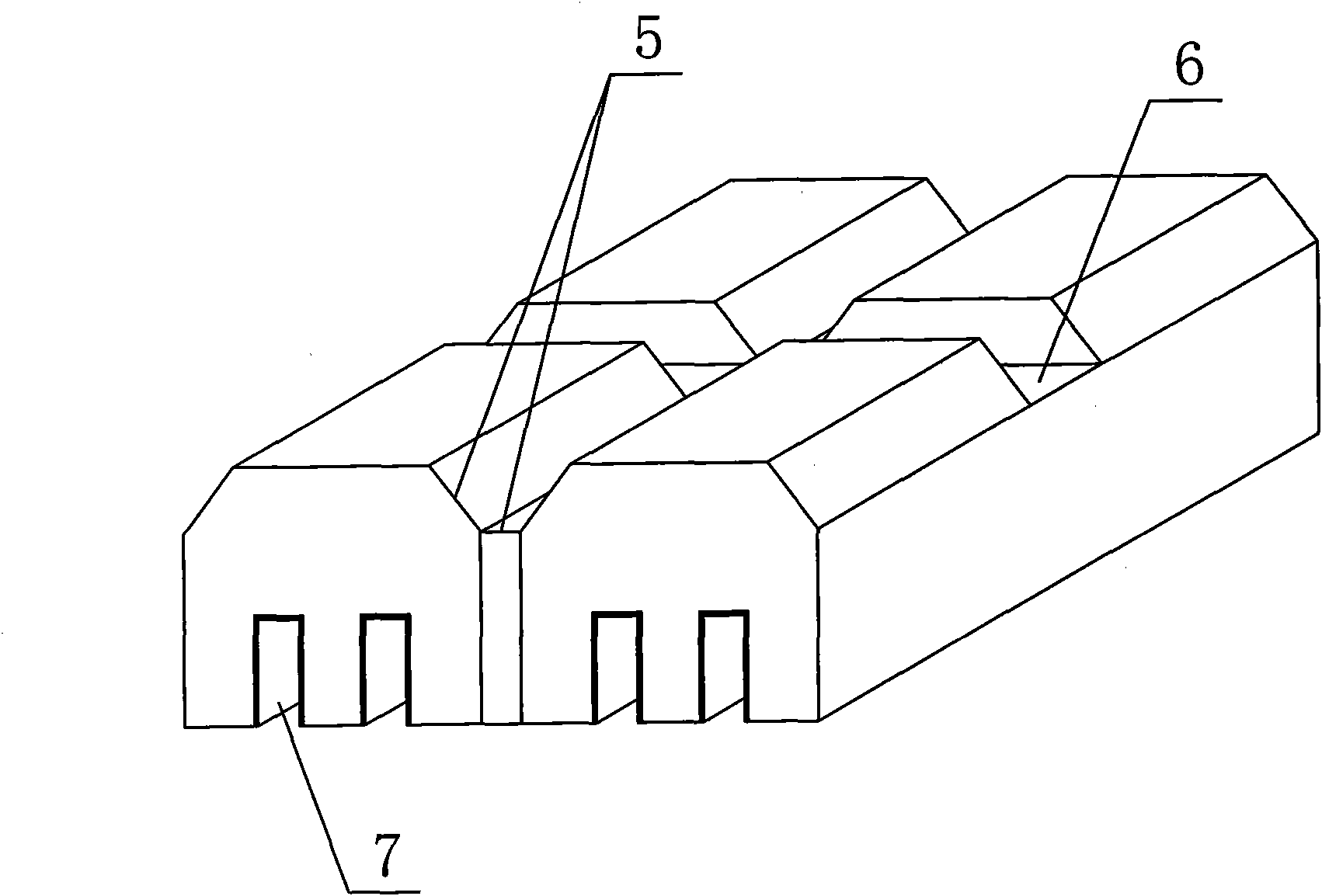

Building method of aluminum electrolysis cell

The invention relates to a building method of an aluminum electrolysis cell, which comprises a conventional building method and comprises the following building steps: (1) when cathode blocks of the electrolysis cell are manufactured, symmetrically chamfering the upper end part of each cathode block along the longitudinal direction, and forming a transverse groove at the top of each cathode block; (2) when the cathode blocks are built, reserving a gap of 20-40mm between every two adjacent cathode blocks, and tamping the gap by cathode tamping paste, wherein the opposite chamfers of the adjacent cathode blocks and the cathode tamping paste filled into the gap form a trapezoidal groove, and the depth of the trapezoidal groove is the same as the depth of the transverse groove at the top of each cathode block; and (3) forming one or two longitudinal grooves at the bottom of each cathode block, laying steel bars of corresponding sizes in each longitudinal groove, and tamping the gap between each cathode block and each steel bar by cathode steel bar paste. The aluminum electrolysis cell built by the method can greatly reduce the horizontal current in aluminum liquid to enable the current density of the cathode blocks and the cathode steel bars to be more uniform, thereby greatly prolonging the service life of the electrolysis cell.

Owner:SNTO TECH GRP

Bottom-discharging aluminum cell

InactiveCN101760760ATo achieve the purpose of saving energy and reducing consumptionReduce dissolution lossMagnetic fieldCathode

The invention discloses a bottom-discharging aluminum cell which is provided with a plurality of cathodes. Each cathode comprises a horizontal cathode steel rod and a vertical cathode steel rod or each cathode comprises a horizontal cathode steel rod and one or more vertical cathode steel rod; the horizontal cathode steel rod or a flat cathode steel block and the vertical cathode steel rod form a T-shaped or phi-shape structure. The bottom of the vertical cathode steel rod is connected with a cathode bus of the aluminum cell; the cathode bus of the aluminum cell is partially gathered on the bottom of the aluminum cell and is partially gathered on the end of the aluminum cell. The bottom-discharging aluminum cell uses the specific cathode structure and bus, so the aluminum liquid and the cathode current of the aluminum cell are uniformly distributed, the level current and the vertical magnetic field are small and the stability of the surface aluminum liquid is excellent.

Owner:CENT SOUTH UNIV

Cathode structure capable of saving energy and homogenizing horizontal current in molten aluminium

The invention relates to a cathode structure of an aluminum electrolysis cell and in particular relates to a cathode structure capable of saving energy and homogenizing horizontal current in molten aluminum. The cathode structure comprises a cathode carbon block and current conducting rods and is characterized in that the current conducting rods protrude out of the bottom surface of the cathode carbon block and are surrounded by wrapping materials; the current conducting rods are divided into a plurality of parts by separation seams along length directions; the current conducting rods above the separation seams are connected with the cathode carbon block by electric connectors; the current conducting rods below the separation seams and above the bottom surface of the cathode carbon block are connected with the cathode carbon block by insulators; the separation seams are filled with insulating materials. The cathode structure has the advantages and effects that the cathode structure substantially reduces the cathode drop and the horizontal current in molten aluminum and improves the stability of an electrolysis cell, so that the electrolysis cell can operate efficiently and stably under the condition of short electrode distance; the cathode structure effectively reduces the energy consumption of tonnage aluminum and has an obvious energy saving effect; meanwhile, the cathode current is distributed more uniformly, so that the service life of the cell is prolonged.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

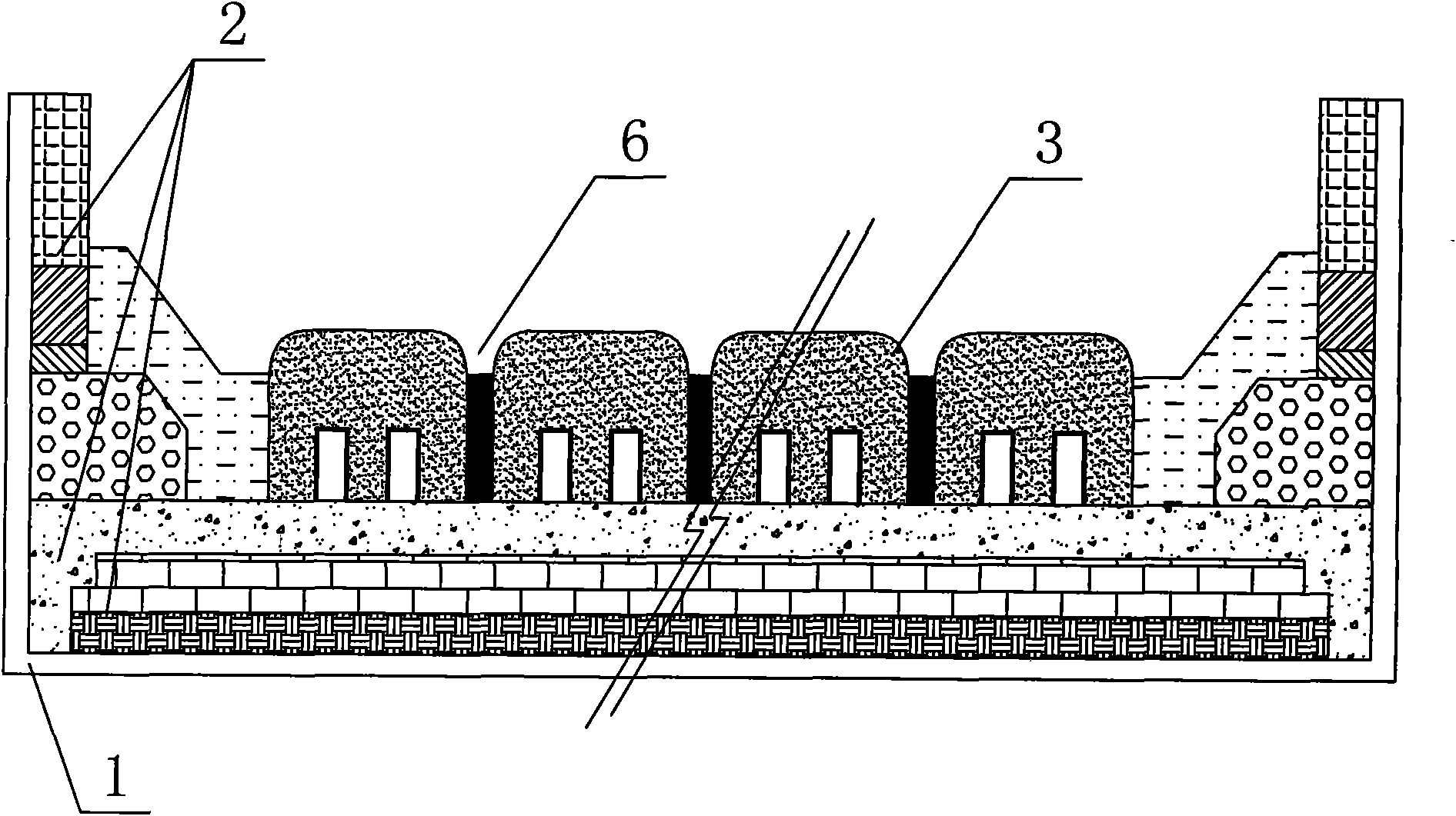

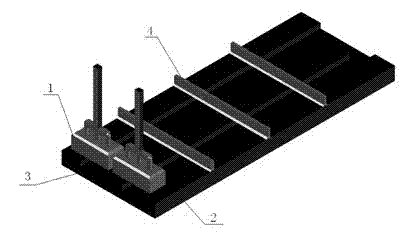

Cell bottom structure of electrolytic cell

The invention discloses a cell bottom structure of an electrolytic cell. The cell bottom structure comprises an electrolytic cell (1) and a cathode bus (2), wherein the bottom of the electrolytic cell (1) is provided with columnar cathode carbon blocks (3) which are perpendicular to the bottom of the electrolytic cell (1); and the lower ends of the columnar cathode carbon blocks (3) are connected with the cathode bus (2). In the cell bottom structure, the column cathode carbon blocks are vertically inserted in the bottom of the electrolytic cell, and the lower ends of the columnar cathode carbon blocks are connected with the cathode bus, so that current which is led in from anode carbon blocks is led out downwards from the columnar cathode carbon blocks through molten aluminum to reduce horizontal current in the molten aluminum; and a cathode which extends into the molten aluminum can effectively reduce fluctuation of the molten aluminum, so that a stable molten aluminum surface is achieved to reduce polar distance between the cathode and an anode and reduce the cell voltage to fulfill the aim of reducing power consumption.

Owner:GUIYANG AL-MG DESIGN & RES INST

Aluminum electrolytic tank composite cathode structure containing a highly conductive skeleton network

The invention discloses an aluminum electrolytic tank composite cathode structure containing a highly conductive skeleton network. Since cathode current collector skeletons are pre-installed inside the cathode, cathode current collector skeletons with different shapes are pre-arranged in a cathode carbon block, so that the cathode structure can redistribute the distribution and the size of the level current in aluminum liquid, and the mechanical properties of the cathode can be improved and the service life of the cathode is improved. By virtue of the cathode, according to structural parameters and types of the materials determined by the actual groove design, the horizontal current density of the aluminum liquid along the long axis and short axis of the electrolytic tank can be significantly reduced and thus the vertical amplitude of fluctuation of the aluminum liquid-electrolyte interface is weakened and the proper melt horizontal movement is maintained, the electrolytic tank can run smoothly in a low polar distance, the energy conservation and consumption reduction are realized, and the processing of the structure is relatively simple and easily implemented.

Owner:CENT SOUTH UNIV

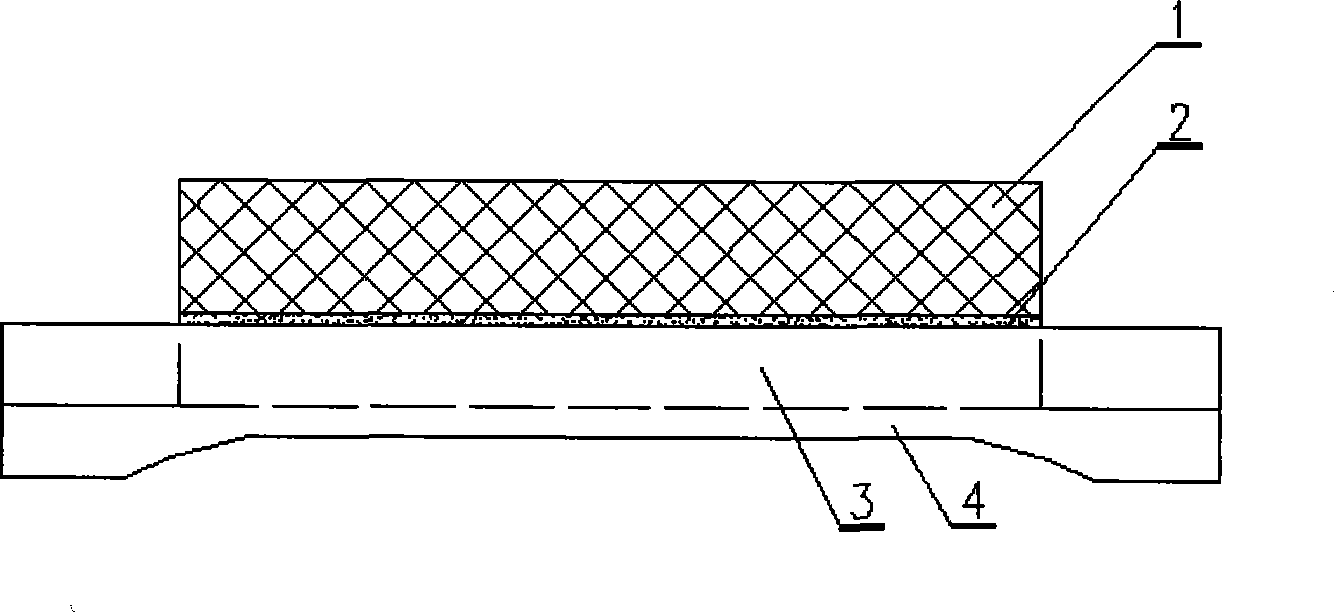

Electric tank cathode structure with conductive plate

The invention discloses a reduction cell cathode structure with a current-conducting steel plate and belongs to the technical field of aluminum electrolysis. The reduction cell cathode structure comprises a cathode carbon block, a cathode collector steel bar, a current-conducting steel plate and an impervious layer. The cathode collector steel bar is positioned in the cathode carbon block. A bottom part of the cathode carbon block is proved with a steel bar groove in a shape fitted with that of the cathode collector steel bar. The cathode carbon block is connected with the cathode collector steel bar through the steel bar groove. The current-conducting steel plate is positioned at a lower part of the cathode carbon block and in the impervious layer. The current-conducting plate is connected with the cathode collector steel bar into a whole to conduct a cathode current. The reduction cell cathode structure reduces horizontal current intensity in aluminum liquid, improves electric energy efficiency and improves the stability and service life of a reduction cell due to the cathode collector steel bar and the current-conducting plate.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

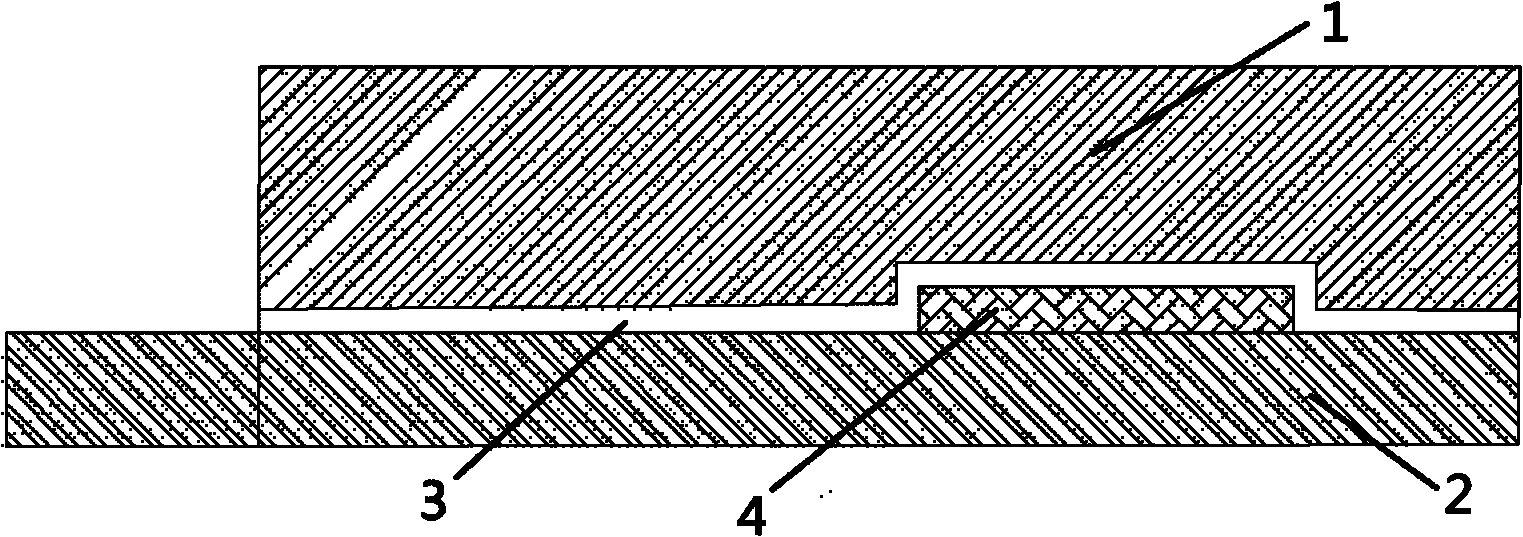

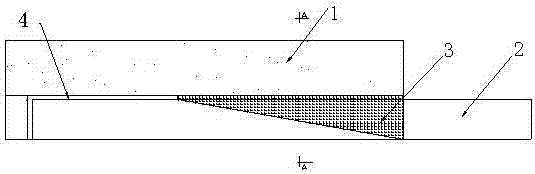

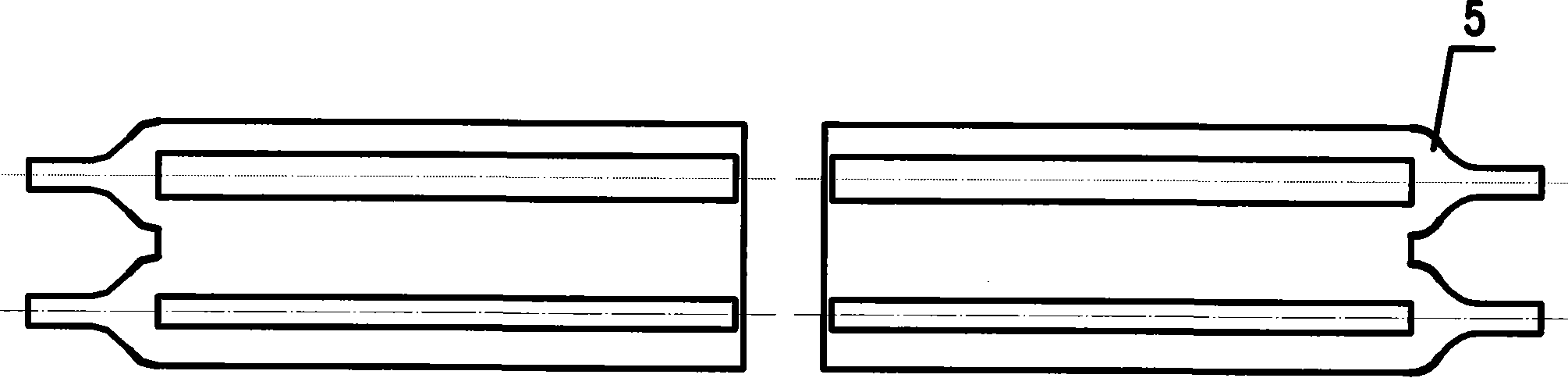

Step type paste bundling cathode structure

The present invention discloses a step type paste bundling cathode structure, wherein a step-shaped paste bundling surface (4) is arranged close to an electricity outlet end of a cathode steel bar (2), the position of the step-shaped paste bundling surface is filled with a high temperature resistance insulation material, the high temperature resistance insulation material is ceramic fiber cotton or other materials having the same effect, and the number of steps can be two or more. The step type paste bundling cathode structure has the following characteristics that: construction is simple, no material processing problem exists, the effect is significant, and the step type paste bundling cathode structure is a cathode structure for easily reducing a horizontal current, has a high practical value, and can be used in old electrolyte tank transformation or new electrolyte tank design.

Owner:GUIYANG AL-MG DESIGN & RES INST

Method for preventing aluminium leakage from side parts and bottom part of aluminium electrolysis bath

The invention relates to a method for preventing aluminium leakage from the side parts and the bottom part of an aluminium electrolysis bath. The method comprises the following steps: firstly teeth are respectively processed at four edges of the top part of each cathode carbon block, then the cathode carbon blocks are arranged on the electrolysis bath to implement tamping of carbon paste in seams between the slopes of the edge parts and the cathode carbon blocks; when the carbon paste surfaces are tamped to the bottom surfaces of the teeth at the peripheries of the cathode carbon blocks and are on the same plane with the bottom edges of the teeth, the teeth at the peripheries of the cathode carbon blocks close to the bath ledges are provided with a ring of refractory bricks or bath-shaped refractory bricks; and a refractory brick or a bath-shaped refractory brick is arranged on the teeth of the middle seam of every two adjacent cathode carbon blocks; and a carbon tamping paste slope is rammed between the side surfaces of the carbon blocks at the edge parts for placing the refractory brick or the bath-shaped refractory brick and the carbon blocks at the edge parts thereof, and a layer of refractory-material board is bonded on a position close to the upper surface of the slope after the slope tamping is finished. The method can avoid the aluminium leakage in cracks caused by tamping paste on artificial extending legs, bewteen the artificial extending legs and the cathode carbon blocks and between two adjacent cathode carbon blocks.

Owner:SHENYANG BEIYE METALLURGIGAL TECH CO LTD

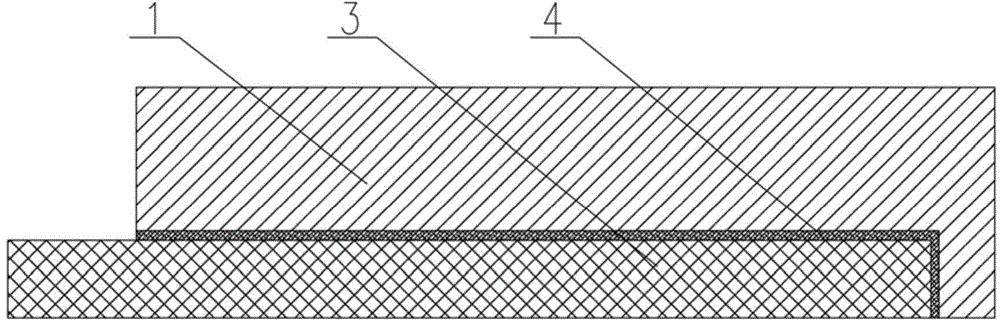

Bottom trough refractory material composite structure of aluminium cell cathode carbon block and manufacturing method thereof

InactiveCN103556182AIncrease the conductive areaLower resistanceElectrical resistance and conductanceThermal insulation

The invention relates to the technical field of an aluminium cell, and particularly relates to a bottom trough refractory material composite structure of an aluminium cell cathode carbon block and a manufacturing method thereof. The bottom trough refractory material composite structure comprises a trough refractory material structure body, wherein the structure body tightly contacts the bottom surface of the cathode carbon block and the surface of a cathode steel rod body protruding on the bottom surface of the cathode carbon block; a groove coupled to the cathode steel rod body part protruding on the bottom surface of the cathode carbon block is formed on the upper surface of the structure body; an anti-seepage layer is arranged at the lower part of the structure body. The manufacturing method comprises the following steps: building the anti-seepage layer and the trough structure refractory material and installing the cathode carbon block, or firstly combining the overall refractory material structure with the cathode carbon block, and then putting the overall combined body on the anti-seepage layer at the bottom of the trough refractory material or other types of thermal insulation materials. By adopting the technical scheme disclosed by the invention, under the condition of not increasing the height of the cathode carbon block, the conductive area of the cathode steel rod can be increased, the resistance of the cathode steel rod is reduced, and the horizontal current in cathode molten aluminum of the aluminium cell is also reduced.

Owner:NORTHEASTERN UNIV LIAONING

Aluminum electrolysis cell cathode structure of horizontal current in controllable regulation aluminum liquid

The invention discloses an aluminum electrolysis cell cathode structure of horizontal current in controllable regulation aluminum liquid. A continuously or partially bulged cathode steel bar is used or a cushion material with high electric conductivity is cushioned at the partial position between a common rectangular steel bar and a cathode carbon block, so that the distribution and the size of the horizontal current in the aluminum liquid can be readjusted by the cathode structure. Structural parameters are determined by the cathode structure according to an actual groove-type design, the horizontal current in the aluminum liquid can be obviously reduced when the cathode structure is used in an aluminum electrolysis cell, and the distribution of the horizontal current in the aluminum liquid can be optimized to prevent an area with higher horizontal current density from being superposed with an area having a larger vertical magnetic field, so that the effects of weakening the verticalfluctuation of the aluminum liquid and stabilizing the horizontal motion of a melt are achieved; therefore, electrolysis can be operated within a relatively short electrode distance, energy consumption can be reduced greatly, and the cathode structure is easy and convenient to process and is easy to realize.

Owner:CENT SOUTH UNIV +2

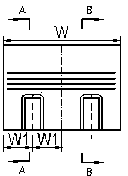

Partition multichamber aluminum electrolysis cell

The invention discloses a partition multichamber aluminum electrolysis cell which comprises an anode (1) and a cathode (2), wherein the cathode (2) is provided with a diversion trench (3); a plurality of partitions (4) are arranged among the anode (1); and the partitions (4) are embedded or arranged on the upper surface of the aluminum electrolysis cell cathode (2) to form the multichamber aluminum electrolysis cell. The partitions (4) adopt an embedded slab structure or flatwise staircase structure. The height of the partitions (4) is slightly greater than that of the molten aluminum layer. The intervals between every two partitions (4) are equal or unequal. By adopting the unique partition technology, the invention can effectively reduce the horizontal current, prevent or reduce the radial flow rate of the molten aluminum layer, reduce the interfacial oscillation and secondary reaction of the molten aluminum, and enhance the stability and current efficiency of the aluminum electrolysis cell, thereby implementing energy saving and consumption reduction.

Owner:GUIYANG AL-MG DESIGN & RES INST

Method for reducing horizontal current in molten aluminum of aluminum electrolysis bath

Disclosed is a method for reducing the horizontal current in liquid aluminum in an aluminum reduction cell, comprising: placing a part of current conducting material at a cathode carbon block, or a steel bar, or a connecting material cathode paste thereof, or phosphorus pig iron, and making the current in the liquid aluminum enter the cathode carbon block evenly, pass through the steel bar, and exit from a side portion of the reduction cell. The method provided by the present invention changes the resistance distribution at the cathode, adjusts the current distribution at the cathode, reduces the horizontal current in the liquid aluminum, improves the stability of the magnetic fluid in the reduction cell, improves the efficiency of the current, and extends the service life of the cell.

Owner:中铝郑州有色金属研究院有限公司

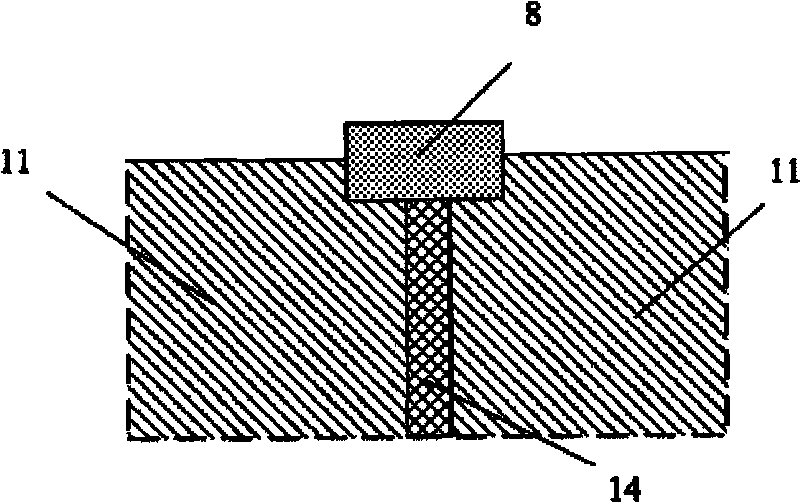

Aluminum cell cathode structure capable of reducing horizontal current and improving current distribution

ActiveCN108396333AUniform current distributionSmall electromagnetic forcePower flowCurrent distribution

The invention discloses an aluminum cell cathode structure capable of reducing horizontal current and improving current distribution. The structure comprises a cathode carbon block and cathode current-conducting rods, one penetrating groove or two coaxial and symmetric long grooves are formed in the bottom face of the cathode carbon block, and grooves are formed in the top face of the cathode carbon block; each cathode current-conducting rod is composed of a rod body, a current conducting claw and claw heads; the current conducting claws are fixedly arranged on the top ends of the rod bodies,three or more claw heads are arranged on each current conducting claw and are located in the grooves, and the positions between the grooves and the claw heads are filled with conductors. According tostructural design, the claw heads can evenly share the current from the cathode carbon block, the current can be more evenly distributed, horizontal current is reduced, the melt interface stability isgood, the groove voltage can be reduced through reducing the electrode distance, and energy consumption reduction is achieved.

Owner:NORTHEASTERN UNIV

Method for reducing horizontal current in aluminum liquid of aluminum reduction cell

The invention discloses a Hall-Heroult electrolysis-process primary aluminum production technique and an aluminum reduction cell for implementing the industrial production method. Particularly, the invention relates to a method for reducing horizontal current in aluminum liquid of the aluminum reduction cell. The method comprises the following steps that: at least one cathode steel bar (3) is bound to or cast in the lower part of a cathode carbon block (1); at least one current-conducting plate or current-conducting bar (5) is laid on the lower part of a cathode carbon block (1); the current-conducting plate or current-conducting bar (5) is partially connected with the cathode steel bar (3) in the cathode carbon block (1); and current is led out from the side of the reduction cell throughthe current-conducting plate or current-conducting bar (5) and the cathode steel bar (3). The method has the advantages of remarkably reducing horizontal current in aluminum liquid under the condition of without changing the mode of leading out cathode current, ensuring more uniform distribution of the cathode current, improving the stability of the reduction cell, prolonging the life span of thecell and enabling the reduction cell to be easier to operate and manage.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE +1

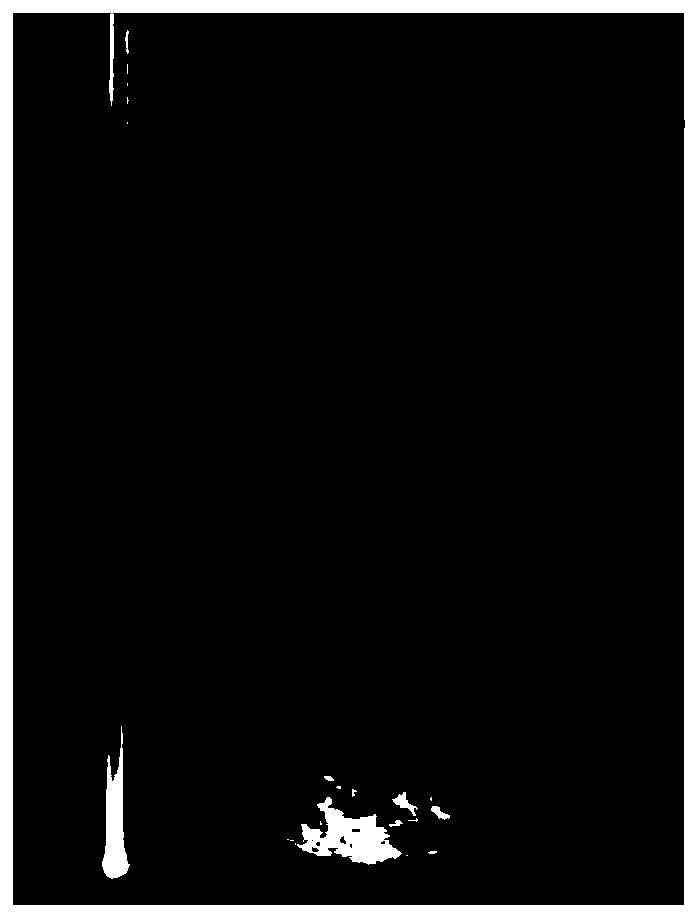

Method for greatly reducing horizontal current in aluminum liquid of aluminum electrolytic cell

ActiveCN102453927BLower level currentEvenly distributedProcess efficiency improvementPower flowEnergy consumption

Disclosed is a cathode structure of an aluminum electrolysis cell, where a cathode steel bar is divided, along a height direction of the cathode steel bar from top to bottom, into at least two portions comprising an upper portion by a dividing seam in a segment close to an end portion of a cathode carbon block along the length direction, the cathode steel bar is connected to the cathode carbon block by an electric conductor in a segment in a middle part of the cathode carbon block which is not divided, the upper portion of the cathode steel bar that is close to the end portion of the cathode carbon block and is divided is connected to the cathode carbon block by an electric conductor, the other portions that are located below the upper portion is insulated from the cathode carbon block by using an insulator, and the dividing seam is filled with a dividing seam insulating material. Disclosed are also an aluminum electrolysis cell comprising the cathode structure and a method for lowering a horizontal current in an aluminum liquid. Through the present invention, the horizontal current in the aluminum liquid is greatly lowered, so that the distribution of cathode current becomes more even, the stability of the electrolysis cell is improved, the service life of the cell is prolonged, the energy consumption per ton of aluminum is effectively lowered, and a significant energy saving effect is achieved.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

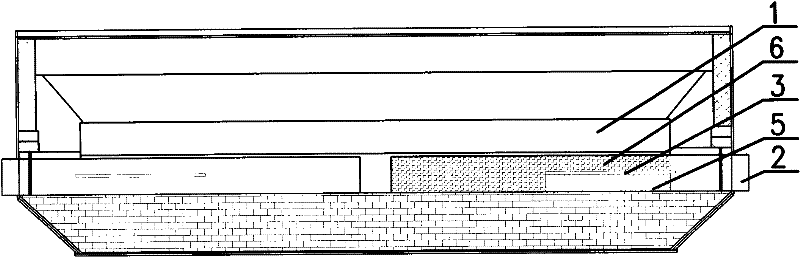

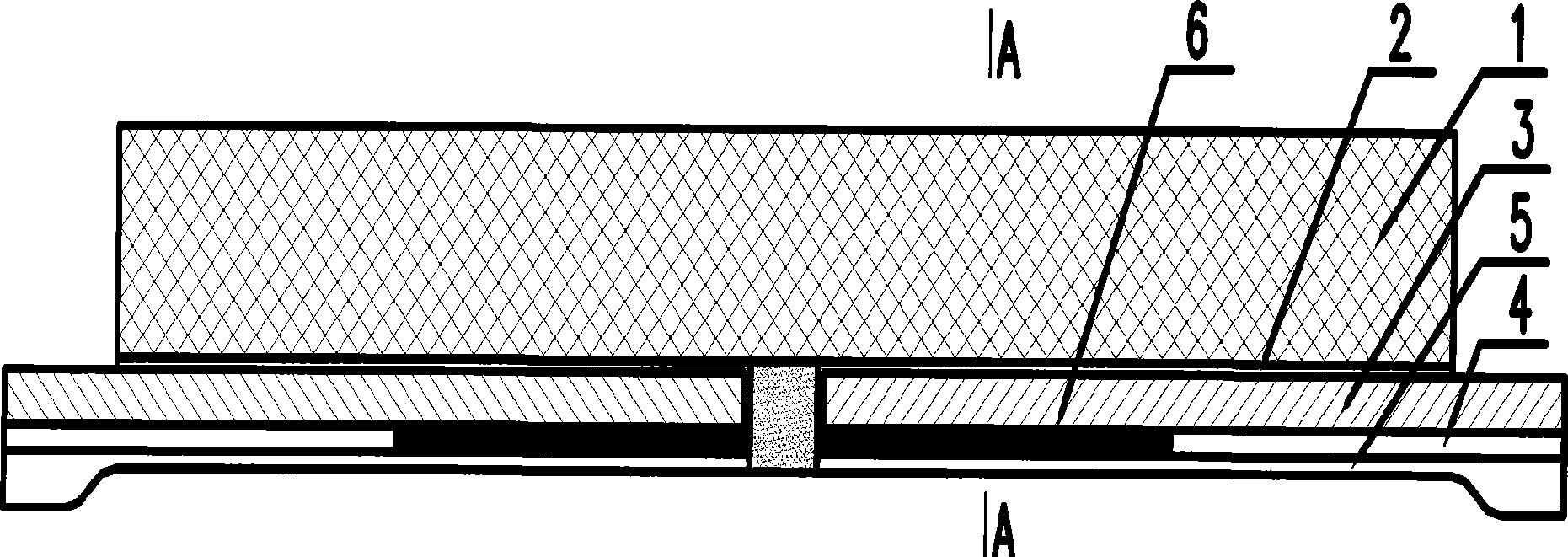

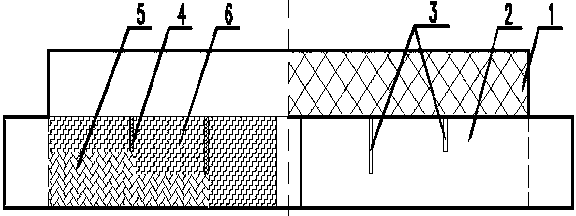

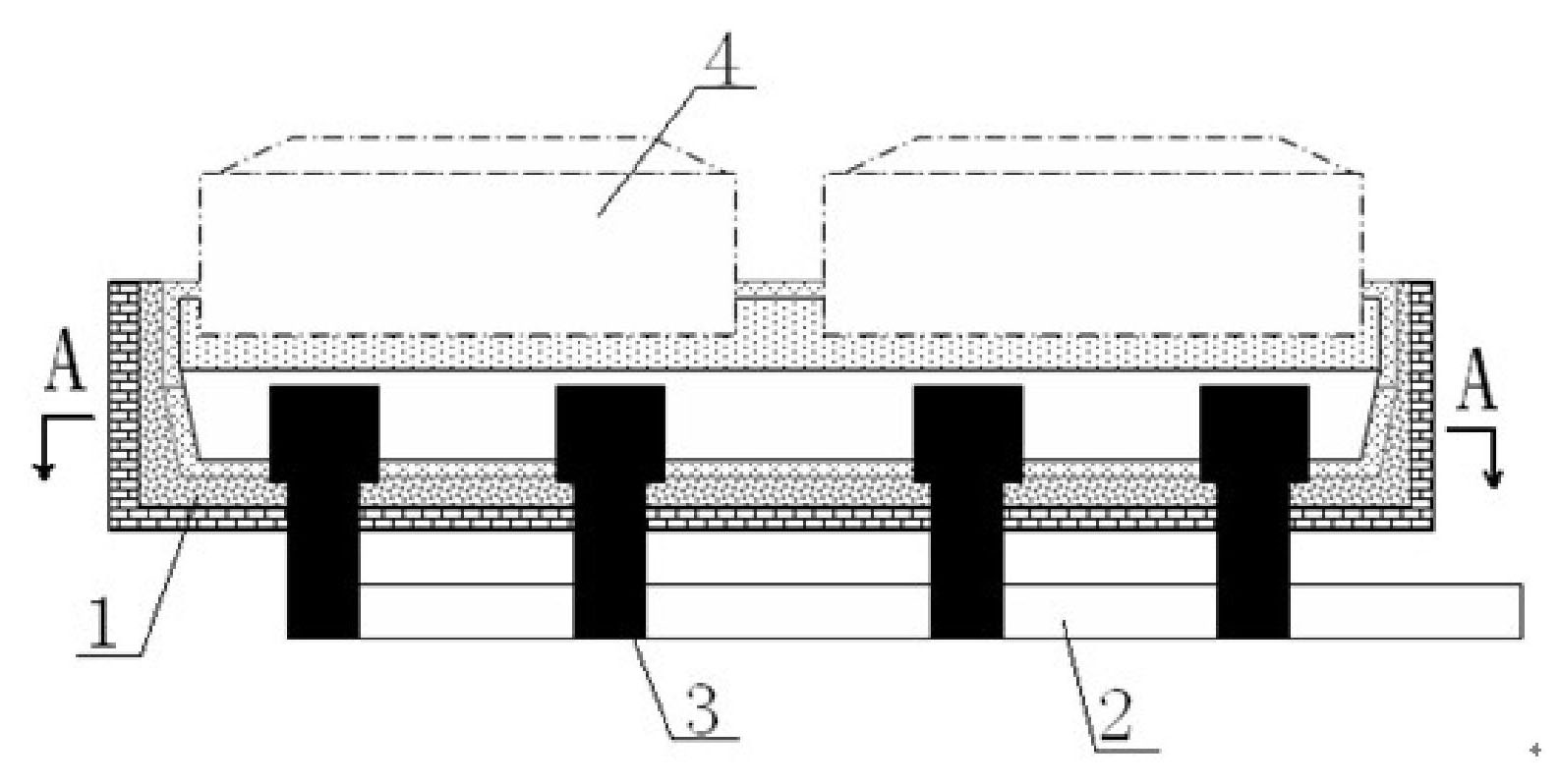

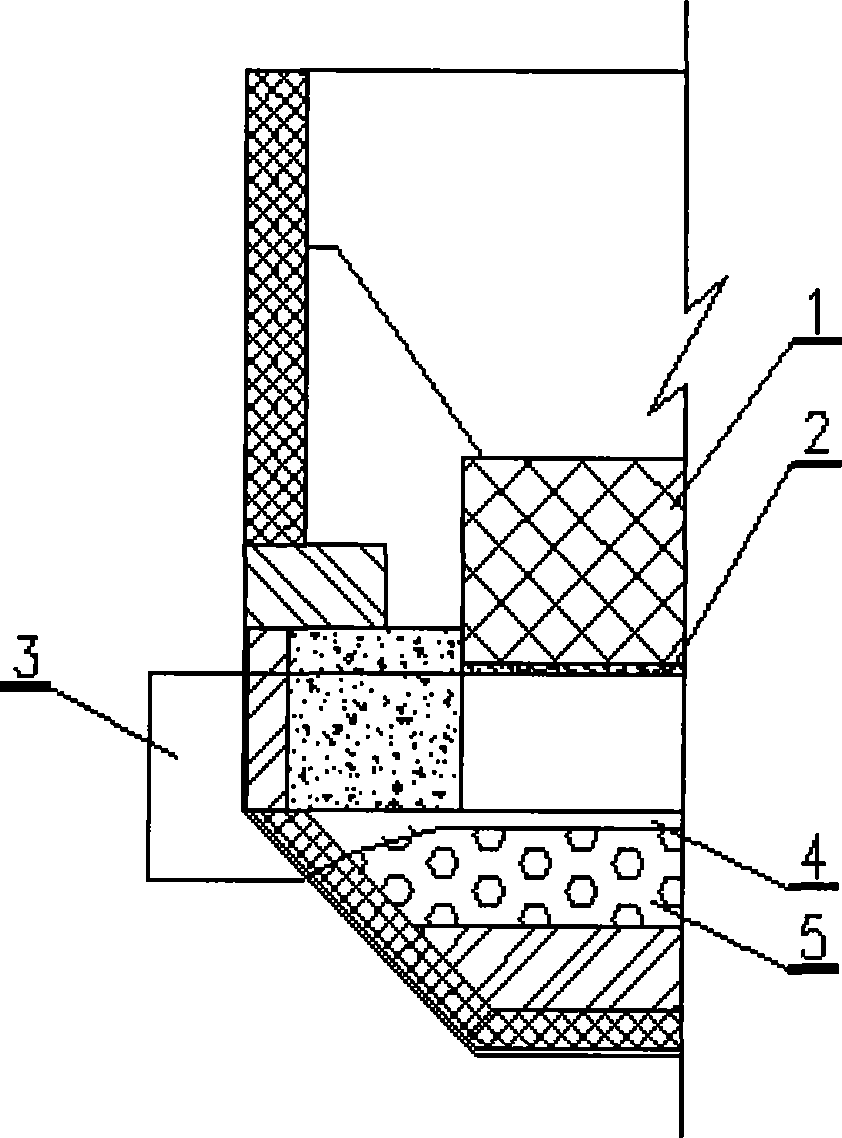

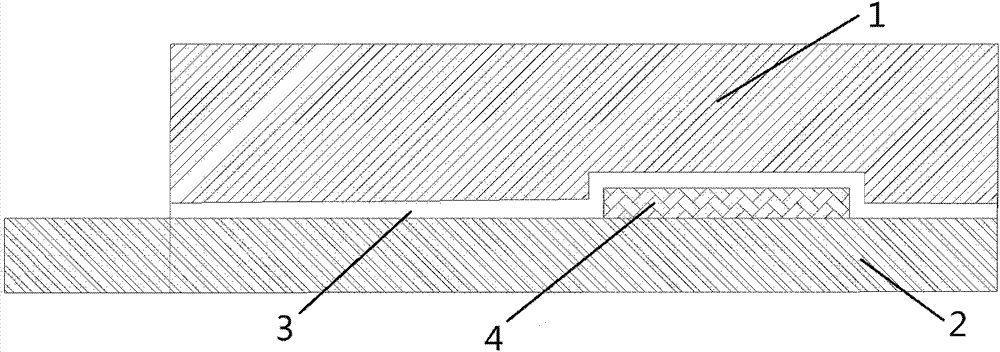

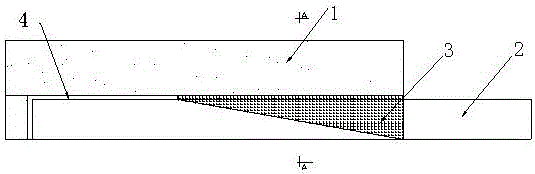

Electrolytic tank capable of greatly reducing horizontal current

The invention discloses an electrolytic tank capable of greatly reducing a horizontal current. The electrolytic tank comprises an anode carbon block (1), a cathode steel bar (2), a hearth (3), a cathode carbon block (4) and the like. The electrolytic tank is characterized in that the cathode steel bar (2) adopts a gradual-changing cathode pasting structure which is an incline-plane or stepped-section cathode pasting structure, and a high-temperature insulation material is filled at the inclined plane or the stepped section; the cathode steel bar (2) is proportionally arranged in the cathode carbon block (4); the width S of the large processing surface (5) of the hearth (3) is controlled at 240-269nm; and the cathode carbon block (4) is aligned at the anode carbon block (1), that is, the width of the cathode carbon block (4) is equal to the width of the anode carbon block (1) and is 600-800mm.

Owner:GUIYANG AL-MG DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com