Aluminum electrolysis cell cathode structure of horizontal current in controllable regulation aluminum liquid

A horizontal current, aluminum electrolytic cell technology, applied in the field of aluminum electrolytic cells, can solve the problems affecting the stability of the magnetic fluid in the cell, deformation of the electrolyte-aluminum liquid interface, and no consideration of pressure drop, etc., to achieve strong work stability and aluminum liquid The effect of small fluctuations and optimized distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

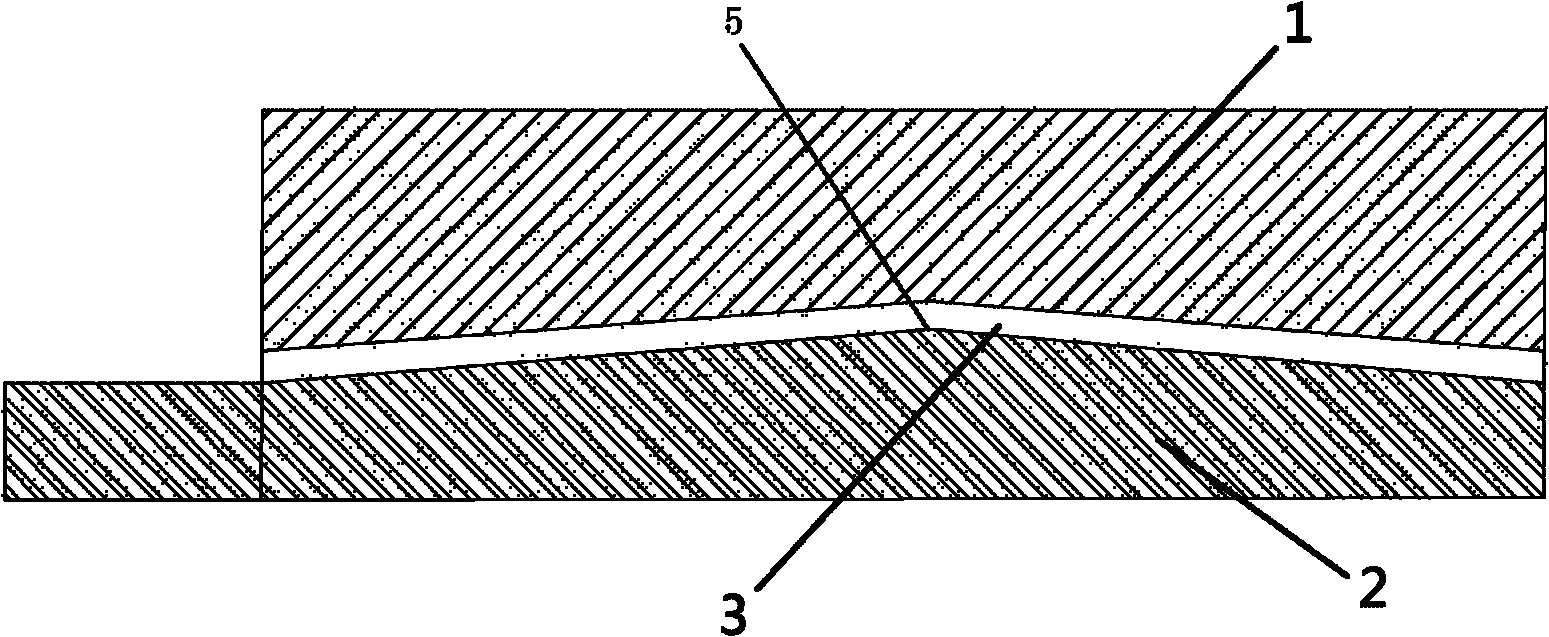

[0024] Such as figure 2 Shown is the sectional view along the length direction of the cathode structure of the aluminum electrolytic cell adopting a long and continuously protruding cathode steel rod of the present invention, which is composed of a cathode carbon block 1, a cathode steel rod 2, and a steel rod carbon paste 3. In this embodiment, the total length of the cathode carbon block 1 is 3000-4000mm, the width is 400-700mm, and the height is 400-600mm. The bottom of the cathode carbon block 1 is provided with a dovetail groove with a continuously changing section along the length direction, and a dovetail groove corresponding to it. A long cathode steel rod 2 with a continuous protrusion 5 is embedded in the groove. The highest protrusion part of the continuous protrusion 5 on the cathode steel rod 2 is 400-1200mm away from the edge of the outlet end of the cathode carbon block 1. The continuous protrusion 5 The height of the highest protrusion is 50-120 mm relative to...

Embodiment 2

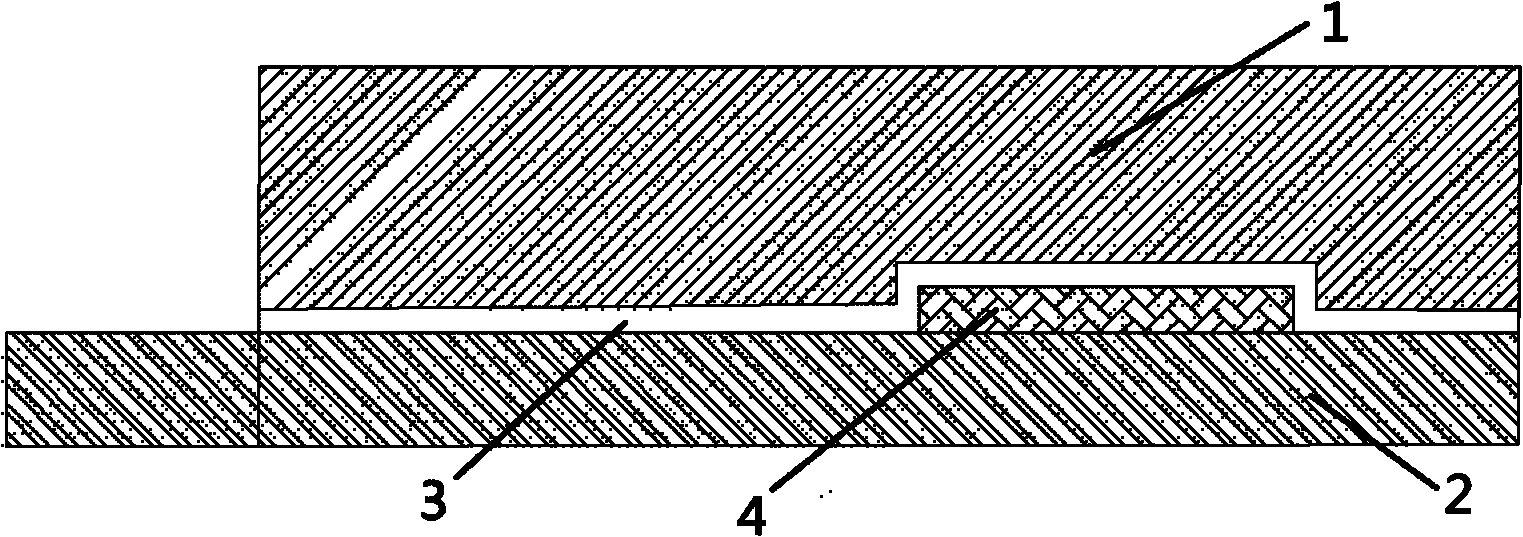

[0026] Such as image 3 Shown is the cross-sectional view of the aluminum electrolytic cell cathode structure length direction using a long and partially raised cathode steel rod of the present invention, which is composed of a cathode carbon block 1, a cathode steel rod 2, a steel rod carbon paste 3, and a heightening material 4 . In this embodiment, the total length of the cathode carbon block 1 is 3000-4000 mm, the width is 400-700 mm, and the height is 400-600 mm. There is a dovetail groove at the bottom of the cathode carbon block 1 along the length direction, and a dovetail groove is embedded in the corresponding dovetail groove. Cathode steel rods 2 with padding materials 4 are partially provided. The cross-section of cathode steel rods 2 is rectangular. Cathode steel rods 2 are processed according to the traditional structure. When assembling the cathode structure, plug the raised parts in the corresponding dovetail grooves The padding material 4 with good electrical ...

Embodiment 3

[0028] Such as Figure 4 Shown is the sectional view along the length direction of the cathode structure of the aluminum electrolytic cell adopting a long and continuously protruding cathode steel rod of the present invention, which is composed of a cathode carbon block 1, a cathode steel rod 2, and a steel rod carbon paste 3. In this embodiment, the total length of the cathode carbon block 1 is 3000-4000 mm, the width is 400-700 mm, and the height is 400-600 mm. Two dovetail grooves with continuously changing cross-sections are opened at the bottom of the cathode along the length direction, and each dovetail groove corresponding to it is Embed a long cathode steel rod 2 with a continuous protrusion 5, the highest protrusion part of the continuous protrusion 5 on the long cathode steel rod 2 is 400-1200 mm from the edge of the outlet end of the cathode carbon block 1, and the continuous protrusion 5 The protrusion height of the highest protrusion part is 50-120 mm relative to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com