Method for preventing aluminium leakage from side parts and bottom part of aluminium electrolysis bath

An aluminum electrolytic cell and electrolytic cell technology, applied in the field of electrolytic aluminum, can solve problems such as aluminum leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

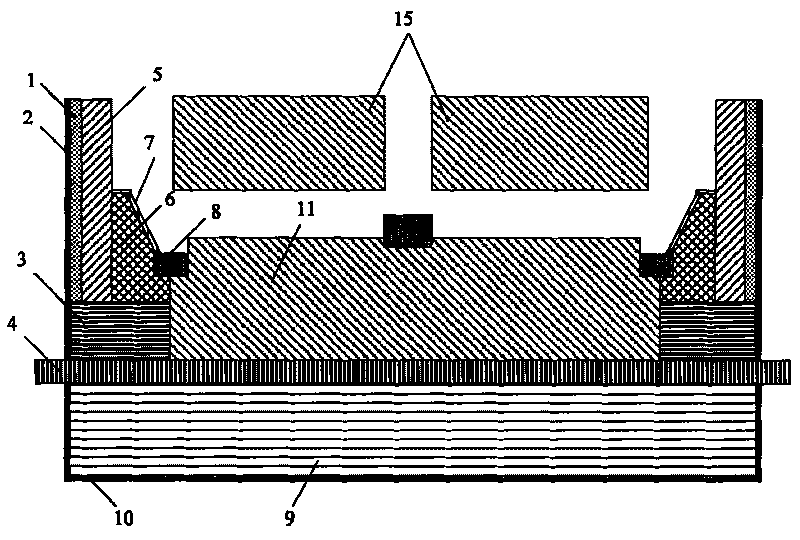

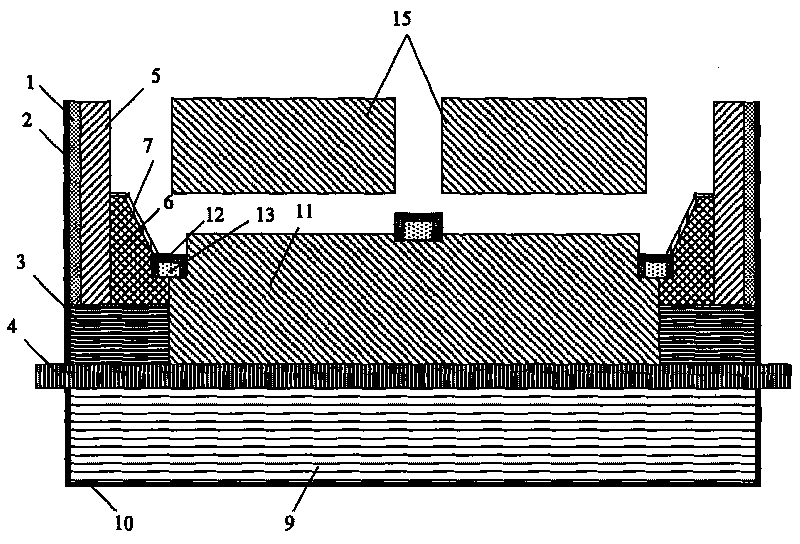

[0027] The method of preventing aluminum leakage from the side and bottom of the aluminum electrolytic cell is carried out in the following steps:

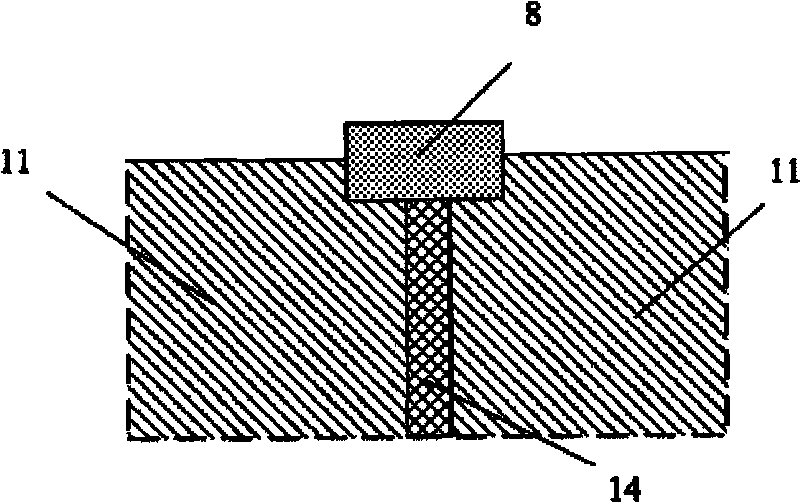

[0028] (1) At first, the top four sides of each cathode carbon block are processed with a mouth, and the edge near the side of the groove is processed into a mouth with a height of 5 cm and a width of 4.5 cm. Each pair of adjacent two cathode carbon blocks are processed into a 4.5cm high and 2.5cm wide mouthpiece above the opposite sides, and a 4.5cm high and 2.5cm wide mouthpiece is formed above the opposite sides of the two adjacent cathode carbon blocks. . Then the cathode carbon block is arranged on the electrolyzer, and the cathode carbon block of the electrolyzer is assembled into the integral cathode of the electrolyzer, and the upper edge of the entire cathode near the periphery of the tank side forms a tooth mouth with a height of 5 cm and a width of 4.5 cm. In addition, the middle part of each cathode carbon block direc...

Embodiment 2

[0034] The method of preventing aluminum leakage from the side and bottom of the aluminum electrolytic cell is carried out in the following steps:

[0035] (1) At first, the top four sides of each cathode carbon block are processed with a mouth, and the edge near the side of the groove is processed into a mouth with a height of 8 cm and a width of 6 cm. Every pair of adjacent two cathode carbon block relative edge parts are processed into high 6cm, wide 3cm tooth mouth, form high 6cm, wide 3cm tooth mouth above the opposite edge portion of two adjacent two cathode carbon blocks. Then the cathode carbon block is arranged on the electrolyzer, and the cathode carbon block of the electrolyzer is assembled into the integral cathode of the electrolyzer, and the upper edge of the entire cathode near the periphery of the tank side forms a mouthpiece with a height of 8 cm and a width of 6 cm. In addition, the middle part of each cathode carbon block directly below the middle seam of th...

Embodiment 3

[0041] The method of preventing aluminum leakage from the side and bottom of the aluminum electrolytic cell is carried out in the following steps:

[0042] (1) At first, the top four sides of each cathode carbon block are processed with a mouth, and the edge near the side of the groove is processed into a mouth with a height of 3 cm and a width of 3 cm. Every pair of adjacent two cathode carbon block relative edge parts are processed into high 3cm, wide 2cm tooth mouth, form high 3cm, wide 2cm tooth mouth above the opposite edge portion of two adjacent two cathode carbon blocks. Then the cathode carbon block is arranged on the electrolyzer, and the cathode carbon block of the electrolyzer is assembled into the integral cathode of the electrolyzer, and the upper edge of the entire cathode near the periphery of the tank side forms a mouthpiece with a height of 3 cm and a width of 3 cm. In addition, the middle part of each cathode carbon block directly below the middle seam of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com