Rubber crawler belt

A rubber crawler and crawler technology, applied to tracked vehicles, power steering mechanisms, steering mechanisms, etc., can solve problems such as foreign matter intrusion, rubber membrane damage, and slit damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, embodiments of the rubber crawler of the present invention will be described with reference to the drawings.

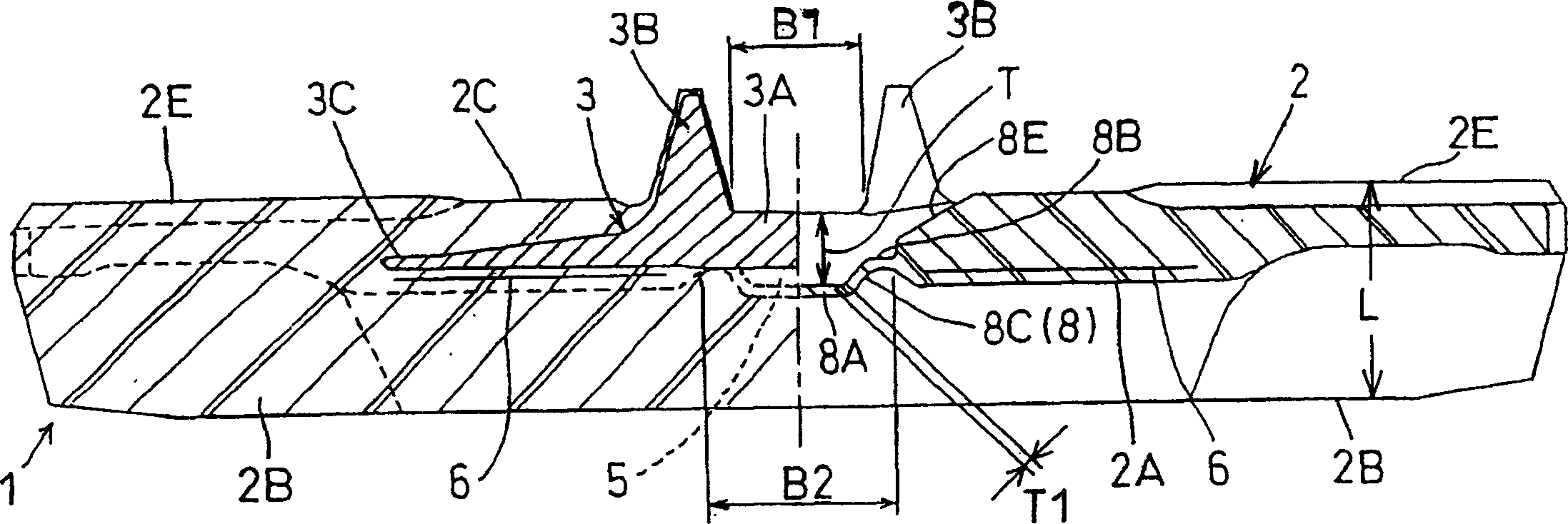

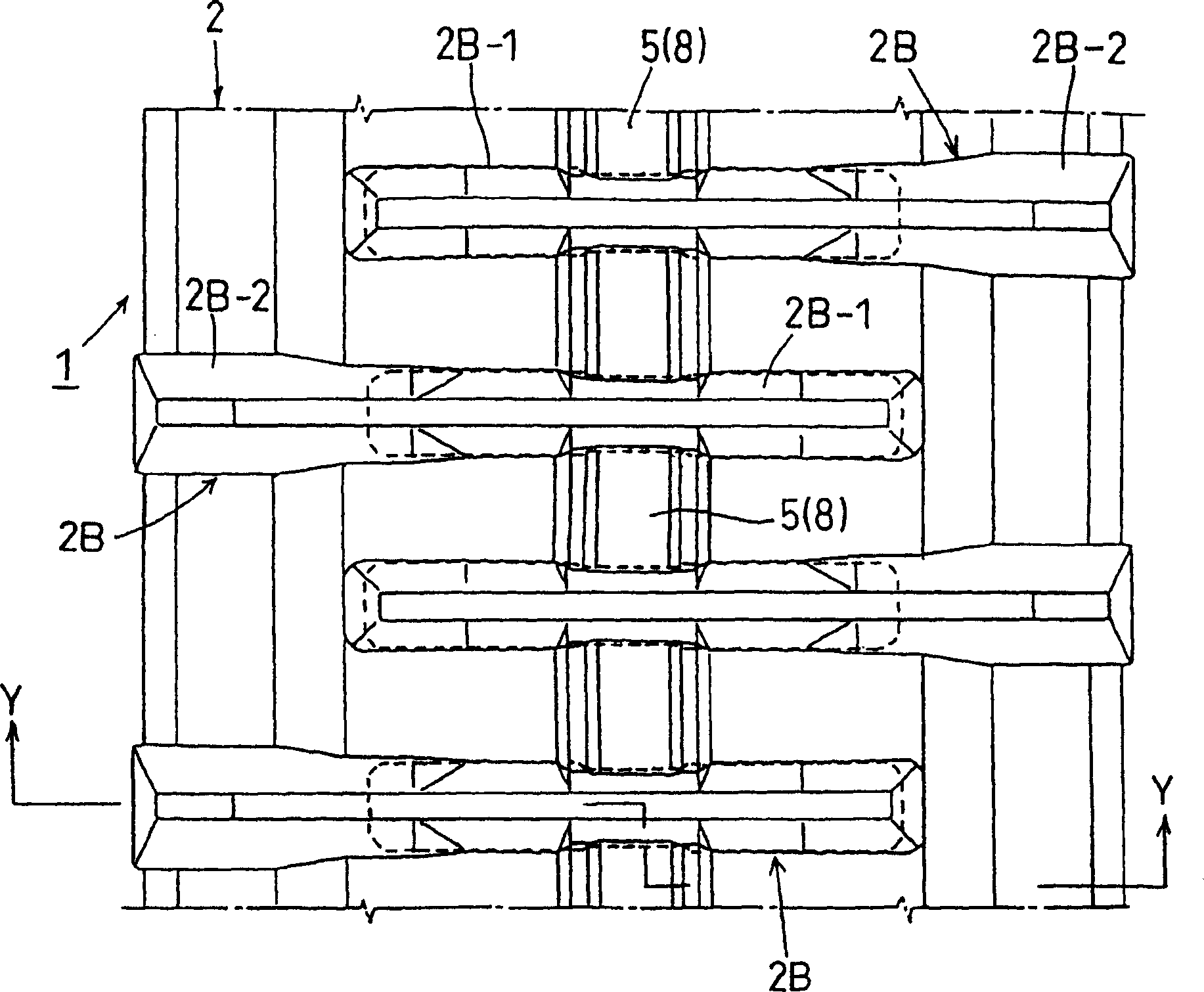

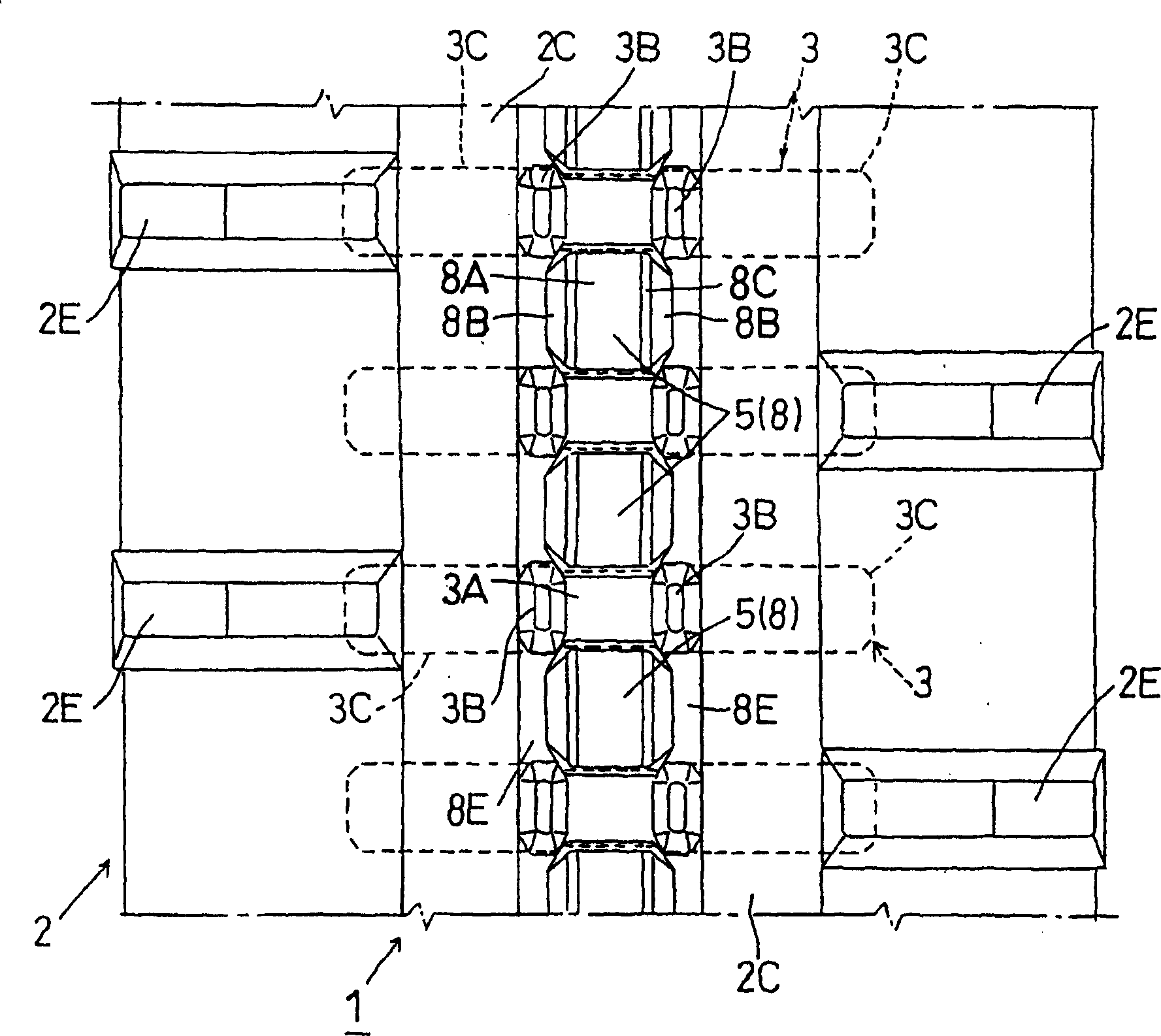

[0039] figure 1 It is a cross-sectional view of the main parts of the rubber track 1 ( figure 2 Y-Y cross-sectional view), figure 2 It is a plan view of the main part viewed from the ground plane (outer peripheral surface), image 3 It is a plan view of the main part viewed from the inner peripheral surface, and Fig. 4 is a side view of the wrapping part, as the first embodiment figure 1 - In FIG. 4 , the rubber crawler 1 is mainly composed of a jointless crawler body 2 substantially made of rubber, and horizontally placed cores (mandrels) 3 embedded in the crawler body 2 at intervals. The joint-shaped crawler body 2 is wound and driven by a driving sprocket (see FIG. 4 ) 4 and a driven pulley (idling pulley) not shown in the figure.

[0040]In the horizontal core body 3, there is a mated portion 3A that engages and disengages with the teet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com