Method for reducing horizontal current in aluminum liquid of aluminum reduction cell

A horizontal current, aluminum electrolytic cell technology, which is applied in the field of reducing the horizontal current in the aluminum liquid of the aluminum electrolytic cell, can solve the problems of the current efficiency being difficult to meet the ideal requirements, harmful electromagnetic force, and reducing the current efficiency, so as to achieve uniform cathode current distribution, Easy to operate and manage, reduce the effect of horizontal current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

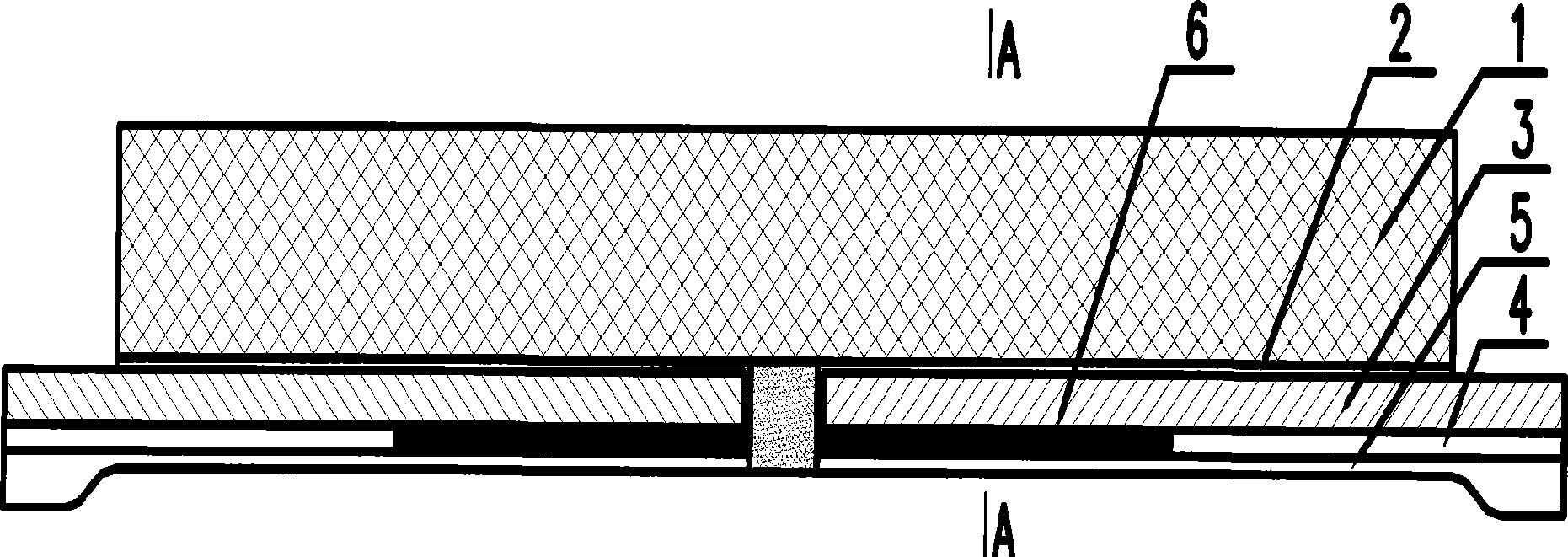

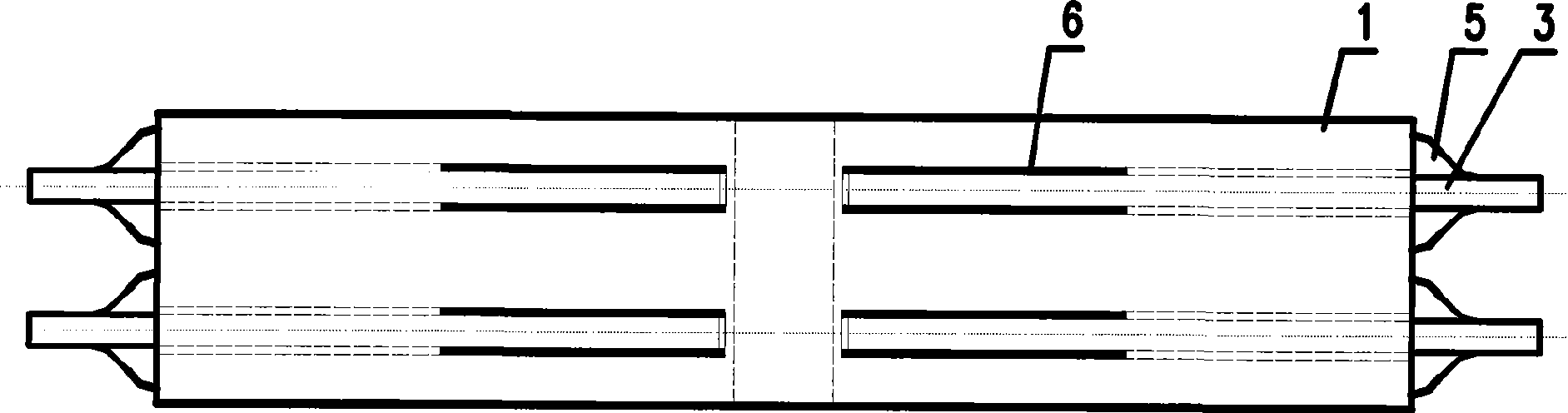

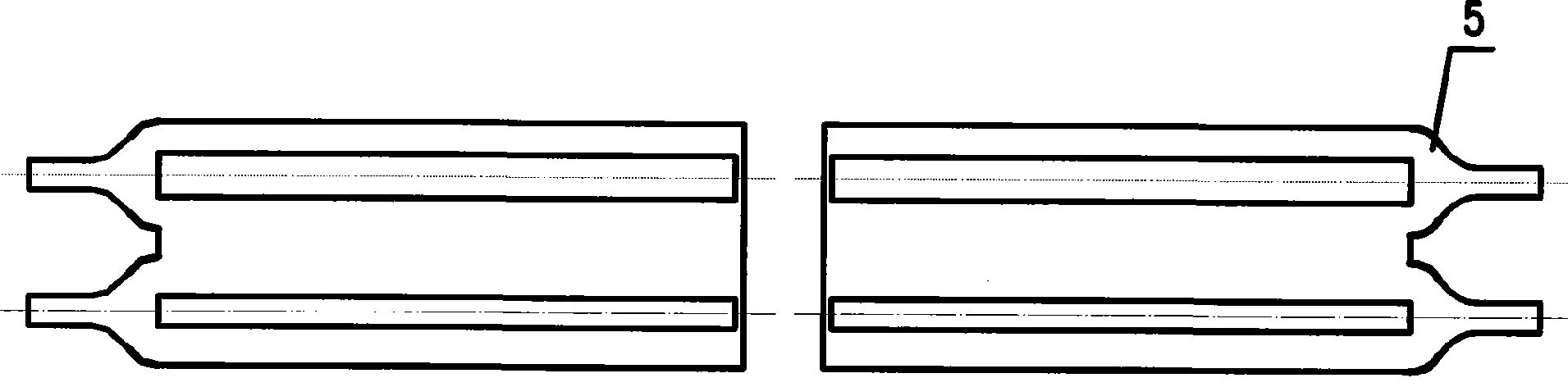

[0044] Such as Figure 1 to Figure 6 As shown, it is an example of reducing the horizontal current in the molten aluminum of an aluminum electrolytic cell in the cathode carbon block 1 provided in a long way. In the cathode carbon block 1, paste or cast iron 2 are used to consolidate or cast four cathode steel rods. Below the cathode carbon block 1, a conductive plate or a conductive rod 5 is directly laid, and the conductive plate or conductive rod 5 is connected with the cathode steel rod 3 at the middle part of the cathode carbon block 1 by welding or other connectors 6, and the conductive plate or conductive rod 5 is arranged on The lower end of the cathode steel rod 3, and an additional conductive plate or conductive rod 5 is added to reduce the resistance from the middle of the cathode carbon block 1 to the cathode bus bar, thereby carrying more current and reducing the relatively concentrated current at the end of the cathode steel rod 3 pressure, the current in the mol...

Embodiment 2

[0046] Such as Figure 7Shown is another example of reducing the horizontal current in the molten aluminum in an aluminum electrolytic cell. In this embodiment, paste or cast iron 2 are used to consolidate or cast four cathode steel rods in each cathode carbon block 1. The difference from embodiment 1 is that the cathode steel rods 3 have variable cross-sections and can be stepped Or gradual change, the end of the cathode carbon block 1 is smaller than the middle section. Other modes are basically the same as in Embodiment 1, the cathode steel rod 3 parts in the groove are connected with the conductive plate or the conductive rod 5, and the shape of the conductive plate or the conductive rod 5 is the same as image 3 and Figure 5 shown.

Embodiment 3

[0048] Figure 8 In order to achieve another example of reducing the horizontal current in the molten aluminum in an aluminum electrolytic cell, paste or cast iron 2 is used to consolidate or cast eight cathode steel rods 3 in each cathode carbon block 1 in this embodiment, and the other methods are the same as those in the embodiment 1 are basically the same, two cathode steel rods 3 in the trench, one of which is connected to the conductive plate or conductive rod 5 laid on the bottom of the cathode carbon block 1, the shape of the conductive plate or conductive rod 5 is the same image 3 and Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com