Electrolytic tank capable of greatly reducing horizontal current

A horizontal current and large amplitude technology, applied in the field of electrolytic cells, can solve the problems of poor working stability and large horizontal current of electrolytic cells, and achieve the effect of simple construction and reduced horizontal current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

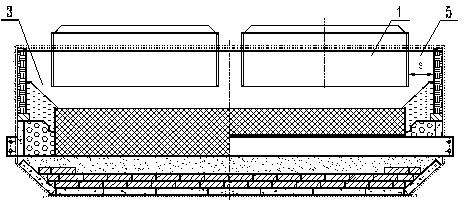

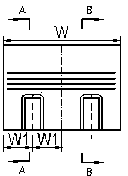

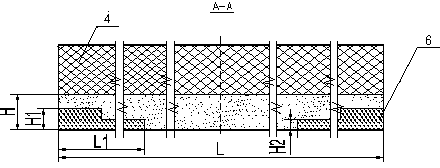

[0049] Embodiment of the present invention: the electrolytic cell includes an anode carbon block 1, a cathode steel rod 2, a furnace 3, and a cathode carbon block 4. The cathode steel rod 2 adopts a "gradient" cathode paste structure, that is, an inclined plane or a stepped cross section The cathode paste structure is filled with high-temperature-resistant insulating materials on the slope or stepped cross-section; the cathode steel rods 2 are arranged in equal proportions in the cathode carbon block 4; the width S of the large surface processing surface 5 of the furnace is controlled within 240-269mm Between; the cathode carbon block 4 is aligned with the anode carbon block 1, and the width of the cathode carbon block is equal to the width of the anode carbon block, which is 665mm.

[0050] The high-temperature-resistant insulating material filled in the slope or stepped section is ceramic fiber cotton, high-strength castable, etc.

[0051] The high temperature resistant insu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com