Electric tank cathode structure with conductive plate

A cathode structure and electrolytic cell technology, which is applied in the field of aluminum electrolysis, can solve difficult problems, improve aluminum liquid and other problems, achieve the effects of reducing horizontal current, improving stability and service life, and improving power efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

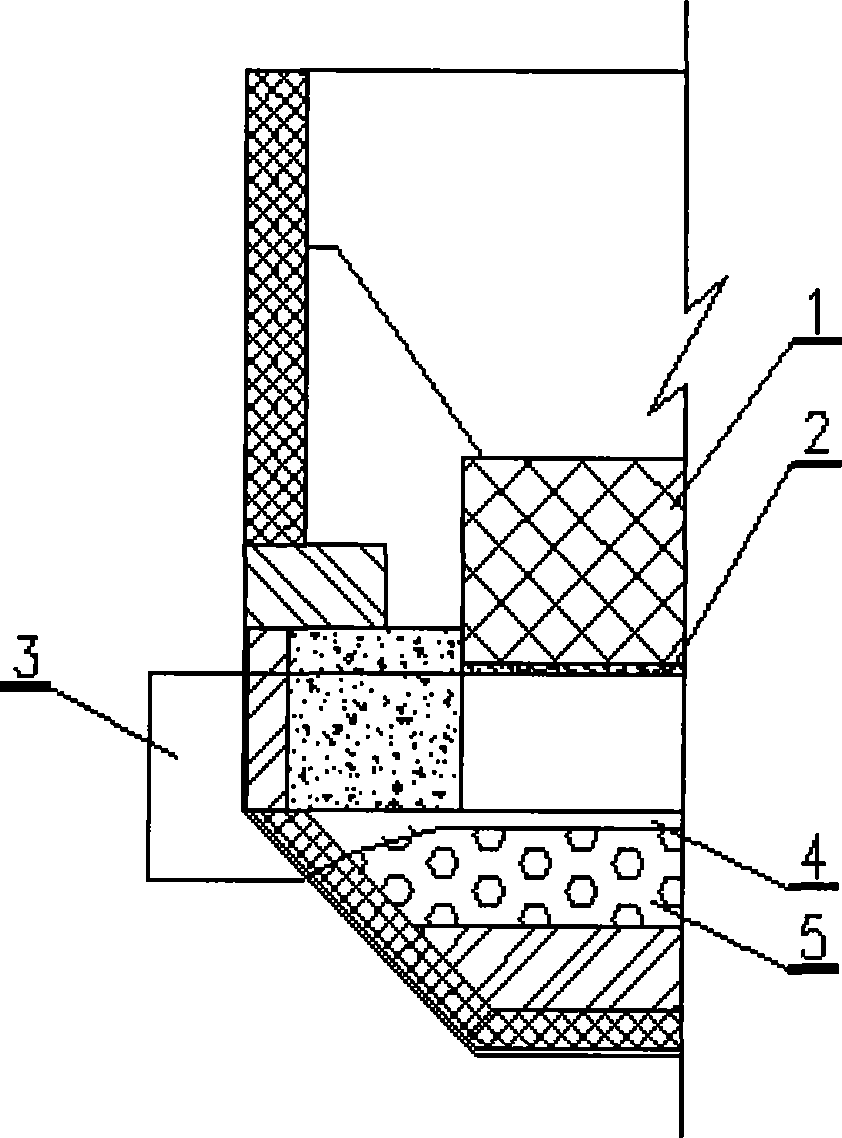

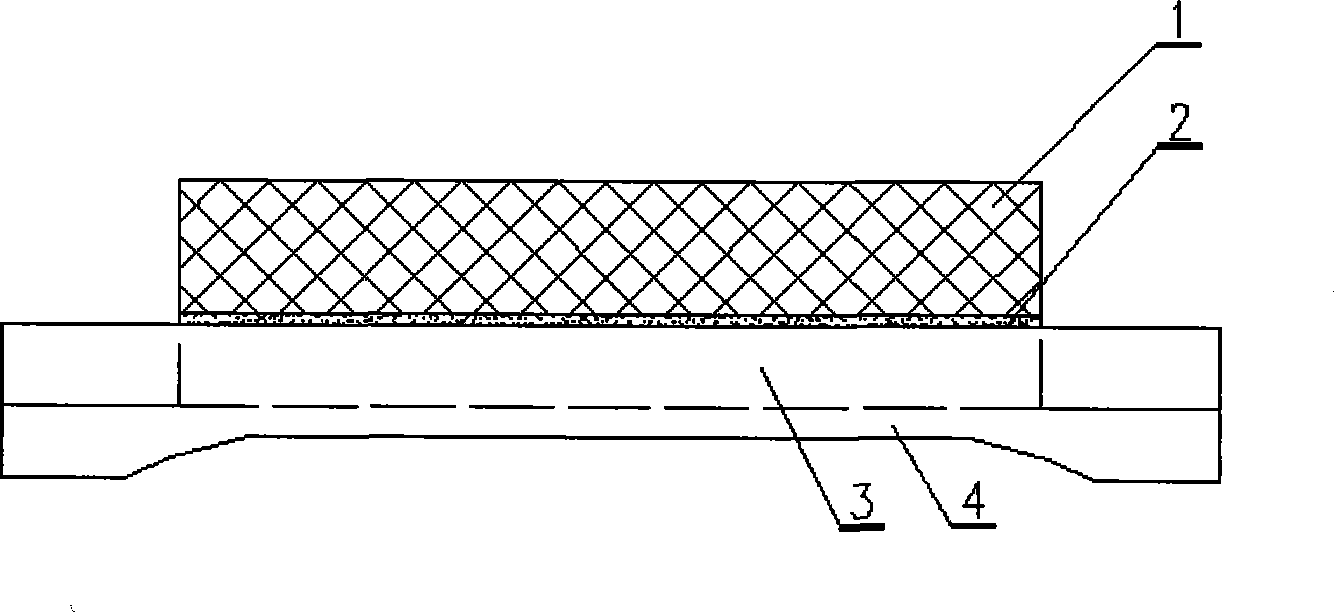

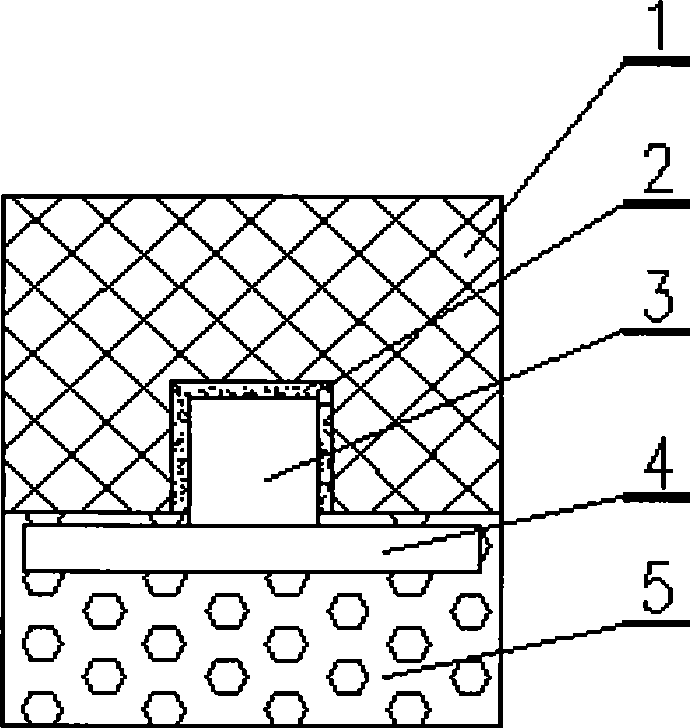

[0021] see figure 1 , The cathode structure of the electrolytic cell with conductive plate provided in this embodiment includes: cathode carbon block 1 , cathode conductive steel rod 3 , conductive steel plate 4 and anti-seepage layer 5 . Wherein, the cathode conductive steel rod 3 is located in the cathode carbon block 1; the bottom of the cathode carbon block 1 is provided with a steel rod groove matching the shape of the cathode conductive steel rod 3, and the cathode carbon block 1 is connected to the cathode conductive steel rod 3 through the steel rod groove; The conductive steel plate is located at the lower part of the cathode carbon block 1 and is located in the anti-seepage layer 5; the conductive steel plate 4 is connected with the cathode conductive steel rod 3 to conduct cathode current as a whole. The width of the conductive steel plate 4 is less than or equal to the width of the cathode carbon block 1 ; the thickness of the anti-seepage layer 5 is not less than ...

Embodiment 2

[0026] The difference between this embodiment and Embodiment 1 is that: the cathode conductive steel rod 3 is two steel rods centered on the cathode, and there is a distance between the two steel rods; correspondingly, the conductive steel rod 4 is two steel rods centered on the cathode. A steel plate, there is a space between the two steel plates, such as Figure 5 shown. In addition, the structure of the cathode of the electrolytic cell with the conductive plate is the same as that of Embodiment 1, and will not be repeated here.

[0027] The invention reduces the horizontal current in the aluminum liquid through the cathode conductive steel rod and the conductive steel plate, improves the electric energy efficiency, and improves the stability and service life of the electrolytic cell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com