Cell bottom structure of electrolytic cell

An electrolytic cell and cell bottom technology, which is applied in the field of aluminum electrolytic cells, can solve the problems of complex force conditions on the tank shell and its surrounding, complex electrolytic cell shell structure, and impact on the state safety of the electrolytic cell. The effect of small fluctuations, design and material simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

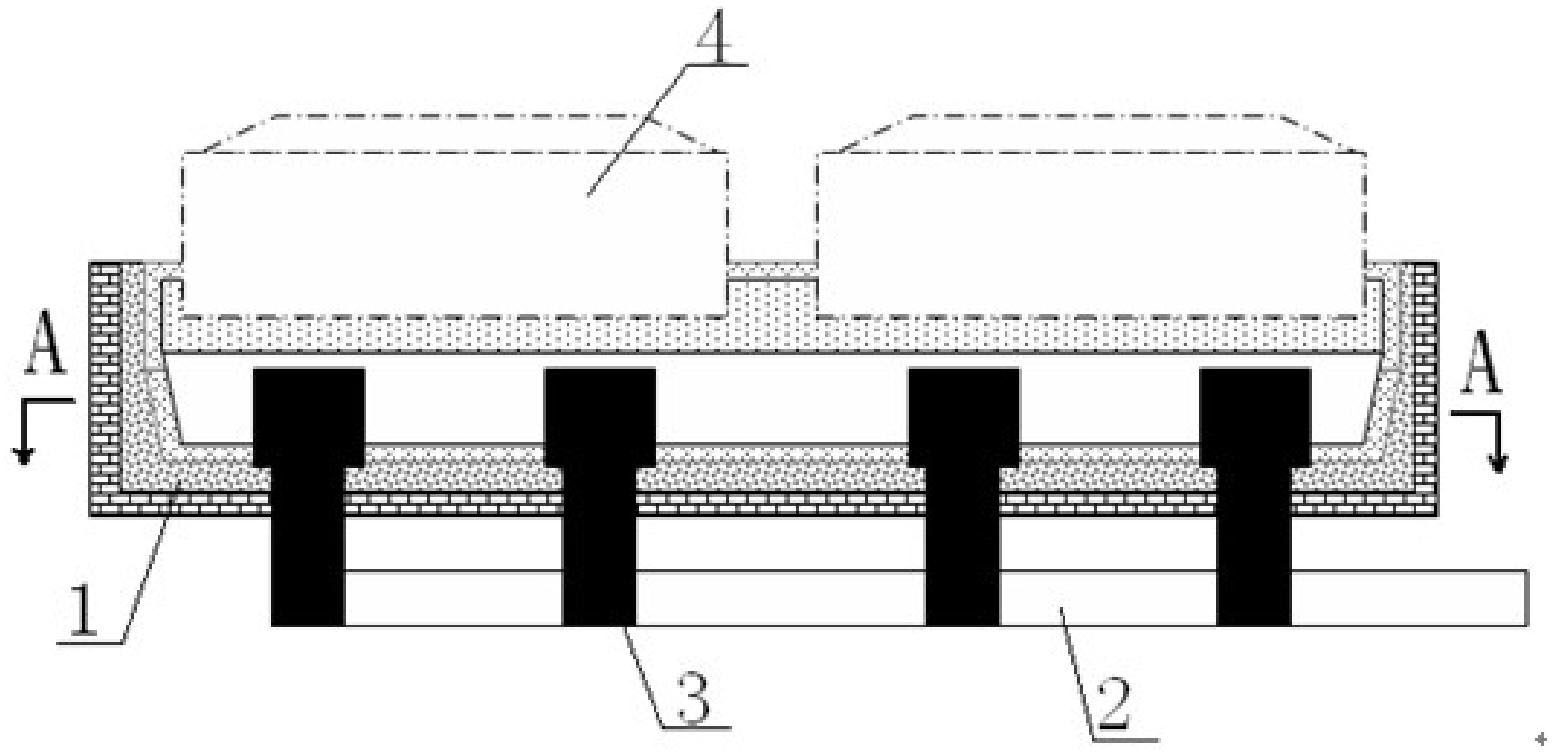

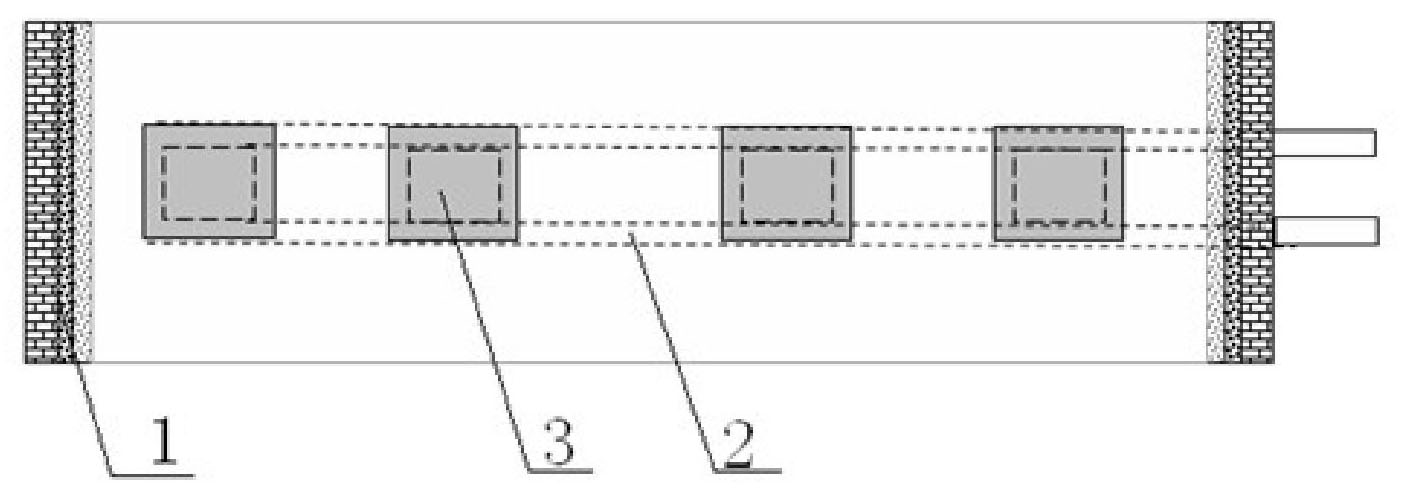

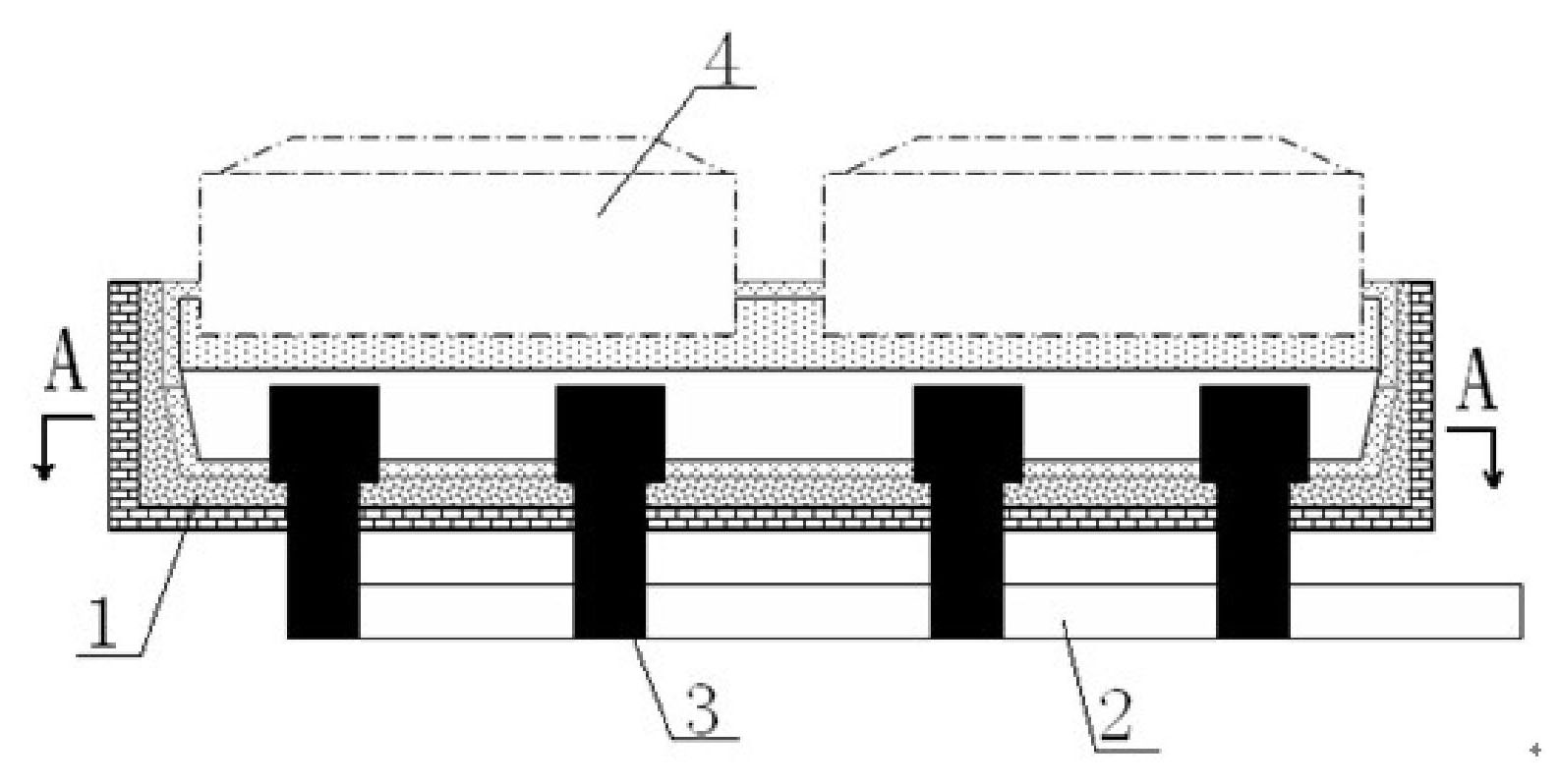

[0013] Embodiment 1: as figure 1 and figure 2 As shown, in the design of the electrolytic cell, the cathode is made into a columnar cathode carbon block 3, and the shape of the columnar cathode carbon block 3 is a quadrangular prism or a stepped quadrangular prism. When placing the columnar cathode carbon block 3 Place the columnar cathode carbon block 3 vertically on the bottom of the electrolytic cell 1, the length of the upper end of the vertically placed columnar cathode carbon block 3 extending into the aluminum liquid of the electrolytic cell 1 is 5-200mm, and the length of the columnar cathode carbon block 3 The lower end is connected with the cathode busbar 2 by bolts. When placing and installing the columnar cathode carbon block 3 perpendicular to the bottom of the electrolytic cell, the columnar cathode carbon block 3 is installed below the anode carbon block 4, the number of columnar cathode carbon blocks 3 below each anode carbon block 1 1 to 4 blocks, the speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com