Building method of aluminum electrolysis cell

An aluminum electrolytic cell and masonry technology, which is applied in the field of aluminum electrolytic cell masonry, can solve problems such as uneven distribution of current density and magnetic field, poor electrolysis effect, and influence on current efficiency, and achieve uniform current density distribution and magnetic field distribution. Uniformity, the effect of reducing DC power consumption per ton of aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

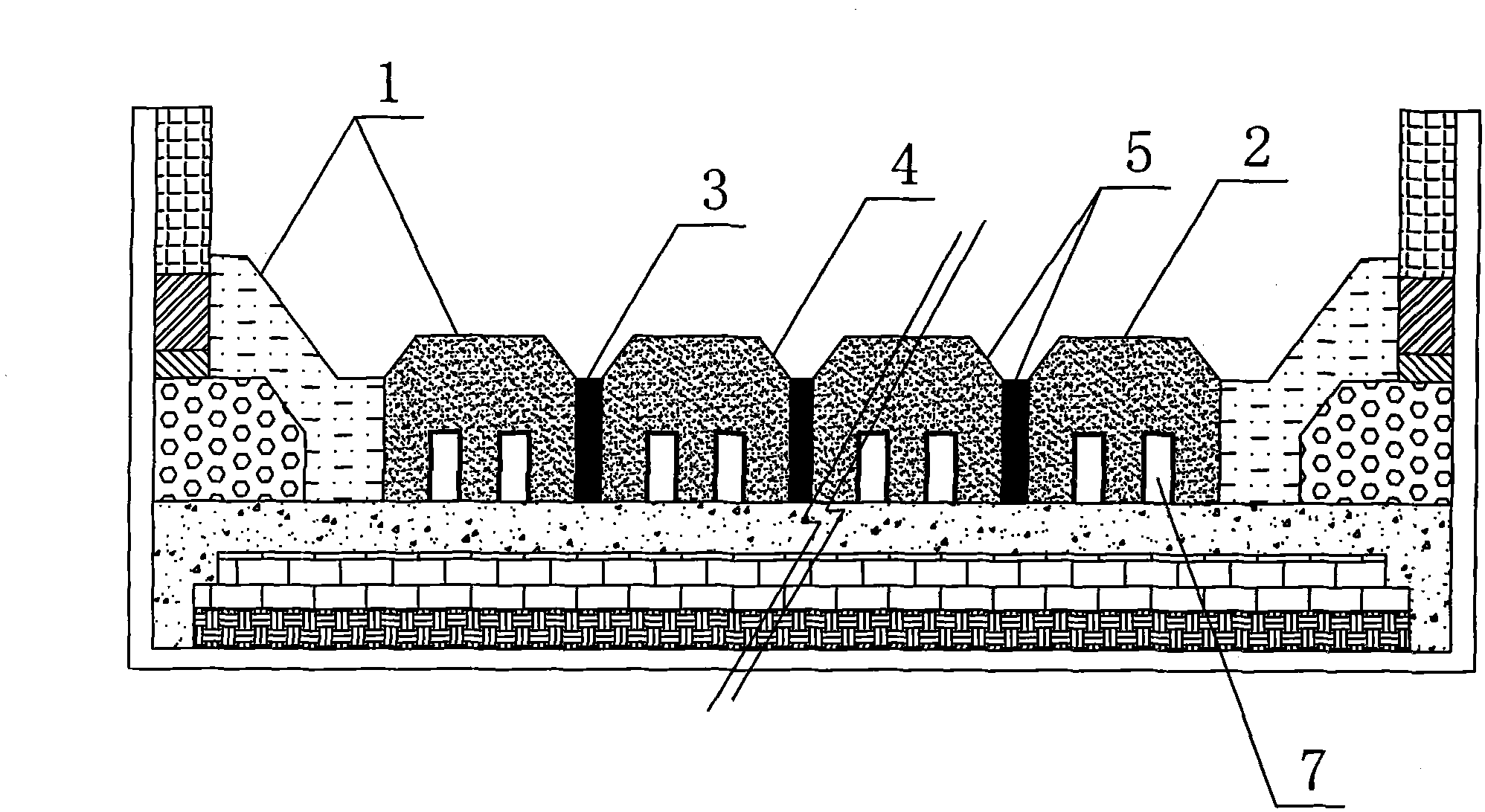

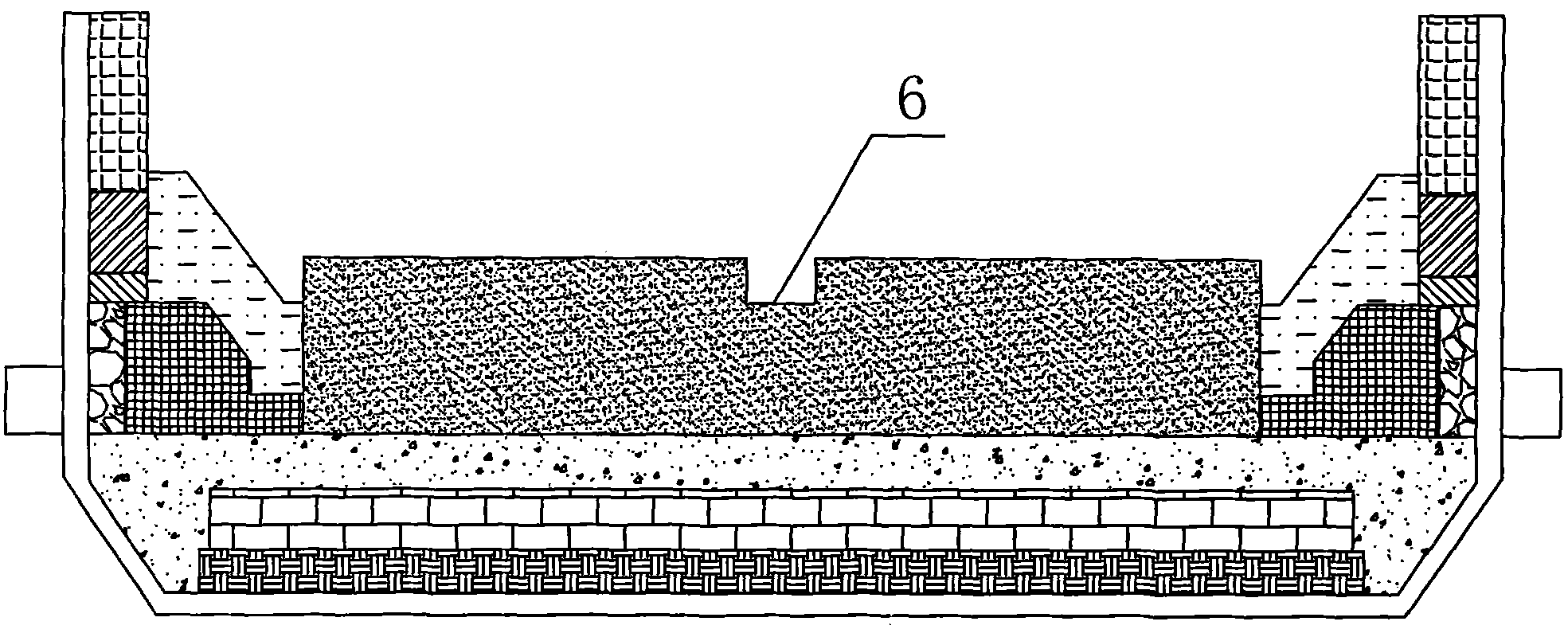

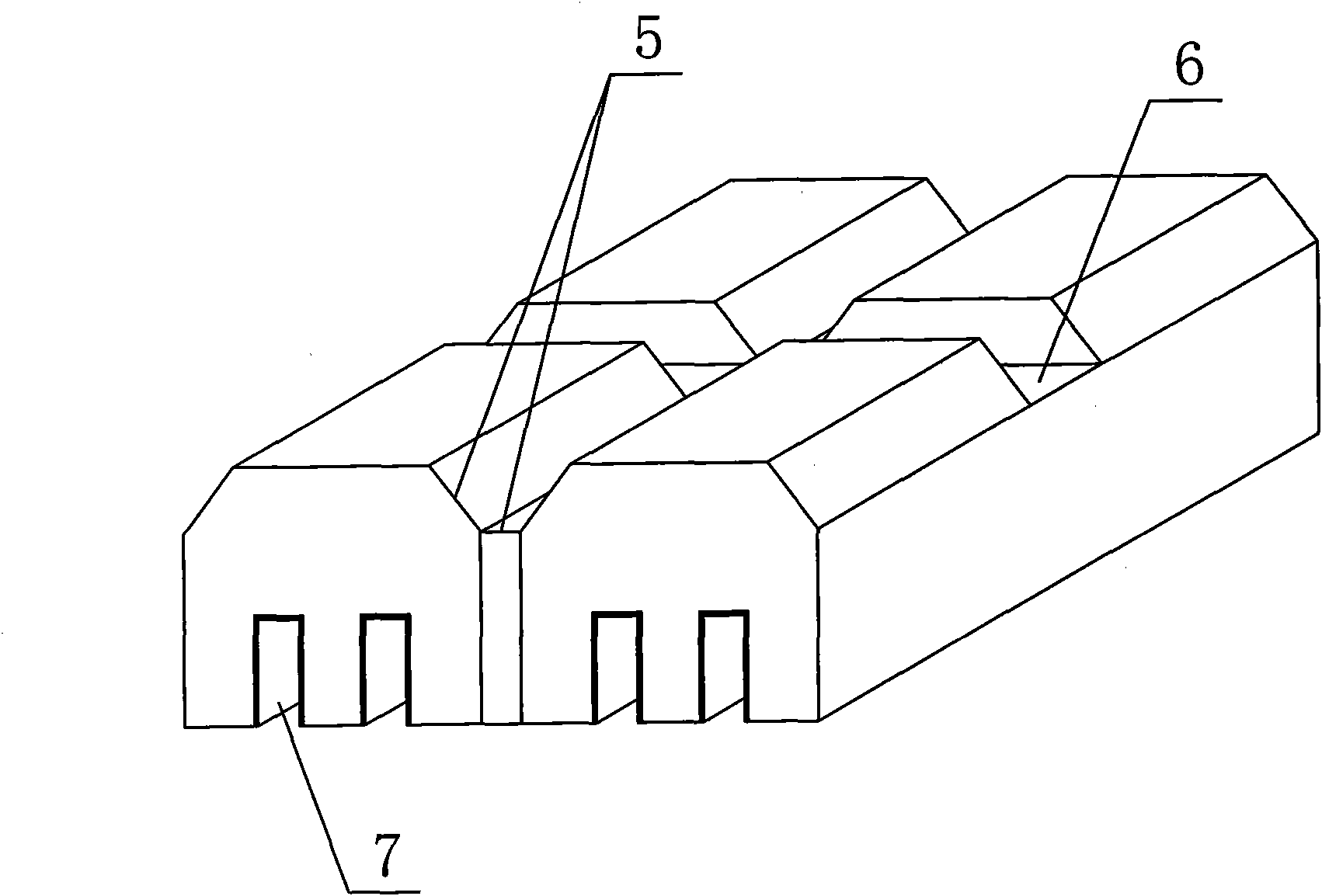

[0026] The masonry method of the aluminum electrolytic cell, in addition to the conventional masonry method, when making the cathode carbon block 2 of the electrolytic cell, perform symmetrical chamfering 4 on the upper end of the cathode carbon block 2 along the longitudinal direction, and open a transverse groove on the top of the cathode carbon block 2. Groove 6; when building cathode carbon blocks, there is a 20mm gap between adjacent cathode carbon blocks 2, and the gaps are tamped with cathode paste 3, and the relative chamfering 4 of adjacent cathode carbon blocks 2 is filled with the gap The cathode paste 3 forms a trapezoidal groove 5, and the depth of the trapezoidal groove 5 is the same as that of the transverse groove 6 at the top of the cathode carbon block 2; two longitudinal grooves 7 are provided at the bottom of the cathode carbon block 2, and the corresponding size is laid in the longitudinal groove 7. The steel rod, the cathode carbon block 2 and the steel ro...

Embodiment 2

[0028] The masonry method of the aluminum electrolytic cell, in addition to the conventional masonry method, when making the cathode carbon block 2 of the electrolytic cell, perform symmetrical chamfering 4 on the upper end of the cathode carbon block 2 along the longitudinal direction, and open a transverse groove on the top of the cathode carbon block 2. Groove 6; when building cathode carbon blocks, a 25mm gap is left between adjacent cathode carbon blocks 2, and the gaps are tamped with cathode paste 3, and the relative chamfering 4 of adjacent cathode carbon blocks 2 is filled with the gap The cathode paste 3 forms a trapezoidal groove 5, and the depth of the trapezoidal groove 5 is the same as that of the transverse groove 6 at the top of the cathode carbon block 2; two longitudinal grooves 7 are provided at the bottom of the cathode carbon block 2, and the corresponding size is laid in the longitudinal groove 7. The steel rod, the cathode carbon block 2 and the steel rod...

Embodiment 3

[0030]The masonry method of the aluminum electrolytic cell, in addition to the conventional masonry method, when making the cathode carbon block 2 of the electrolytic cell, perform symmetrical chamfering 4 on the upper end of the cathode carbon block 2 along the longitudinal direction, and open a transverse groove on the top of the cathode carbon block 2. Groove 6; when building cathode carbon blocks, there is a 30mm gap between adjacent cathode carbon blocks 2, and the gaps are tamped with cathode paste 3, and the relative chamfering 4 of adjacent cathode carbon blocks 2 is filled with the gap The cathode paste 3 constitutes a trapezoidal groove 5, and the depth of the trapezoidal groove 5 is the same as that of the transverse groove 6 at the top of the cathode carbon block 2; a longitudinal groove 7 is opened at the bottom of the cathode carbon block 2, and steel of corresponding size is laid in the longitudinal groove 7. The cathode carbon block 2 and the steel rod are tampe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com