Patents

Literature

137results about How to "Change flow state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

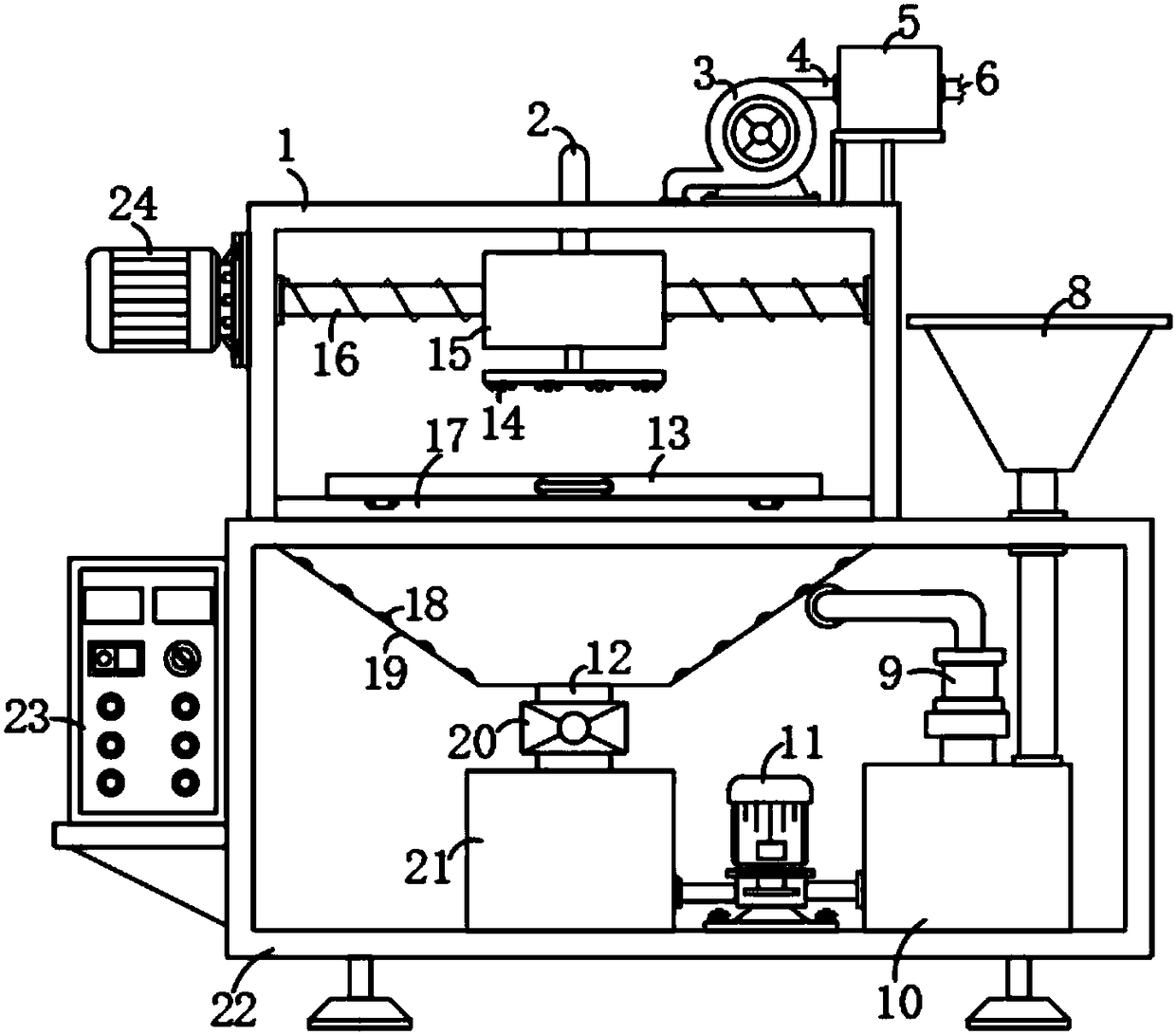

Testing device and method for measuring relationship between nozzle inside flow and cavitation erosion under multiple working conditions

ActiveCN105604755AMeet the actual working conditionsChange flow stateEngine testingFuel injection apparatusFuel oilFuel supply

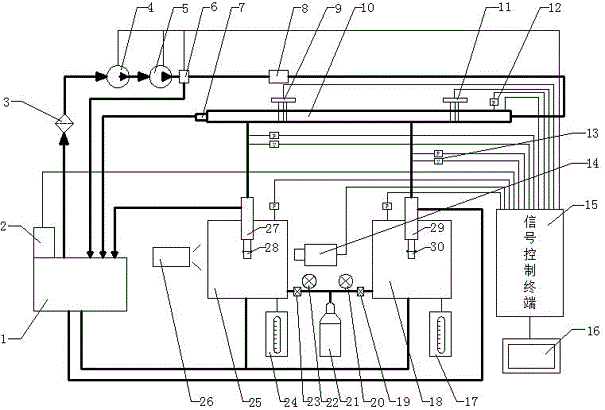

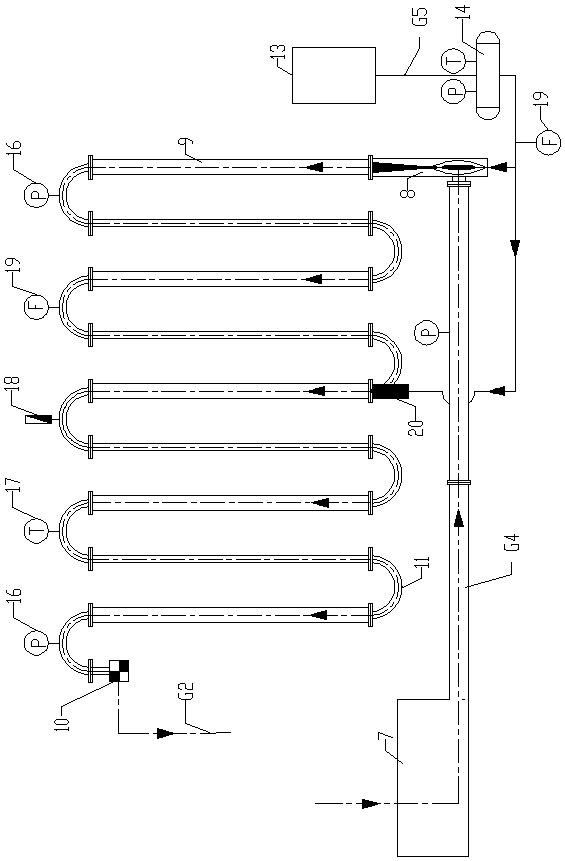

The invention discloses a testing device and method for measuring the relationship between nozzle inside flow and cavitation erosion under multiple working conditions. The testing device comprises a pressure control system, a signal testing system, an injection system and a fuel supply system; the pressure control system comprises a first electromagnetic oil pressure control valve, a second electromagnetic oil pressure control valve, a pressure regulating valve, a pressure limiting valve and a back pressure cavity; the signal testing system comprises pressure sensors, flow sensors, a signal control terminal, a CCD high-speed digital camera and a computer; the injection system comprises oil atomizers and nozzle head caps; the fuel supply system comprises an oil tank, a heating tile, a fuel oil filter, an electric fuel pump, a high-pressure oil pump, a turbulator and a common-rail oil pipe. By means of the testing device, test research on influences on nozzle inside cavitation caused by nozzle inside cavitation flow generated by different injection pressures, back pressure, the fuel spray nozzle structure, the fuel temperature and the pipe inside flow state can be carried out, and measurement of influence factors of nozzle inside cavitation caused by nozzle inside cavitation flow of a diesel engine under multiple working conditions is achieved.

Owner:JIANGSU UNIV

Dynamic pressure bearing device

ActiveCN1766356AReduce vibration and noiseSpeed up the flowBearing componentsSliding contact bearingsEngineeringMechanical engineering

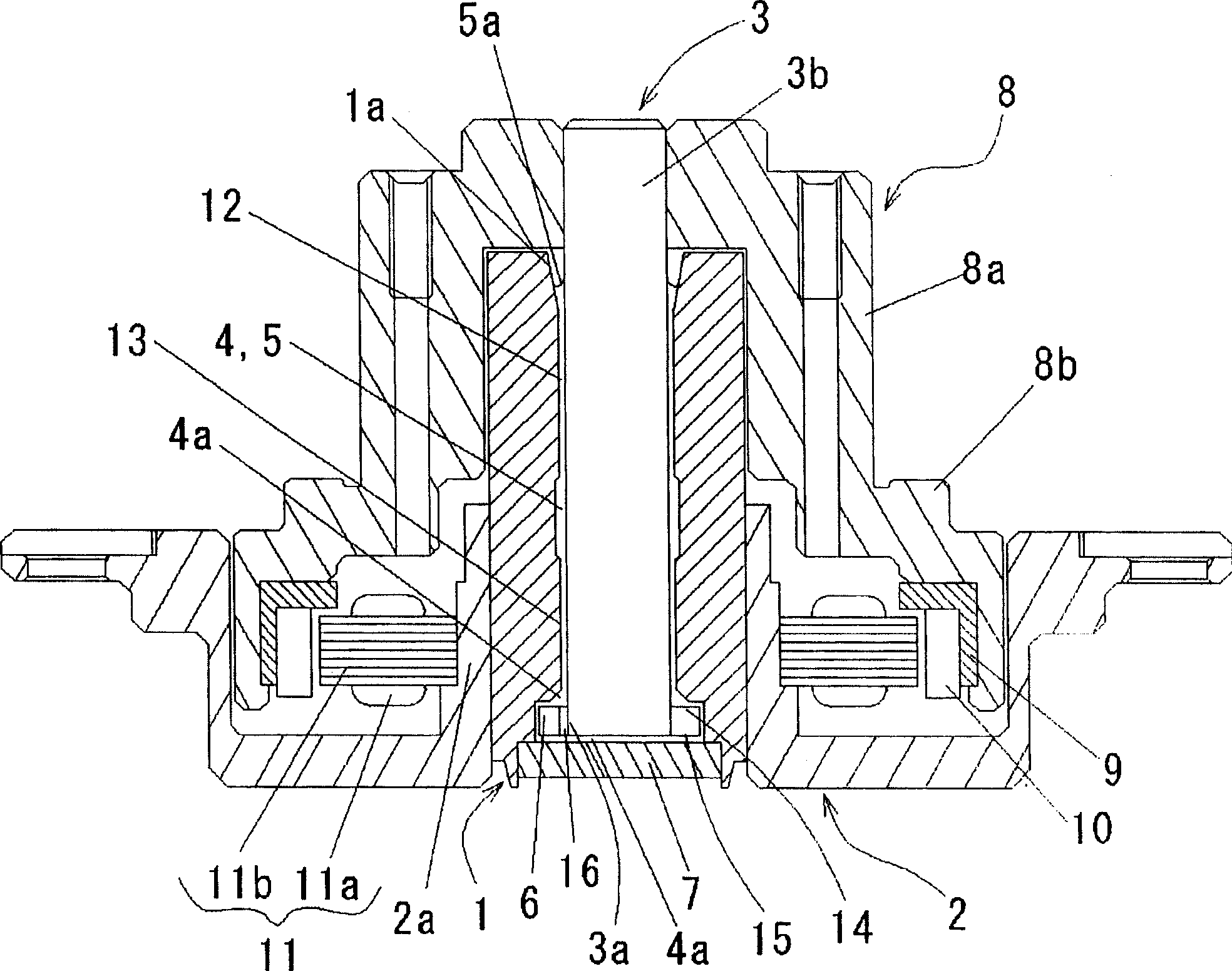

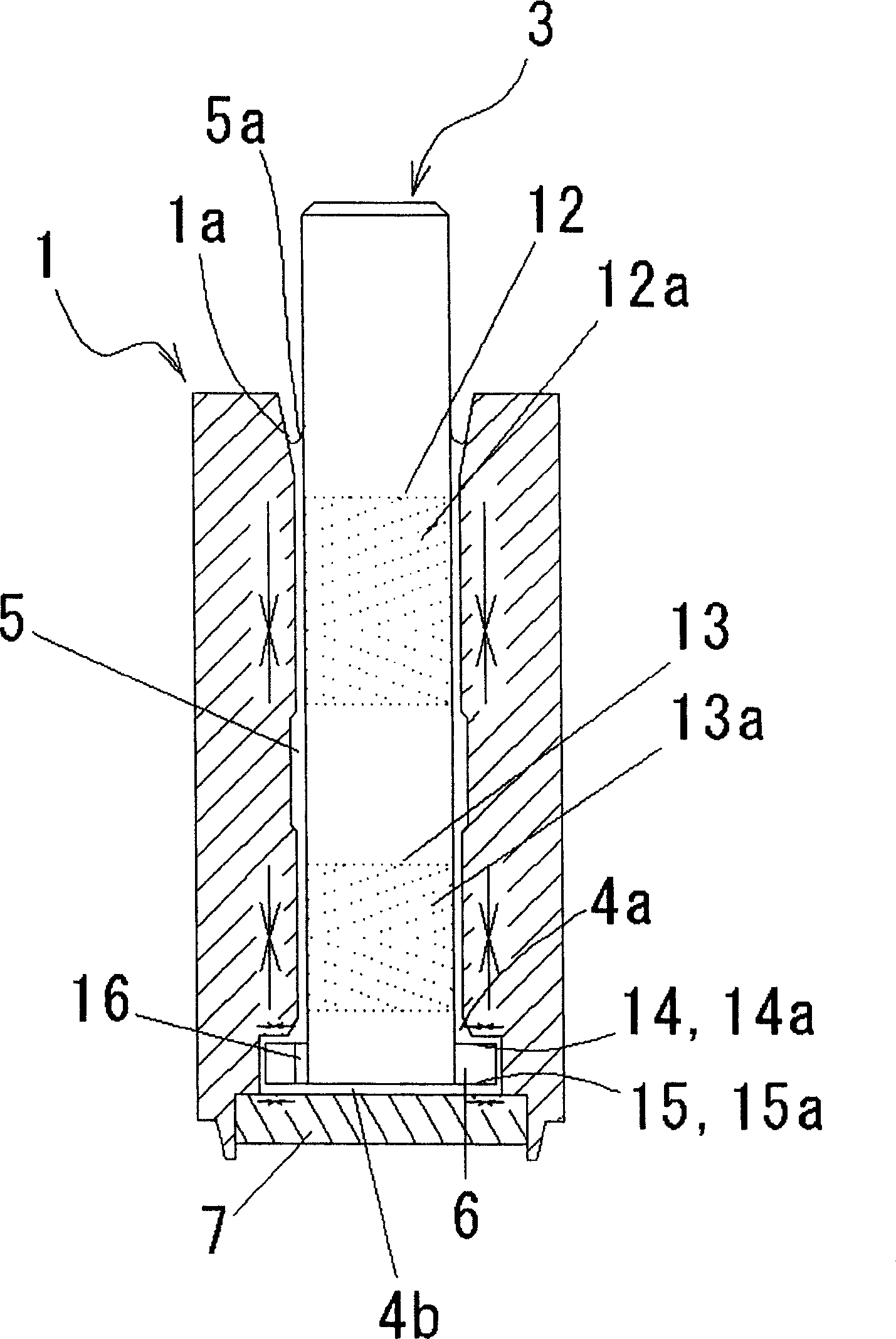

In the tiny gap (4) between the underside radial bearing part (13) and the top surface thrust bearing part (15) of the shaft (3), thrust plate (6) and bearing sleeve (1) In the wider flow channel (4a) surrounded by the circumferential corner part (1c), chamfering is performed at the inner circumferential corner part (1c) of the bearing sleeve (1), wherein the wider flow channel (4a) is in the radial direction of rotation The width is formed wider than that of the communication hole (16) located below the wider flow passage (4a) in the radial direction of rotation, thereby smoothing the flow of the lubricating fluid (5) from the communication hole The holes (16) flow into the wider flow channel (4a).

Owner:NIDEC CORP

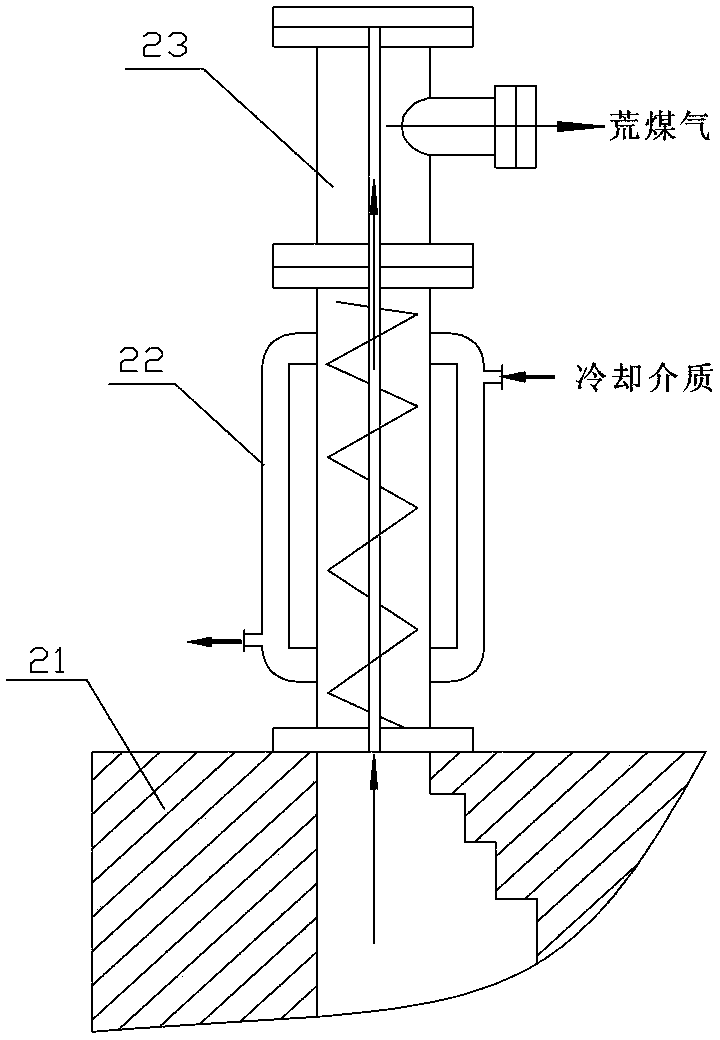

Heat-exchange type ascending tube and coke oven

ActiveCN103509564AReduce the temperatureChange flow stateEnergy inputStationary tubular conduit assembliesCarbonizationCooling medium

The invention provides a heat-exchange type ascending tube and a coke oven. The heat-exchange type ascending tube comprises an inner tube for conveying raw coke oven gas; both ends of the inner tube are respectively communicated with a coke oven carbonization chamber and a crossover tube. The heat-exchange type ascending tube also comprises an outer tube. The outer tube is arranged on the outer side of the inner tube; a cooling accommodating cavity is formed between the outer tube and the inner tube; the outer tube is provided with an input port and an output port which are communicated with the cooling accommodating cavity; a gas-state cooling medium for recycling heat in the raw coke oven gas goes into the cooling accommodating cavity from the input port and then flows out of the cooling accommodating cavity from the output port; the inner side of the inner tube is provided with a spiral guide rod arranged along the axial direction of the inner tube. The heat-exchange type ascending tube not only can reduce the temperature of the raw coke oven gas and recycle a part of heat in the raw coke oven gas, but also can reduce the usage amount of ammonia water and decrease the recycling cost of the raw coke oven gas.

Owner:HUATAI YONGCHUANG BEIJING TECH CO LTD

Heat tracing turbulent layer fluidized drag-reducing flow conveying pipe and method thereof

InactiveCN104565592AImprove transportation efficiencyHigh tensile strengthPipe heating/coolingFluid dynamicsSkin effectEngineering

The invention discloses a heat tracing turbulent layer fluidized drag-reducing flow conveying pipe and a method thereof. The heat tracing turbulent layer fluidized drag-reducing flow conveying pipe is formed by a plurality of single-section conveying pipes and a master controller. Each single-section conveying pipe mainly includes an arched pipe, a fluid heat tracing pipe, an insulating layer, a pipe wall heat tracing pipe, a pipe upper cover, a fluid temperature monitoring device, a wall temperature monitoring device and a temperature controller. The heat tracing turbulent layer fluidized drag-reducing flow conveying pipe aims at existing heating conveying of high-viscous and congealable fluid, combines the existing skin effect heat tracing technology and the fluid drag reducing control technology by aid of the design of the round conveying pipe arched fluid interface, and achieves control on the fluidized flow state of the fluid turbulent layer in the pipe near the fluid string surface on the basis of the congeal removing and viscosity reducing effects of the skin effect heat tracing technology by maintaining the temperature difference of the wall surface of the arched pipe and the fluid in the pipe. Thus, pressure drop loss of fluid during conveying can be further reduced, the conveying efficiency can be improved, and energy saving and consumption reducing can be promoted.

Owner:ZHEJIANG UNIV

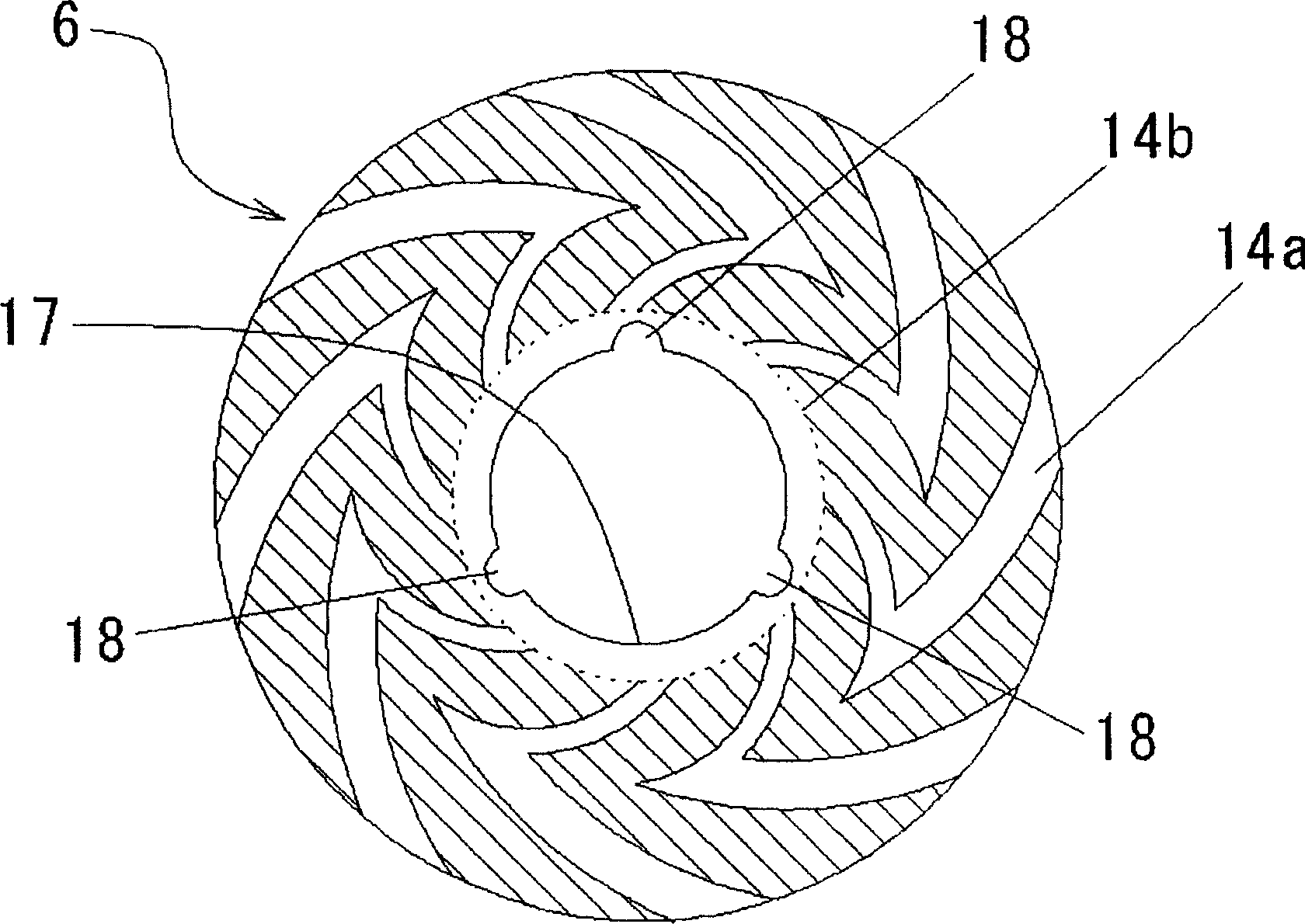

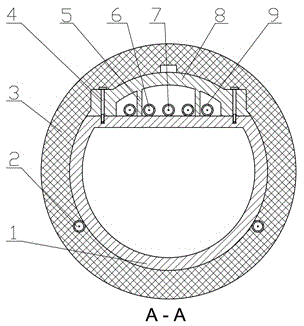

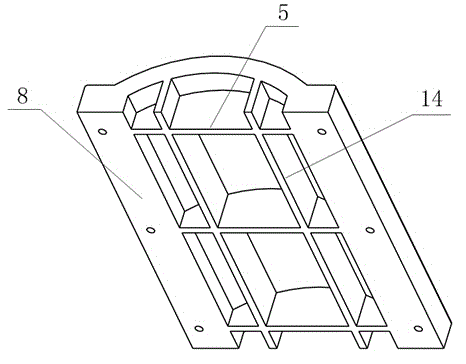

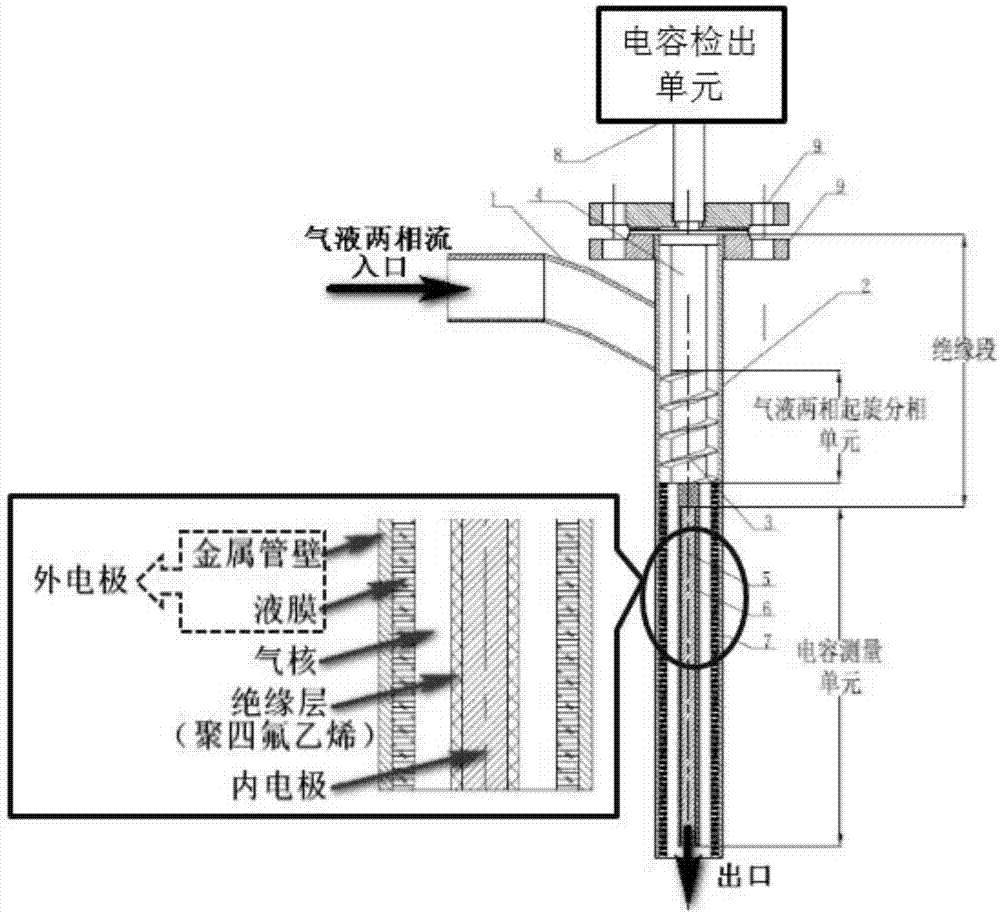

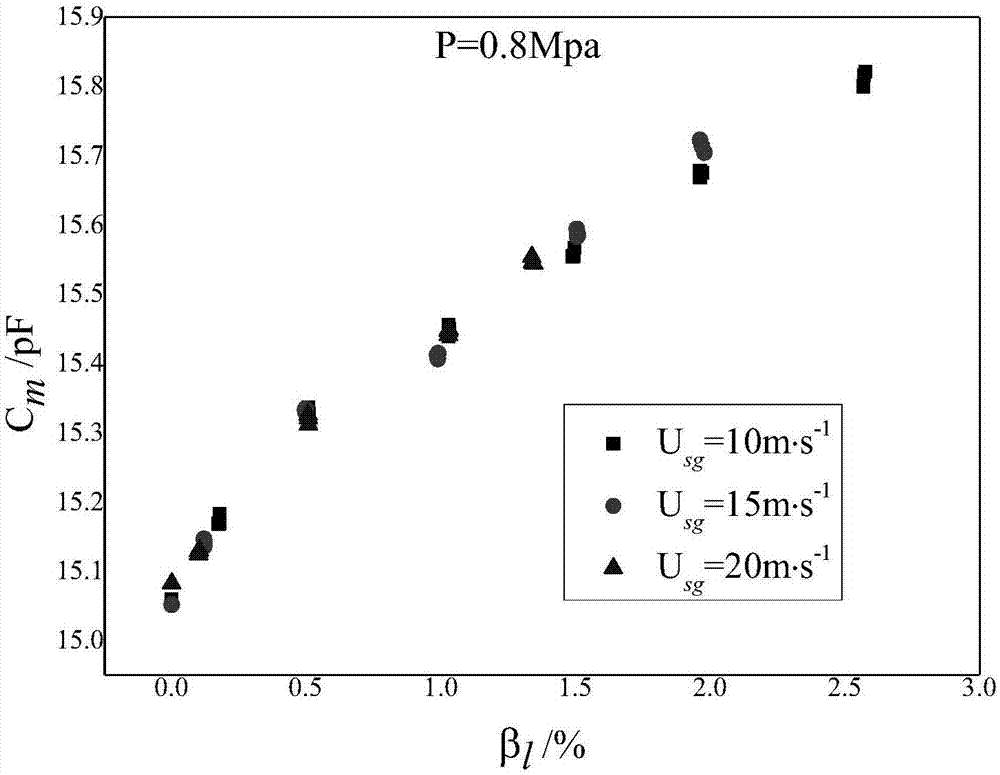

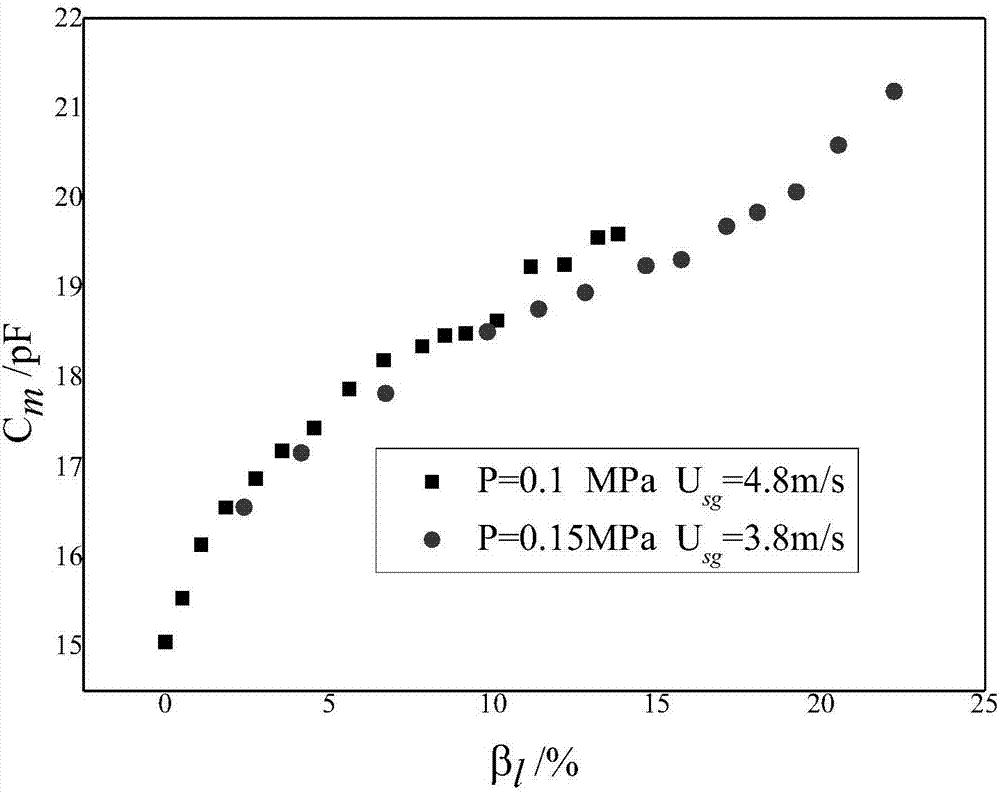

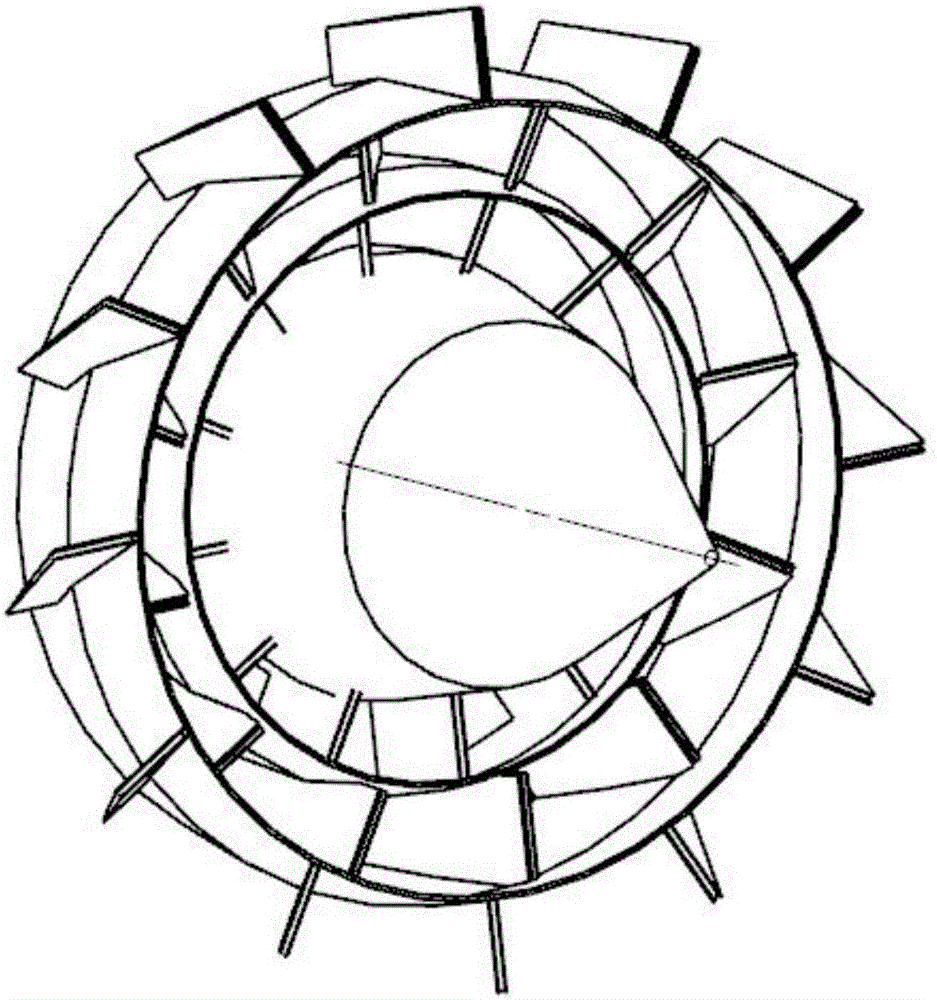

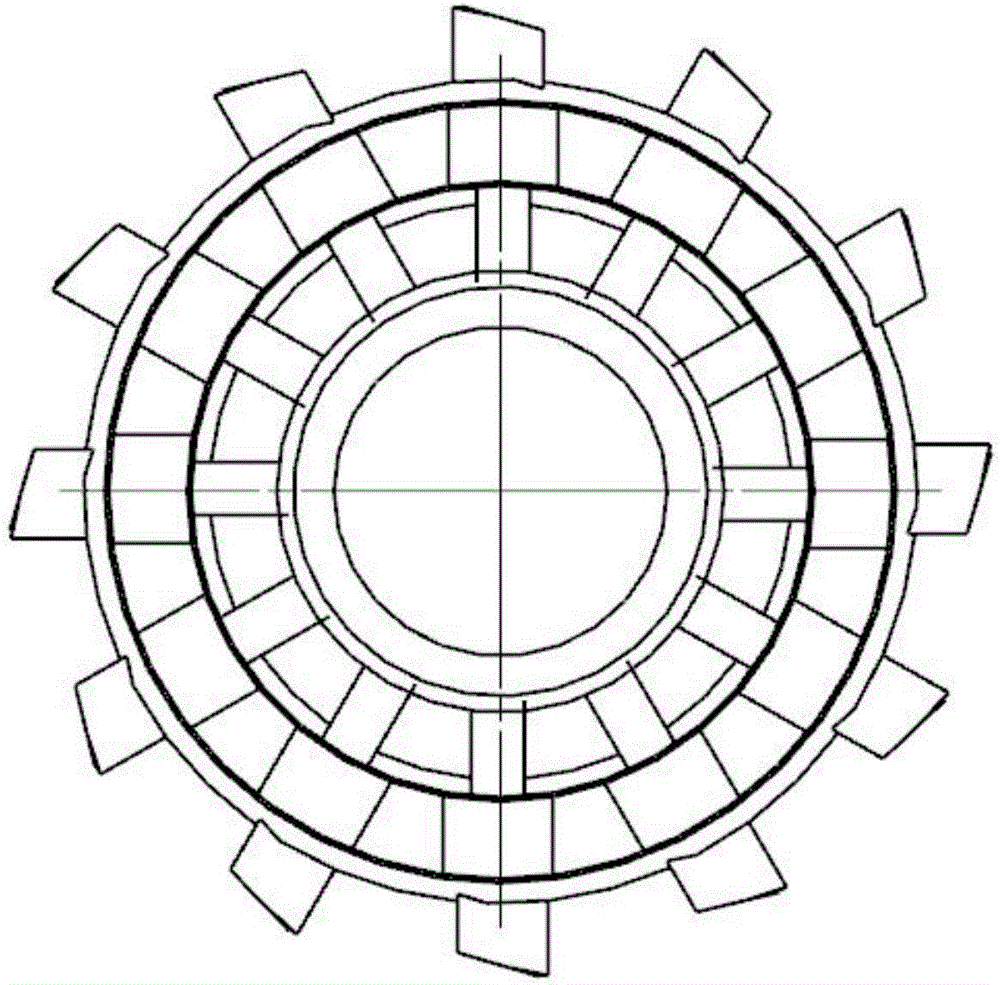

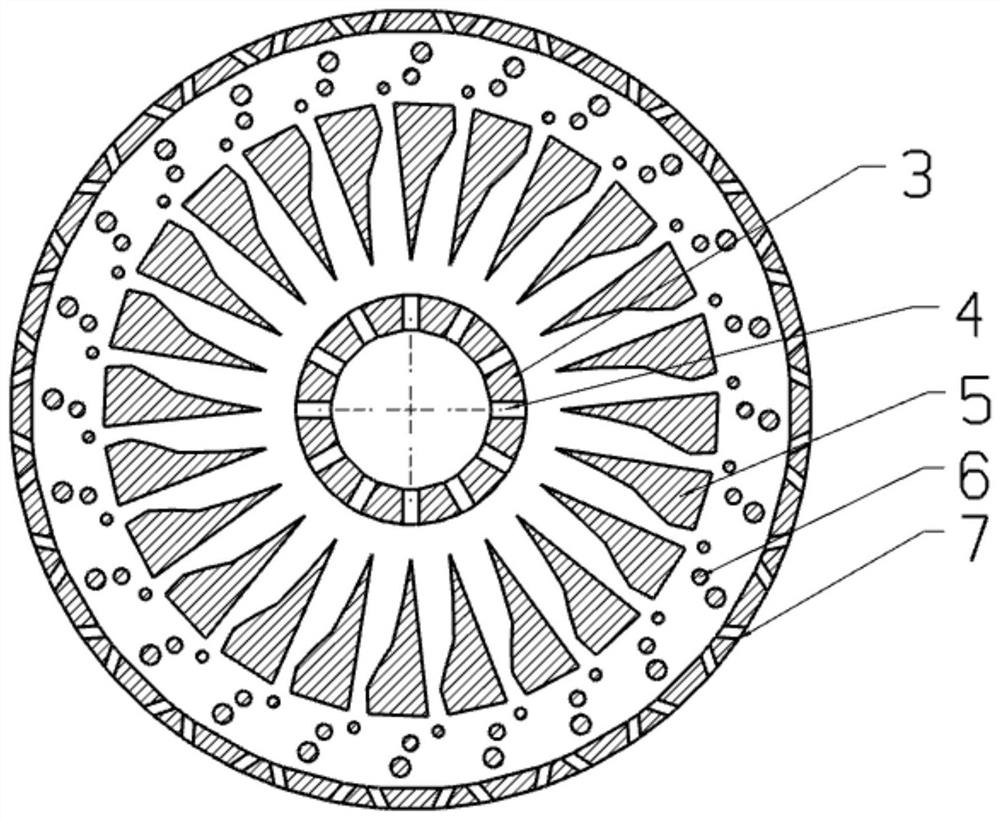

Gas-liquid two-phase flow swirl phase separation type capacitor moisture content measuring device

InactiveCN107422000AChange flow stateStable and effective flow pattern adjustmentMaterial capacitanceSpiral bladeEngineering

The invention belongs to the technical field of gas-liquid two-phase measurement and relates to a gas-liquid two-phase flow swirl phase separation type capacitor moisture content measuring device. The device comprises a swirl phase separation unit and a capacitor measuring unit, wherein the swirl phase separation unit is located on the upper part of the device and comprises an outer pipe wall and spiral blades fixed in the outer pipe wall, and a space between the spiral blades and the outer pipe wall is named a first phase medium flow space; the capacitor measuring unit is located on the lower part of the device and comprises a metal pipe wall and an inner electrode, the metal pipe wall is taken as an outer electrode, the inner electrode is fixed in the metal pipe wall and externally covered with an insulating layer, a space between the metal pipe wall and the insulating layer is named a second phase medium flow space, and the two phase medium flow spaces are communicated with each other; and an opening connected with a fluid tangential inlet pipeline is formed in the outer pipe wall, the tangential angle of the fluid tangential inlet pipeline is the same as the spiral rising angles of the spiral blades, and therefore, fluid can enter the swirl phase separation unit along the tangential angle.

Owner:TIANJIN UNIV

Fluid magnetization tube , magnetization device and magnetization system

InactiveCN1807270ALow costSimple structureWater/sewage treatment by magnetic/electric fieldsMagnetizationElectrical polarity

The disclosed fluid magnetization tube comprises: a magnetic tube with axial-magnetized magnetic rings with opposite polarity between neighbor ones, space rings of non-ferric-magnetic material and an annular tube; a high-permeability guide magnetic tube coaxial with the magnetic tube and owned a flow channel, or another magnetic tube with two magnetic rings in one section with same height and opposite magnetized direction; some members with straight or curve axis for location, fixing and guiding flow; two cove boards on both ends contained arc channels of flat shape or cylinder face to locate the tubes on both radial and axial directions. The opposite magnetization device comprises a plurality of magnetization tubes parallel inserted in the shell, and two end cap grooves to connect near tubes in series or parallel or mixture. The magnetization system uses said magnetization device and normal pump and power gear device for fluid cycle magnetization, which has high efficiency, simple structure, variable forms, small volume, light weight, and low cost.

Owner:朱澄清

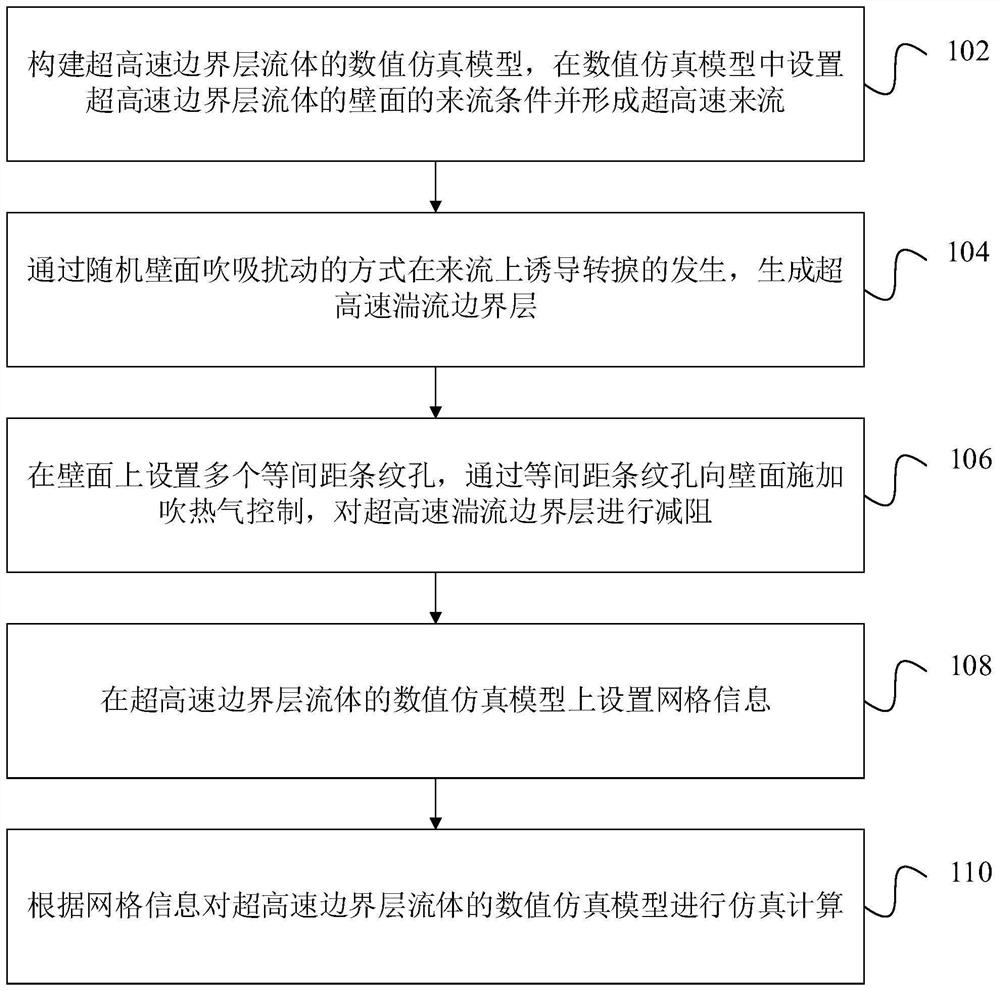

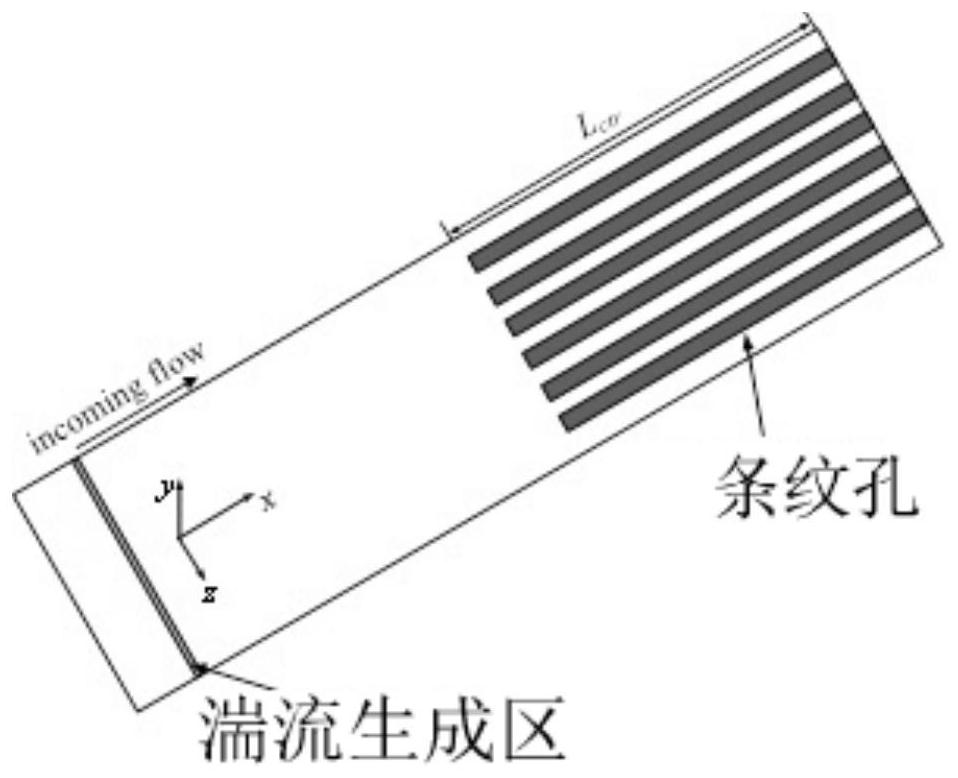

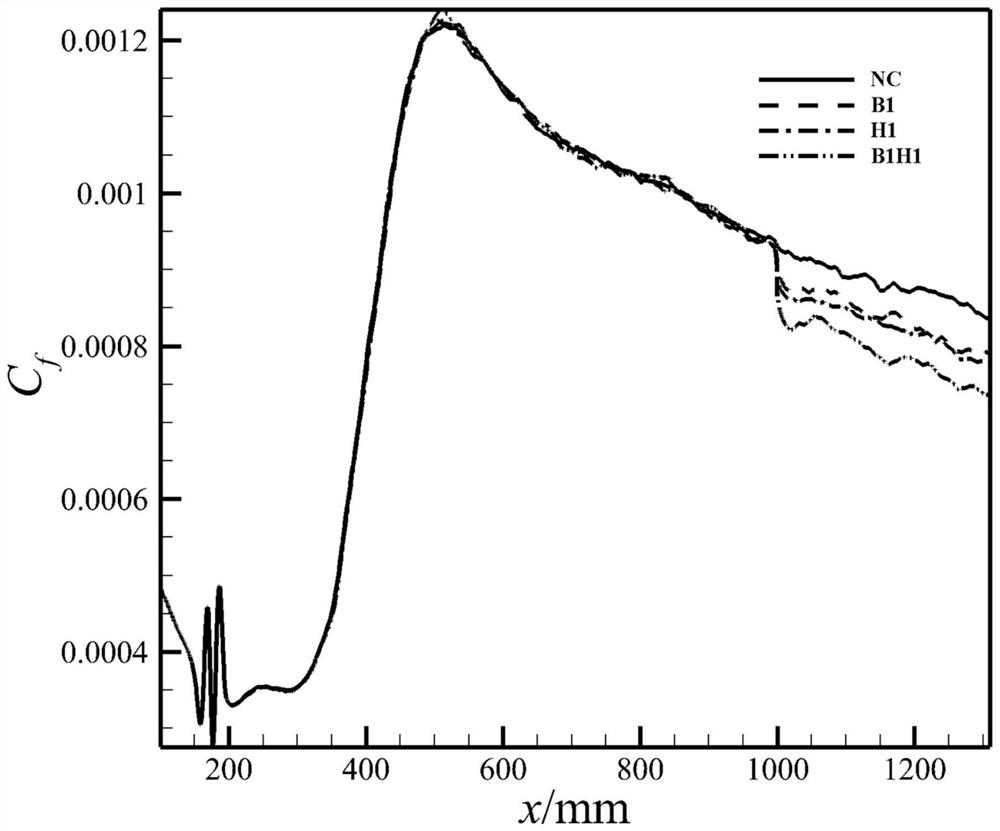

Ultra-high-speed turbulence boundary layer drag reduction control method

ActiveCN112395694AChange flow stateInhibit up-spray/down-sweep activityGeometric CADSustainable transportationUltra high speedFlight vehicle

The invention relates to an ultra-high-speed turbulence boundary layer drag reduction control method, a simulation method, a simulation device, computer equipment and a storage medium. The ultra-high-speed turbulence boundary layer drag reduction control method comprises the steps that array type stripe holes are formed in the local wall face, forming a turbulence boundary layer, of an ultra-high-speed aircraft in the flow direction, and when the aircraft flies at an ultra-high speed, hot air is blown to the wall face from the stripe holes through a wall face hot air blowing device arranged onthe surface of the ultra-high-speed aircraft; and drag reduction control is performed on the turbulence boundary layer of the ultra-high-speed aircraft. The simulation method comprises the steps thata numerical simulation model of superspeed boundary layer fluid is constructed, incoming flow conditions are set, transition is induced, and a superspeed turbulence boundary layer is generated; hot air blowing control is applied to the wall surface through the equidistant stripe holes; simulation calculation is carried out on the numerical simulation model according to the set grid information, and the effectiveness and superiority of the ultrahigh-speed turbulence boundary layer drag reduction control method based on speed and temperature coupling are analyzed.

Owner:NAT UNIV OF DEFENSE TECH

Pumping assistor

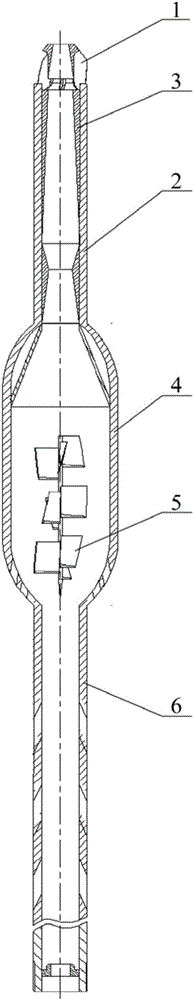

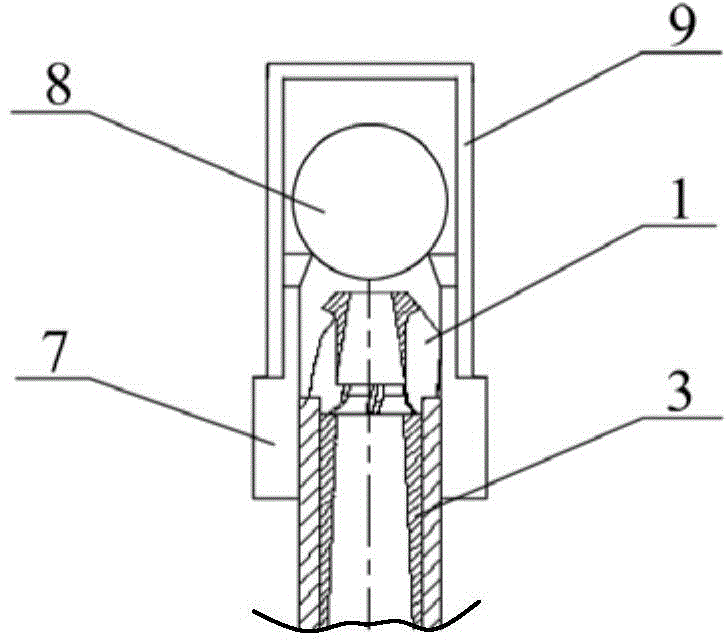

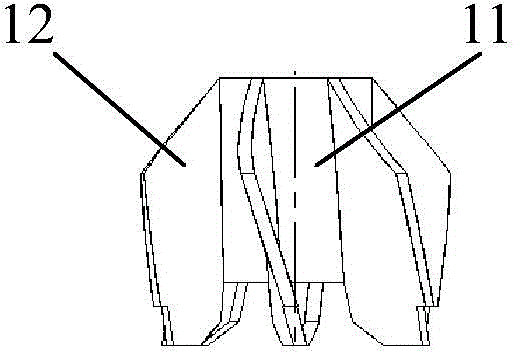

ActiveCN104405344AIncrease the instantaneous line speedImprove fill factorPositive displacement pump componentsFluid removalTransducerEngineering

The invention discloses a pumping assistor used for an oil well pump. The pumping assistor comprises a sieve tube, a liquid inlet barrel, a rotary mixer, an oil tube, a flow rate changing device and an ejector, wherein the sieve tube is used for filtering oil well output liquid; the liquid inlet barrel comprises an upper section, a middle section and a lower section, and the lower section of the liquid inlet barrel is connected with the upper end of the sieve tube; the rotary mixer is arranged inside the liquid inlet barrel, and comprises a rotating shaft and blades arranged on the rotating shaft; the upper end of the oil tube is connected with a pump seat of the oil well pump, and the lower end of the oil tube is connected with the upper section of the liquid inlet barrel; the flow rate changing device is arranged inside the oil tube, and comprises at least one stage of flow rate transducer; the ejector is arranged at the top end of the oil tube and is positioned inside the pump seat; the ejector comprises an ejection barrel and a spiral plate arranged on the outer side of the ejection barrel. Under the precondition of unchanging formation pressure and feed liquid capacity, electricity is not used, namely the instant line speed of the oil well outlet liquid can be improved, so that pressure energy is changed into kinetic energy, the liquid flow rate is quickened, the liquid flow state is changed, the filling coefficient of the pump is improved, and the yield is increased.

Owner:新疆赢华石油技术服务有限公司

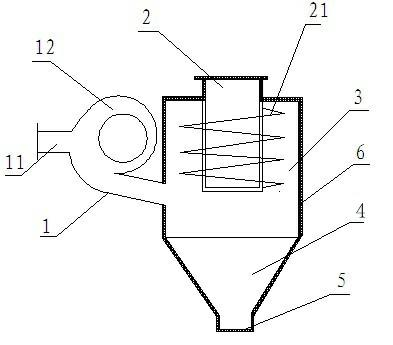

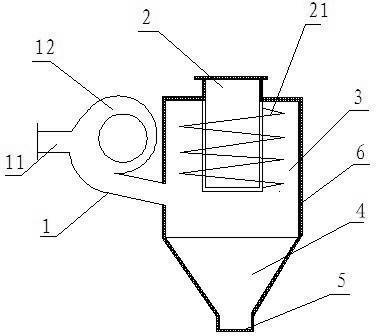

Cyclone dust collector with spiral air inlet pipe

InactiveCN102671778AChange flow stateReduce secondary dustReversed direction vortexCycloneEngineering

The invention discloses a cyclone dust collector with a spiral air inlet pipe, and belongs to the cyclone dust collector field. The cyclone dust collector comprises an air inlet pipe, a cyclone, an air outlet pipe, a spiral stream guidance blade, a conical dust collector and a dust outlet, the air inlet pipe is arranged on one side of the cyclone, the spiral stream guidance blade is fixed on the air outlet pipe and extend into the cyclone, the conical dust collector is connected to the lower bottom of the cyclone and is communicated with the cyclone, the dust outlet is arranged at the lower end of the dust collector, the air inlet pipe is designed in a spiral pipeline structure, traditional straight blow type air inlet pipes are replaced, one end of the air inlet pipe is an air inlet, and the other end is fixed onto and communicated with the outer wall of the cyclone. According to the mode, the cyclone dust collector with the spiral air inlet pipe can change flow conditions of airflows inside the cyclone, possibilities of secondary dust raising and dust rising circulation phenomena of the conical portion are effectively reduced, centrifugal force of dust particles is increased because the rotation speed of airflows inside the dust collector is increased, fine particles which cannot be removed by traditional cyclone dust collectors can be removed, and the cyclone dust collector has high dust particle separation efficiency.

Owner:郭丰亮

Nickel-chromium alloy furnace tube for cracking furnace and preparation method thereof

ActiveCN106554799AImprove thermal stabilityChange flow stateThermal non-catalytic crackingNickel Chromium AlloysHigh heat

The invention relates to the field of nickel-chromium alloy furnace tubes for cracking furnaces, and discloses a nickel-chromium alloy furnace tube for a cracking furnace and a preparation method thereof. The nickel-chromium alloy furnace tube comprises a furnace tube, an intensified heat transfer member arranged in the furnace tube and an oxidizing film formed on the inner surface of the furnace tube, wherein the oxidizing film contains an oxide of one or more elements such as Cr, Mn, Ni, Fe, Al and Si. According to the nickel-chromium alloy furnace tube for the cracking furnace provided by the invention, an inert protective film with relatively high heat stability is formed on the inner surface of the furnace tube, so that a catalytic coking phenomenon can be inhibited or alleviated; meanwhile, the intensified heat transfer member is arranged in the furnace tube, so that the flow condition of a fluid can be changed, the coefficient of heat conduction can be improved, and free radical coking and polycondensation coking can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

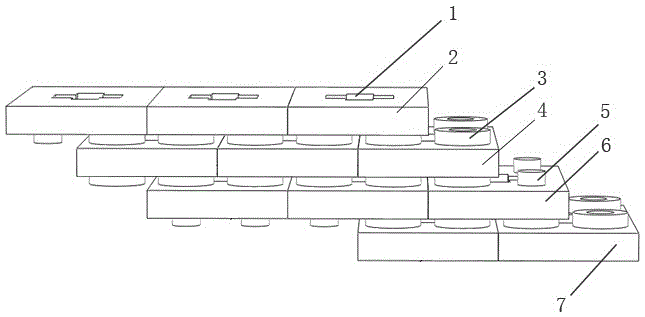

Injection mold hot runner valve type vibration type nozzle device

An injection mold hot runner valve type vibration type nozzle device is provided with a mold body which comprises a fixed template and a shunting template, wherein the shunting template is provided with a sub-runner and the fixed template is provided with a fixed template main runner and at least two fixed template valve holes; the upper part of the shunting template is provided with a shunting template main runner and a shunting template valve hole; a valve rod is respectively arranged in each fixed template valve hole and the shunting template valve hole below the fixed template valve hole;discharging holes are arranged at the lower part of the shunting template; a nozzle is arranged in each discharging hole; the diameter of the bottom part of the valve rod is larger than the diameter of the upper port of the nozzle; a vibration-starting piece which is connected at the upper end of the valve rod, a gate switch located at the side of the vibration-starting piece, and a spring locatedbelow the vibration-starting piece, are arranged in each fixed template valve hole; the vibration-starting piece comprises a shell body and a vibration-starting ring; the switch of the valve rod to the nozzle is controlled by the gate switch; and each vibration-starting coil and the gate switch are controlled by a control circuit. The injection mold hot runner valve type vibration type nozzle device has the advantages of simple structure, low energy consumption and convenient adjustment.

Owner:SHANGHAI HUFAN AUTOMOTIVE PLASTIC PARTS

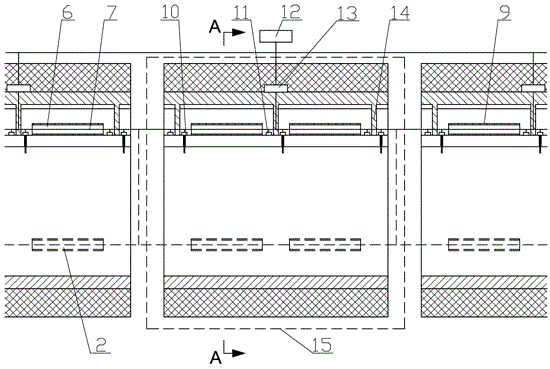

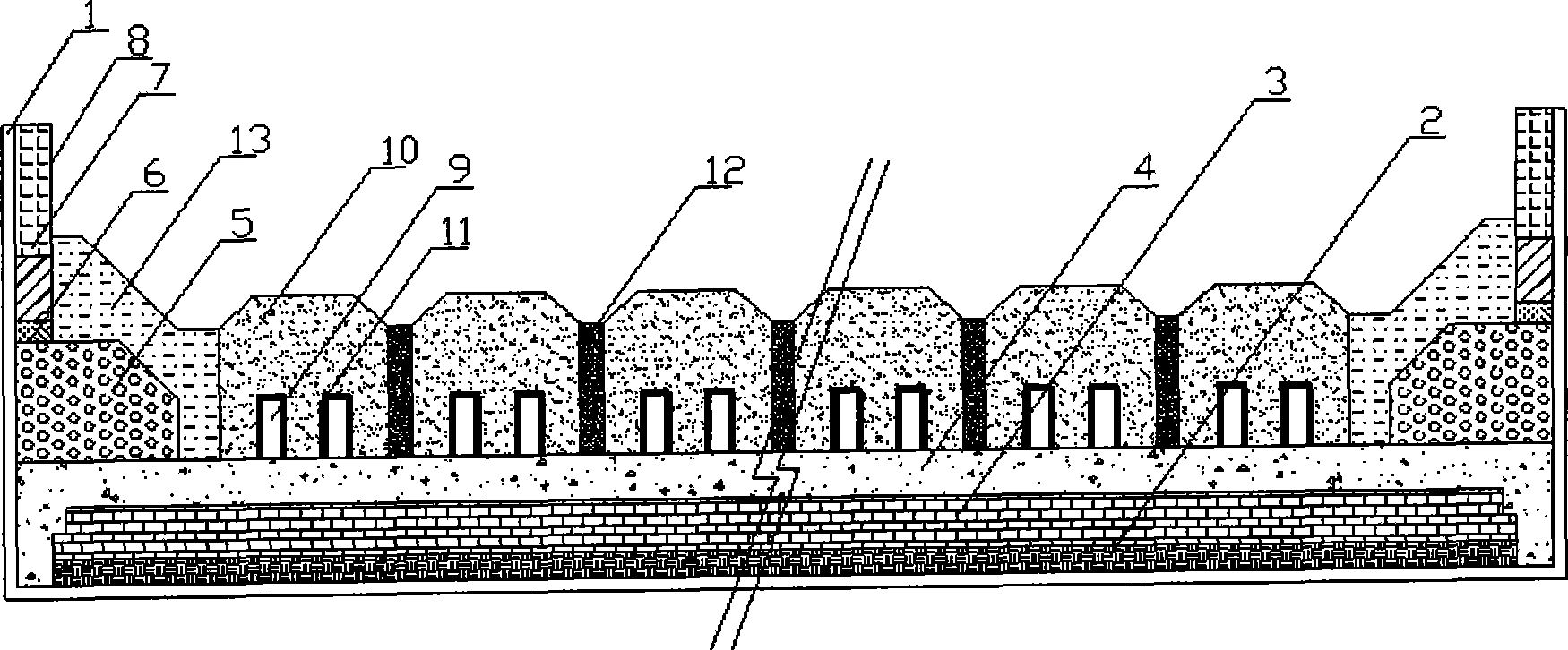

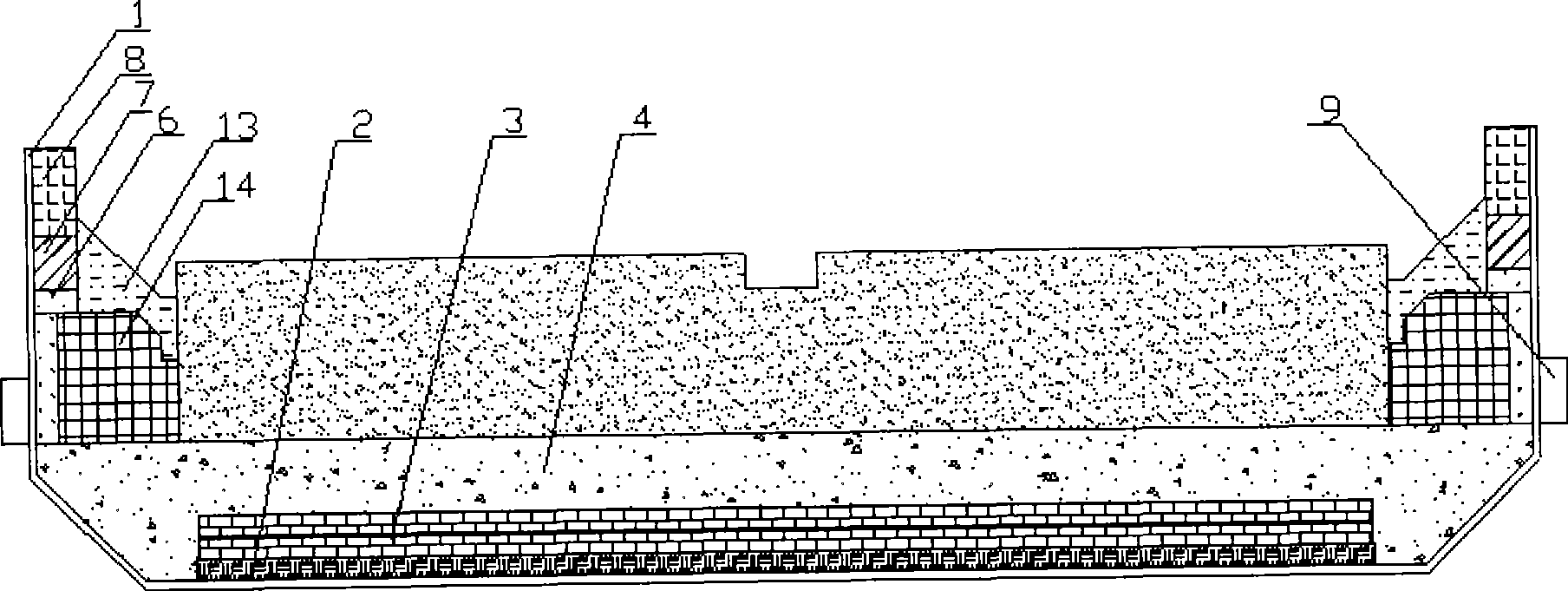

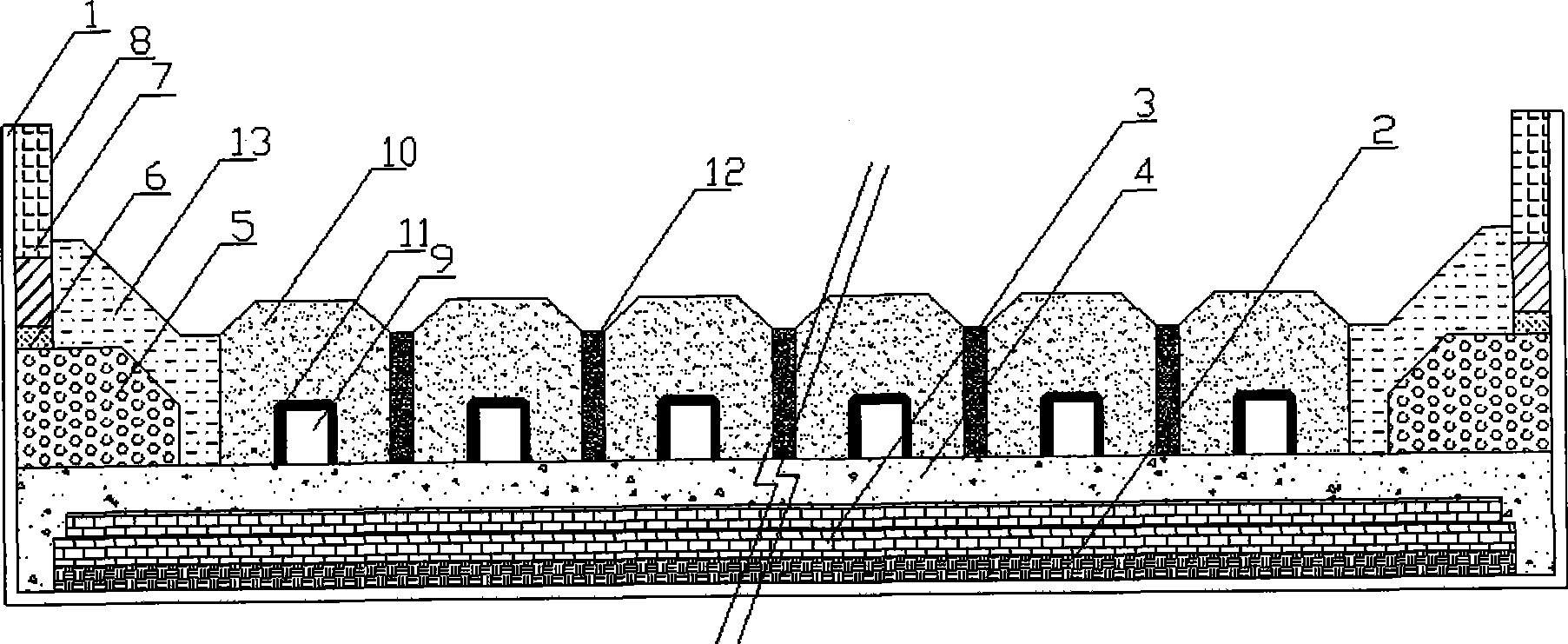

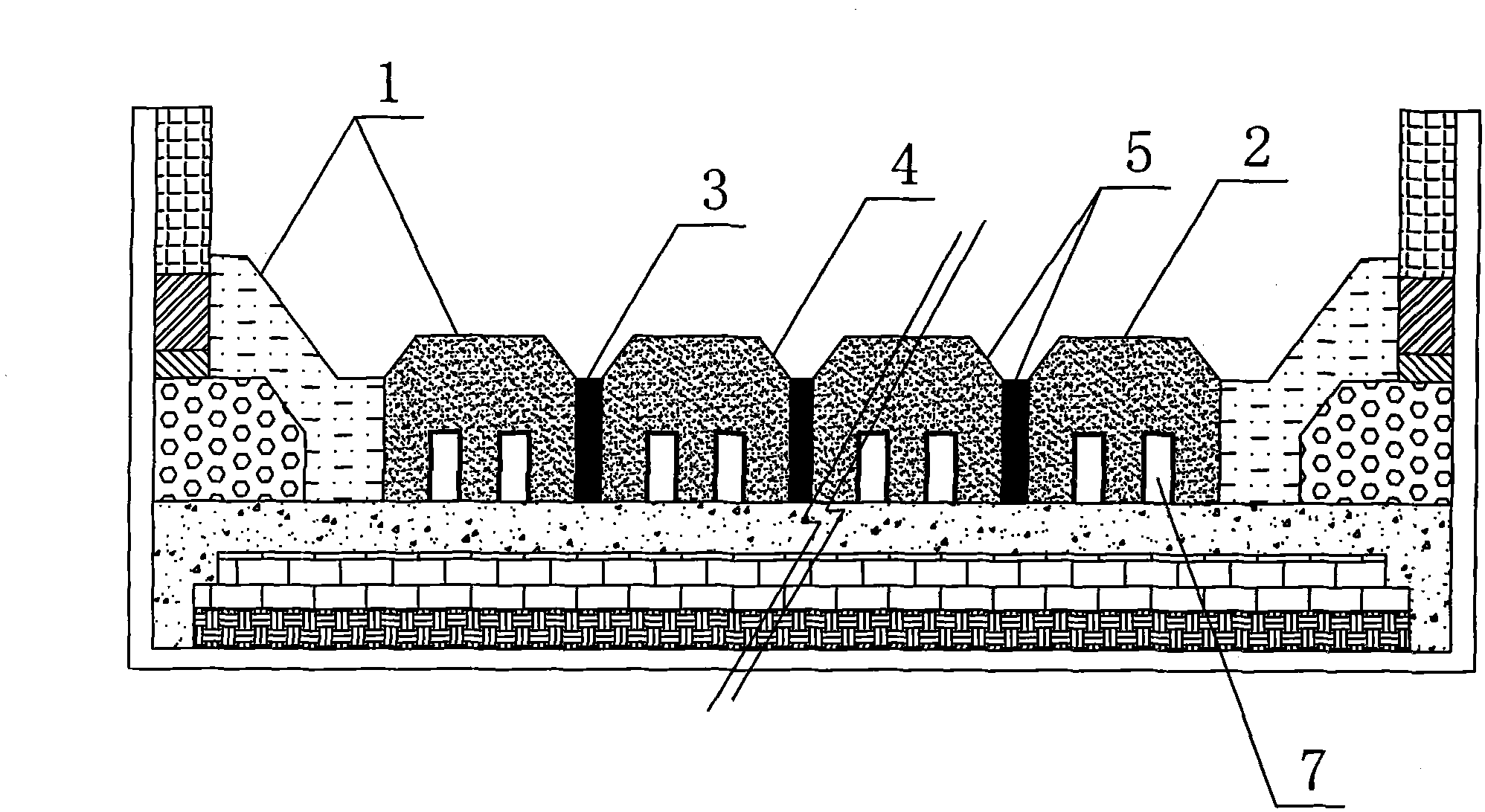

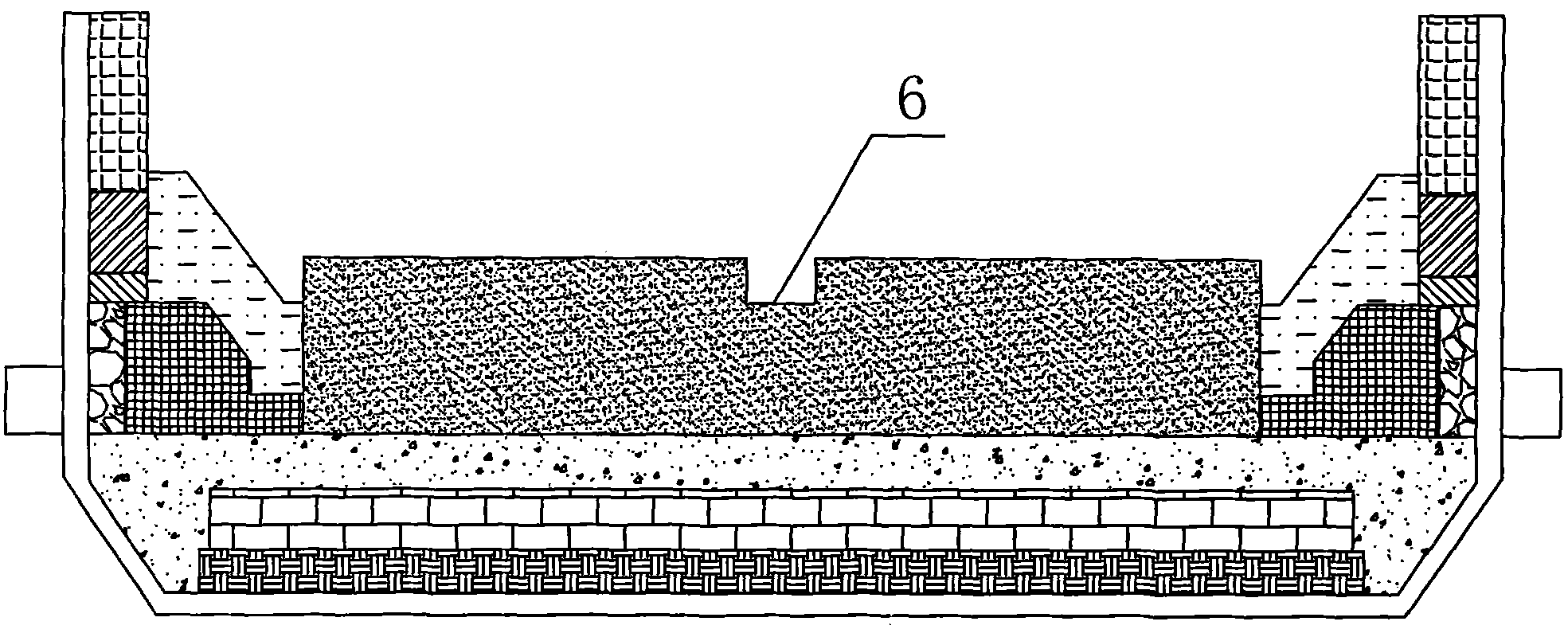

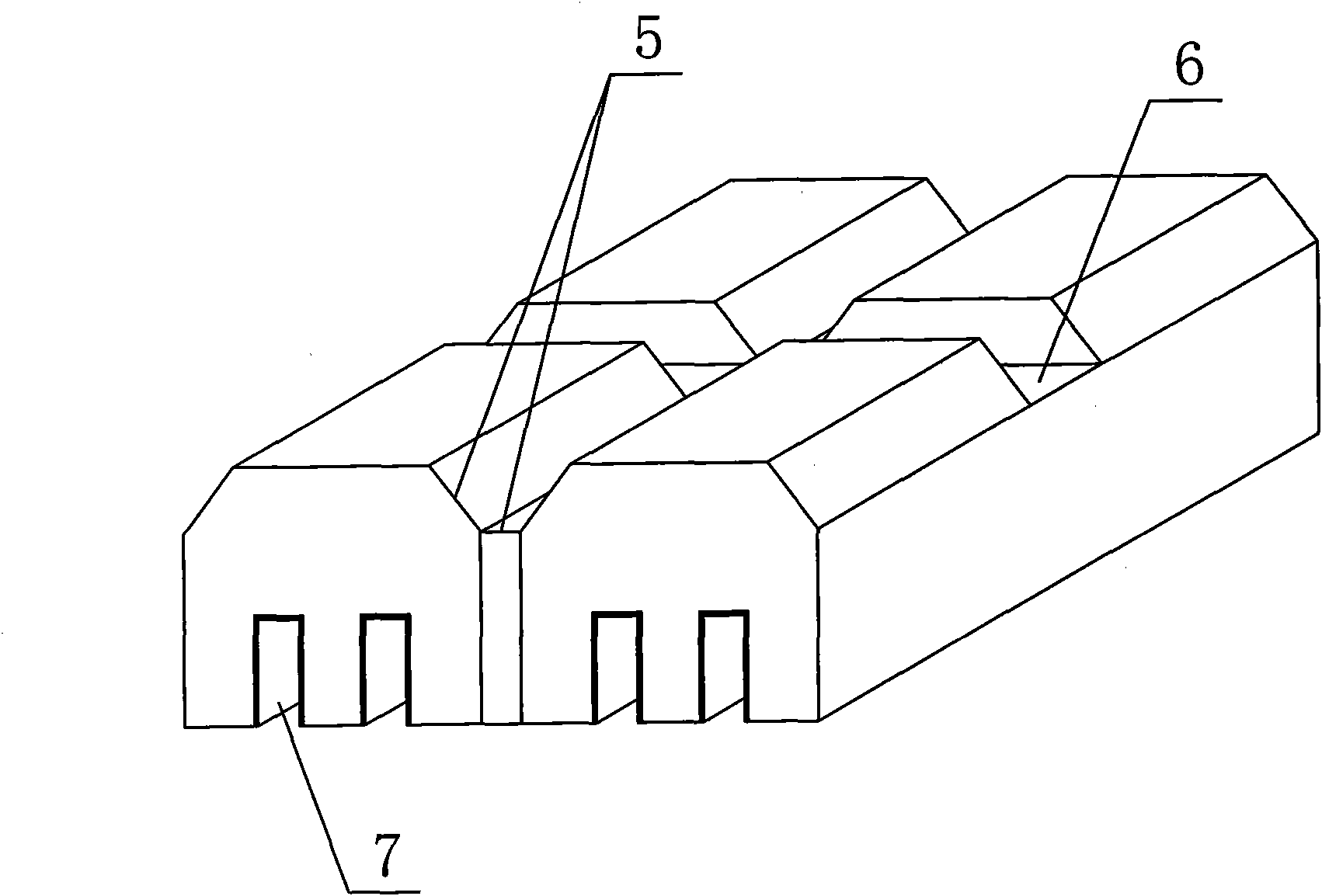

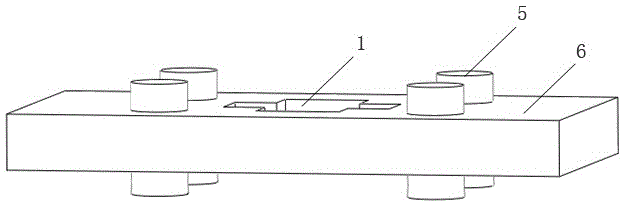

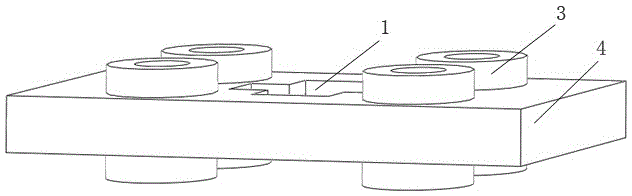

Novel energy-saving aluminum cell with chamfering grooving cathode

The invention relates to a novel energy-saving aluminum electrolytic cell with a chamfered grooved cathode. The aluminum electrolytic cell is characterized in that: a cathode carbon block adopted by the electrolytic cell is a chamfered and grooved novel carbon block; the upper part of the cross section of the carbon block is a trapezoid; the upper surface of the middle part of the longitudinal section of the carbon block is provided with a through rectangular tank; and the whole surface of the cathode on the bottom of the electrolytic cell is in the form of a plurality of dovetail grooves orthogonal with a rectangular groove. The novel energy-saving electrolytic cell can not only bring about evener current density distribution of an aluminum liquid, the cathode carbon block and a steel rod, but also improve the even distribution of a magnetic field, reduces the stress produced by the magnetic action on the aluminum liquid, effectively reduces the flow velocity of the aluminum liquid, changes the flow state of the aluminum liquid, changes the turbulent flow into the laminar flow, reduces the fluctuation of an electrolyte and the aluminum liquid in the cell, and consequently reduces the polar pitch and the pressure fall in the cell and realizes energy conservation and consumption reduction of electrolyzation.

Owner:HUNAN CHUANGYUAN ALUMINUM IND

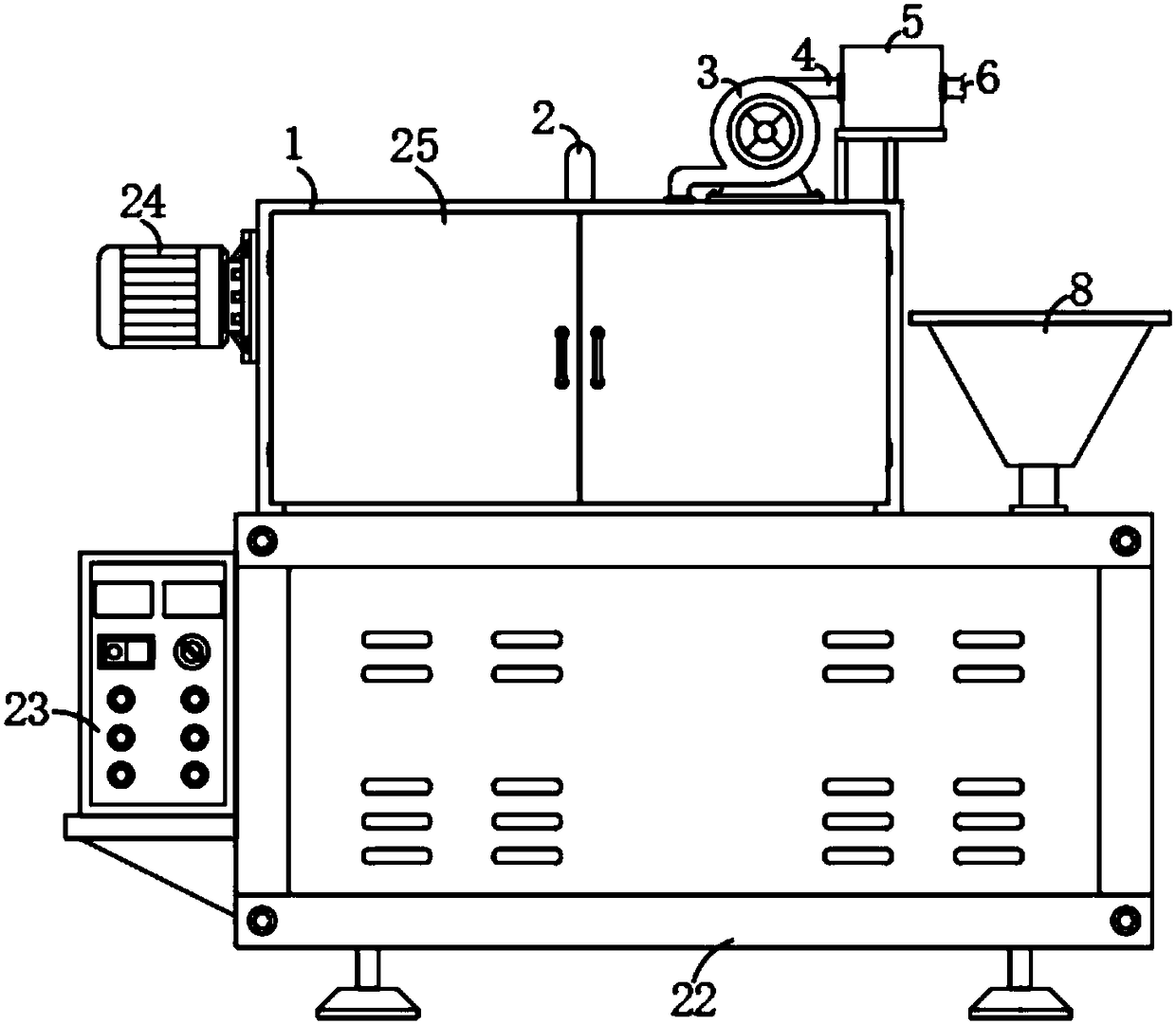

Anti-blocking environment-friendly printing and dyeing equipment

InactiveCN108396494AReduce labor intensityImprove work efficiencyGas treatmentDispersed particle separationWorking environmentEngineering

The invention discloses anti-blocking environment-friendly printing and dyeing equipment. The equipment comprises a machine box body, a printing and dyeing bin is fixed to one side of the upper surface of the machine box body, and a collecting tank is arranged on the top in the machine box body; one side of the upper surface of the printing and dyeing bin is provided with an induced draft fan, andthe side, close to the induced draft fan, of the upper surface of the printing and dyeing bin is fixedly provided with a filtering box through an F-shaped support; the air inlet end of the induced draft fan is connected with the printing and dyeing bin through a pipeline, and an air delivery pipe is connected between the air outlet end of the induced draft fan and the filtering box; a plurality of flow guiding convex blocks are arranged on the two sides of the inner wall of the collecting tank at equal intervals. The induced draft fan and the filtering box are arranged, so that air purification is achieved, harmful gas is prevented from being discharged and polluting the environment, and a health and comfortable working environment is formed; the flow guiding convex blocks are arranged, so that the flow state and the flow speed of a dye are changed, flowing of the dye is promoted, the dye is prevented from being condensed, rapid backflow of the dye is achieved, and printing and dyeingof the equipment are more efficient.

Owner:长兴超特纺织有限公司

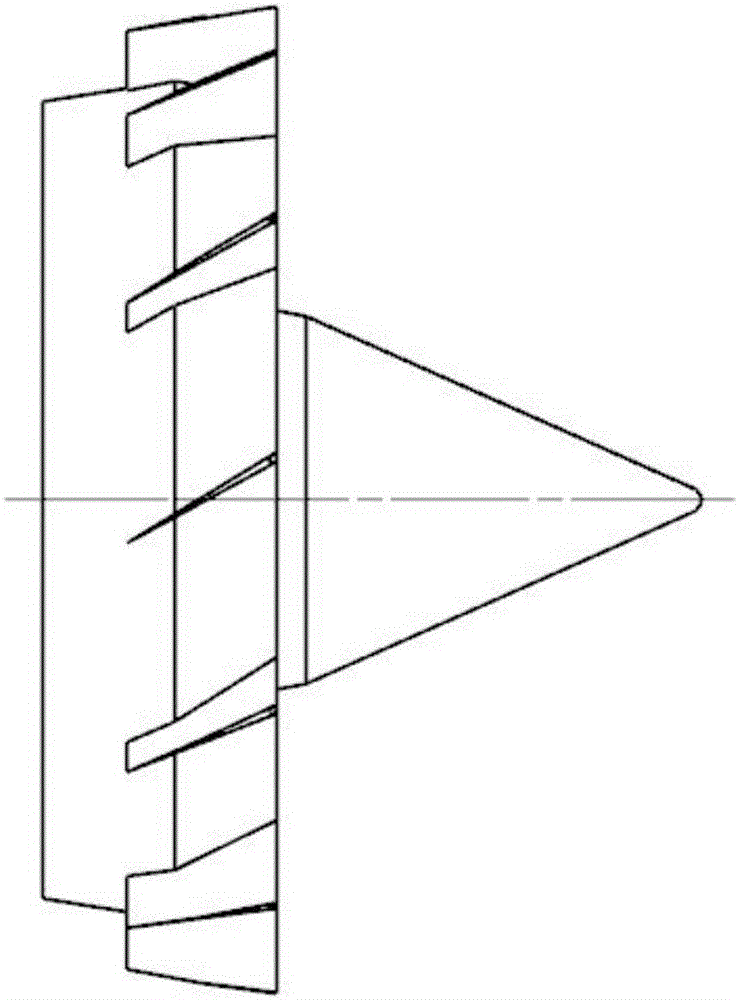

Three-level rotational flow structure of afterburner head

InactiveCN106678870AReduce the air flow rateStable combustionContinuous combustion chamberThree levelFuel oil

The invention provides a three-level rotational flow structure of an afterburner head. A large-ranged recirculation zone can be generated by the structure in an afterburner, so that flame burning is stabilized, and meanwhile, the pressure loss can be reduced, the fuel oil atomization degree in the afterburner is reinforced, burning efficiency is improved, and the wall face can be effectively cooled; by reasonably setting the rotary angle of a whole flow supporting plate, an airflow reversely flows in a rotational-flow mode, so that shear force between fuel oil and air is increased, and the fuel oil atomization degree is improved; the flowing direction of the airflow is not suddenly changed, and thus flowing resistance is small; and an airflow rotational flow is subjected to wall-adherent movement, so that an air film is formed between the afterburner wall face and a burning zone, and the cooling effect of the afterburner wall face is guaranteed. The three-level rotational flow structure of the afterburner head has the advantages that the difficulty, caused by the over-high airflow speed in the afterburner, of igniting and maintaining stable burning of flame can be effectively improved, and the smaller pressure loss is achieved; and meanwhile, the fuel oil atomization level can be improved, and further efficient burning can be ensured.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Processing method of nichrome furnace tube for pyrolysis furnace

ActiveCN106554797AImprove thermal stabilityChange flow stateThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingEnhanced heat transferChromium nickel

The invention relates to the field of nichrome furnace tubes for pyrolysis furnaces and discloses a processing method of a nichrome furnace tube for a pyrolysis furnace. The method comprises the following steps of: in the atmosphere of low-oxygen partial-pressure gas, heating the nichrome furnace tube to 600-1100 DEG C at a heating speed lower than 150 DEG C / h, and performing heat preservation for 5-100 hours, wherein the nichrome furnace tube is internally provided with an enhanced heat transfer component. By use of the nichrome furnace tube, which is processed by the method, for the pyrolysis furnace, the operation cycle of the pyrolysis furnace can be obviously prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

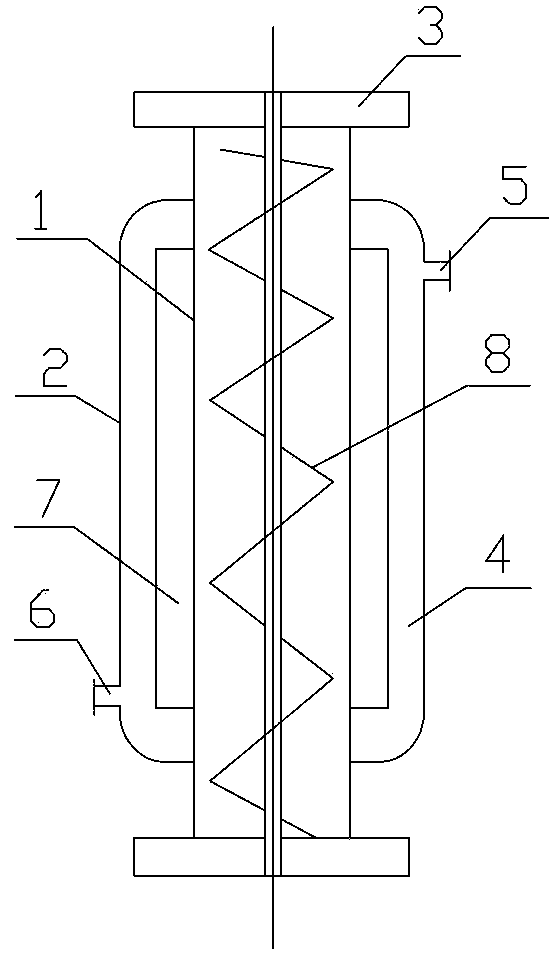

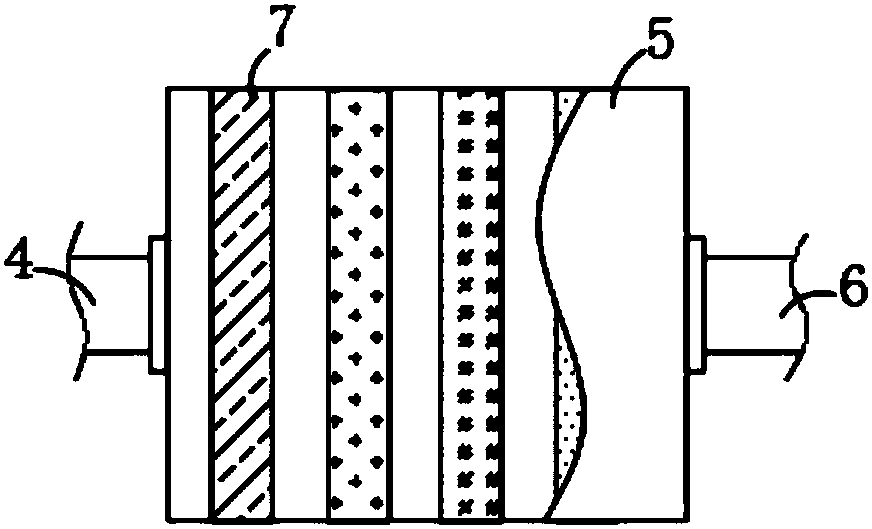

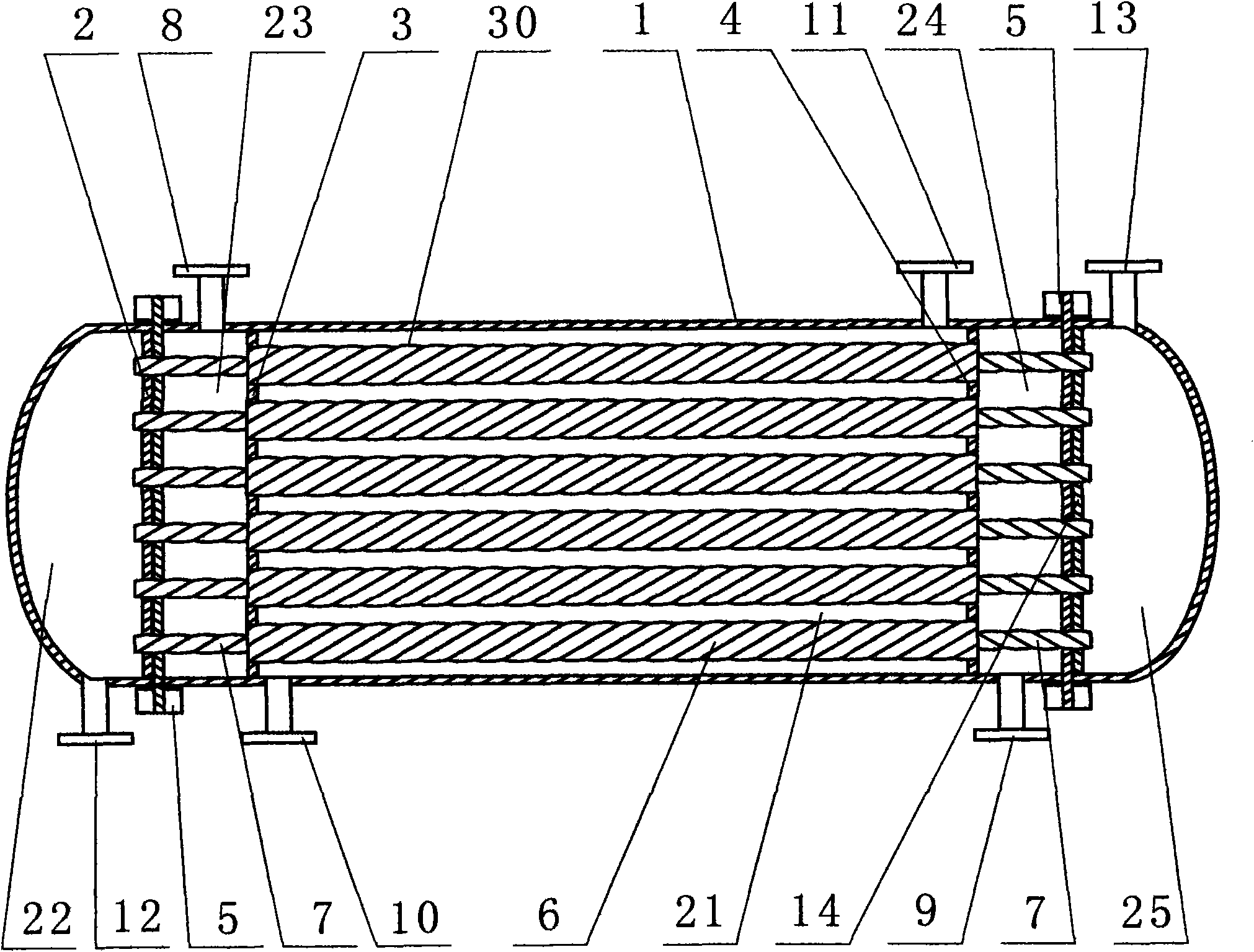

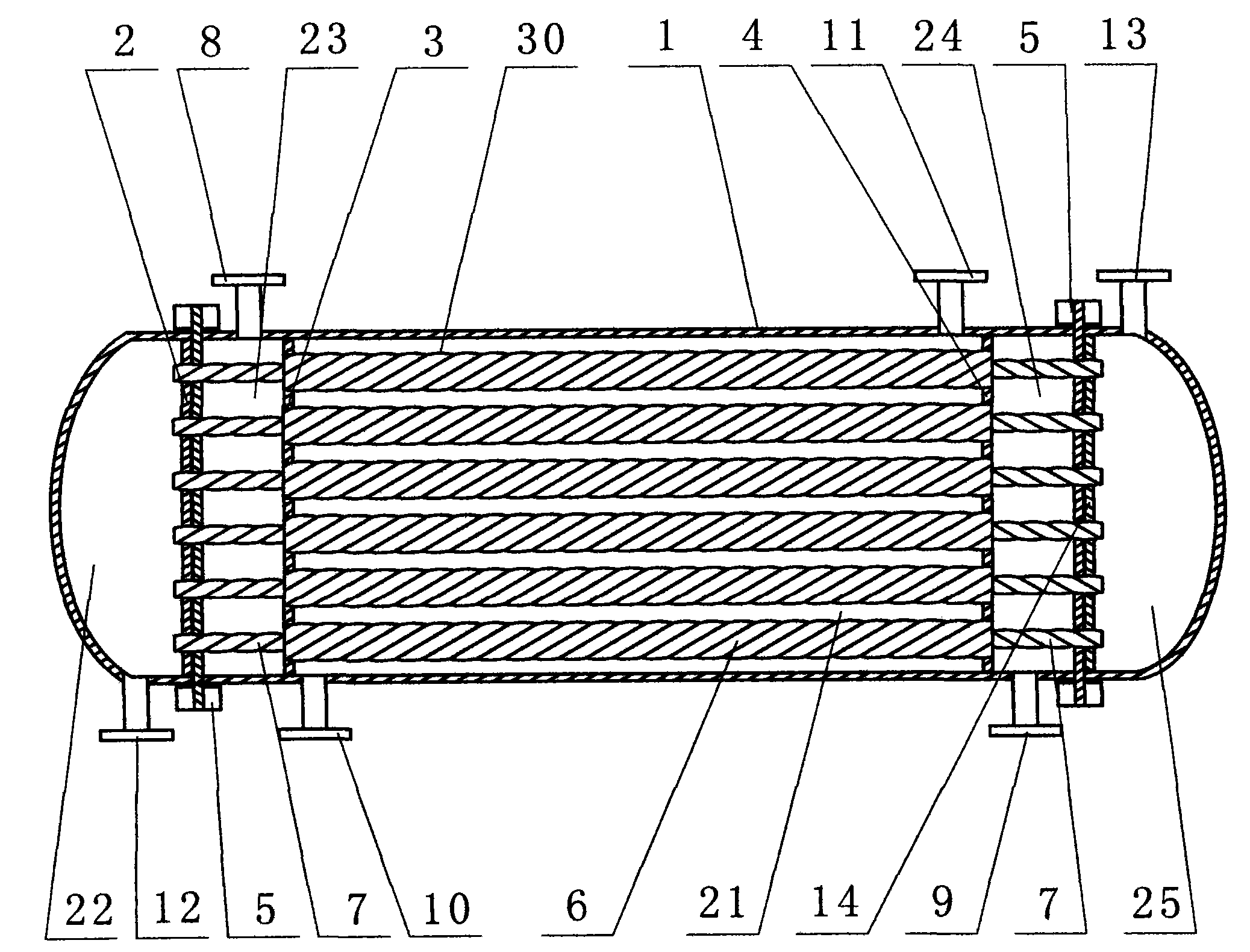

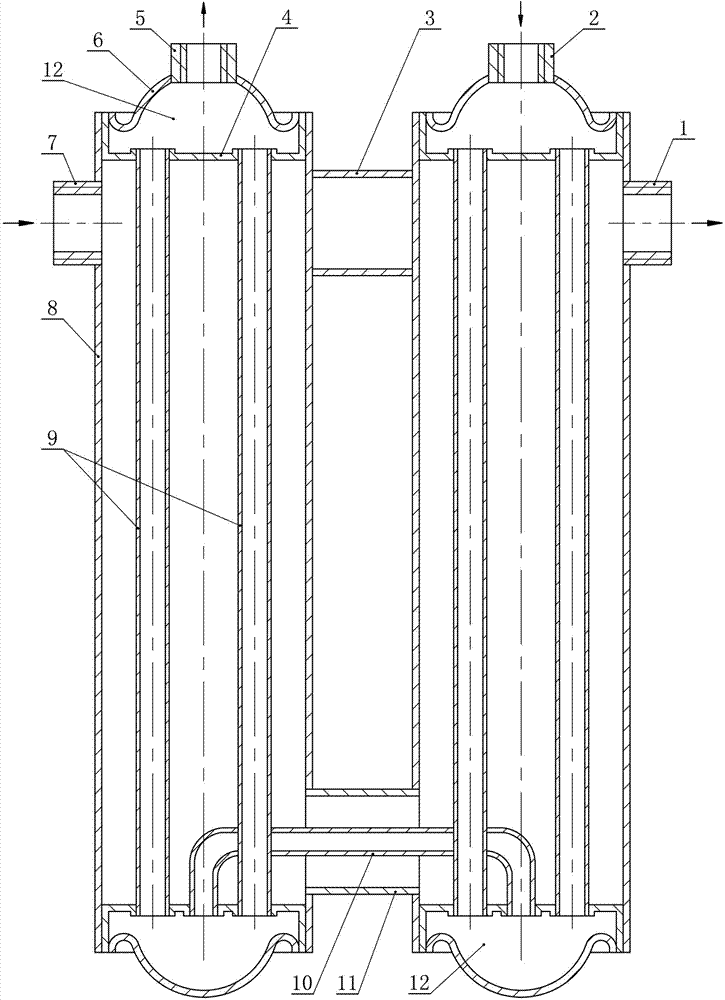

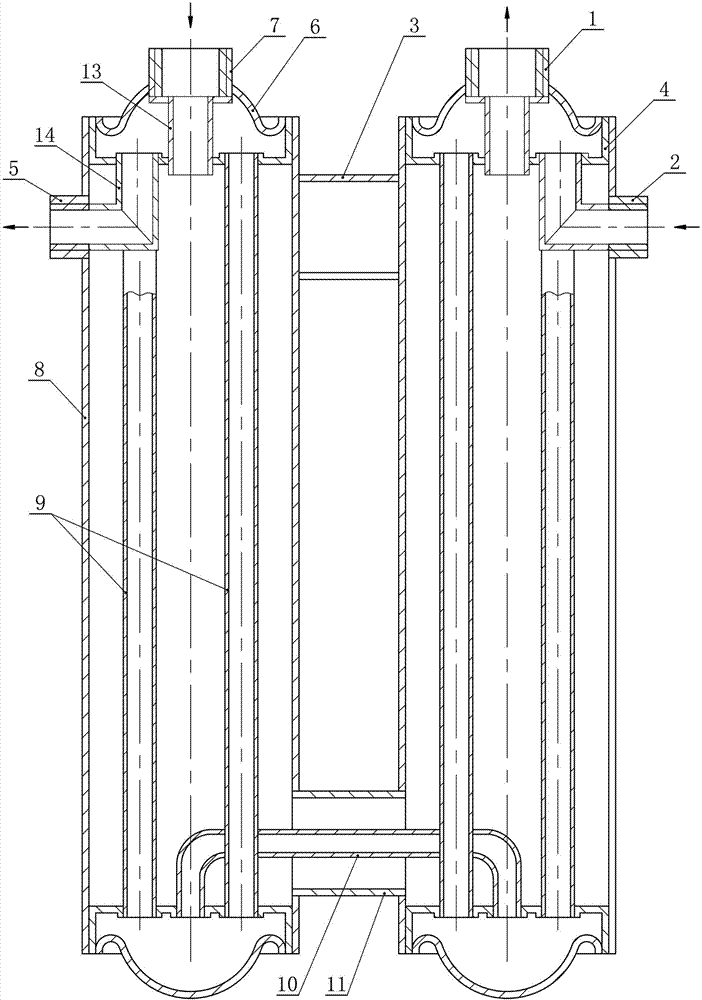

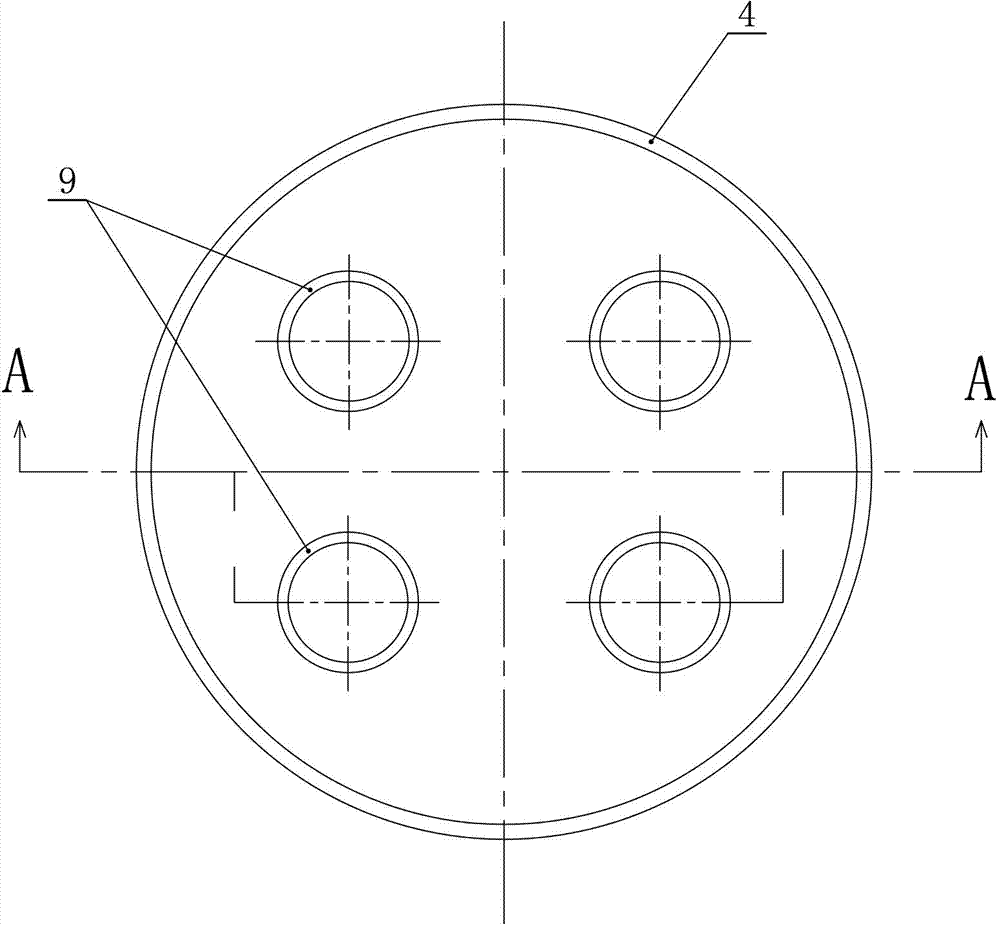

Energy-saving high efficiency rapid condenser

InactiveCN102486353AIncreased turbulence intensityChange flow stateSteam/vapor condensersTubular elementsHermetic sealEngineering

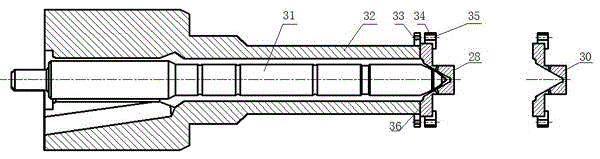

The invention discloses an energy-saving high efficiency rapid condenser. The rapid condenser is characterized in that a shell of the condenser is internally provided with a combined type heat exchange tube (30), the combined type heat exchange tube (30) is composed of an outer pipe (6) with larger diameter and an inner pipe with small diameter (7), and the outer pipe (6) is slightly shorter than the inner pipe (7); the pipe wall of the outer pipe (6) is twisted into a spiral shape, and the pipe wall of the inner pipe (7) is twisted into the spiral shape which is opposite to the outer pipe (6); the outer pipe (6) is sleeved on the exterior of the inner pipe (7), and the two ends of the outer pipe (6) are respectively stretched from the inner pipe (7); the two ends of the outer pipe (6) are respectively stretched into thru holes of a second septum (3) and a third septum (4) in the shell (1), and the outer pipe (6), the second septum (3) and the third septum (4) are in hermetic seal connection; and the two ends of the inner pipe (7) are respectively stretched into thru holes of a first septum (2) and a fourth septum (14), and the inner pipe (6), the first septum (2) and the fourth septum (14) are connected in a sealing mode.

Owner:王成东

High strength and high efficiency fluid magnetizing tube, magnetizing device and system

InactiveCN1821109AImprove technical indicatorsImprove magnetization efficiencyWater/sewage treatment by magnetic/electric fieldsEnergy based chemical/physical/physico-chemical processesEngineeringHigh intensity

The present invention provides high strength and high efficiency fluid magnetizing tube, magnetizing device and magnetizing system, and belongs to the field of fluid magnetizing technology. The fluid magnetizing tube includes a magnetic tube, a magnetic conducting tube, and a locating and guiding element to form one or several fluid channels and has straight or curved axis. The magnetic tube includes a magnetic ring, an isolating ring of non-ferromagnetic material and a duct; the magnetic conducting tube is high permeability duct or one other magnetic tube; and the end plates possess fluid channel. The magnetizing device includes a casing and several magnetizing tubes connected serially and / or in parallel. The magnetizing system has magnetizing device, conventional pump and power device to perform circular fluid magnetizing. The present invention has high strength axial and radial magnetic field and high fluid magnetizing efficiency.

Owner:朱澄清

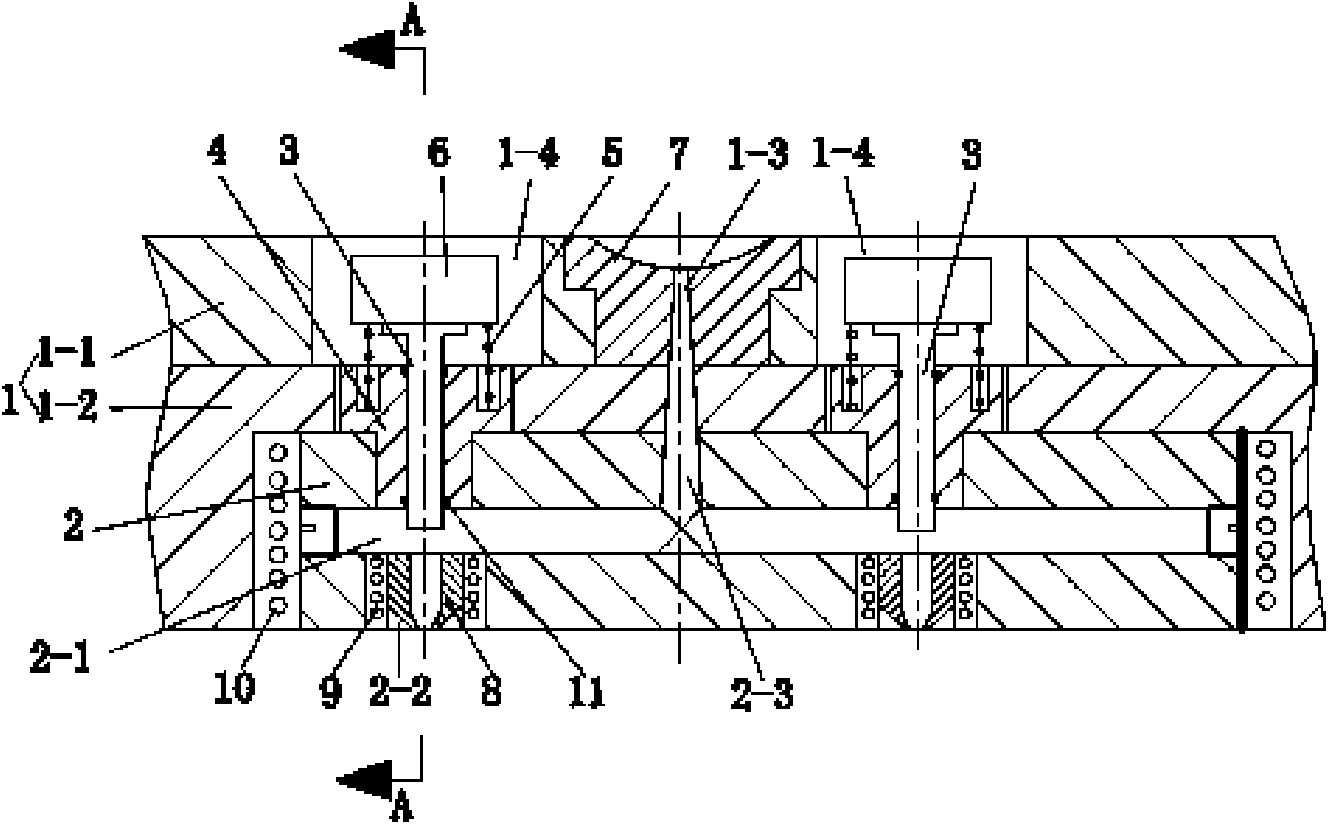

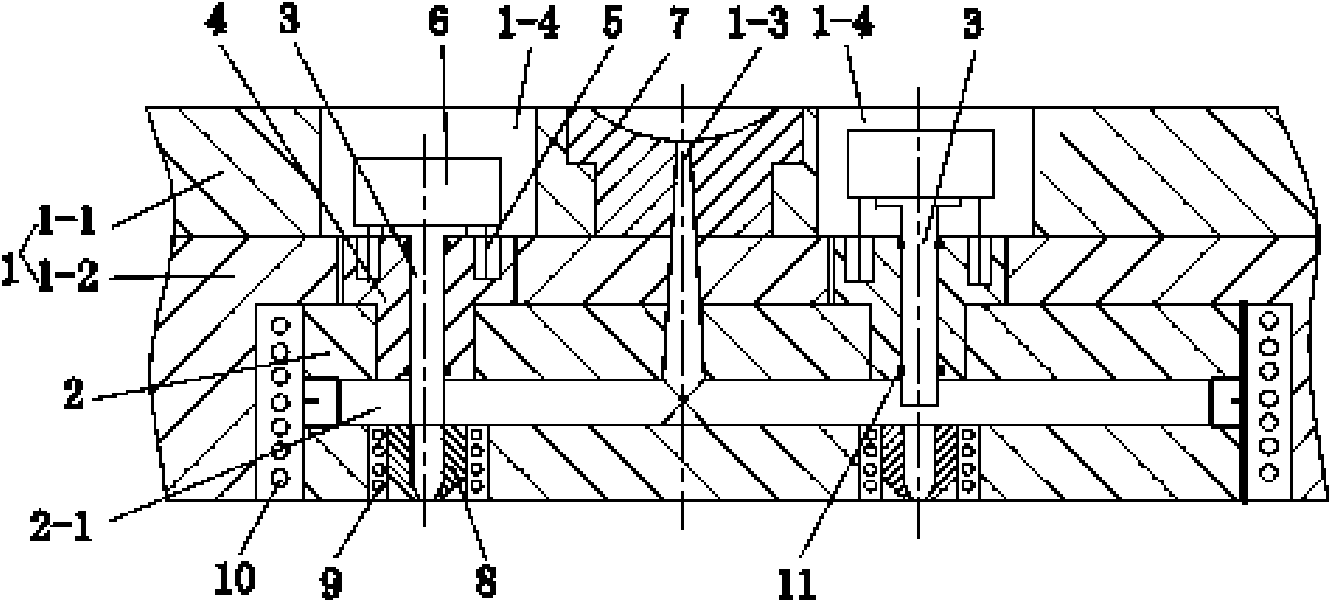

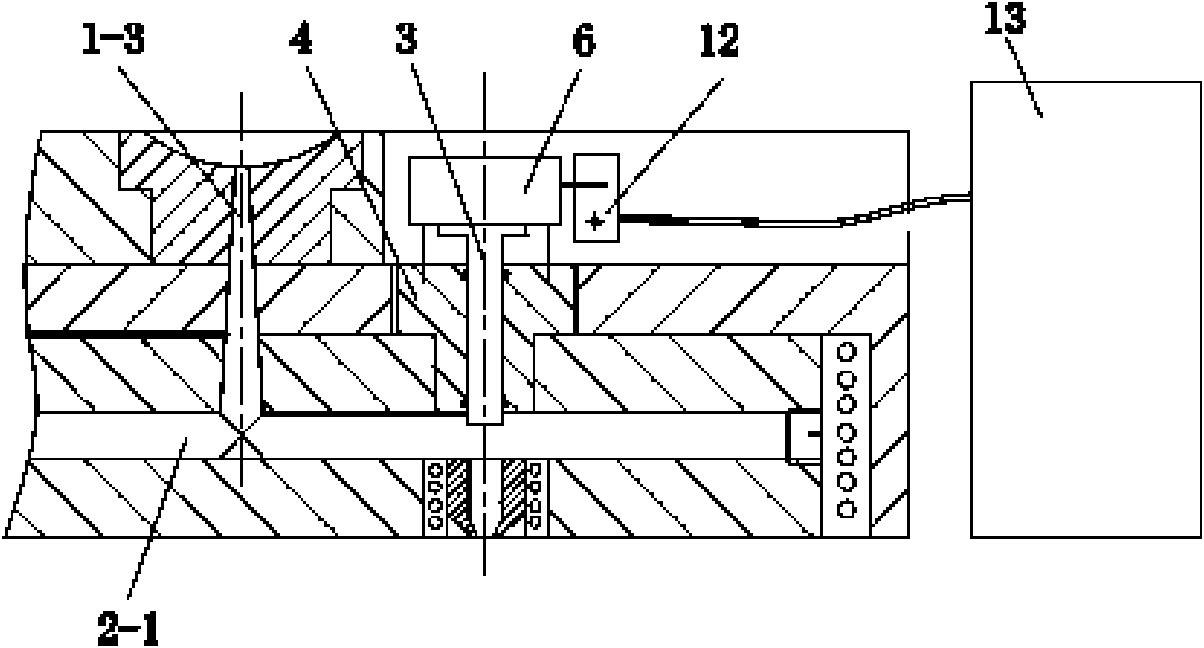

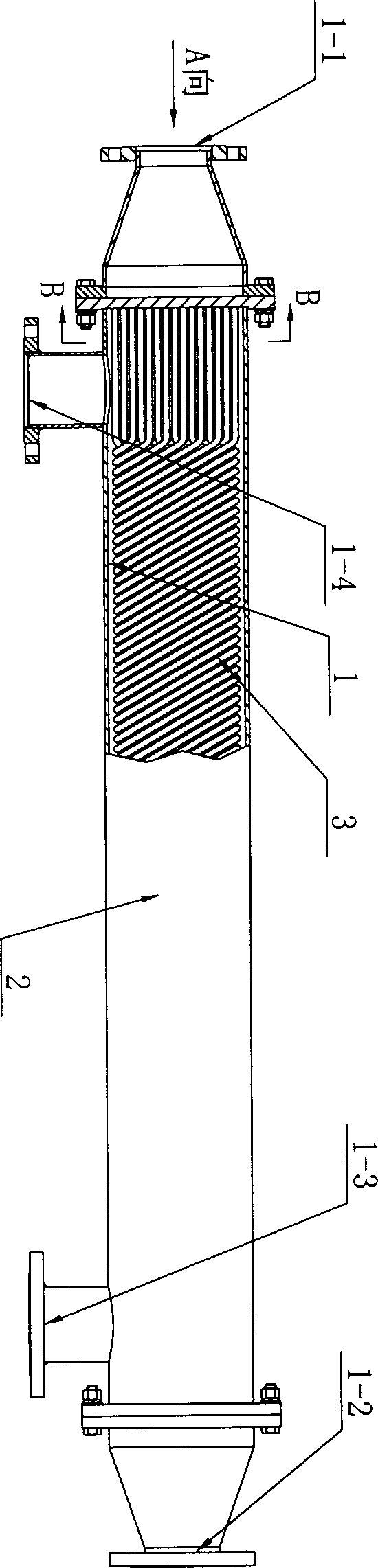

Reverse helically-coiled tube type cooler

InactiveCN104457333AIncrease the heat exchange areaSave spaceStationary tubular conduit assembliesTubular elementsHeat transfer efficiencyEngineering

The invention relates to a reverse helically-coiled tube type cooler and belongs to the technical field of convection heat exchange. An oil inlet (1-1) and an oil outlet (1-2) are arranged on the two ends of a box (1), a water inlet (1-3) and a water outlet (1-4) are arranged on the two ends of the side surface of the box (1) respectively, a shell (2) is arranged on the outer side of the box (1), a plurality of layers of reverse helically-coiled tube bundles (3) are concentrically arranged in the box (1); the helical winding directions of the odd number layers and the even number layers of the reverse helically-coiled tube bundles (3) are opposite; the flowing state of fluid is changed, and thus strong turbulence effect is formed. Moreover because the length of the reverse helically-coiled tube type cooler is 4-6 times as long as the length of the shell, heat exchange medium inside and outside the heat exchange pipe bundles can be subjected to complete heat exchange. The pressure bearing capacity is high, the structure is compact, the heat stress can be slowly released, the heat exchange coefficient is large, the heat exchange efficiency is high, and the cooler has considerable flexibility, adaptability and reliability.

Owner:HAIAN TIANRUN MACHINERY TECH

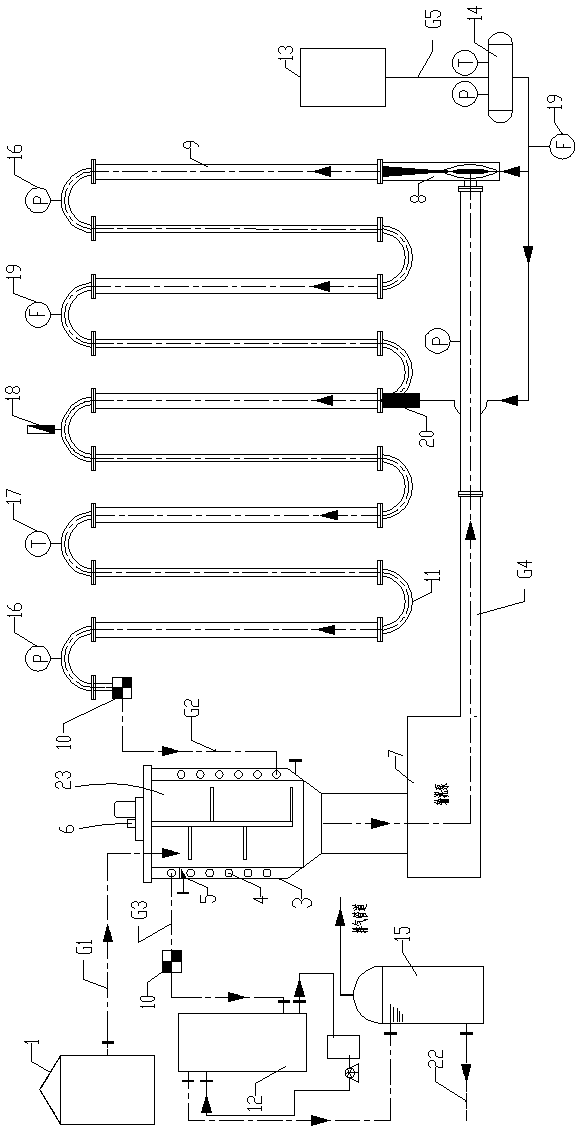

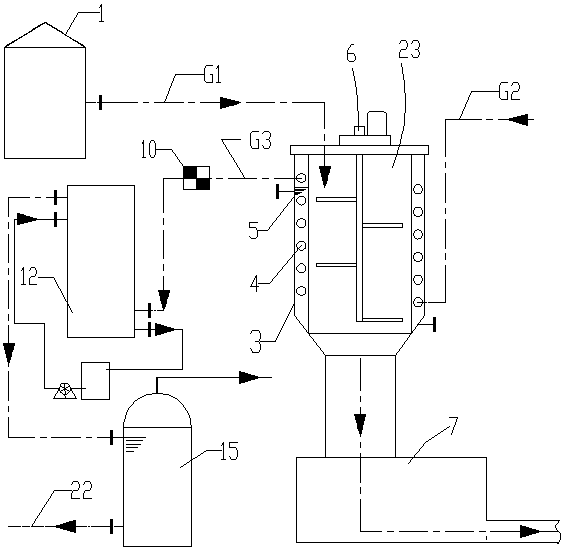

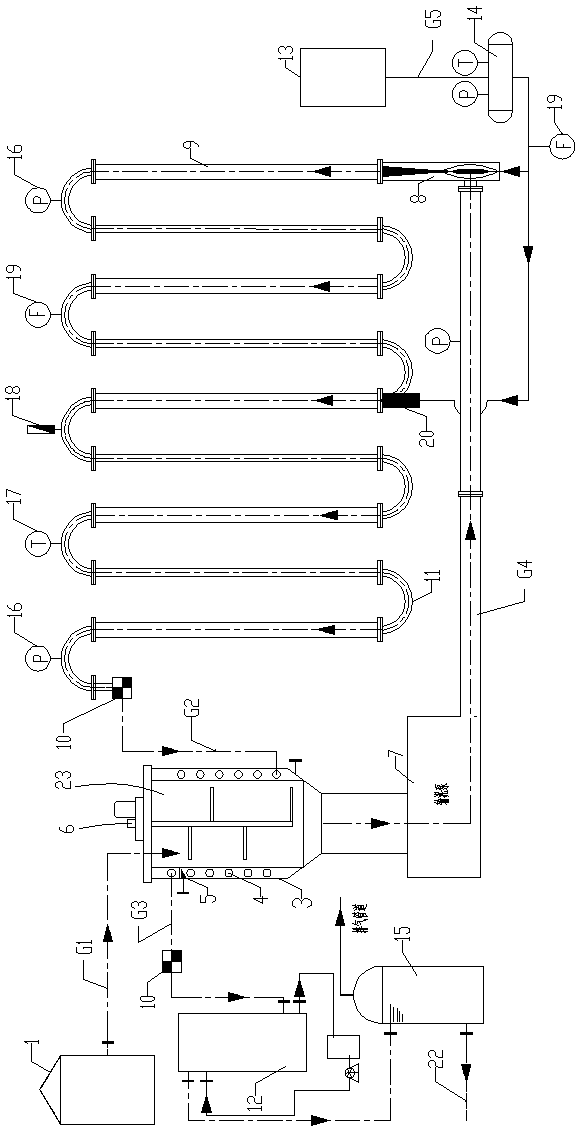

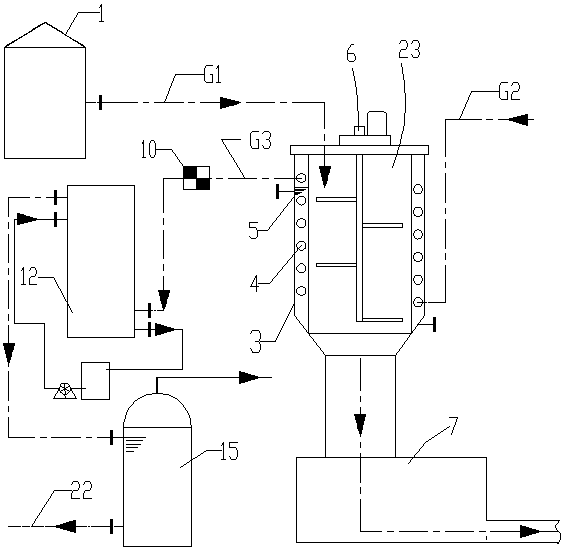

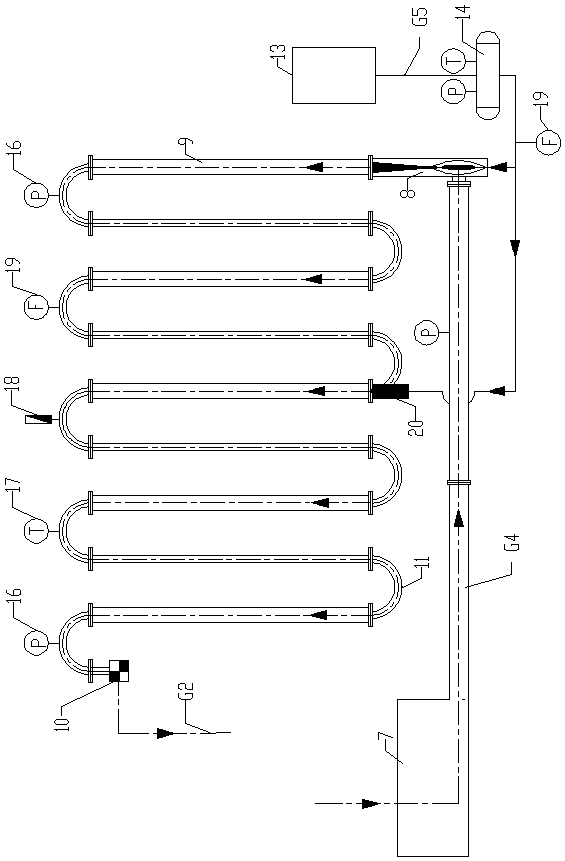

Sludge pyrohydrolysis system

PendingCN110902996AImproved thermal hydrolysis effectWell mixedSludge treatment by pyrolysisByproduct vaporizationSludgeProcess engineering

The invention discloses a sludge pyrohydrolysis system comprising a sludge storage tank, a sludge preheating device, a sludge conveying pump and a steam source, a pyrolysis sludge storage tank, a sludge pyrohydrolysis pipeline and a steam sludge ejector; a to-be-treated sludge outlet in the sludge storage tank communicates with a feeding port of the sludge preheating device; a discharge port of the sludge preheating device communicates with a sludge inlet of the sludge conveying pump; a sludge outlet of the sludge conveying pump communicates with a first inlet of the steam sludge ejector; a steam supply port of the steam source communicates with a second inlet of the steam sludge ejector; an outlet of the steam sludge ejector communicates with an inlet of the sludge pyrohydrolysis pipeline, a pressure relief discharger at a pyrohydrolysis sludge outlet of the sludge pyrohydrolysis pipeline communicates with a coil pipe inlet of a heat recovery coil pipe, and a coil pipe outlet of the heat recovery coil pipe communicates with an inlet of the pyrolysis sludge storage tank through a discharge pipeline E via the pressure relief discharger and the heat exchanger in sequence. The sludgepyrohydrolysis system is simple in structure, relatively low in cost, high in pyrohydrolysis efficiency, energy-saving and environment-friendly.

Owner:湖州中环水务有限责任公司 +1

Building method of aluminum electrolysis cell

The invention relates to a building method of an aluminum electrolysis cell, which comprises a conventional building method and comprises the following building steps: (1) when cathode blocks of the electrolysis cell are manufactured, symmetrically chamfering the upper end part of each cathode block along the longitudinal direction, and forming a transverse groove at the top of each cathode block; (2) when the cathode blocks are built, reserving a gap of 20-40mm between every two adjacent cathode blocks, and tamping the gap by cathode tamping paste, wherein the opposite chamfers of the adjacent cathode blocks and the cathode tamping paste filled into the gap form a trapezoidal groove, and the depth of the trapezoidal groove is the same as the depth of the transverse groove at the top of each cathode block; and (3) forming one or two longitudinal grooves at the bottom of each cathode block, laying steel bars of corresponding sizes in each longitudinal groove, and tamping the gap between each cathode block and each steel bar by cathode steel bar paste. The aluminum electrolysis cell built by the method can greatly reduce the horizontal current in aluminum liquid to enable the current density of the cathode blocks and the cathode steel bars to be more uniform, thereby greatly prolonging the service life of the electrolysis cell.

Owner:SNTO TECH GRP

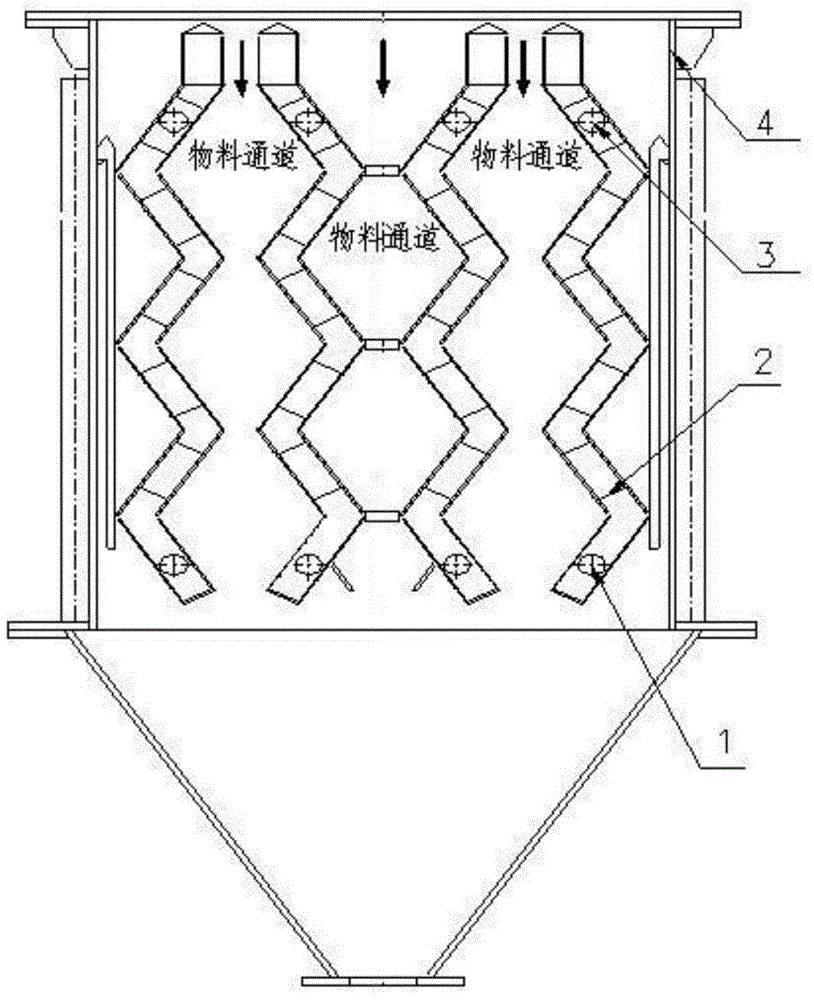

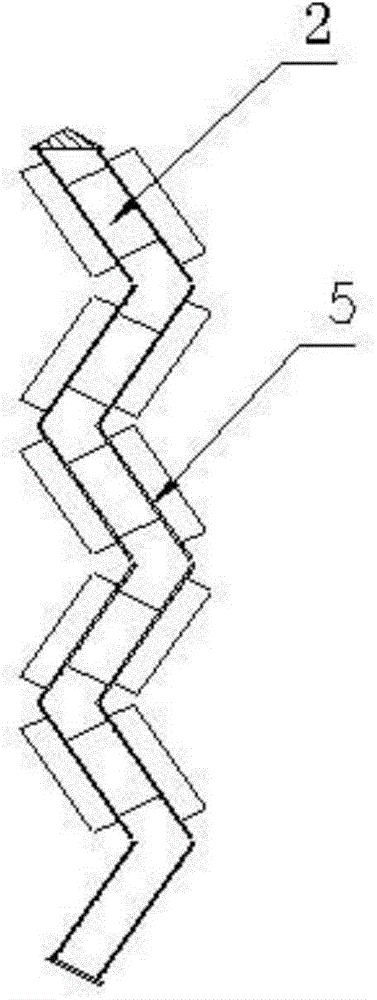

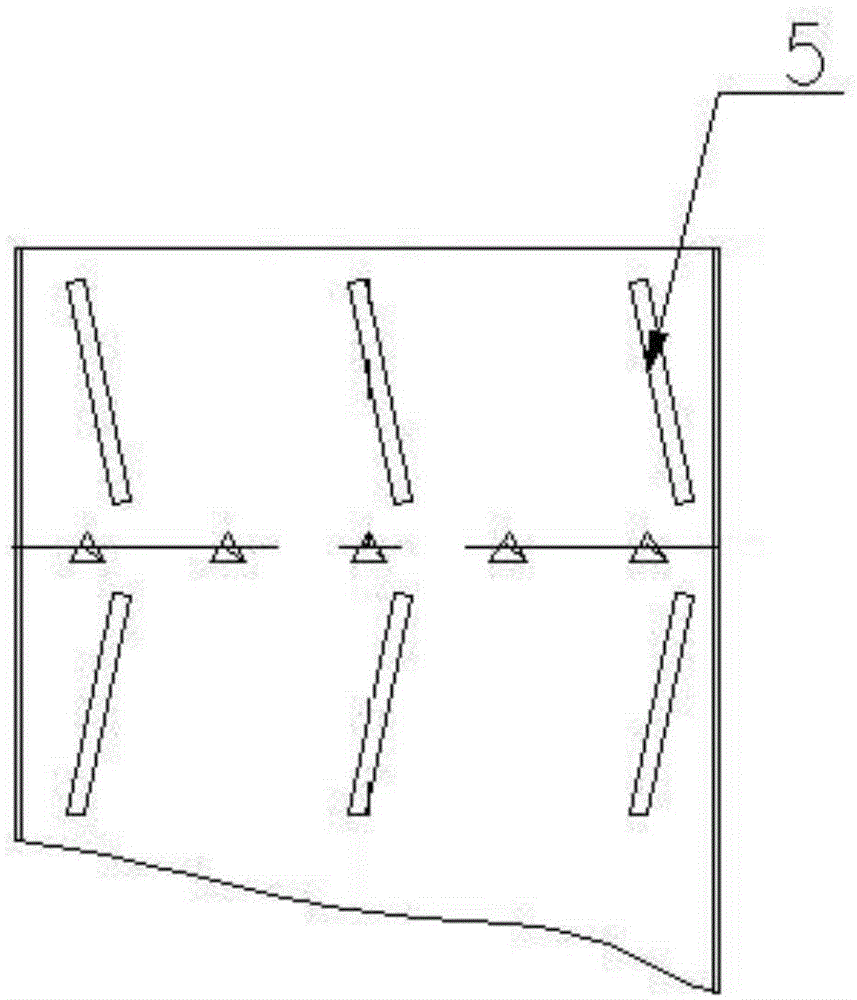

Vertical type powdered coal drying preheating device based on partition wall heat exchange

The invention discloses a vertical type powdered coal drying preheating device based on partition wall heat exchange. The vertical type powdered coal drying preheating device comprises an air inlet, an air discharge pipe, heat exchange cavities, a shell and a thin wall plate. The vertical type powdered coal drying preheating device is characterized in that the shell is arranged perpendicular to the ground; two ends of each heat exchange cavity are respectively provided with the air inlet pipe and the air discharge pipe, at least two heat exchange cavities are both arranged in the shell, a material channel is reserved between the heat exchange cavity and the heat exchange cavity, and the outer surface of the heat exchange cavity is welded on the thin wall plate. The vertical type powdered coal drying preheating device based on partition wall heat exchange, which is disclosed by the invention, is simple in structure and can be used for increasing the radiating area, changing the flow state of a coal material and enhancing the heat exchange effect.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Multi-cold water pipe and multichannel heat absorption open-type communicating heat exchanger and manufacturing process thereof

InactiveCN102788523AAchieve heat exchange effectSave materialArc welding apparatusStationary tubular conduit assembliesEngineeringThermal water

The invention discloses a multi-cold water pipe and multichannel heat absorption open-type communicating heat exchanger and a manufacturing process thereof and is used for changing cold water into hot water to take a bath in families. Porous inner plates are respectively and fixedly welded in both ends of more than two heat supply pipes; end sealing plates are fixedly welded outside both ends of each heat supply pipe; cold water heat collection distribution chambers are formed by the porous inner plates and the end sealing plates; each two heat supply pipes are welded to be communicated through a heat supply pipe communicating straight pipe; more than two cold water pipes are interpenetrated into each heat supply pipe; both ends of each cold water pipe and the porous inner plates are welded to be communicated in the manner of opening; a cold water communicating pipe penetrates through the heat supply pipe communicating straight pipe, and both ends of the cold water communicating pipe and the porous inner plates in the adjacent two heat supply pipes are welded to be communicated; a cold water inlet / outlet and the cold water heat collection distribution chambers of side pipes at both sides of the heat supply pipes are welded to be communicated; and a warm air inlet / outlet and the side pipes at both sides of the heat supply pipes are welded to be communicated. According to the multi-cold water pipe and multichannel heat absorption open-type communicating heat exchanger disclosed by the invention, the heat absorption area is increased by fully utilizing an effective heat source through multi-dividing wall heat absorption and stepped heat transfer, therefore, the heat absorption is rapid, and the heat exchange efficiency that the temperature is changed in the manner of gradient is high.

Owner:张伟

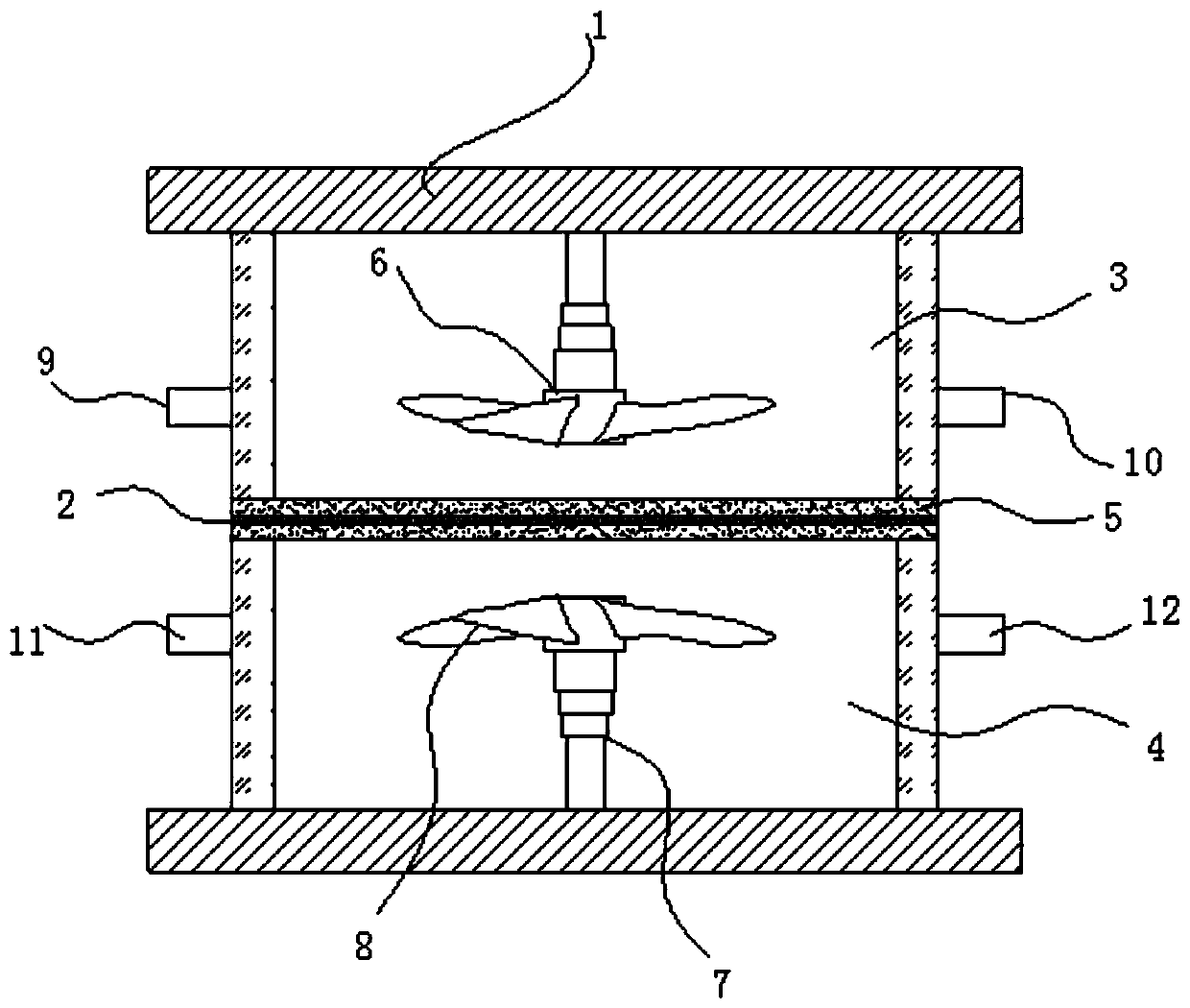

Positive osmosis membrane module for slowing down external concentration polarization and membrane pollution

PendingCN110201543AReduce pollutionChange flow stateSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisImpellerConcentration polarization

The invention discloses a positive osmosis membrane component for slowing down external concentration polarization and membrane pollution. A positive osmosis membrane divides a permeation device bodyinto a raw material liquid side corridor and a suction liquid side corridor, the connecting part of the positive osmosis membrane and the permeation device body is sealed by a sealing ring; and impellers are arranged in the raw material liquid side corridor and the suction liquid side corridor. The raw material liquid side corridor is provided with a raw material liquid side water inlet and a rawmaterial liquid side water outlet. The suction liquid side corridor is provided with a suction liquid side water outlet and a suction liquid side water inlet. A raw material liquid enters the raw material liquid side corridor through the raw material liquid side water inlet, flows out from the raw material liquid side water outlet, drives the impeller to rotate in the flow process, a suction liquid flows out from the suction liquid side water outlet, and drives the impeller to rotate in the flow process, the liquid flow state is changed, and the liquid mixing speed is accelerated. The positiveosmosis membrane component has the beneficial effects that the rotation of the impellers changes the fluid flow state, thereby slowing down the polarization phenomenon of the external concentration difference, improving the membrane flux and reducing the membrane pollution.

Owner:SOUTHWEST JIAOTONG UNIV

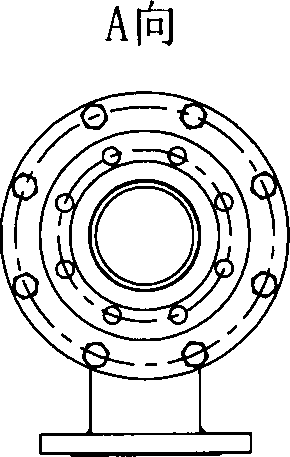

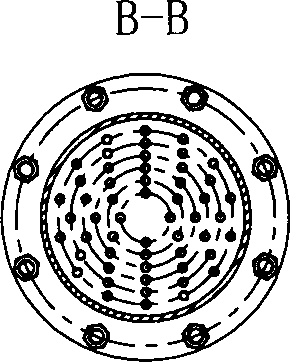

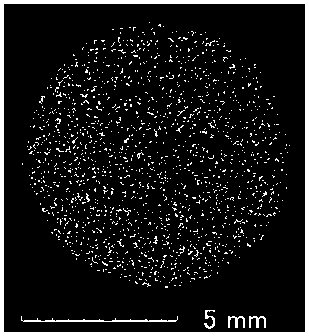

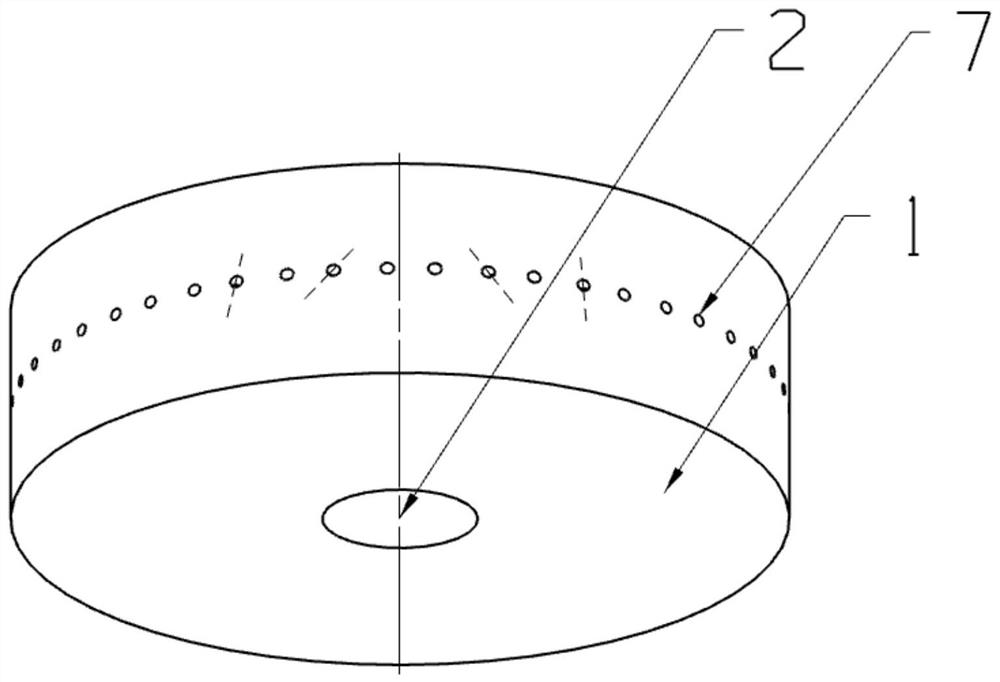

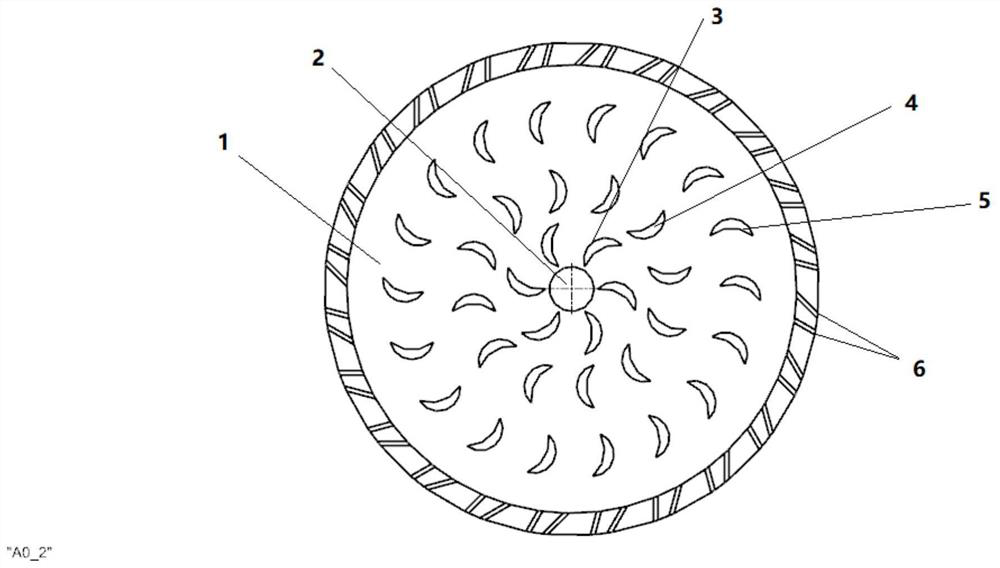

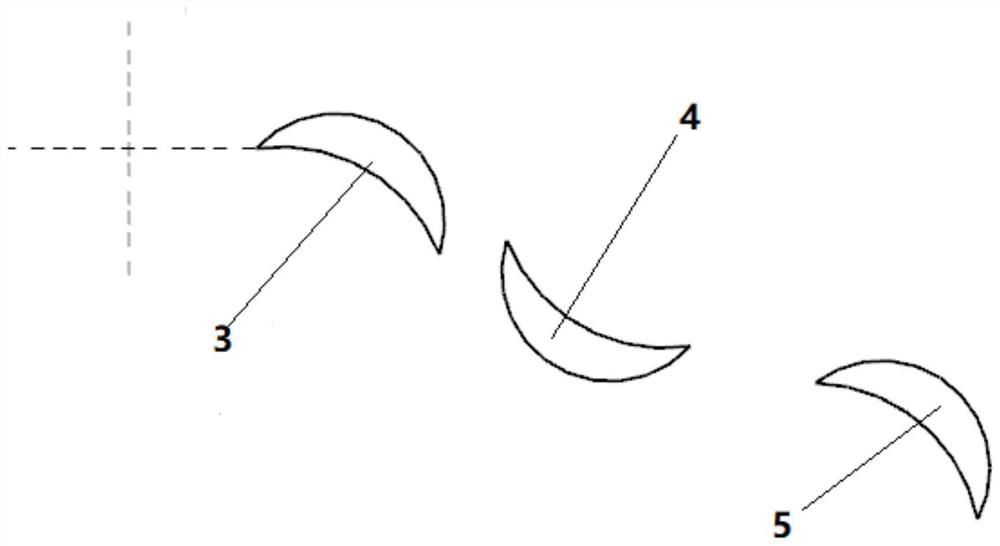

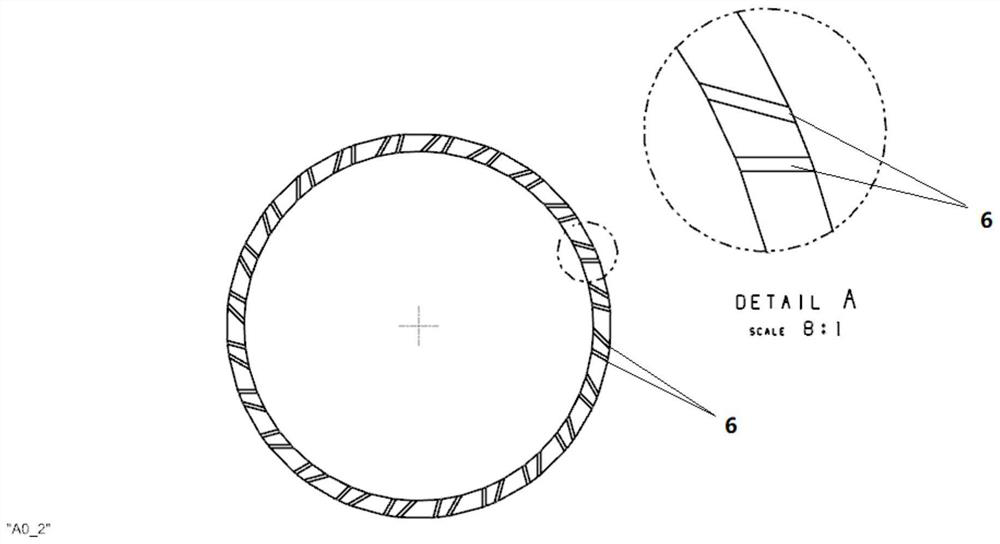

Tool cathode and method for improving flatness of electrolytic milling bottom surface

The invention relates to a tool cathode capable of improving the flatness of the bottom face subjected to electrolytic milling and grinding machining and a method and belongs to the field of electrolytic milling and grinding composite machining. A plurality of water outlet holes are distributed in the end face of the tool cathode and covered with an abrasive grain layer. The radii of the end facewater outlet holes are equal, and the circular centers of the water outlet holes are located on intersection points of a plurality of concentric circles and straight lines. The circular centers of theconcentric circles serve as the center of the end face of the tool cathode, and the radii of the concentric circles are increased sequentially. The straight lines all pass through the center of the end face of the tool cathode, the number of the straight lines is equal to the number of the concentric circles, and the included angles between all the adjacent straight lines are equal. All the end face water outlet holes are symmetrically distributed along the straight line. In work, because of the effect of the end face water outlet holes, an electrolyte rapidly flows towards the two sides of the machined bottom face of a workpiece, flowing of the electrolyte in the middle area of the machined bottom face of the workpiece is restrained, and finally the machined bottom face, with the good flatness, of the workpiece can be obtained. The flatness of the bottom face subjected to electrolytic milling and grinding machining can be effectively improved, and application and popularization of the technology are promoted.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

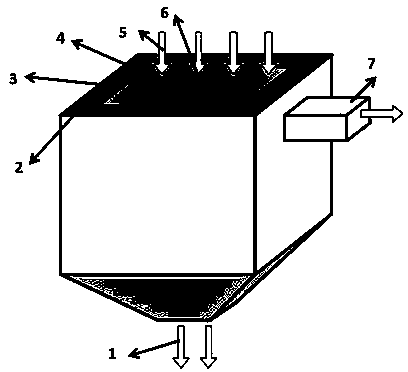

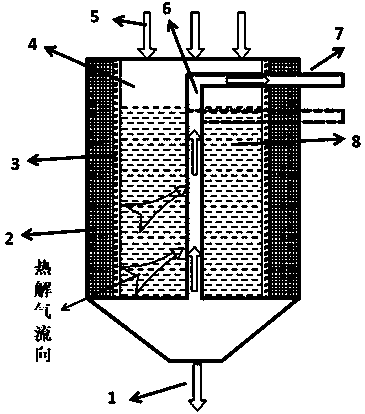

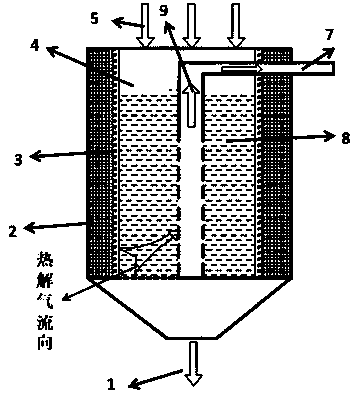

Oriented pyrolysis reactor based on ray heating

The invention discloses an oriented pyrolysis reactor based on ray heating, and relates to a pyrolysis reactor. The reactor device comprises a semi-coke outlet (1), a heat insulation and reflection layer (2), a ray emission source (3), a ray heating chamber (4), a pyrolysis sample inlet (5), a pyrolysis gas outlet (7) and a pyrolysis product channel (6) which is arranged in the ray heating chamber; and ray heating is used to achieve rapid and efficient pyrolysis of low-order fossil energy, renewable wastes and other materials. A gas flow path for the pyrolysis gas to flow from a high-temperature zone to a low-temperature zone is formed. The reactor has prominent characteristics when used, achieves rapid heating by using rays, achieves rapid heat transfer through improving the gas directionby internal members, reduces secondary reactions, and facilitates the improvement of the yield and the quality of tar through the filtering bed effect of centralized centering output of the gas. Thereactor has the advantages of reliability and easiness in design, reasonable structure, suitableness for various pyrolysis materials, and good industrial amplification prospect, and can be widely promoted and applied.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

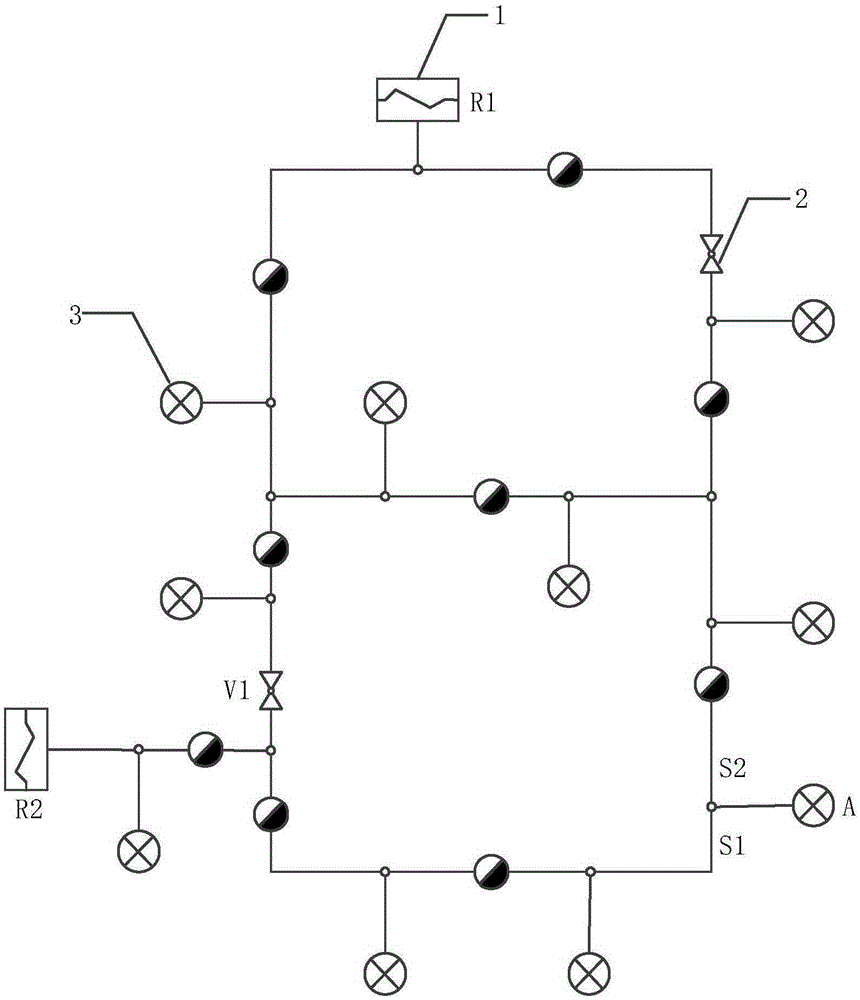

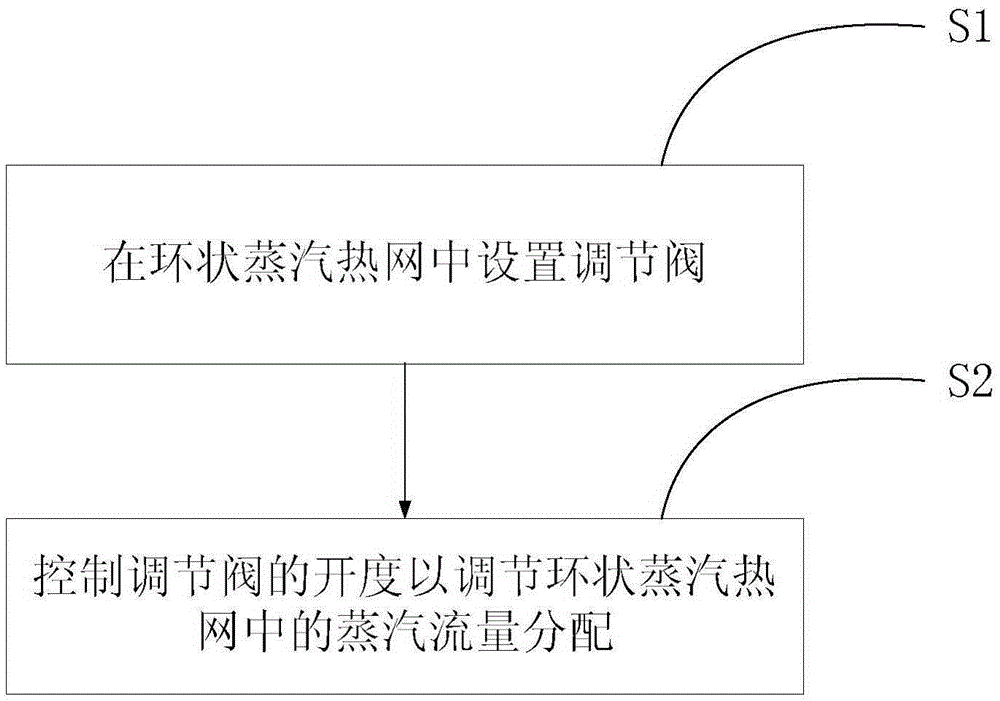

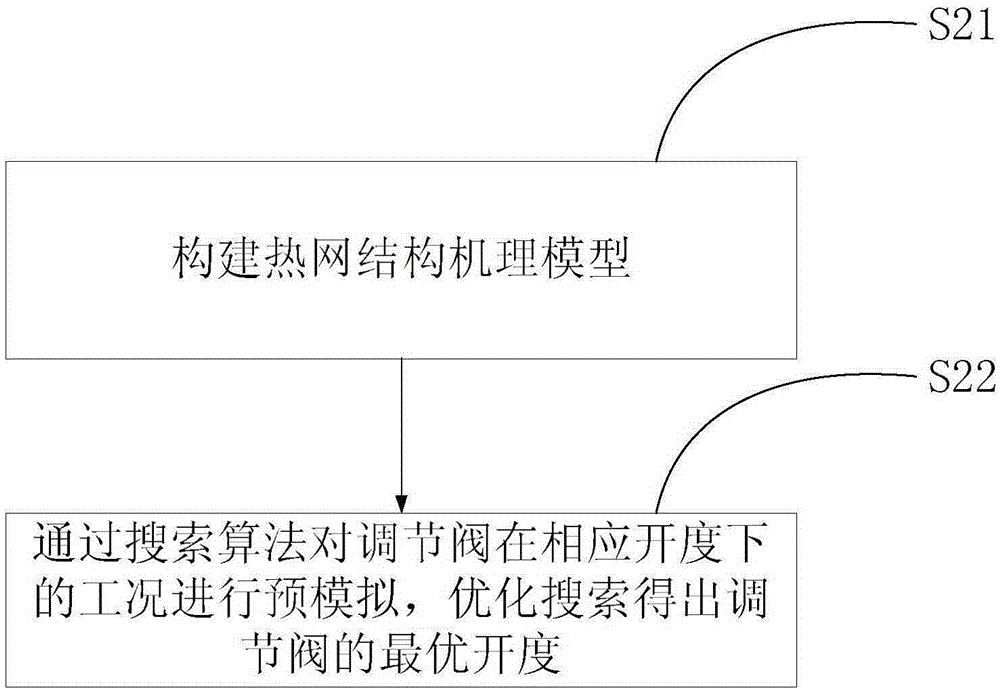

Online optimization and adjustment method and system for steam supply quality of annular steam heat-supply network

ActiveCN105240688AOptimize the quality of steam supplyChange allocationPipeline systemsTraffic capacityAutomatic control

The invention relates to an online optimization and adjustment method and system for a steam supply quality of annular steam heat-supply network. The method comprises the steps that S1, an adjustment valve is additionally arranged inside the annular steam heat-supply network; and S2, the opening degree of the adjustment valve is controlled to adjust the flow distribution of steam inside the annular steam heat-supply network so that adjustment can be achieved to reach the steam quality of each heat user in the annular steam heat-supply network system. As the adjustment valve is additionally arranged in the annular steam heat-supply network, the ideal opening degree optimization scheme of the adjustment valve is obtained through an intelligent searching algorithm, and the opening degree of the adjustment valve is adjusted by an automatic control system, so that the flow distribution and flow state of the steam in the annular steam heat-supply network are changed, optimization of the steam supply quality of the annular steam heat-supply network under different working conditions is achieved, the defect that long time is wasted as a traditional searching algorithm adopts enumeration calculation and comparison is also overcome, and the computational efficiency is improved.

Owner:CHANGZHOU ENGIPOWER TECH

Fabricated coast wave-proof dam

InactiveCN105862674ADefuse destructive powerChange flow stateCoastlines protectionEnvironmental effectSea waves

The invention relates to a fabricated coast wave-proof dam and in particular relates to a fabricated coast wave-proof dam which is applicable to coast retaining wall and guard dam with strong wind and high waves and resistant to wave impact. The fabricated coast wave-proof dam is of the structure that a plurality of prefabricated concrete dam block bodies are mutually plugged and piled up in a shape of stairs to a design height, wherein the concrete dam blocks are classified into four types A, B, C and D. The fabricated coast wave-proof dam has the advantages that all the concrete dam blocks are respectively prefabricated in a factory, transported to a construction site and then positioned and mounted, concrete does not need to be poured on the spot, mounting is convenient and efficient, environmental influence is small, the prefabricated concrete dam blocks are subjected to fixed size standardized production in the factory, production efficiency is high, product quality is good, and manpower resource is greatly saved; and the fabricated coast wave-proof dam can effectively release and relieve a wave impact force, collapsing force of wave to a dam is resolved, safety is enhanced, and service life of the wave-proof dam is greatly prolonged.

Owner:SHENYANG JIANZHU UNIVERSITY

Double-turbulent-flow combined oil flinger

InactiveCN113028452AImprove combustion efficiencyBroken atomization effect is goodContinuous combustion chamberCooling effectEngineering

The invention provides a double-turbulent-flow combined oil flinger. The double-turbulent-flow combined oil flinger is composed of a flinger body, a flow divider, special-shaped turbulent-flow blades, bubble distribution turbulent-flow columns and opposite punching holes. The flow divider is of a cover cap structure with a lateral opening and is installed on an oil inlet. The special-shaped turbulent-flow blades are evenly distributed at the outlet of the flow divider in the circumferential direction, and channels between the blades limit the flow direction of working media. The bubble turbulent-flow columns are different in size and are distributed at the rear ends of the turbulent-flow blades. And the opposite punching holes are alternately distributed in the central wall surface of the oil flinger. Fuel oil enters the flow divider from an oil inlet, then is forked and turned at the position of the turbulent-flow blades, and collides for multiple times in the area of the turbulent-flow columns to break a liquid film, and finally, a better atomization effect is achieved at a opposite punching nozzle. And moreover, the fuel oil has a cooling effect on a high-speed rotating shaft and can also be preheated, so that the combustion efficiency of an engine using the oil flinger is relatively high.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Pyrohydrolysis method of sludge

ActiveCN110734210AImproved thermal hydrolysis effectWell mixedSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeProcess engineering

The invention discloses a pyrohydrolysis method of sludge. The pyrohydrolysis method comprises the following steps: quickly and fully mixing sludge to be treated with steam, wherein introducing the sludge to be treated with a certain pressure into a first inlet of a steam sludge ejector, meanwhile, introducing steam with a certain pressure and temperature into a second inlet of the steam sludge ejector, and rapidly and fully mixing the sludge to be treated and the steam in the steam sludge ejector and then introducing an obtained mixture into a sludge pyrohydrolysis pipeline; carrying out pyrohydrolysis in the sludge pyrohydrolysis pipeline, wherein controlling the pyrohydrolysis temperature in the sludge pyrohydrolysis pipeline to be 110-225 DEG C, the pressure to be 0.5-3 Mpa, the reaction time to be 0.1-1 hour, and discharging the sludge obtained through pyrohydrolysis through a pressure relief discharger at a sludge outlet. The pyrohydrolysis method of sludge can quickly realize full mixing of steam and sludge, and is high in heat transfer efficiency; and energy saving and environment protection are achieved.

Owner:浙江绿治环保技术有限公司 +1

Combined oil thrower

ActiveCN111609424AImprove combustion efficiencyChange flow stateContinuous combustion chamberCooling effectEngineering

The invention provides a combined oil thrower. An engine using an oil thrower fuel nozzle is high in combustion efficiency, has a cooling effect on a shaft rotating at high speed, and also preheats fuels, so that atomization, evaporation and organization combustion are facilitated. A turbulent flow support column is arranged in a cavity, and an interactive nozzle is adopted, so that purposes of improving fuel atomization level and improving outlet temperature field distribution are achieved. A liquid working medium is collided, branched and turned by the turbulent flow support column device for multiple times, and a thin liquid film is torn and broken more thoroughly; and fuels thrown at high speed are collided at the nozzle, so that the final atomization effect is better.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com