Heat-exchange type ascending tube and coke oven

A heat-exchanging, coke oven technology, applied in the coking field, can solve the problems of increased water consumption in the condensing blast section, increased raw gas recovery costs, and increased ammonia water consumption, so as to reduce industrial water consumption, reduce energy consumption, and reduce The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The heat-exchanging riser pipe provided in Embodiment 1 is used to connect the coke oven carbonization chamber and the bridge pipe, so as to introduce the raw coal gas discharged from the coke oven carbonization chamber into the bridge pipe for cooling. Different from the prior art, when the raw coal gas flows through the heat exchange riser, part of the heat is recycled.

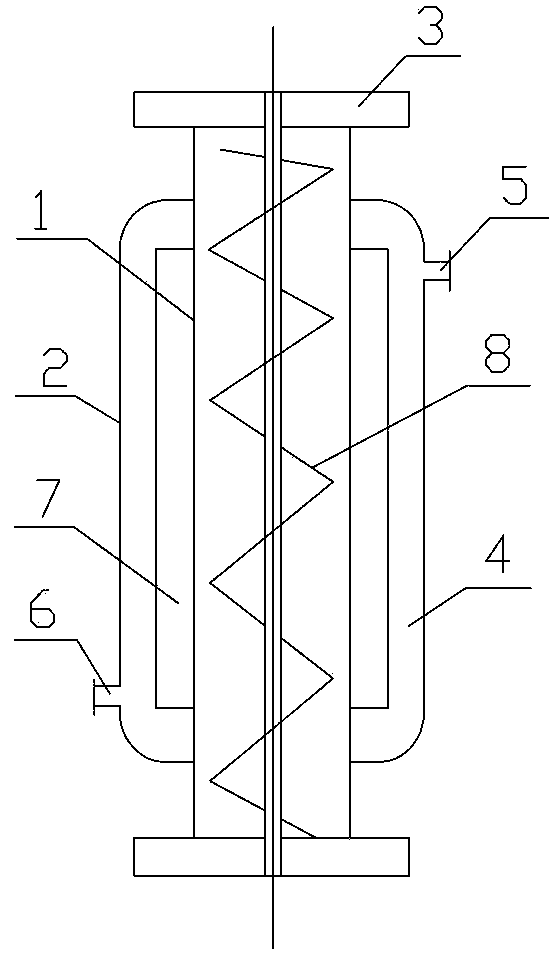

[0024] figure 1 It is a structural schematic diagram of a heat exchange riser according to Embodiment 1 of the present invention. like figure 1 As shown, the heat-exchanging riser includes an inner pipe 1 and an outer pipe 2. The inner pipe 1 is used to transport raw gas, and both ends of the inner pipe are provided with flanges 3 for connecting the coke oven carbonization chamber and the bridge pipe. The connection between the coking chamber of the coke oven and the bridge pipe can also use other connecting parts except the flange.

[0025] The outer tube 2 is sleeved on the outside of the inner ...

Embodiment 2

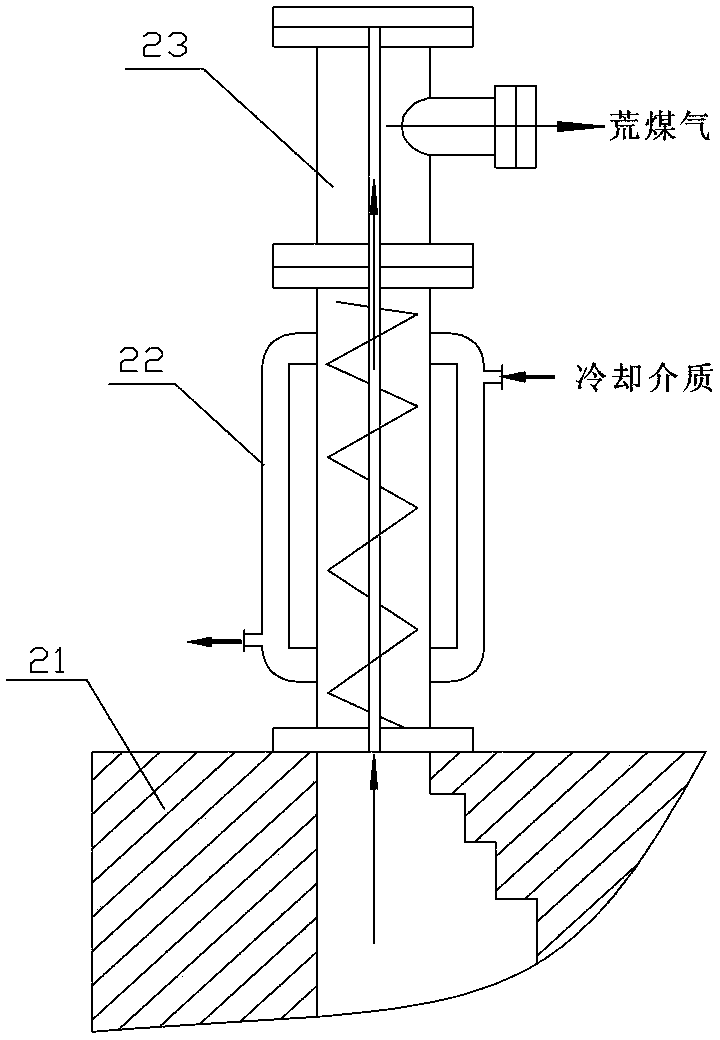

[0035] Embodiment 2 provides a coking oven, figure 2 It is a partial structural schematic diagram of the coke oven in Example 2 of the present invention. like figure 2As shown, the coke oven includes a coke oven carbonization chamber 21, a riser pipe 22 and a bridge pipe 23. One end of the riser pipe 22 communicates with the coke oven carbonization chamber 21, and the other end of the riser pipe 22 communicates with the bridge pipe 23. The raw coal gas that 21 discharges enters bridge pipe 23 through riser pipe 22. In the second embodiment, the riser 22 adopts the heat exchange type riser described in the first embodiment, the temperature of the raw coal gas can be reduced by means of the heat exchange type riser, and part of the heat in the raw gas can be recovered and utilized.

[0036] In the coke oven provided in Example 2, the riser pipe used to connect the coke oven carbonization chamber and the bridge tube adopts the heat exchange type riser pipe provided by the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com