Cyclone dust collector with spiral air inlet pipe

A technology of cyclone dust collector and air inlet pipe, which is applied in the direction of the device where the axial direction of the swirl flow can be reversed, the swirl flow device, etc., which can solve the problem of secondary dust raising, affecting the dust removal efficiency of the dust collector, and gas-solid separation of the dust collector Performance degradation and other problems, to achieve high separation efficiency and reduce the effect of secondary dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

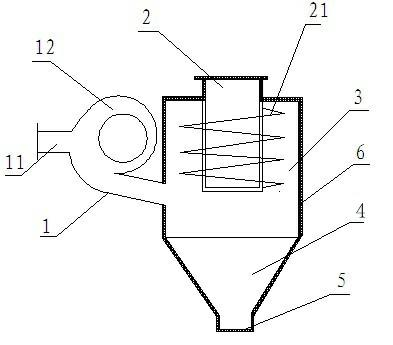

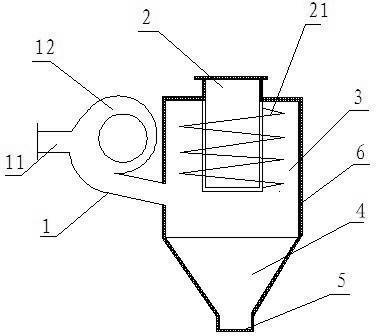

[0014] see figure 1 , the embodiment of the present invention comprises: air inlet pipe 1, cyclone 3, air exhaust pipe 2, spiral guide vane 21, conical ash collector 4 and ash discharge port 5, and air inlet pipe 1 is arranged on one side of cyclone 3 , the spiral guide vane 21 is fixed on the exhaust pipe 2 and the lower end extends into the cyclone 3, the lower end of the cyclone 3 is connected with a conical ash collector 4 communicating with the cyclone 3, and the lower end of the ash collector 4 is provided with an ash discharge port 5. The air inlet pipe 1 is a spiral pipe 12 structure, one end is an air inlet 11, and the other end is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com