Combined oil thrower

An oil thrower and combined technology, which is applied in combustion methods, combustion chambers, combustion equipment, etc., can solve the problems of uneven oil throwing, small fuel atomization cone angle, and improvement of crushing and atomization effects, etc., to achieve Better atomization effect and better outlet temperature field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described now in conjunction with accompanying drawing:

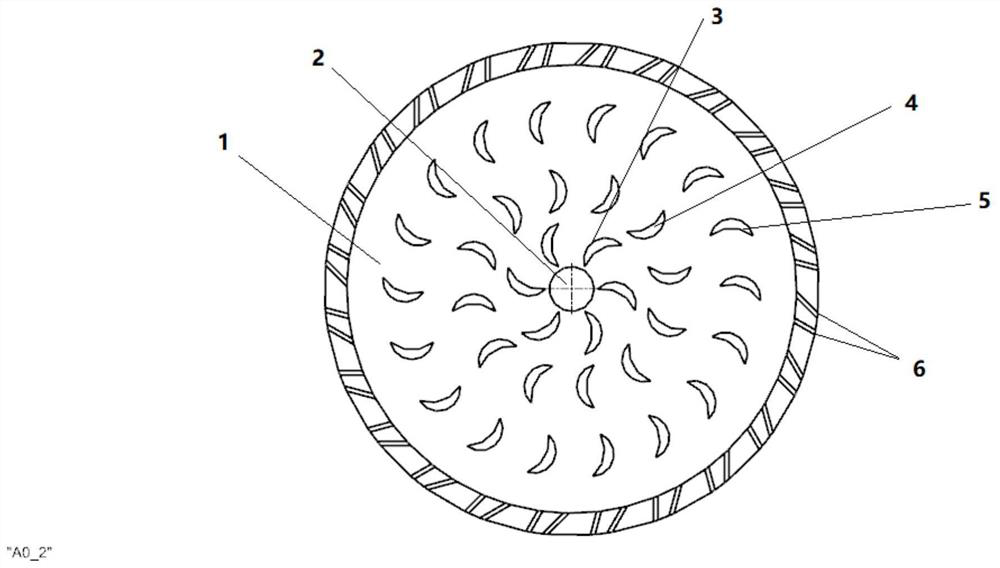

[0021] combine figure 1 , the invention provides a combined oil flinger.

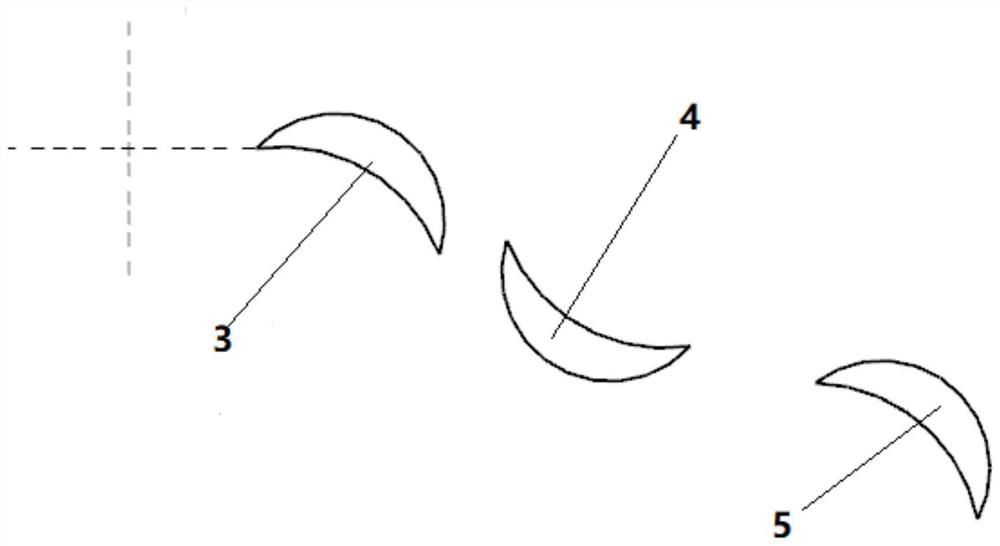

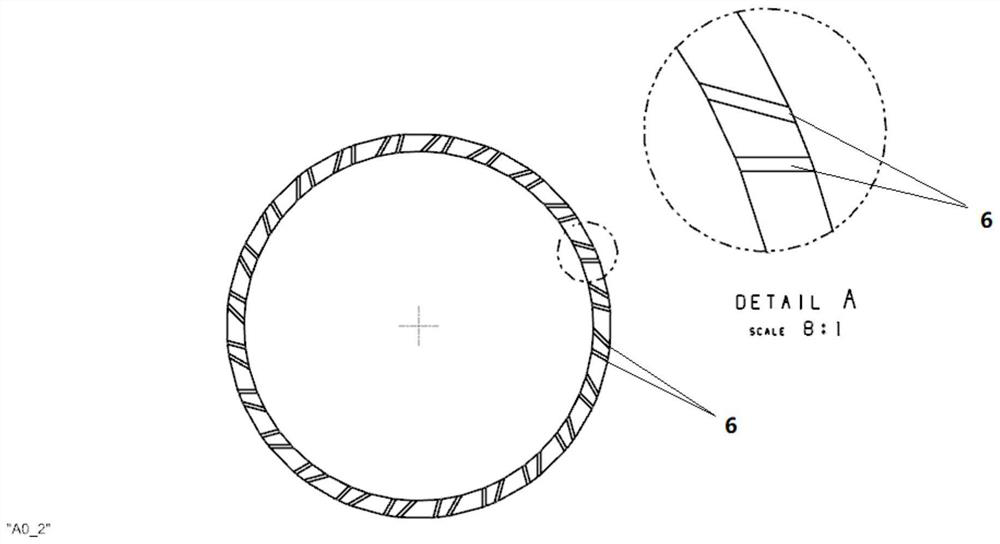

[0022] Specific process: liquid fuel flows into the cavity of the oil thrower through the inlet 2 of the oil delivery pipe, and passes through the equalizer 3, which is the first-level spoiler column, to ensure that the amount of fuel injected by each oil hole is equal and the temperature field at the outlet of the combustion chamber is evenly distributed. Afterwards, it flows through the secondary spoiler column 4 and the third-stage spoiler column 5 in sequence. Due to the high-speed rotation of the main disc 1 of the oil thrower, the fuel in the cavity is expanded into a thin film. When the thin film impacts the spoiler strut device, the flow state of the liquid working medium is changed many times, colliding, bifurcating, changing direction, tearing, the shape of the thin liquid film changes more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com