Patents

Literature

94results about How to "Reduce secondary dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

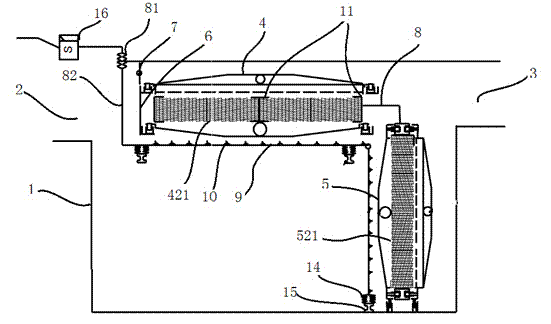

Method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in evaporation manner and device of method

InactiveCN102380278ALow running costConvenient sourceCombination devicesWater/sewage treatmentAir preheaterFlue gas

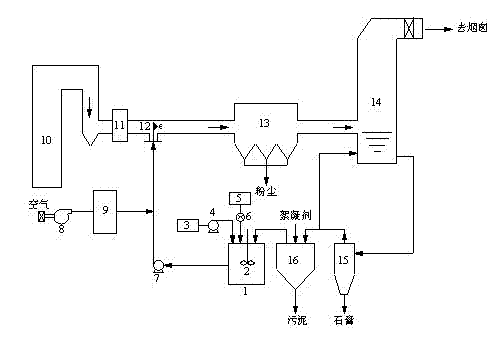

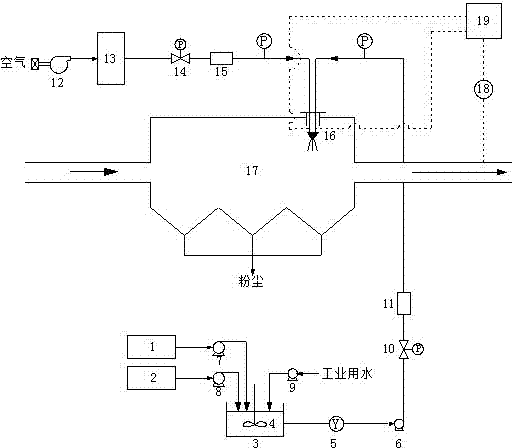

The invention discloses a method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in an evaporation manner and a device of the method. The method particularly includes steps that agglomeration liquor prepared by desulfuration wastewater, high polymer adhesive and wetting agent is sprayed into an inlet flue of an electric precipitator and is evaporated by the aid of heat of flue gas, in an evaporation process, the wetting agent promotes dust to enter drops of the agglomeration liquor, the high polymer adhesive is connected with PM2.5 via a polymer chain with polar groups, the grain diameter of the PM2.5 is prompted to be enlarged, so that the PM2.5 can be gathered by the follow-up electric precipitator, the desulfuration wastewater is evaporated completely, suspended matters and dissolvable pollutants in the wastewater are converted into solid to be dissolved out, and the suspended matters and the dissolvable pollutants in the wastewater, together with dust in the flue gas, are gathered by the electric precipitator. The device consists of a boiler, an air preheater, the electric precipitator, a desulfurizing tower, a hydraulic cyclone, a desulfuration wastewater clarification tank and an agglomeration liquor preparation tank, and a double-fluid atomizing nozzle is arranged in the flue between the air preheater and the electric precipitator.

Owner:SOUTHEAST UNIV

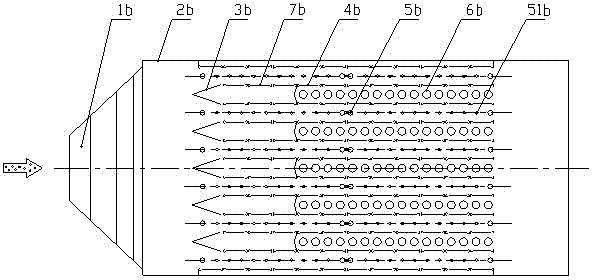

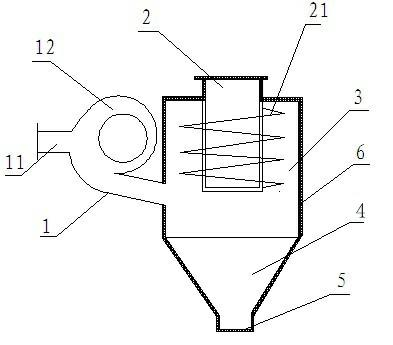

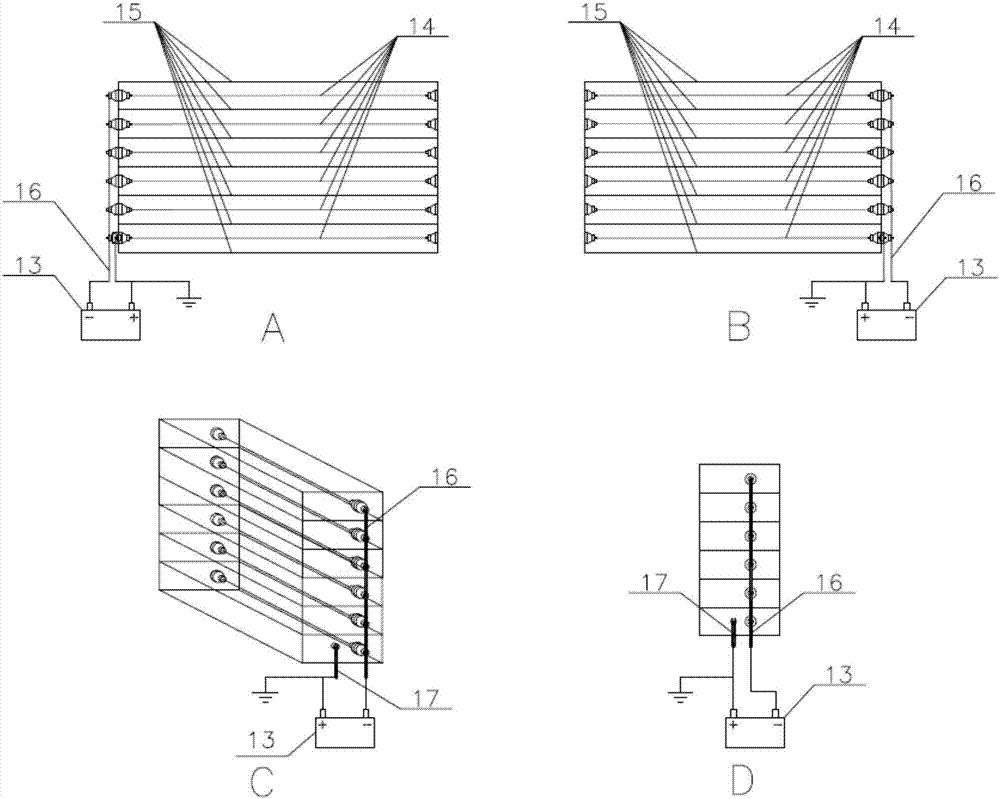

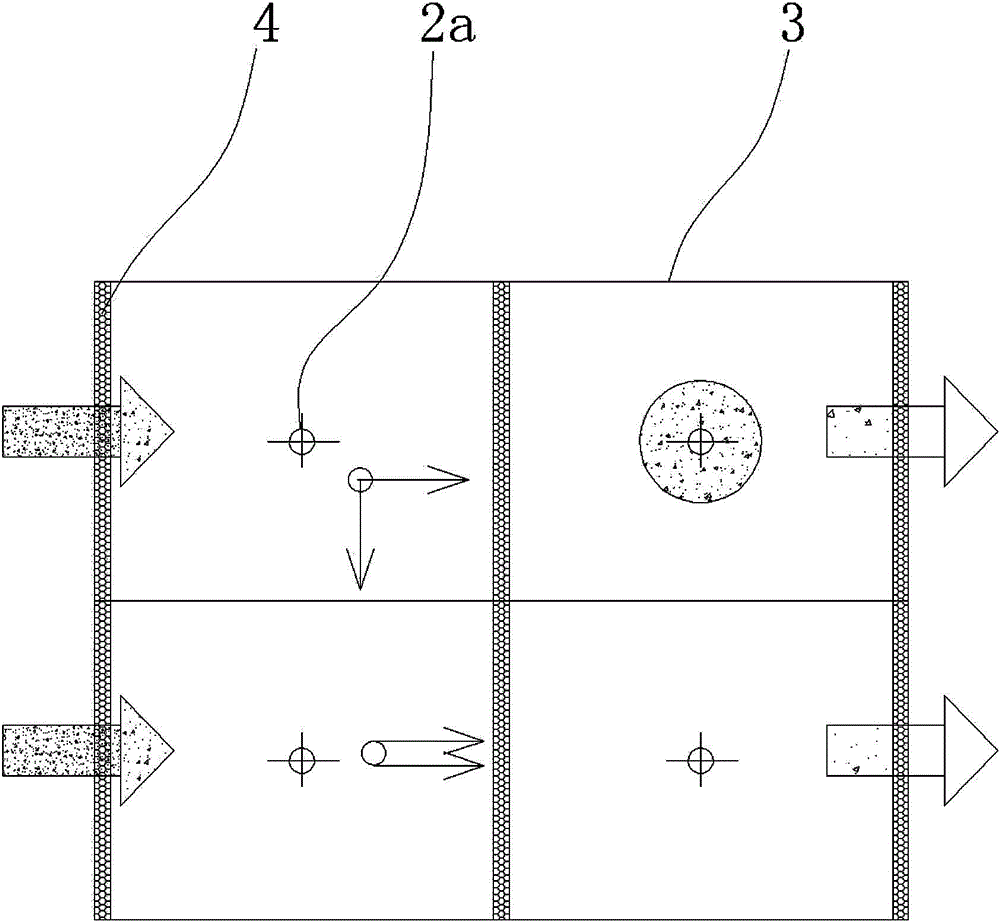

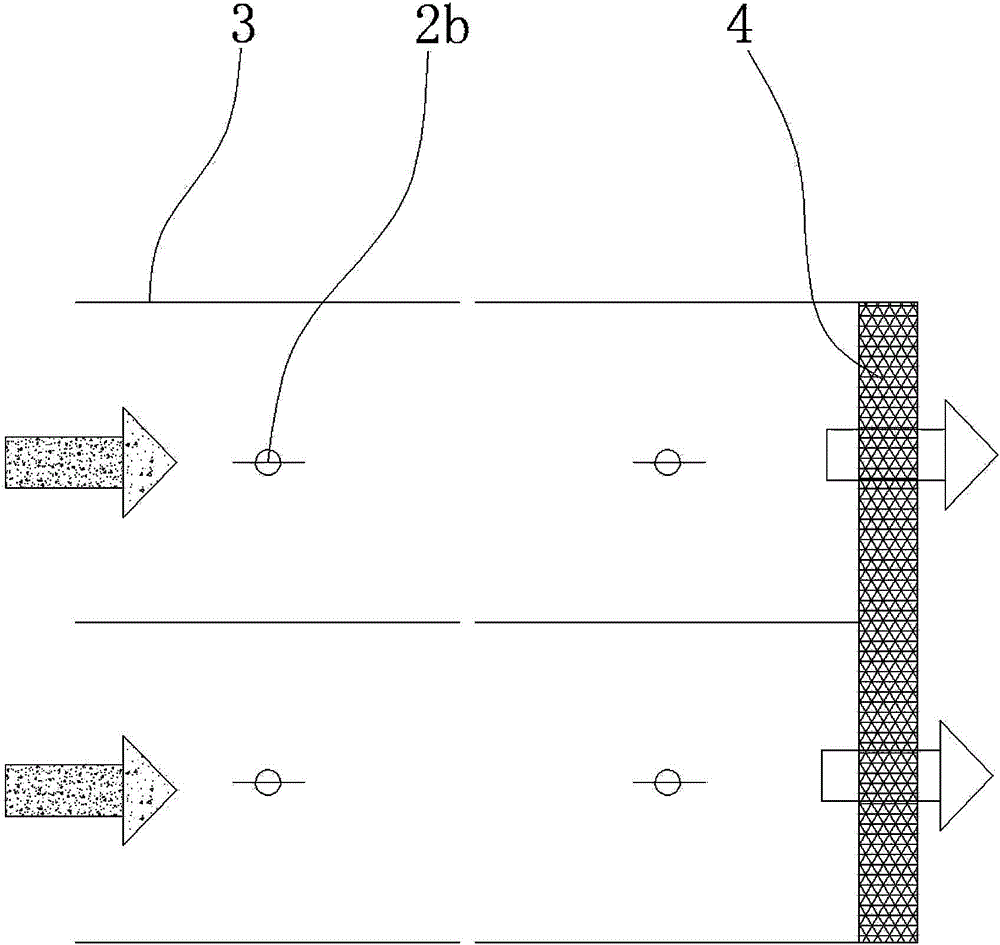

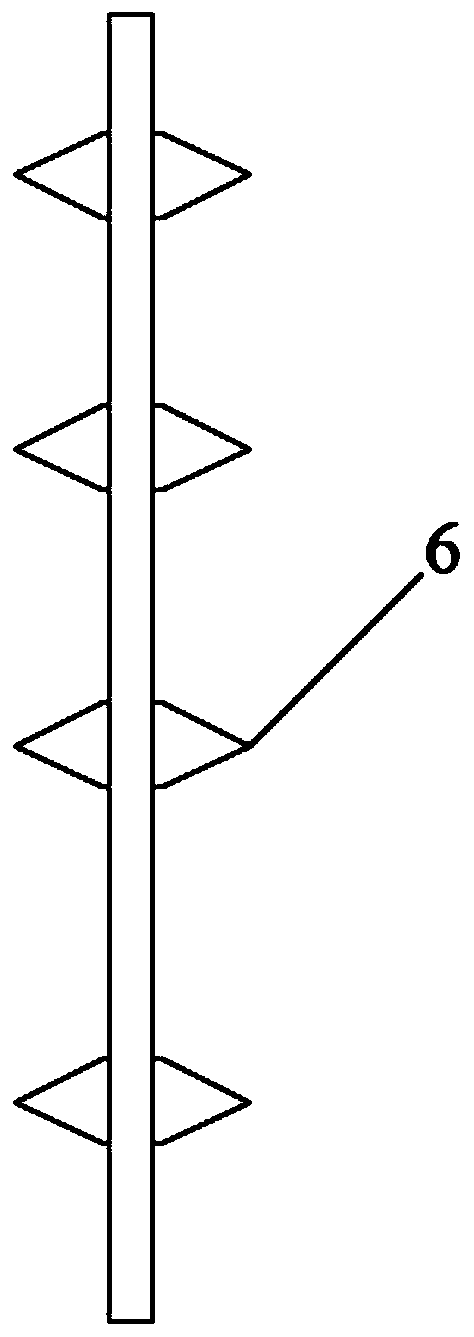

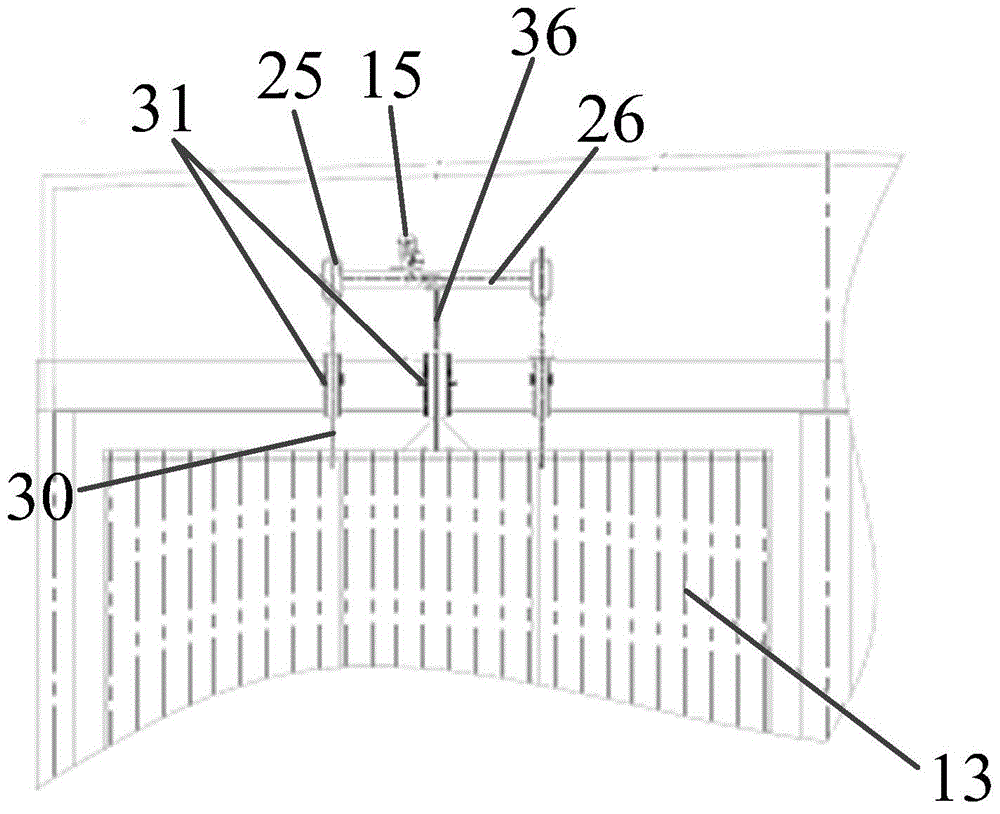

Transverse polar plate bipolar static agglomeration dedusting device and dedusting method thereof

InactiveCN103817007AAvoid scourReduce secondary dustElectrode constructionsHigh-voltage direct currentEngineering

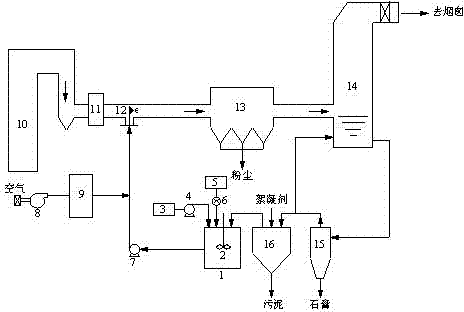

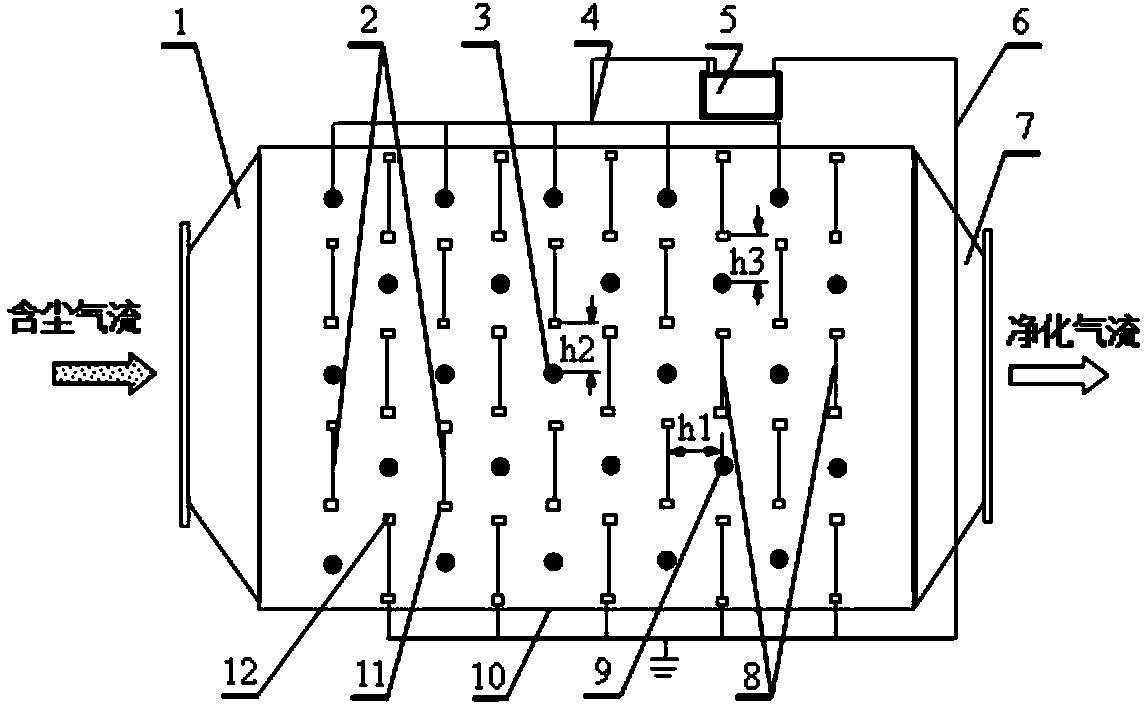

The invention discloses a transverse polar plate bipolar static agglomeration dedusting device and a dedusting method thereof, which solve the problem that the conventional dedusting device is complex in structure and relatively poor in dedusting effect. The invention adopts the technical scheme that the transverse polar plate bipolar static agglomeration dedusting device comprises a deduster casing as well as an air inlet pipe and an air outlet located at the two ends of the deduster casing; a plurality of cathode frameworks and a plurality of anode frameworks are vertically, alternately and uniformly arranged in the deduster casing in the direction of an airflow; a plurality of cathode plates and a plurality of cathode coronal lines are alternately and uniformly distributed on the cathode frameworks in the vertical direction, and a plurality of anode plates and a plurality of anode coronal lines are alternately and uniformly arranged on the anode frameworks; moreover, the cathode coronal lines are corresponding to the central lines of the adjacent anode plates in the direction of the airflow, and the anode coronal lines are corresponding to the central lines of the adjacent cathode plates in the direction of the airflow; the cathode frameworks are connected with the high-voltage output ends of a high-voltage DC power supply via a high-voltage cable, and the anode frameworks are connected with the grounding pole of the high-voltage DC power supply via a grounding cable. The transverse polar plate bipolar static agglomeration dedusting device is simple in structure, small in size, simple and convenient to operate, outstanding in the dust collection effect of the reverse sides of the transverse polar plates, small in reentrainment of dust, and has the effect of static agglomeration dedusting.

Owner:武钢集团有限公司 +1

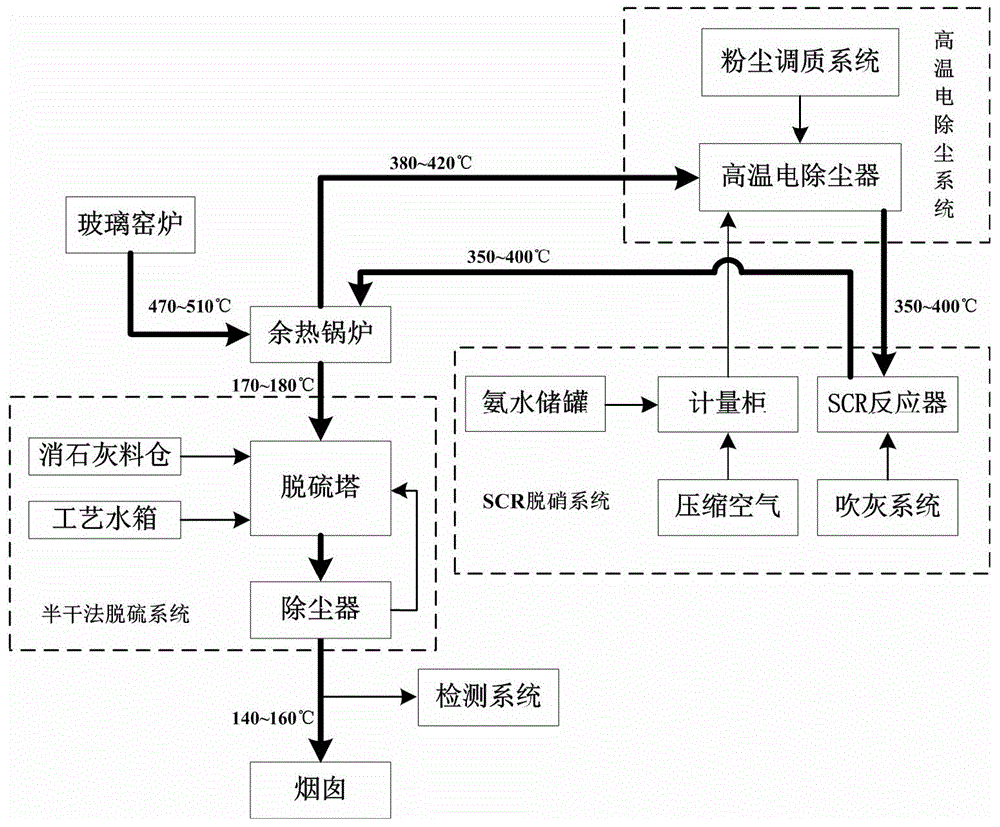

Comprehensive purification process of glass kiln smoke

InactiveCN104984640AImprove dust removal efficiencyHigh temperature resistantDispersed particle separationIncreasing energy efficiencyAtmospheric airEngineering

The invention discloses a comprehensive purification process of glass kiln smoke. The comprehensive purification process comprises the process flows of performing waste heat recovery on high-temperature smoke generated by a glass kiln through a waste heat boiler, leading the smoke into a high-temperature electric precipitator system for high-temperature smoke dust removal treatment in the section of the waste heat boiler at 380 to 420 DEG C, cooling the standard smoke after dust removal to 350 to 400 DEG C, so as to satisfy the requirement of the best active temperature of an SCR denitration catalyst, then leading the smoke after dust removal into an SCR denitration system for removing NOx, leading the smoke after denitration back to the waste heat boiler for waste heat recovery, and leading the smoke into a desulfurization system with a semidry method after the smoke in the waste heat boiler is cooled to 170 to 180 DEG C, so that the standard smoke after desulfurization is cooled to 140 to 160 DEG C and then is discharged into the atmospheric environment through a chimney. The glass kiln smoke after process treatment by adopting the comprehensive purification process reaches the regulations of related national environmental protection discharge standards of a glass industry, the dust discharge concentration is lower than 50 mg / m<3>, the NOx discharge concentration is lower than 700 mg / m<3>, and the SO2 discharge concentration is lower than 400 mg / m<3>.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

Roof greening structure and construction method

InactiveCN103982009AWith retentionDelay structural agingRoof improvementClimate change adaptationVegetationEngineering

The invention discloses a roof greening structure and a construction method. The roof greening structure comprises a waterproof polyurethane layer, a mortar protection layer, a waterproof leakproof two-cloth one-film layer, a plastic roof plant support module, a permeable filter layer, a filter layer, a matrix layer, a permeable filter layer, a plant layer and a vegetation layer which are overlapped or paved on the roof in sequence from the bottom to top. The roof greening structure is simple in structure, easy to implement and obvious in effect. The roof greening structure has advantages of heat insulation, rainwater interception, dust re-entrainment reducing, building structure aging delaying and building life span prolonging.

Owner:ANHUI GREEN BUILDING TECH

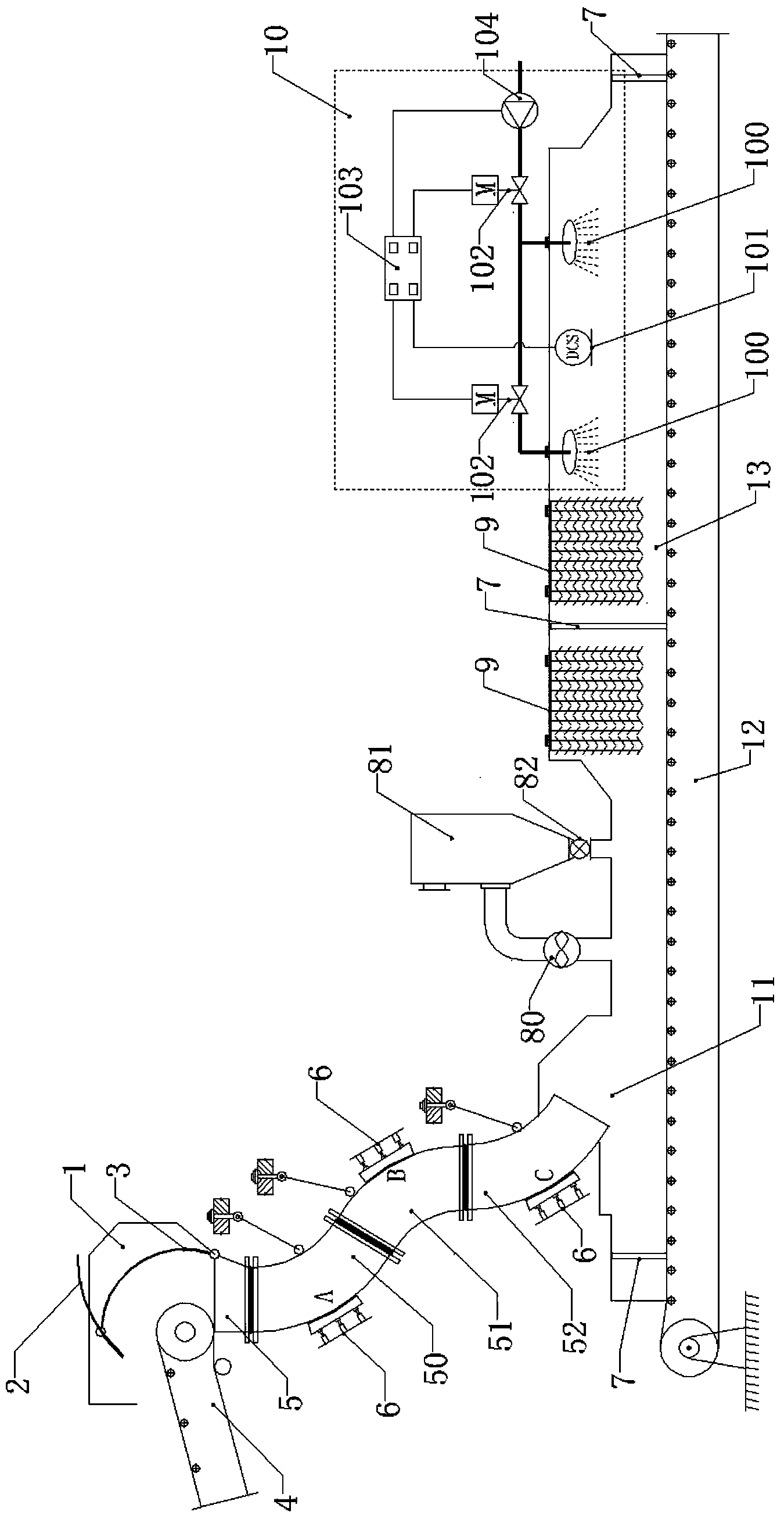

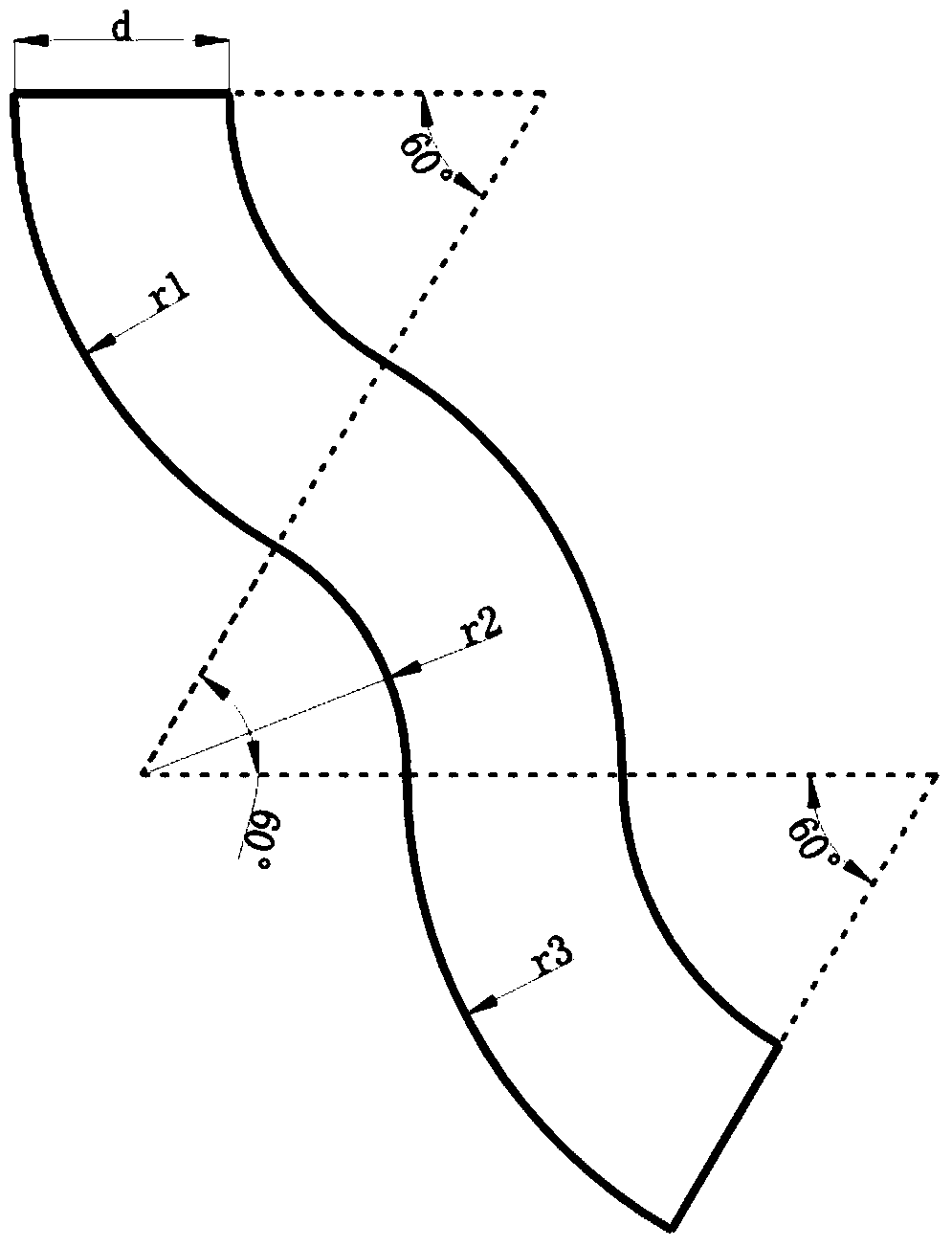

Anti-blockage, dust suppression and noise reduction coal transport system for power plant

ActiveCN104386470AGood dust removal effectEasy to remove cloth bagCleaningDiscrete element simulationThroat

The invention discloses an anti-blockage, dust suppression and noise reduction coal transport system for a power plant. The coal transport system comprises an upstream conveying device, a coal falling pipe and a downstream conveying device, wherein the discharging end of the upstream conveying device is used for feeding materials into the feeding hole of the coal falling pipe; the discharging hole of the coal falling pipe is used for feeding the materials to the feeding end of the downstream conveying device; the coal falling pipe comprises a throat hopper and a three-arc-segment coal falling pipe. The three-arc-segment coal falling pipe is designed on the basis of discrete element simulation EDEM, and has high coal type adaptability. By adopting a flow channel, the blockage of coal particles can be well prevented; meanwhile, the collision angles of the coal particles and a pipeline are reduced, and the advantage of reducing noise is realized. The three-segment coal falling pipe is spliced by adopting a deflection way, and a hydraulic damping device is arranged on a bend collision point, so that wear of the pipeline can be reduced effectively. Meanwhile, the speed of the coal particles is limited, soft landing of the coal particles and a downstream conveying belt is realized, impact on the conveying belt is reduced, and the production of dust is reduced.

Owner:SOUTHEAST UNIV

Method for improving efficiency of electric deduster for removing particulate matter 2.5 (PM2.5) dust in flue gas

InactiveCN103418491AIncrease moisture contentImprove removal efficiencyElectrostatic separationParticulatesFlue gas

The invention relates to the environmental protection technology field of flue gas, and particularly relates to a method for improving efficiency of an electric deduster for removing particulate matter 2.5 (PM2.5) dust in the flue gas. The flue gas is pretreated before entering the electric deduster, and a treatment method of coupling ultrasonic reunion by water vapor spraying is used for pretreatment; further the water vapor can be sprayed by cis-spraying, reverse spraying or sprayed with a certain angle with the flow direction of the flue gas, the spraying quantity of the water vapor is designed to be 0.02-0.1 kg / m<3>, and the temperature of the water vapor is 100-150 DEG C; and further while the water vapor is sprayed into the flue gas, the flue gas is also treated by ultrasonic, the ultrasonic frequency is selected to be 20 kHZ-30 kHZ, and the ultrasonic power is selected to be 80 W-400 W. After the pretreatment of the flue gas, the highest removal efficiency of the PM2.5 can reach above 99%.

Owner:国家电投集团远达环保装备制造有限公司

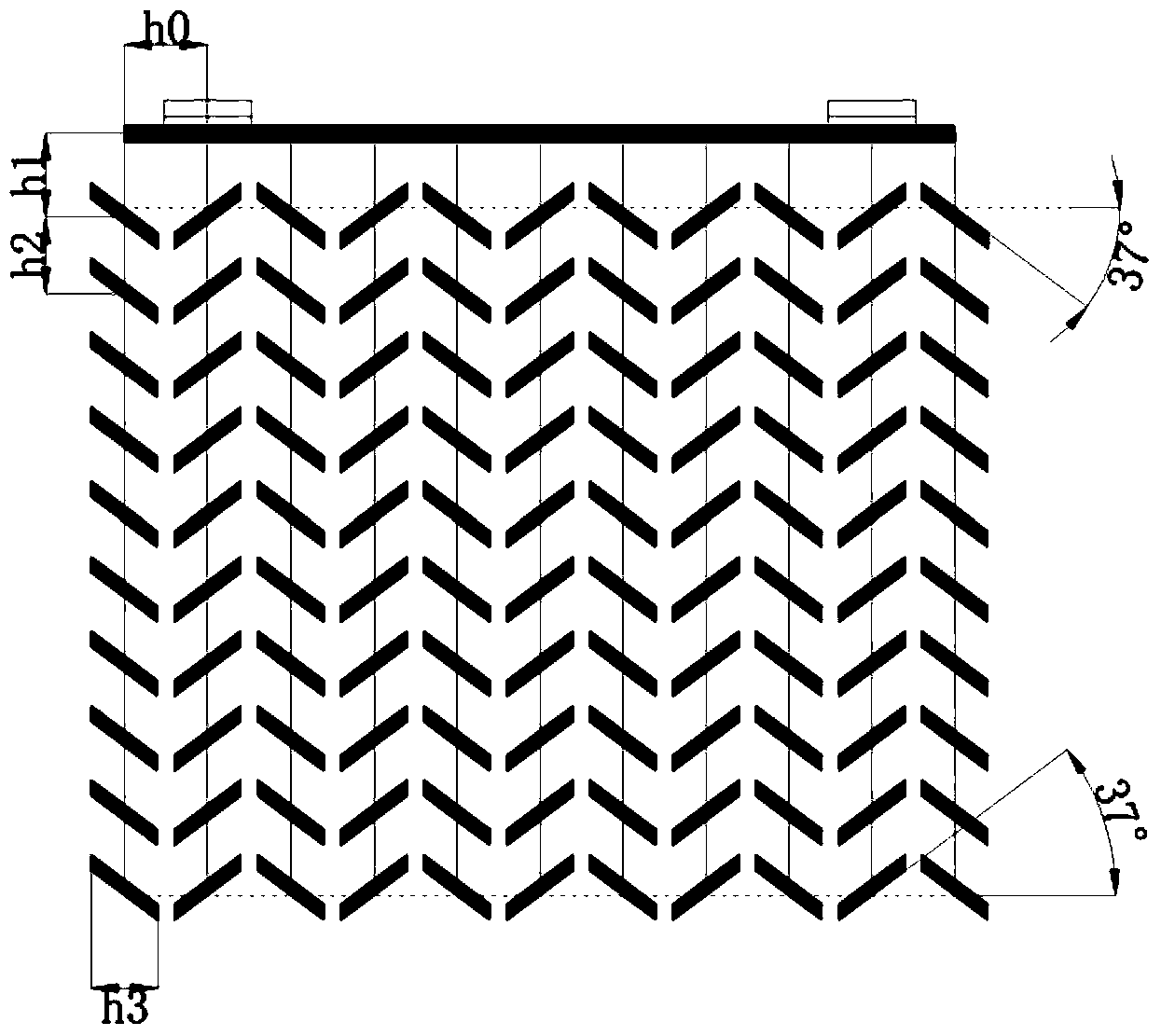

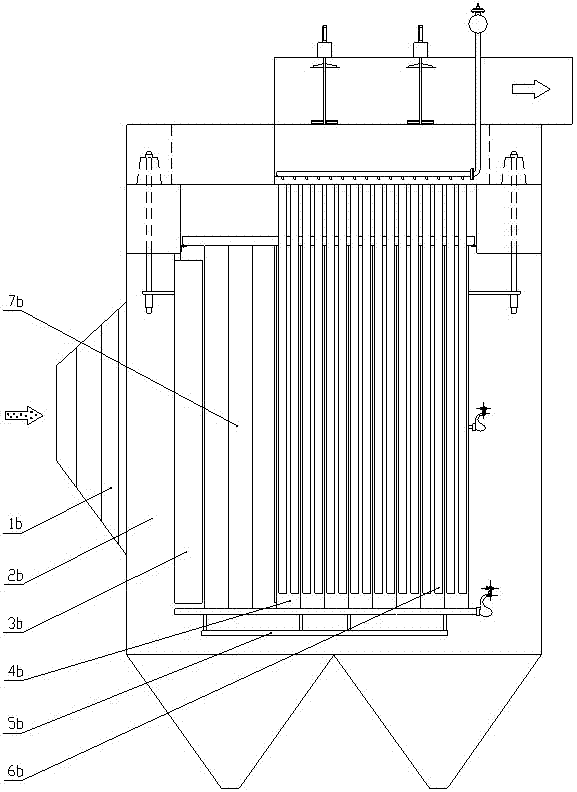

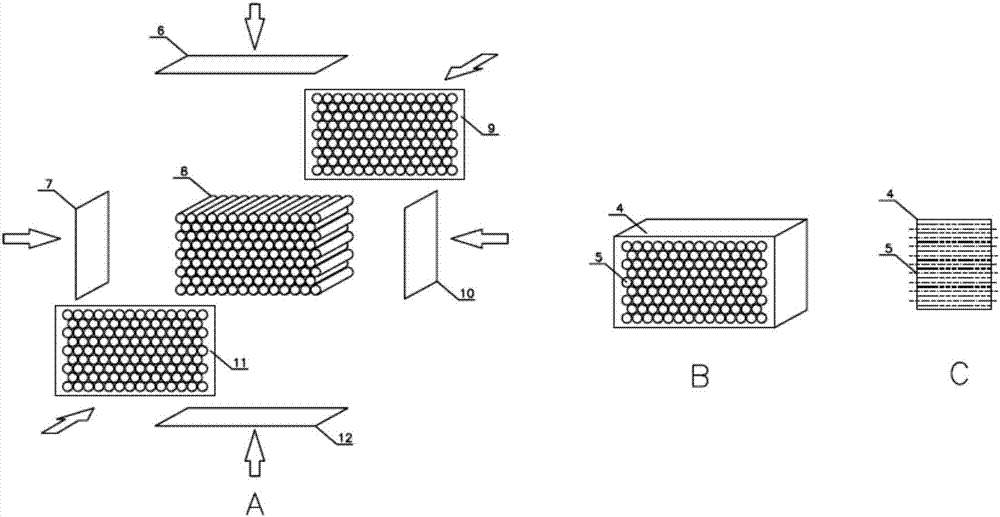

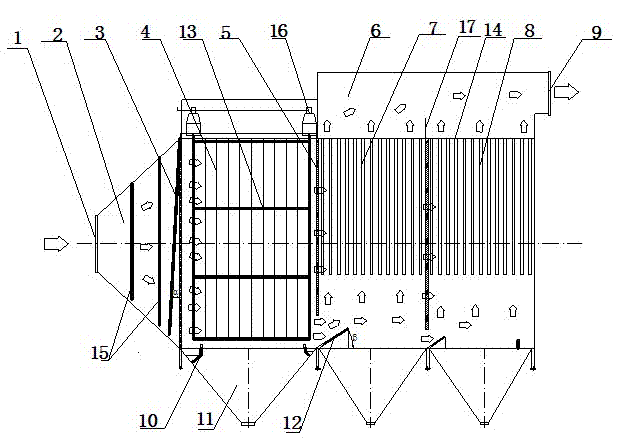

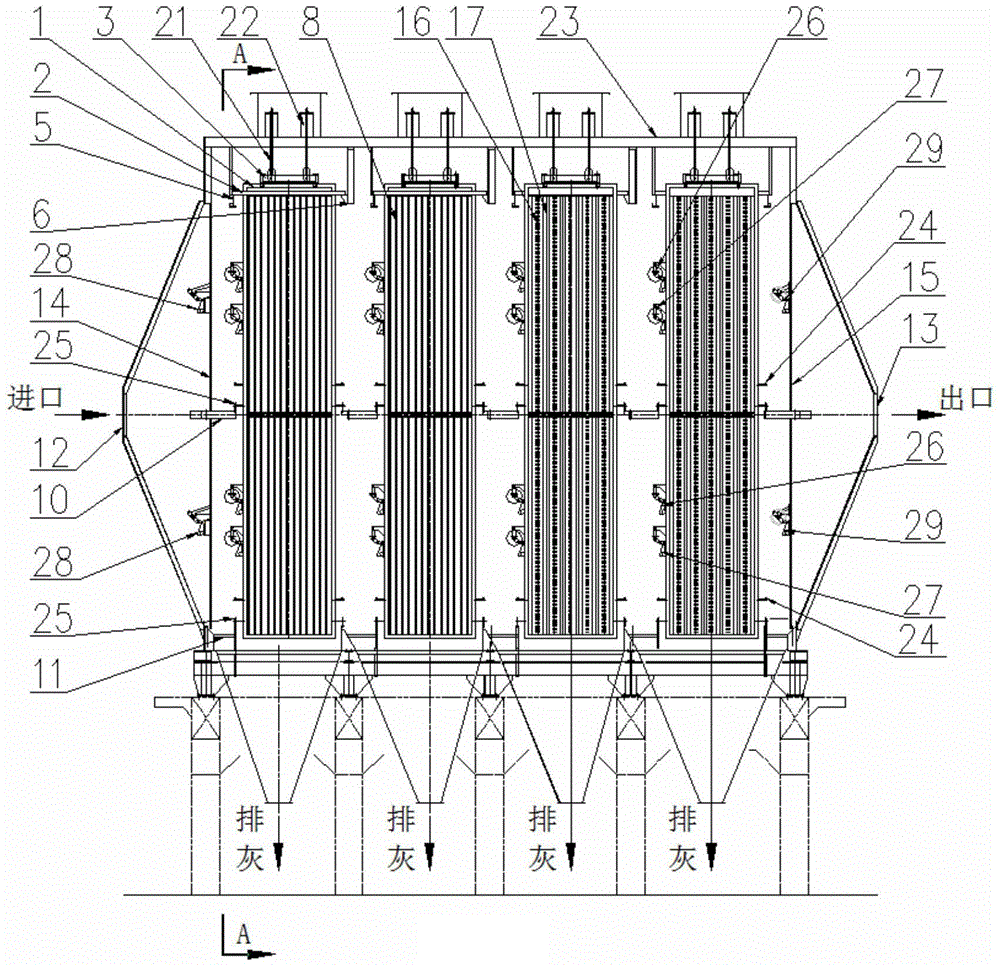

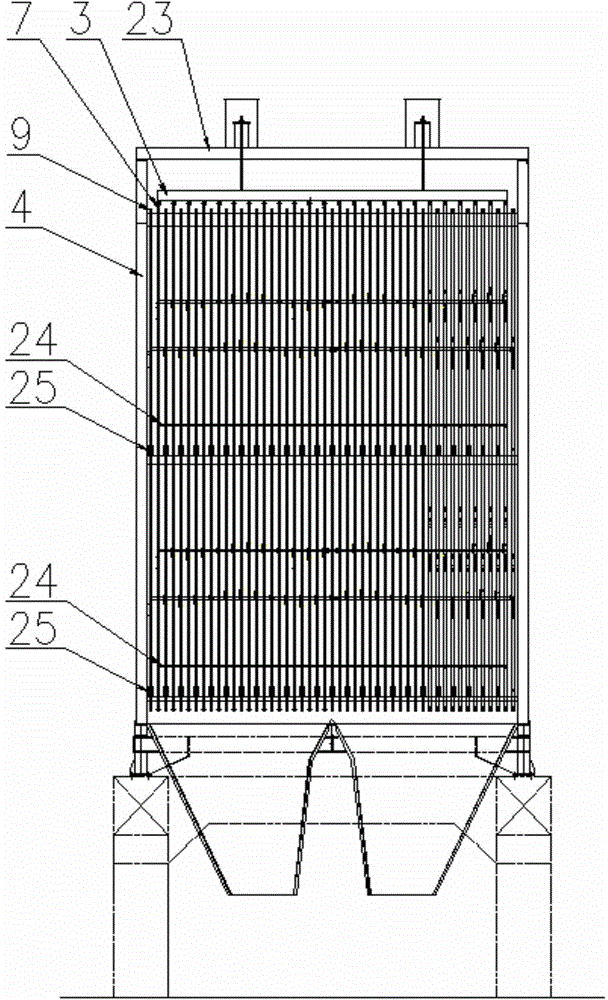

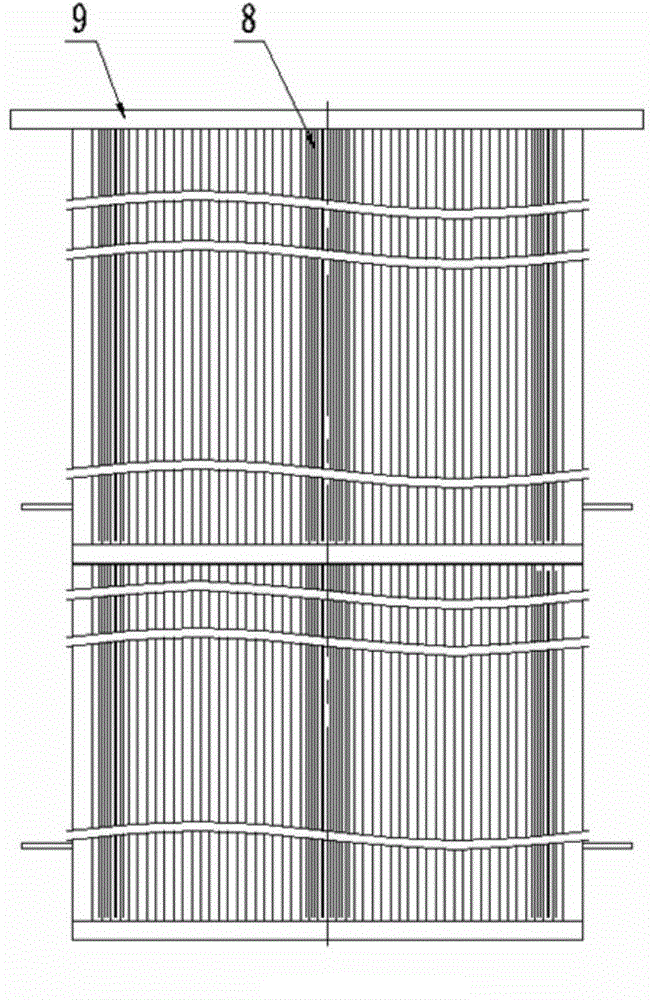

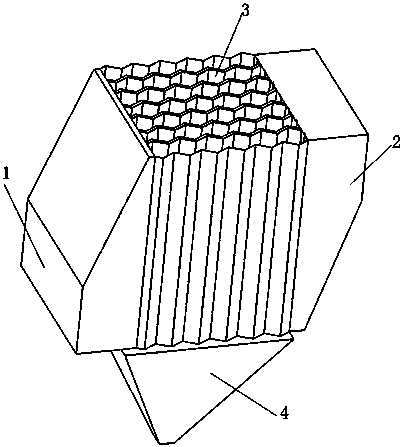

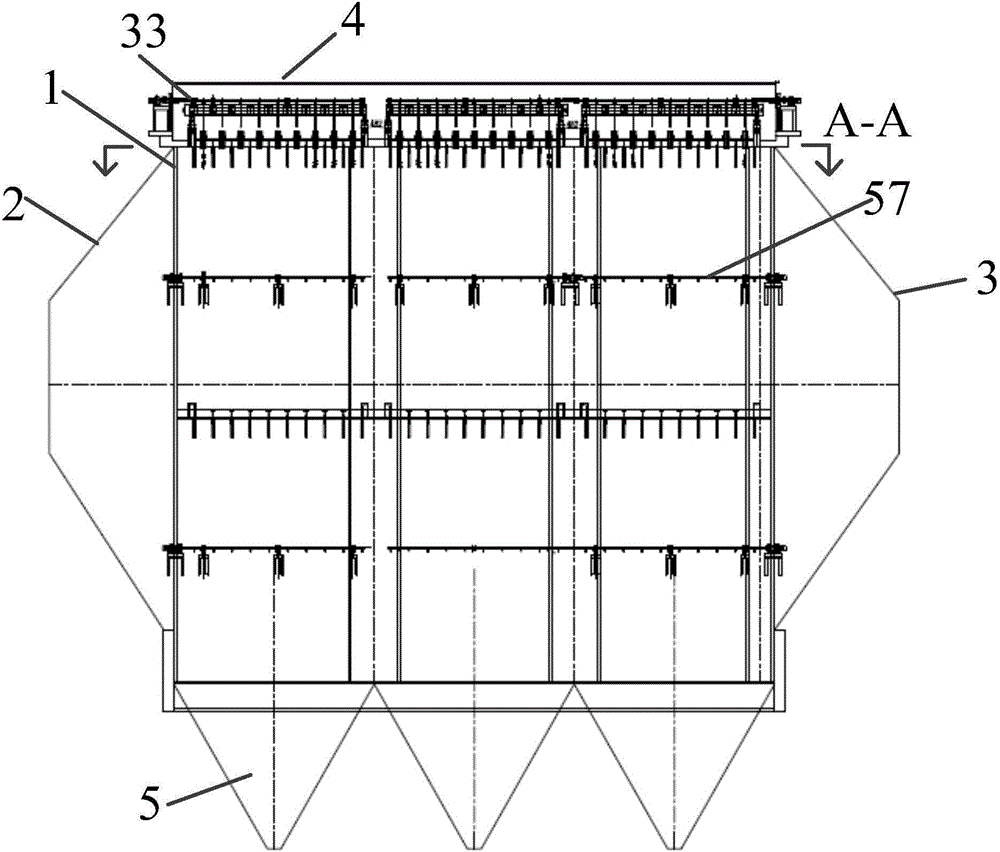

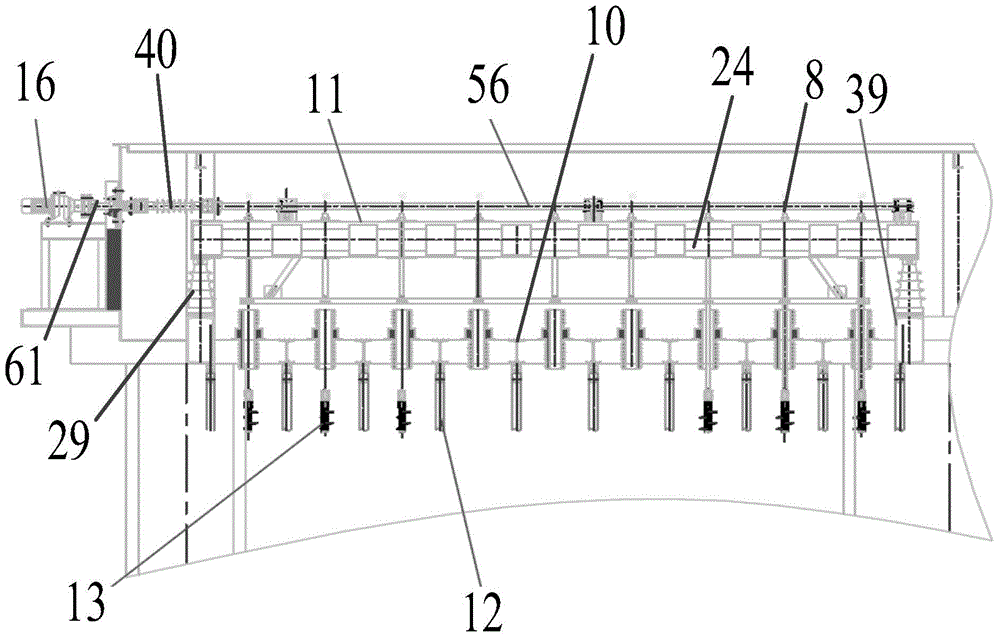

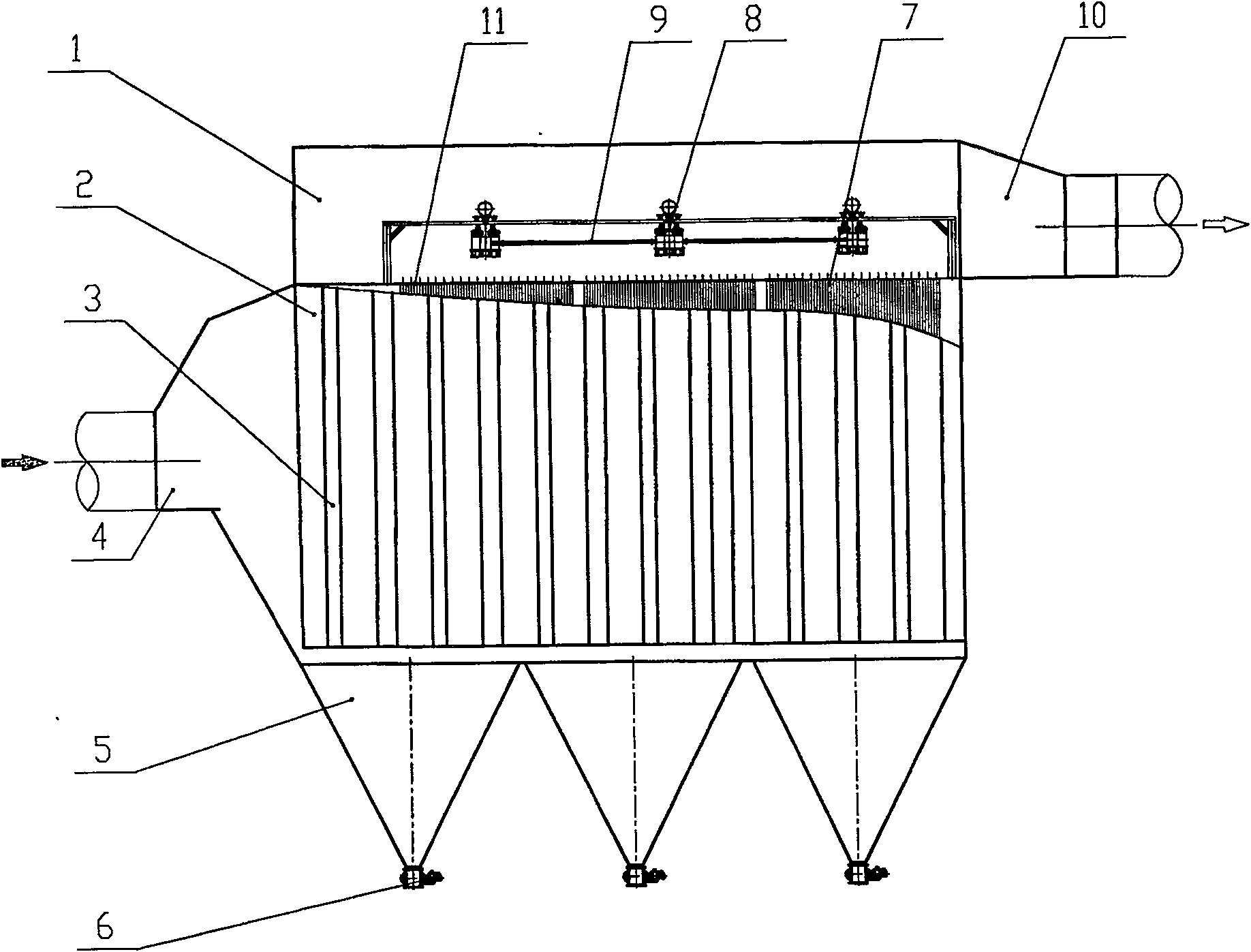

Embedded type electric bag compound dust remover

InactiveCN103203156AImprove dust removal efficiencyLow running costCombination devicesDispersed particle filtrationMechanical engineeringDust abatement

The invention discloses an embedded type electric bag compound dust remover comprising a front-stage electric field dust-removing region and an embedded type electric bag compound dust removing region, which are sequentially arranged in a shell from front to back, wherein in the embedded type electric bag compound dust removing region, two sides of each piece of a back-stage corona electrode framework are provided with a dust-collecting pore plate or a rows of the dust-collecting pore plates; spaces between the two dust-collecting pore plates or the two rows of the dust-collecting pore plates are back-stage electric field channels; at least one filtering bag set comprising a row of filtering bags is arranged between any two adjacent back-stage electric field channels; and vent holes on the dust-collecting pore plates are air flow channels for smoke in the back-stage electric field channels to enter the filtering bag set. The height of the dust-collecting pore plates and the height of the corona electrode frameworks are commonly about 4 meters higher than the length of the filtering bags of the filtering bag set, so that a lot of dust, including falling dust when the dust in the filtering bags is removed, can be captured below the filtering bag set; and with adoption of a longer filtering bag dust removing period, the dust-removing efficiency of the dust remover can be further improved and the service life of the filtering bags can be prolonged.

Owner:XIAMEN GONGYUAN ENVIRONMENTAL SCI & TECH CO LTD

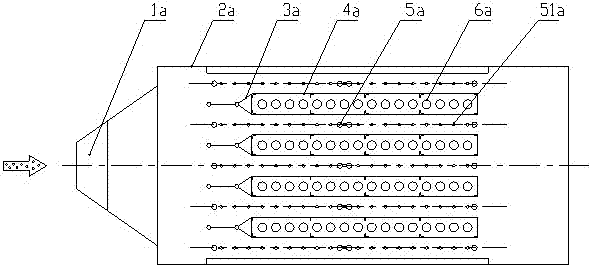

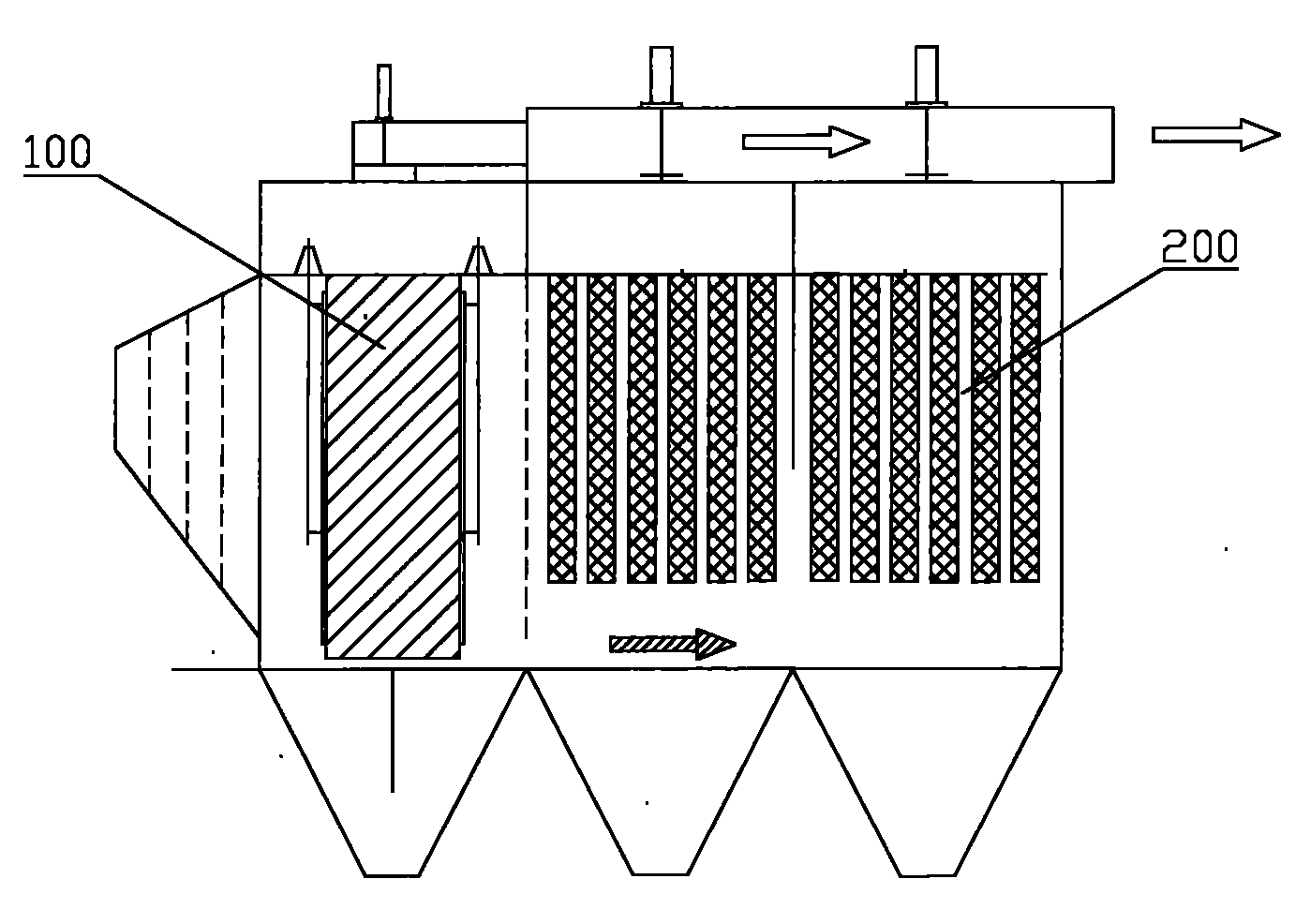

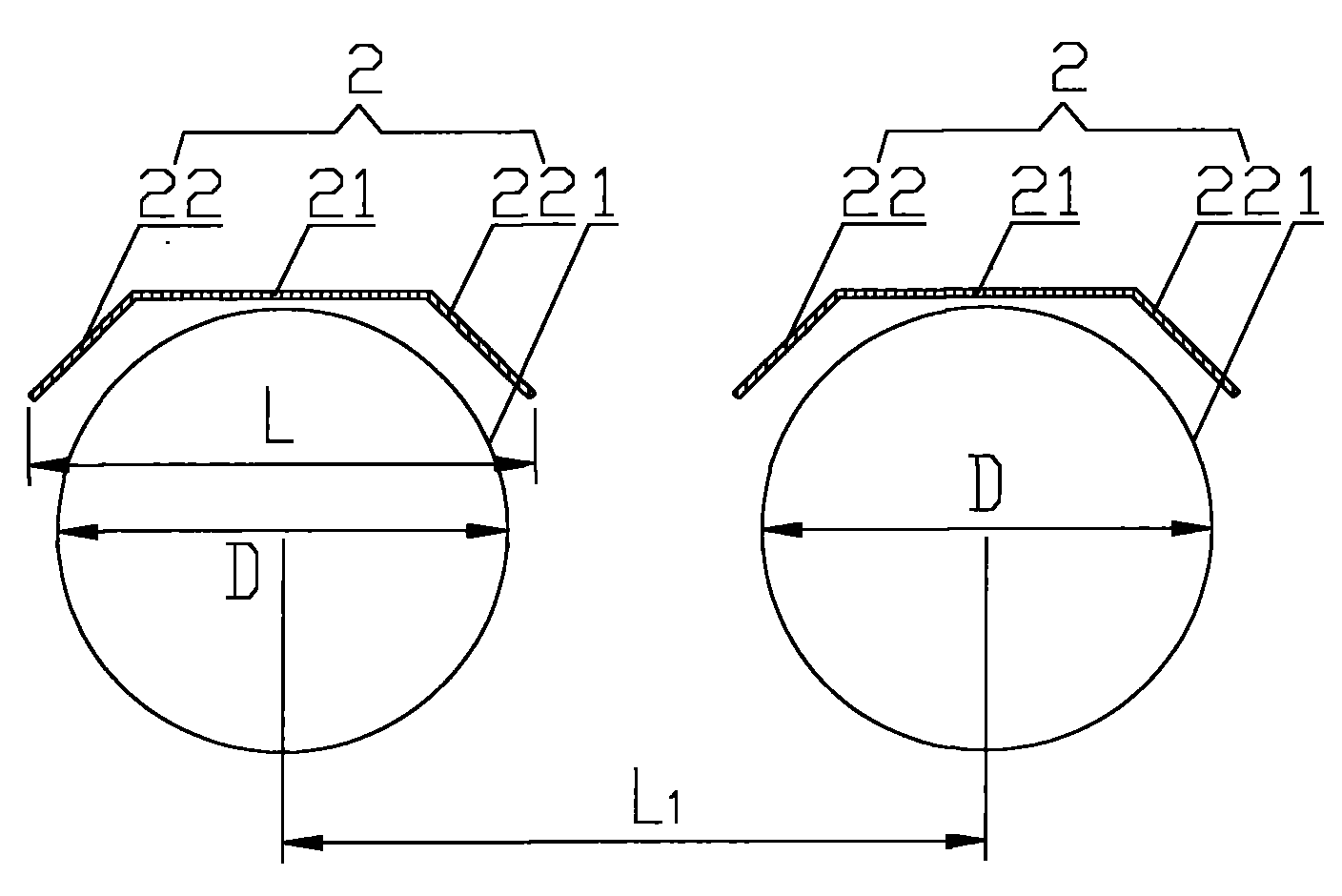

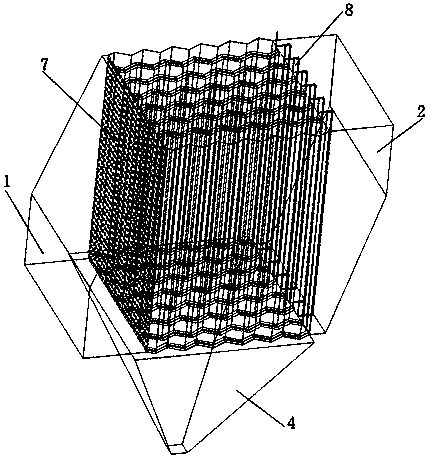

Electrostatic-bag composite dust-collector

ActiveCN101837216ASmall filter resistanceNot easy to loseDispersed particle filtrationFlue gasEngineering

The invention discloses an electrostatic-bag composite dust-collector comprising an electric-bag mixing area, wherein the electrostatic-bag mixing area consists of a plurality of filtering bag rows and a plurality of electric field channels; each filtering bag row and each electric field channel are generally parallel and are arranged at intervals; each filtering bag row is at least provided with a row of filtering bags (1); each electric field channel is at least provided with two anode plates (2); gaps between adjacent anode plates (2) form an airflow passage; flue gas flowing through the electric field channels enters the filtering bag rows through the airflow passage; one anode plate (2) is arranged on the outer side of each filtering bag (1) adjacent to the electric field channel; and the width of the anode plate (2) is more than or equal to the diameter of the filtering bag (1), so that the filtering bags and discharge electrodes of the electric field channels are separated by the anode plates (2). The electrostatic-bag composite dust-collector not only improves the chargeability of dust and the dust collecting efficiency, but also effectively prevents the filtering bags (1) from being adjacent to the discharge electrodes (3) directly, thereby effectively prolonging the service life of the filtering bags (1) and reducing the cost for dust collection.

Owner:FUJIAN LONGKING

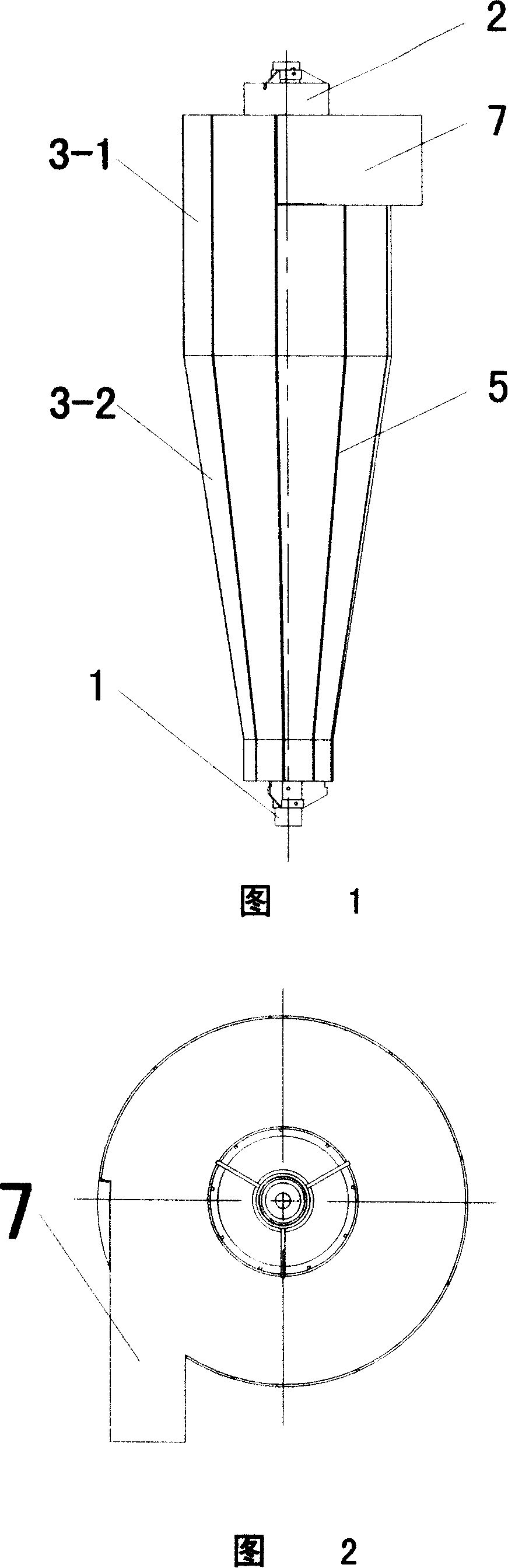

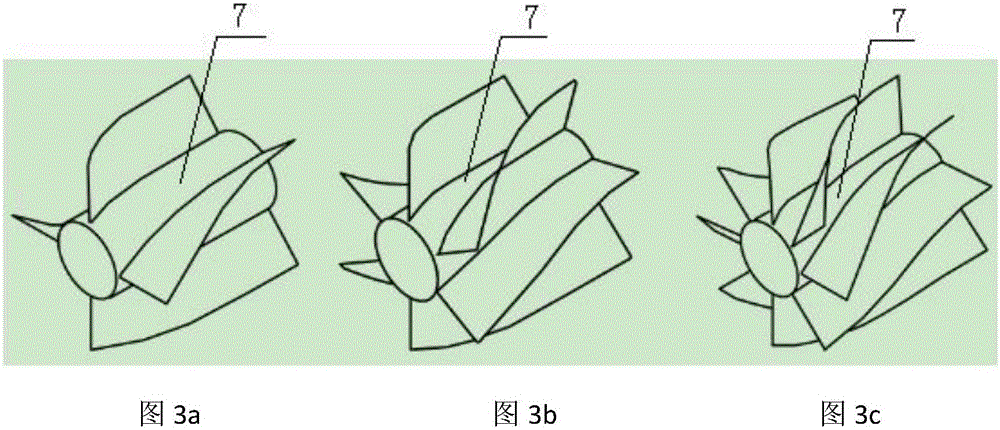

Cyclone type dust-cleaning device cyclone

InactiveCN101147895AReduce wearImprove dust removal efficiencyReversed direction vortexCycloneEngineering

The present invention relates to a concrete structure of cyclone rotor of cyclone dust collector. It includes an external cylindrical body whose external form is made into the form of column and is communicated with a conical body, an internal cylindrical body with tangential air inlet and an exhaust pipe placed in the central upper portion of said internal cylindrical body. It is characterized by that between the external cylindrical body and internal cylindrical body a supporting steel strip is arranged and connected on the surface of said internal cylindrical body from top to bottom, and the gap formed between external cylindrical body and internal cylindrical body can be divided into several powder dust channels from top to bottom by means of said supporting steel strip, and the described internal cylindrical body is formed from column-shaped upper cylindrical body and cone-shaped lower cylindrical body.

Owner:SHANGHAI UNIV OF ENG SCI

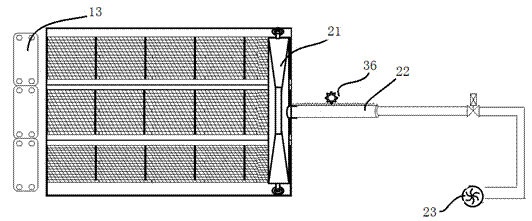

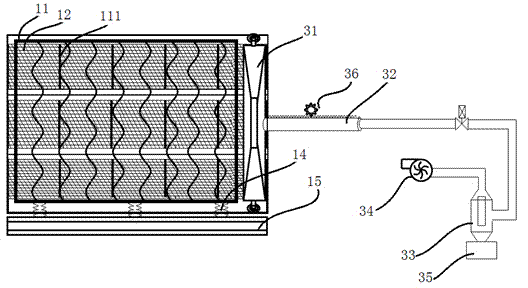

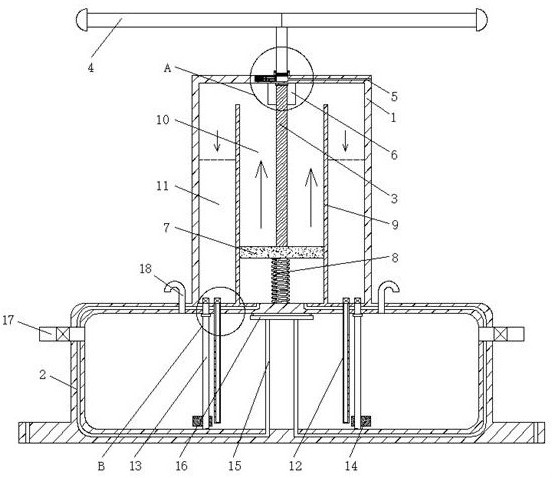

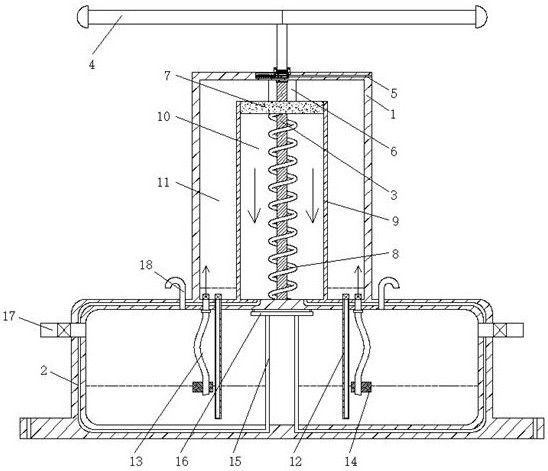

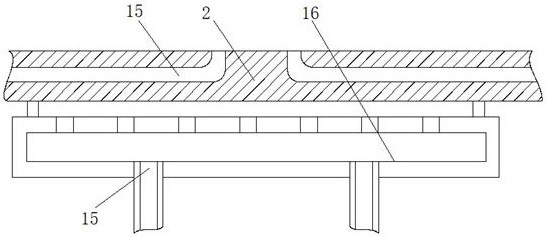

Method and device for spray of agglomerator solution by electric dust collector to promote PM2.5 removal

InactiveCN104759347AImprove the effect of reunionImprove efficiencyElectrostatic separationElectric fieldWetting

The invention discloses a method for spray of an agglomerator solution by an electric dust collector final stage electric field to promote PM2.5 removal. The method specifically includes: after removal of coarse particles in a preceding stage electric field, spraying an agglomerator solution prepared from a high polymer binder and a wetting agent into an electric dust collector final stage electric field, utilizing the heat contained in flue gas to evaporate the agglomerator solution, with the wetting agent promoting dust to enter agglomerator solution liquid drops in the evaporation process; and connecting the high polymer binder with PM2.5 through a polar group equipped polymer chain, promoting increase of the PM2.5 particle size so as to be in favor of electric dust collector trapping and reduction of reentrainment. The invention also relates to a device specifically for the method. The agglomerator solution is sprayed into the electric dust collector final stage electric field to mainly agglomerate PM2.5 fine particles that are difficult to remove, reduce the interference of coarse dust to PM2.5 agglomeration and enhance the PM2.5 agglomeration and growth effect. At the same time, evaporation of agglomerator solution liquid drops can reach the purposes of flue gas humidification and conditioning.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

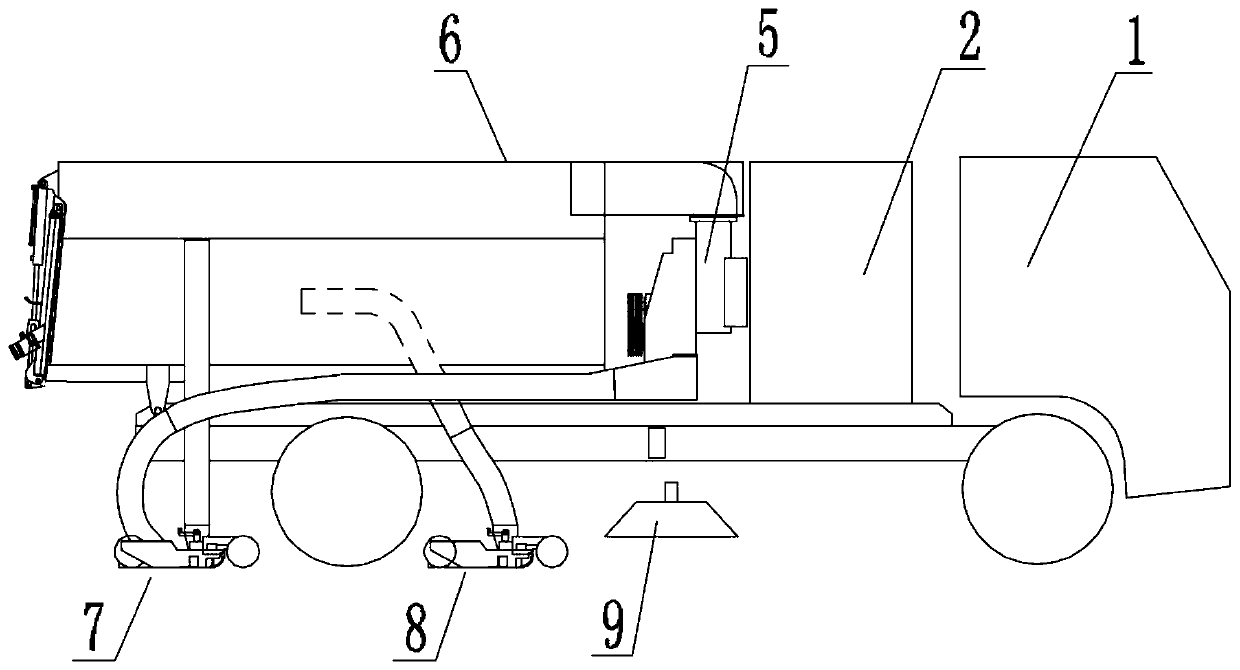

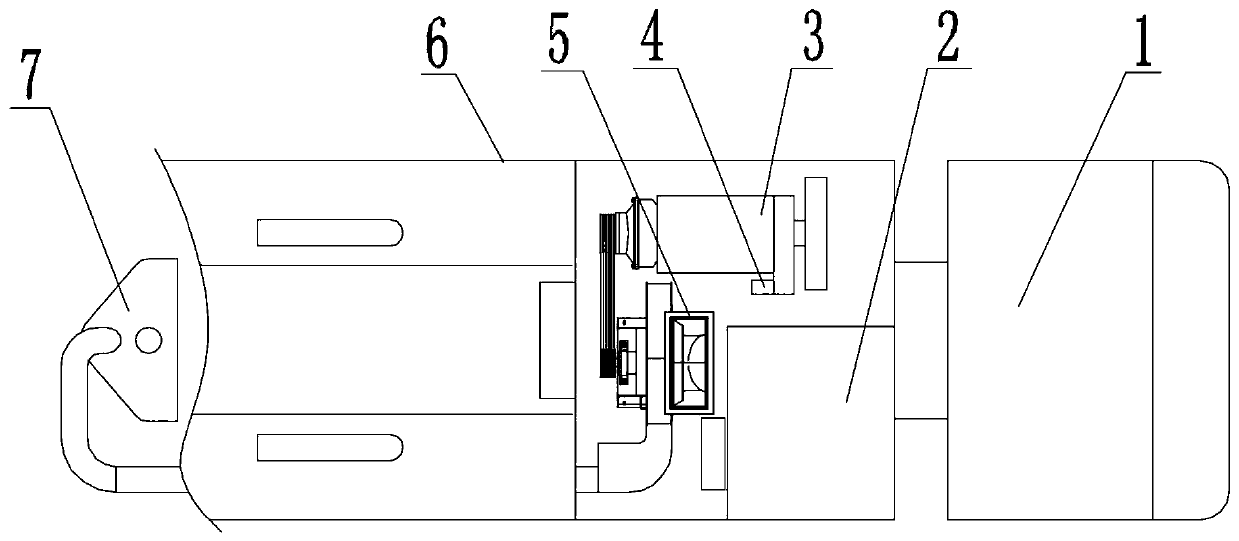

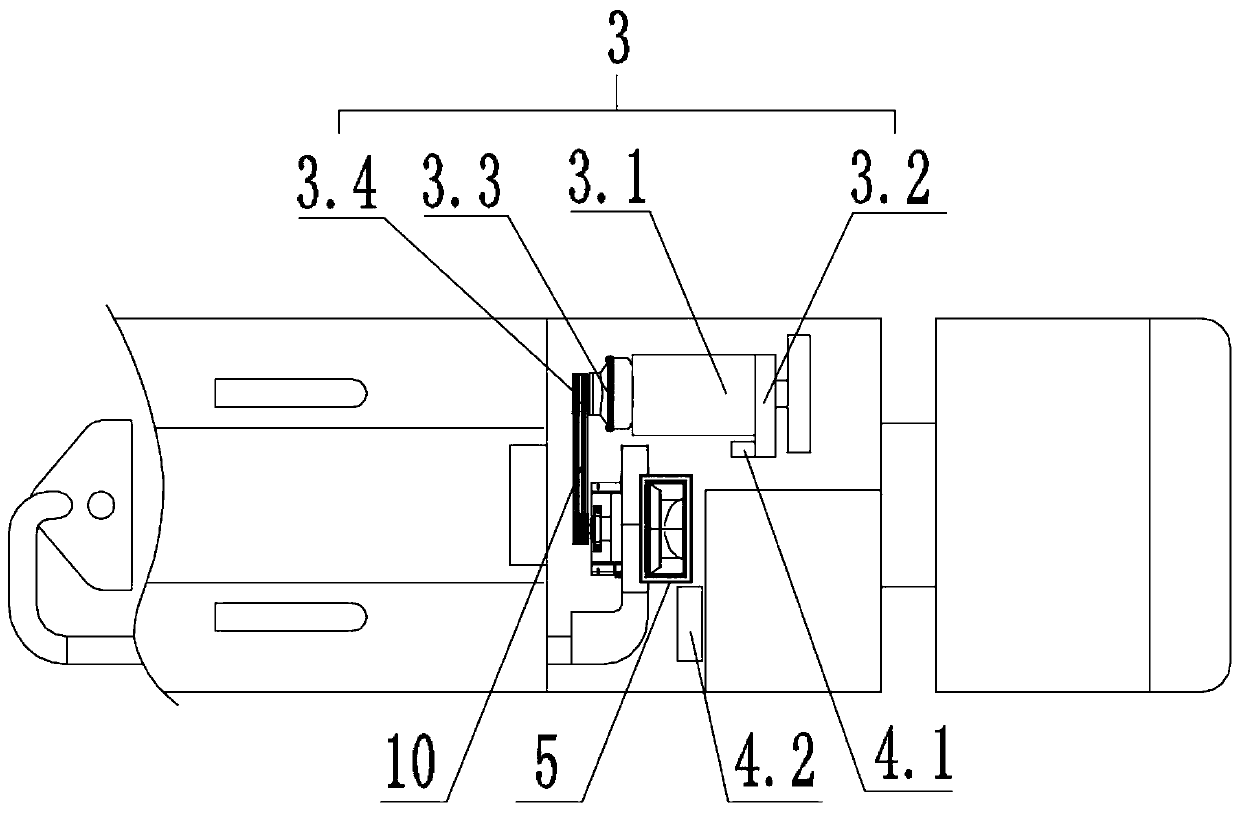

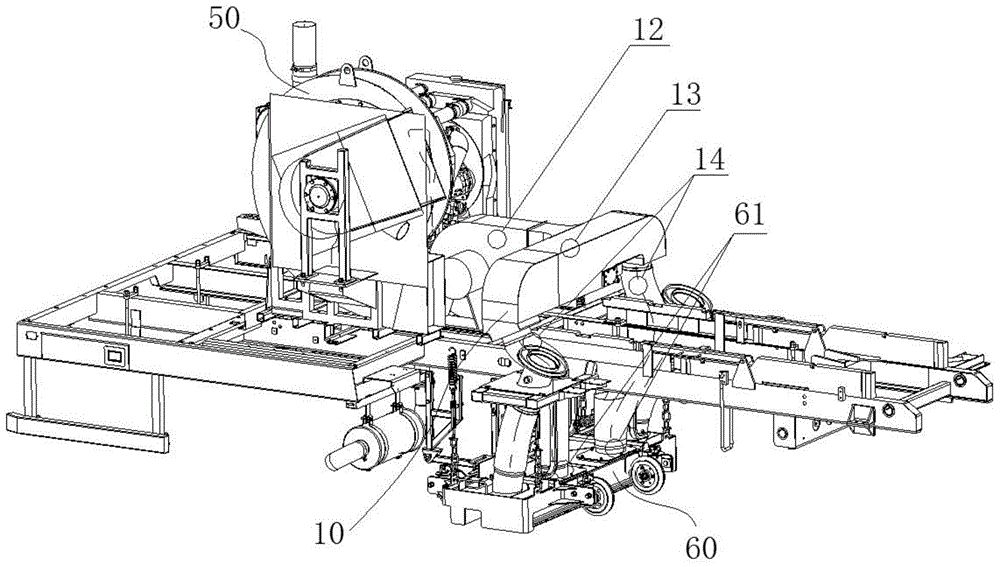

Pressure-differential classification suction pickup sweeper

The invention discloses a pressure-differential classification suction pickup sweeper, which comprises a sweeper chassis. A water tank, an auxiliary engine, a hydraulic driving system, a fan, a garbage can, a blowing-suction-type suction nozzle mechanism, a pure-suction-type suction nozzle mechanism, a sweeping mechanism and a sweeping spraying system are arranged on the sweeper chassis; and the hydraulic driving system and the fan are powered by the auxiliary engine, the blowing-suction-type suction nozzle mechanism is powered by the fan, the sweeping spraying system is powered by a chassis battery, the sweeping mechanism and the garbage can are powered by the hydraulic driving system, the blowing-suction-type suction nozzle mechanism and the pure-suction-type suction nozzle mechanism both communicate with the garbage can, the blowing-suction-type suction nozzle mechanism is used for conducting suction pickup on garbage with the large specific weight, and the pure-suction-type suctionnozzle mechanism is used for conducting suction pickup on garbage with the small specific weight. According to the pressure-differential classification suction pickup sweeper, the garbage, with the different specific weights, such as leaves, floating dust and earth and stone particles can be subjected to separated suction pickup, the pavement sweeping efficiency and cleanliness can be improved greatly, reentrainment can be reduced greatly, and the advantages of high operation efficiency, good cleaning effect, low energy consumption and the like are achieved.

Owner:中国重汽集团湖北华威专用汽车有限公司

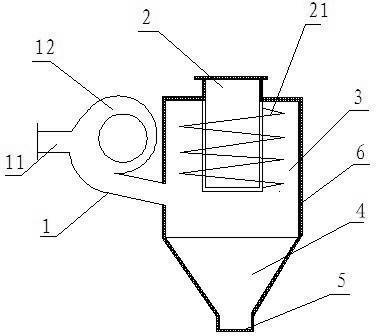

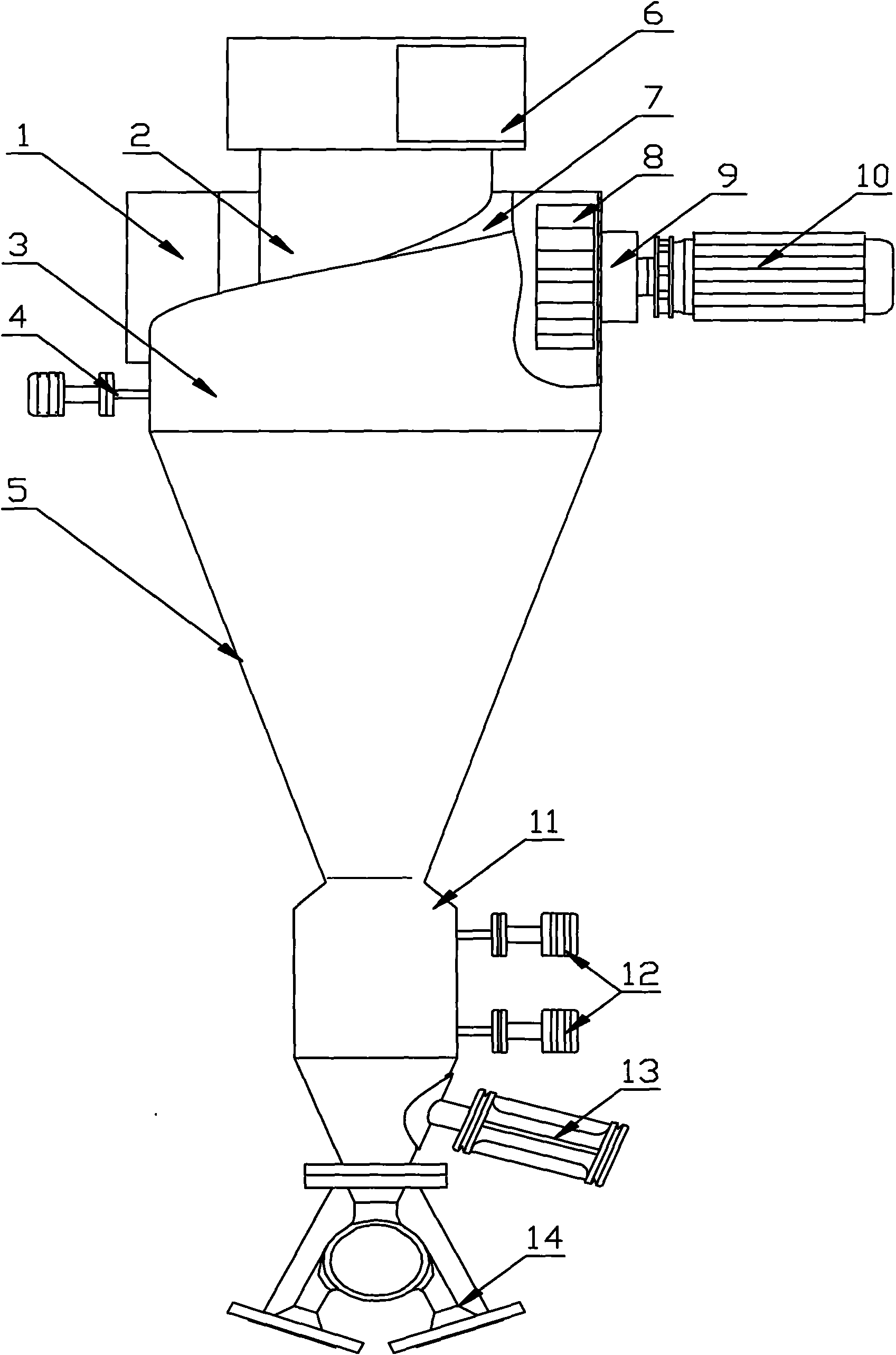

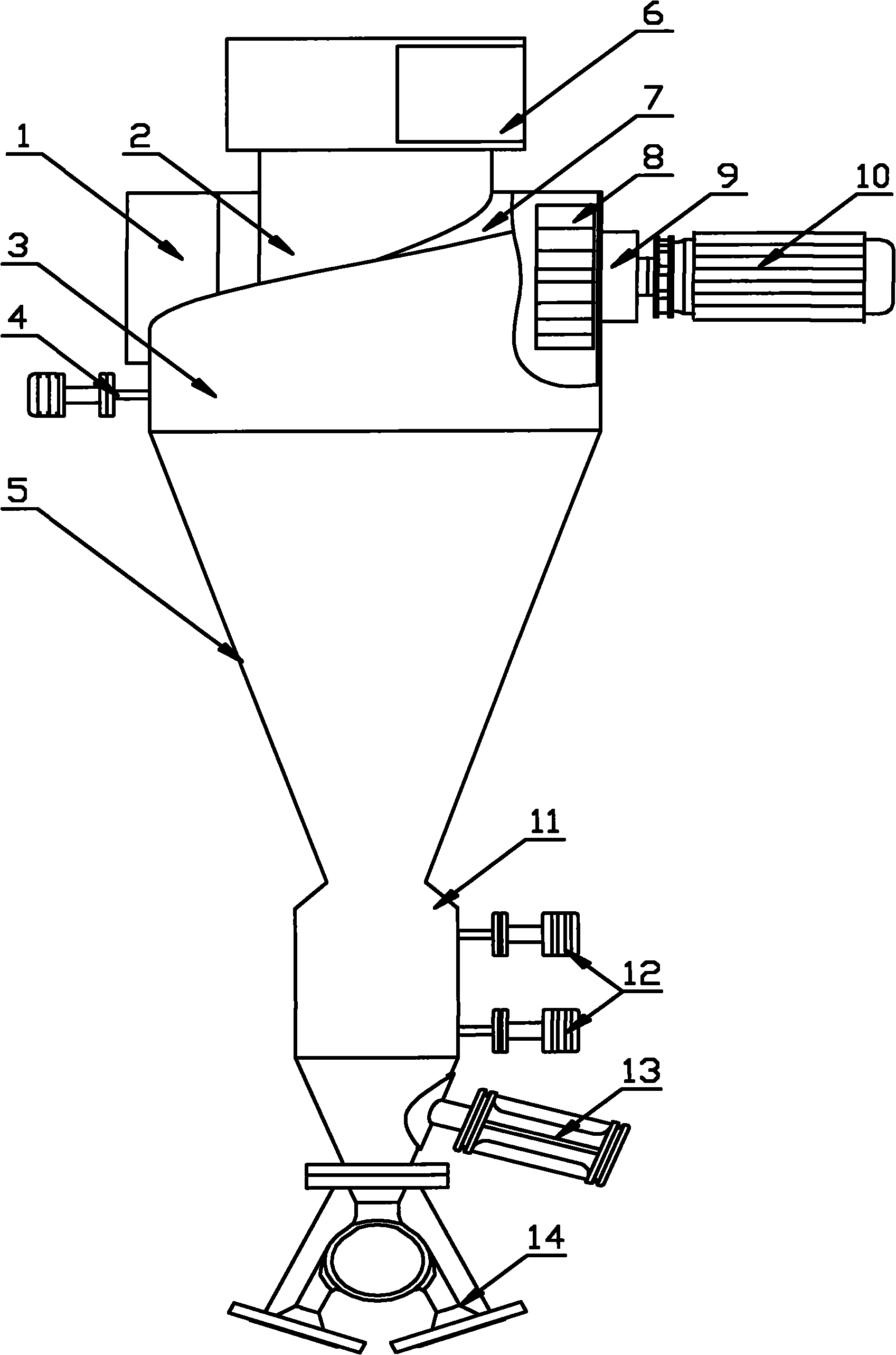

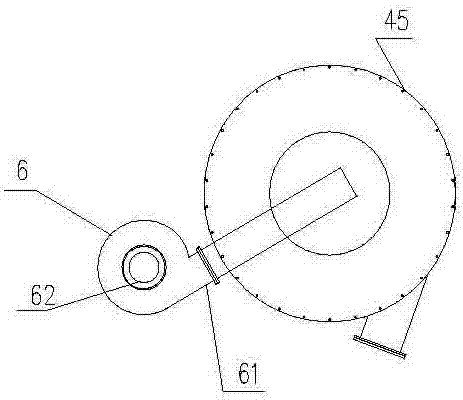

Cyclone dust collector with spiral air inlet pipe

InactiveCN102671778AChange flow stateReduce secondary dustReversed direction vortexCycloneEngineering

The invention discloses a cyclone dust collector with a spiral air inlet pipe, and belongs to the cyclone dust collector field. The cyclone dust collector comprises an air inlet pipe, a cyclone, an air outlet pipe, a spiral stream guidance blade, a conical dust collector and a dust outlet, the air inlet pipe is arranged on one side of the cyclone, the spiral stream guidance blade is fixed on the air outlet pipe and extend into the cyclone, the conical dust collector is connected to the lower bottom of the cyclone and is communicated with the cyclone, the dust outlet is arranged at the lower end of the dust collector, the air inlet pipe is designed in a spiral pipeline structure, traditional straight blow type air inlet pipes are replaced, one end of the air inlet pipe is an air inlet, and the other end is fixed onto and communicated with the outer wall of the cyclone. According to the mode, the cyclone dust collector with the spiral air inlet pipe can change flow conditions of airflows inside the cyclone, possibilities of secondary dust raising and dust rising circulation phenomena of the conical portion are effectively reduced, centrifugal force of dust particles is increased because the rotation speed of airflows inside the dust collector is increased, fine particles which cannot be removed by traditional cyclone dust collectors can be removed, and the cyclone dust collector has high dust particle separation efficiency.

Owner:郭丰亮

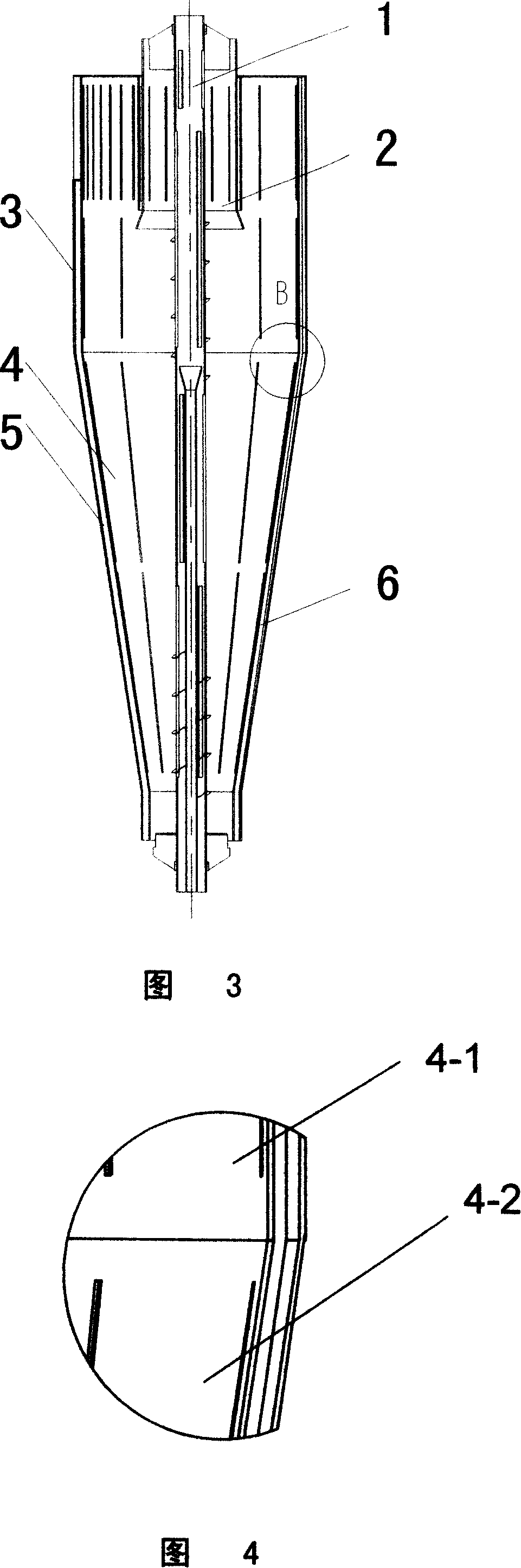

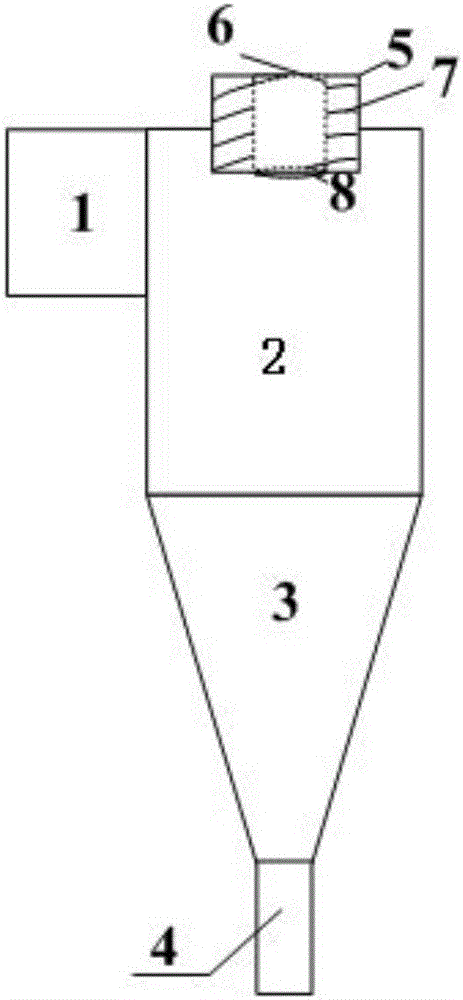

Double-barrel inner turbine central cylinder of cyclone separator

InactiveCN106000667ASlow down periodic tail waggingImprove flow field distributionReversed direction vortexCycloneSteam line

The invention discloses a double-barrel inner turbine central cylinder of a cyclone separator. The double-barrel inner turbine central cylinder comprises a central cylinder outer barrel which is inserted into the top of a separator barrel body, a central cylinder inner barrel arranged in the central cylinder outer barrel, a central cylinder inner turbine arranged between the central cylinder outer barrel and the central cylinder inner barrel, and a central cylinder guide cover which is arranged on the inner bottom of the central cylinder, wherein the central barrel inner turbine adopts a spiral steam-line type structure; a rotation direction of blades of the central cylinder inner turbine is different from that of gas flow; the central cylinder inner turbine is provided with 1-8 blades; an included angle between the tangential line of each blade and the circumferential direction is a blade mounting angle being 10-100 degrees; and the central cylinder guide cover is in the shape of bullet. By virtue of the depth, penetration depth of the central cylinder is shortened, integral resistance of the cyclone separator is reduced, flow fields in the separator are optimized, gas-flow tail waggling is relieved, flying dust is avoided and separation efficiency is improved; and the associated scheme can be used for efficiency-enhancing modification of the cyclone separator and design of a high-efficiency low-resistance cyclone separator.

Owner:HUANENG CLEAN ENERGY RES INST

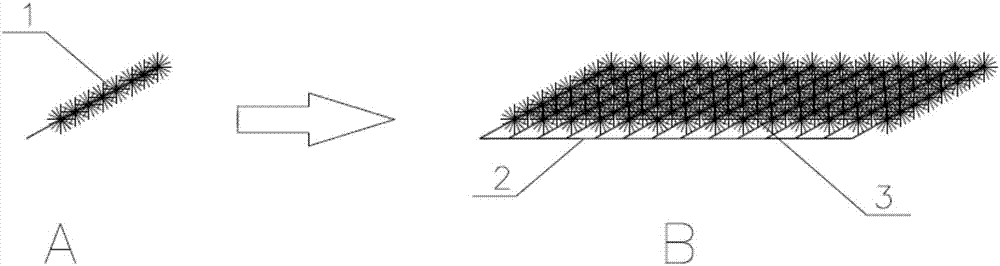

Preparation method of efficient dedusting module

ActiveCN107115968AAdjustable sizeAvoid Flappy Escape AgainExternal electric electrostatic seperatorElectrode constructionsElectricityBristle

The invention discloses a preparation method of an efficient dedusting module, and belongs to the technical fields of dedusting and environmental protection. The method comprises the steps that firstly, dust particles in airflow are charged with electricity through a pre-charger; airflow passes through cylindrical metal pore passages filled with twisted wire brushes; the wall surfaces of the pore passages and brush handles of the twisted wire brushes in the pore passages are loaded with voltage; and the dust particles entering the pore passages fly to the wall surfaces of the pore passages or the brush handles of the twisted wire brushes according to the principle that opposites attract, dust is captured, captured dust is not liable to escape under the action of brush bristles, and when the surfaces of the brush bristles of the twisted wire brushes are coated with a viscous insulating liquid, dust can be firmly adsorbed. The module is low in resistance, high in dedusting efficiency and relatively suitable for dedusting purification of indoor air.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

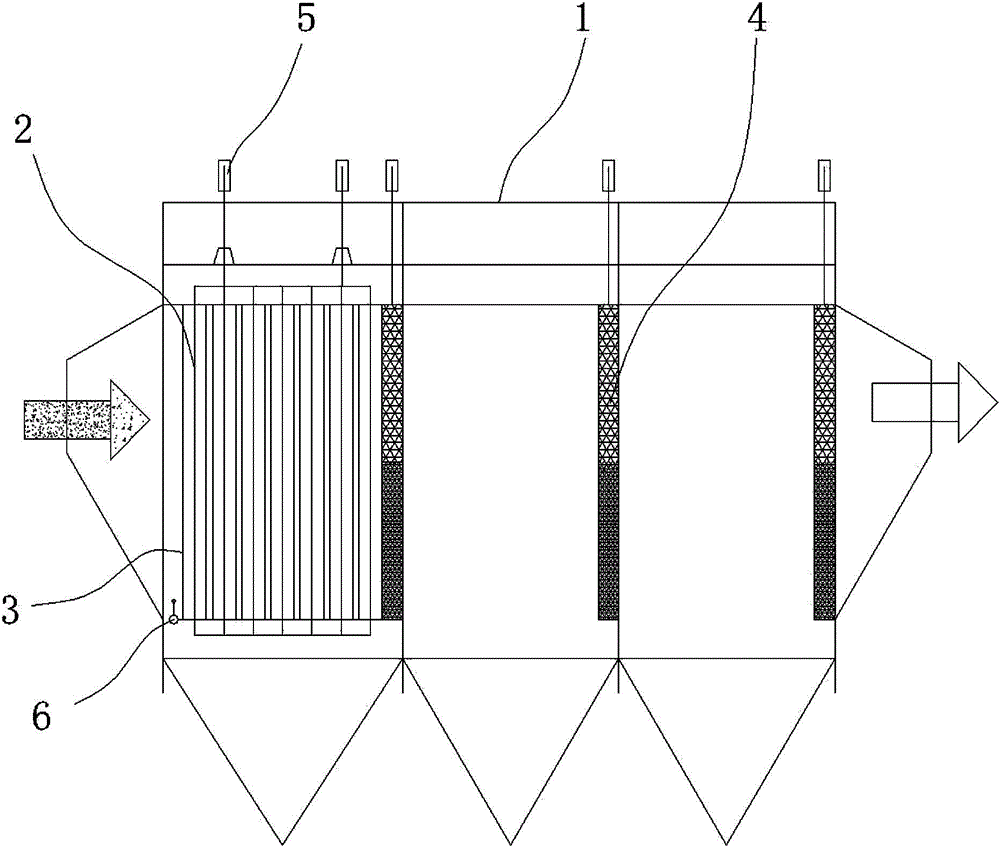

Skewed gas flow electric bag composite dust remover

InactiveCN102824804AImprove dust removal efficiencyReduce dust concentrationCombination devicesFlow diversionRe entrainment

The invention discloses a skewed gas flow electric bag composite dust remover, which comprises a gas flow distribution region, an electric dust removing region and a bag dust removing region from left to right, wherein the lower parts of the electric dust removing region and the bag dust removing region are provided with dust collecting regions; a clean gas region is positioned on the upper part of the bag dust removing region; the gas flow distribution region comprises two gas flow distribution plates which are arranged vertically, and a skewed gas flow distribution plate; the electric dust removing region comprises a cathode line, an anode plate and a high-pressure electric device; the joint between the electric dust removing region and the bag dust removing region is provided with an electric bag bonding plate; the bag dust removing region comprises a gas flow diversion plate, a bag, a framework and a tube nest; the framework and the bag construct a whole body which is arranged on the tube nest; each dust collecting region consists of an ash hopper and an ash hopper baffle plate; and the clean gas region mainly comprises clapboards. Optimal gas flow distribution in the electric bag composite dust remover is realized, the generation of eddy current in the electric dust removing region is reduced, the running resistance of the bag dust removing region is reduced, re-entrainment is reduced, and low-resistance efficient running of the electric bag composite dust remover is ensured.

Owner:SOUTH CHINA UNIV OF TECH

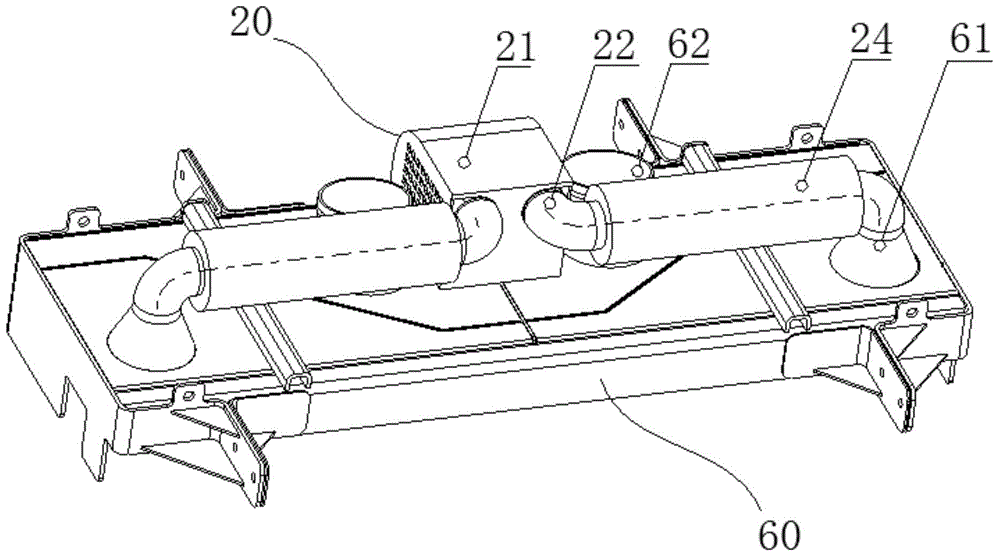

Reverse blowing system of road sweeper and road sweeper

The invention discloses a reverse blowing system of a road sweeper and the road sweeper. The reverse blowing system comprises a reverse blowing fan and a reverse blowing flow path, wherein an inlet of the reverse blowing fan communicates with atmosphere, and an outlet of the reverse blowing fan communicates with an inlet of the reverse blowing flow path; an outlet of the reverse blowing flow path communicates with reverse blowing interfaces, wherein the reverse blowing interfaces are arranged on a sucker of the road sweeper and communicate with an inner cavity of the sucker. Because the reverse blowing system adopts the reverse blowing fan which is independent of a centrifugal fan for sweeping, outside clean air is used for reverse blowing, and reversed blown air carrying dust from a dustbin cannot be directly exhausted to the atmosphere; therefore, secondary raising dust is reduced.

Owner:XCMG CONSTR MACHINERY

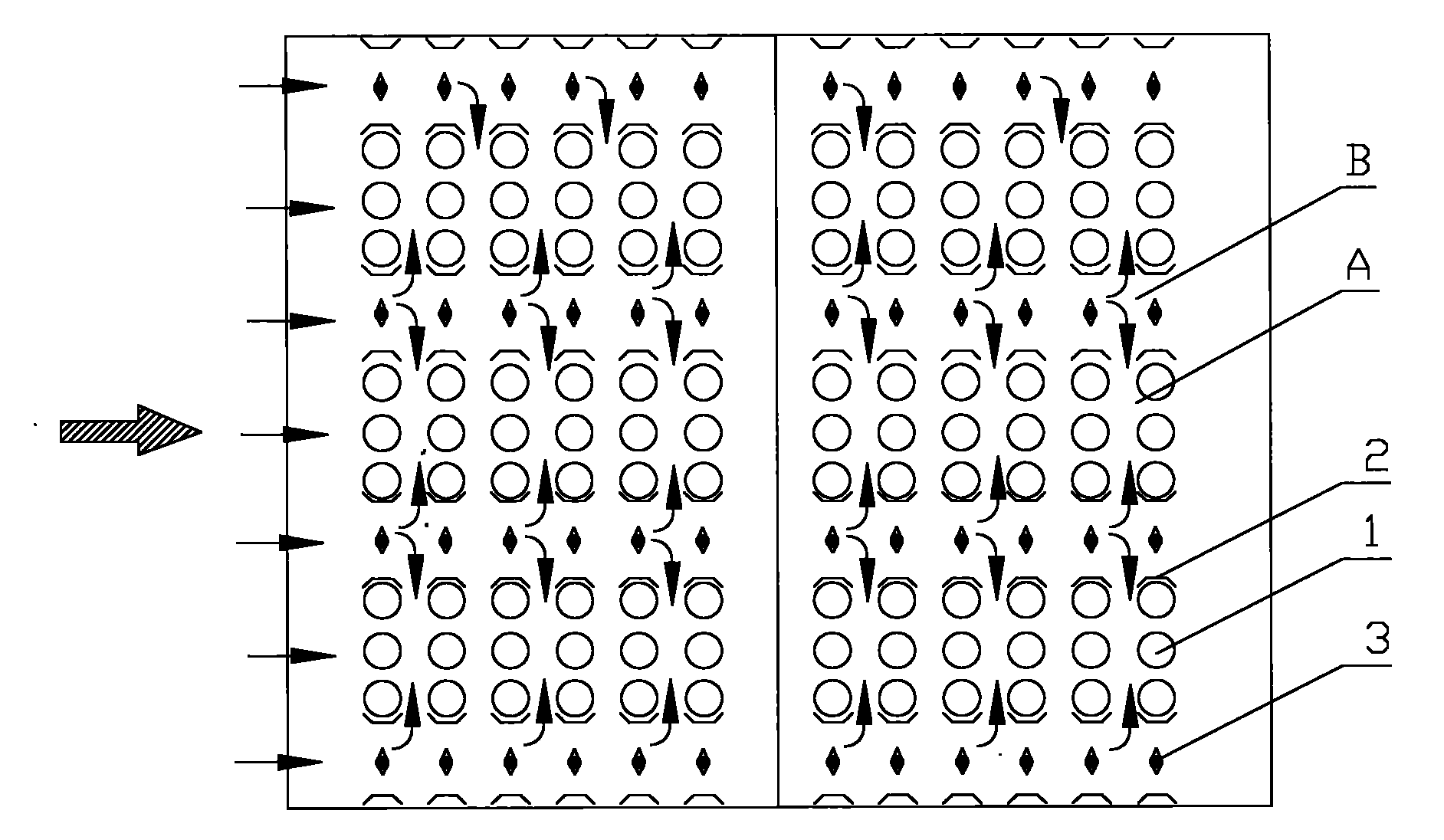

Two-dimensional anode dust collection electric precipitator

InactiveCN105195318AIncrease dust collection areaImprove dust removal efficiencyExternal electric electrostatic seperatorElectrode constructionsChemistryElectric field

The invention relates to a two-dimensional anode dust collection electric precipitator. The two-dimensional anode dust collection electric precipitator comprises a flue gas channel, wherein a discharging cathode wire and a transverse dust collection anode plate are alternatively matched and distributed in an electric field region of the flue gas channel; and the transverse dust collection anode plate is parallel to a gas flow direction. The two-dimensional anode dust collection electric precipitator is characterized in that the electric field region of the flue gas channel is internally additionally provided with a longitudinal dust collection anode plate vertical to the gas flow direction at least; and each longitudinal dust collection anode plate is a through type pore plate. The two-dimensional anode dust collection electric precipitator has the advantages that the inner space of an electric field is sufficiently utilized; when the anode plate is arrayed in the parallel gas flow direction (namely a first dimension, or named as a transverse direction), the through type dust collection anode plate is arranged in the vertical gas flow direction (namely a second dimension, or named as a longitudinal direction; and dust collection area is doubled under the condition that the space of the electric precipitator is not increased and four-directional discharging cathode wires are adopted so that electric corona is relatively concentrated, the intensity of the electric corona is relatively strong, and the dust collection effect is relatively good.

Owner:解标

Reentrainment control method for low-low temperature electric dust remover

The invention discloses a reentrainment control method for a low-low temperature electric dust remover. The rapping period and the rapping sequence are controlled. As for the rapping period, back corona is not generated, that is, rapping is not conducted when secondary voltage and secondary current of terminal electric fields are not changed obviously, or rapping is conducted once when the dust accumulation thickness of a positive pole plate is 1-2 mm, and the time for rapping the terminal electric fields once is 12-20 hours. As for the rapping sequence, the last two electric fields are not rapped at the same time, all chambers of the terminal electric fields are not rapped at the same time, and the cathodes and anodes of the terminal electric fields are not rapped at the same time. According to the reentrainment control method for the low-low temperature electric dust remover, rotary electrode electric fields are arranged on the downstream of a conventional fixed electric field in the smoke flow direction. Compared with the prior art, the control method has the advantages that by controlling the rapping period and the rapping sequence, shortening rapping time, reducing the rapping frequency and using the staggered rapping mode, reentrainment is reduced, or the rotary electrode electric fields are increased to adsorb smoke dust in smoke and reduce reentrainment; by the adoption of the method, reentrainment can be effectively reduced, and dust removal efficiency is improved.

Owner:浙江菲达环保科技股份有限公司

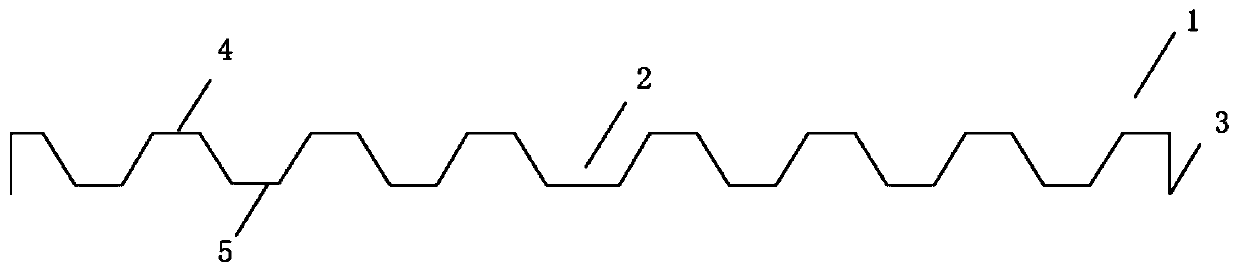

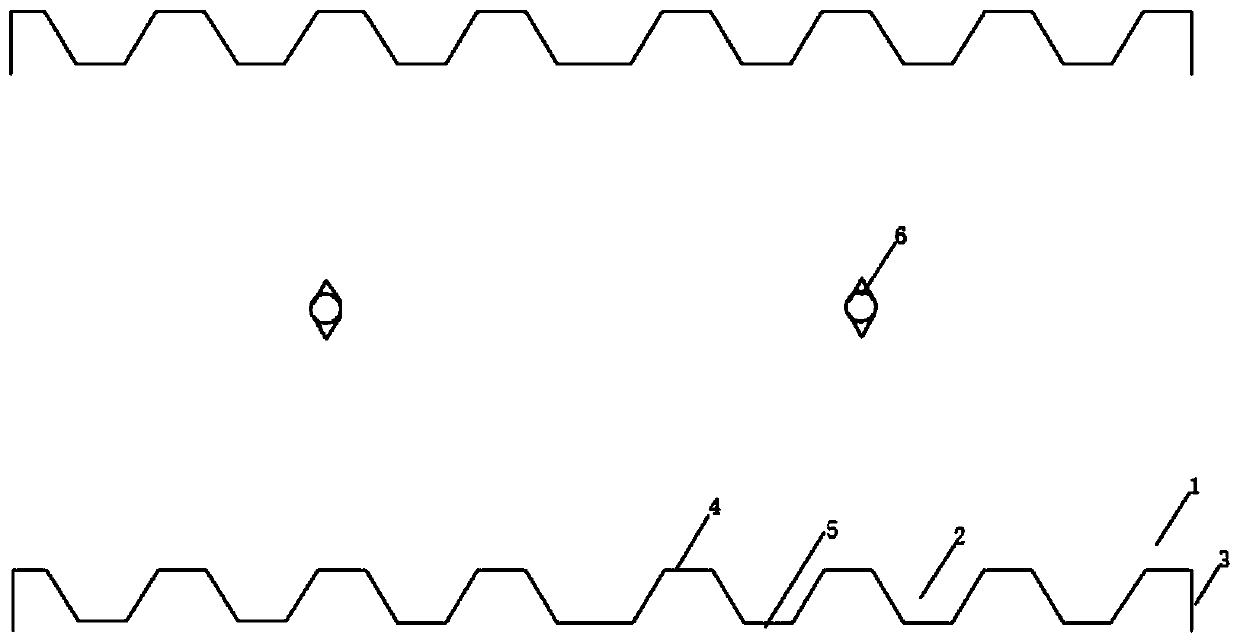

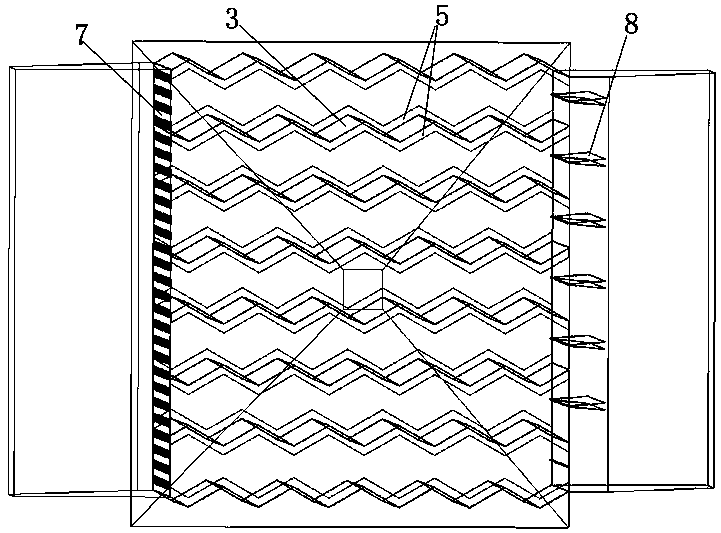

Dust collection polar plate based on particle trap effect, novel polarity form and efficient electrostatic dust collector

PendingCN110876985AIncrease the strength of the dust collection fieldSuppress restartElectrode constructionsElectrodes cleaningParticulatesParticle physics

The invention relates to a dust collection polar plate based on a particle trap effect, a novel polarity form and an efficient electrostatic dust collector. The dust collection polar plate is bent toform a plurality of convex folded plates and grooves, particle traps are formed at the grooves, a novel polarity form of matching the dust collection polar plate with the multi-angle double-thorn electrode is low in dust accumulation thickness and high in field intensity at the convex parts of the particle traps, and particles at the convex parts easily enter the traps under the action of airflowdrag force or rapping. The thickness of accumulated dust in the grooves is large, but the field intensity in a formed dust layer is low, inter-particle breakdown and interference to discharge are prevented, the operating voltage working interval is increased, and the electrostatic dust collector is formed in cooperation with an intelligent rapping system. According to the invention, reentrainmentdust is reduced, the effective field intensity loss of high-specific-resistance fly ash is reduced, and the specific resistance application range and the working temperature window of the electric precipitator are widened. The dust collection polar plate has the advantages of improving corona current, strengthening fine particle charge, improving dust removal efficiency and the like, can reduce operation cost, and has high industrial applicability and operation reliability.

Owner:ZHEJIANG UNIV

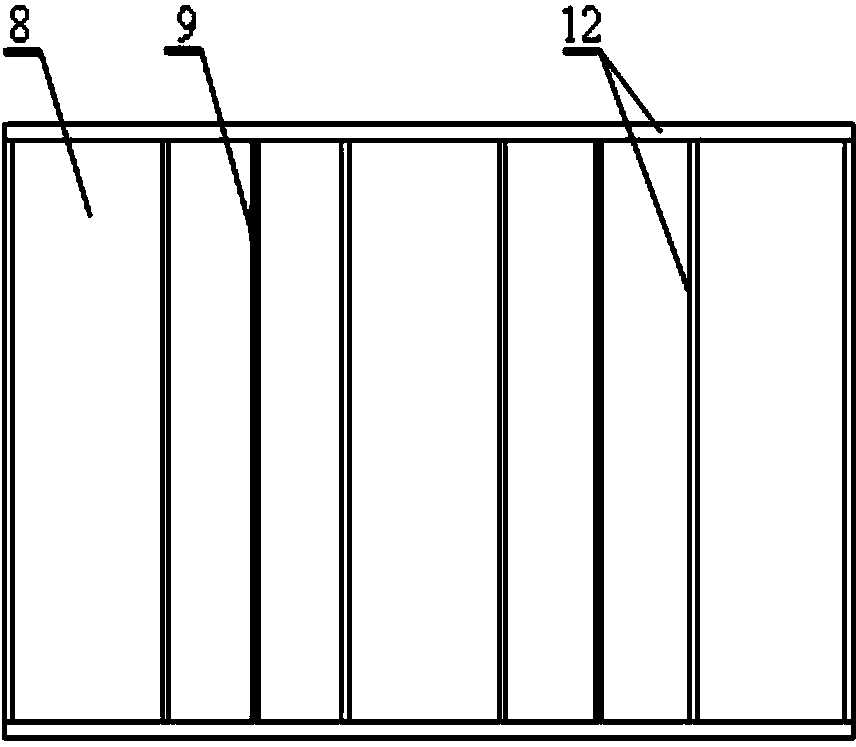

High-temperature electric dust-removing system for flue gas of industrial kilns

InactiveCN104984826AHigh temperature resistantImprove dust removal efficiencyExternal electric electrostatic seperatorElectrode constructionsArray data structureEngineering

The invention discloses a high-temperature electric dust-removing system for flue gas of industrial kilns. The high-temperature electric dust-removing system comprises a shell, wherein the shell is internally provided with a plurality of groups of high-voltage electric fields, wherein each group of high-voltage electric fields comprises a plurality of dust collecting electrodes, discharging electrodes and auxiliary electrodes which are vertically distributed; the electric field is divided into a plurality of parallel channels by the dust collecting electrodes; the discharging electrodes and the auxiliary electrodes are positioned at the middle parts of the channels to form staggered distribution; the discharging electrodes and the auxiliary electrodes are arranged in a discharging electrode frame; the dust collecting electrodes are vertically arranged in a dust collecting electrode frame; the dust collecting electrode frame and the discharging electrode frame are connected with clamping grooves on a cross beam at the top part of the shell in a clamping manner and are hung on a lifting beam; and the lifting beam is suspended on a top beam of the shell by a supporting insulator. The high-temperature electric dust-removing system disclosed by the invention has the characteristics of high-temperature resistance, high dust removing efficiency, long service life, less dust re-entrainment and long-term and stable operation and the like and can be applicable to dust removal of high-temperature flue gas of the industrial kilns below 500 DEG C.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

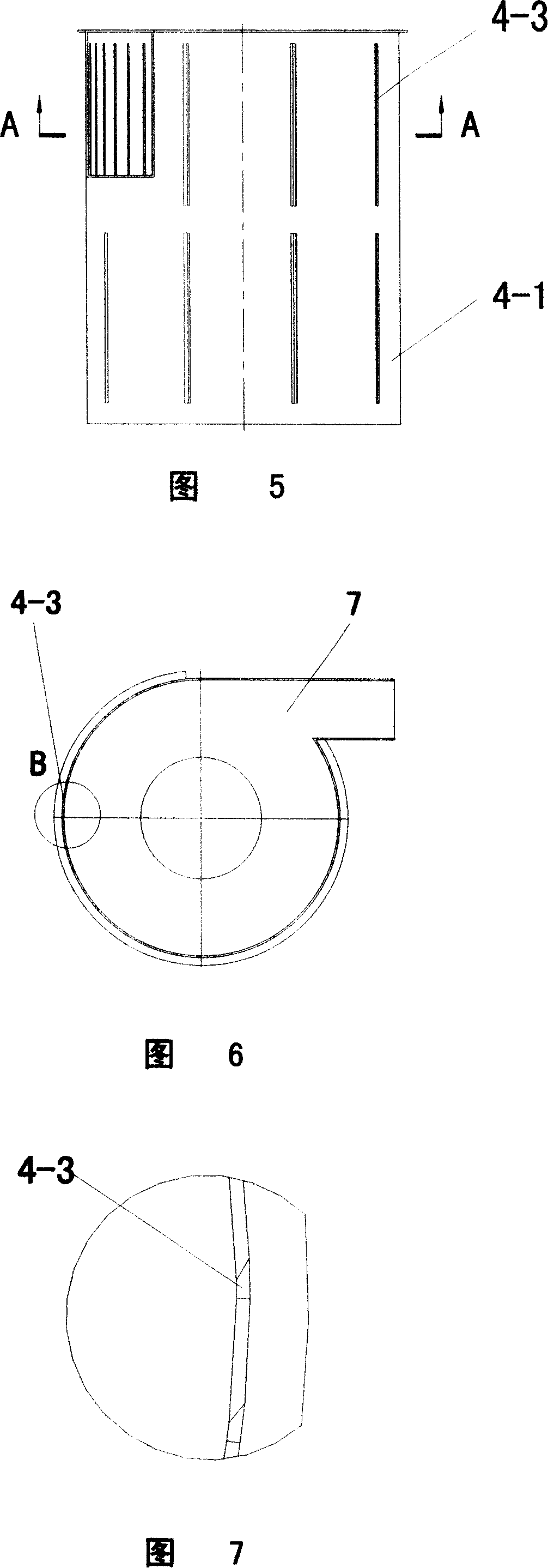

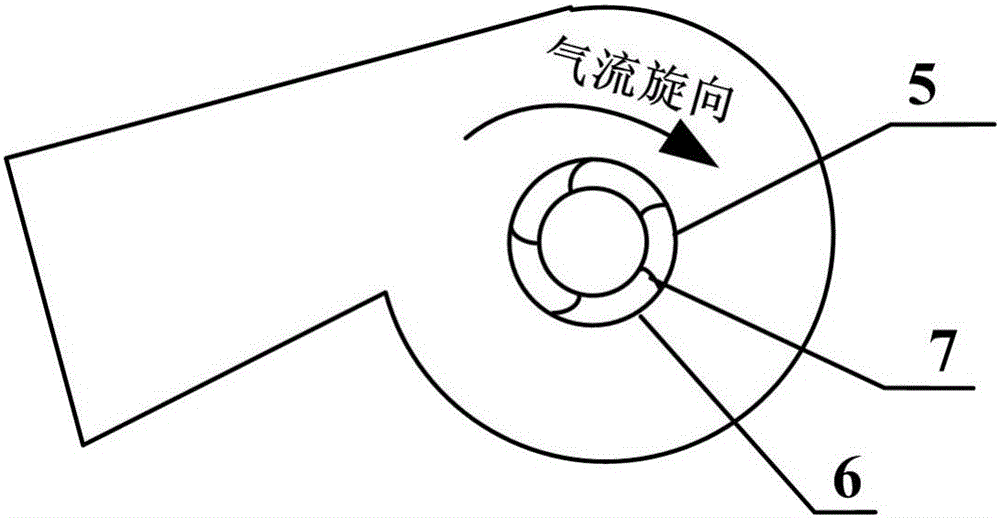

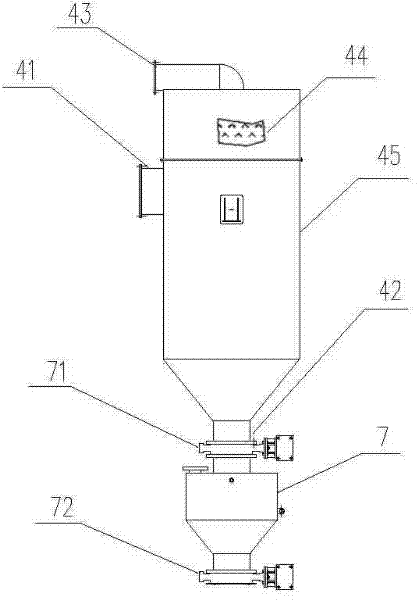

Power cyclone separator

ActiveCN101961687AAvoid short circuitPrevent radial movementReversed direction vortexCycloneFrequency conversion

The invention discloses a power cyclone separator, comprising a cylinder body, a cone body, a dust-collecting hopper and a discharge valve, wherein the lower section of the cylinder body is connected with the cone body; the upper section of the cylinder body is provided with a spiral guide plate; a purified gas outlet and a gas inlet are arranged on the cylinder body and are connected by an exhaust pipe inside the cylinder body; a flow velocity transmitter is arranged on one side of the gas inlet; a frequency conversion motor is arranged on one side opposite to the gas inlet and is connected with a jumping mechanism arranged on the inner side of the cylinder body through a shaft seal; the lower part of the cone body is connected with the dust-collecting hopper; a charge level indicator is arranged at the upper part on one side of the dust-collecting hopper; a pneumatic hammer is arranged at the lower part of the dust-collecting hopper; and the bottom of the dust-collecting hopper is connected with the discharge valve. The power cyclone separator is especially suitable for low flow velocity and high-temperature air flow dust separation with normal pressure working conditions at the inlet so as to improve the dust collecting efficiency.

Owner:SHANGHAI KIMKEY ENVIROMENTAL S&T

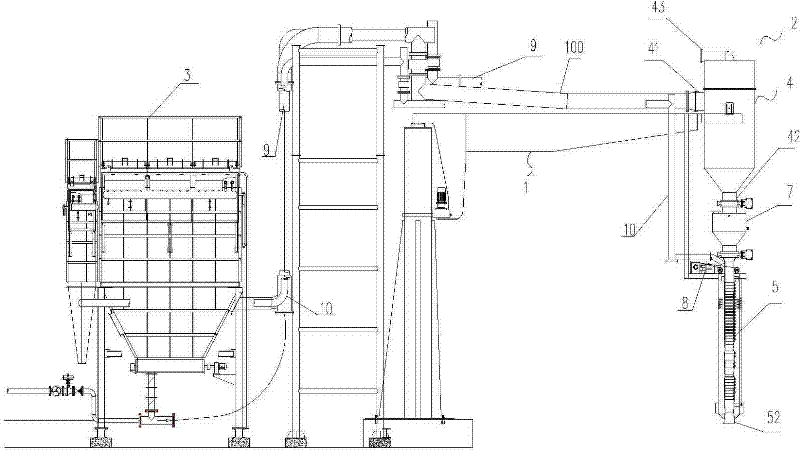

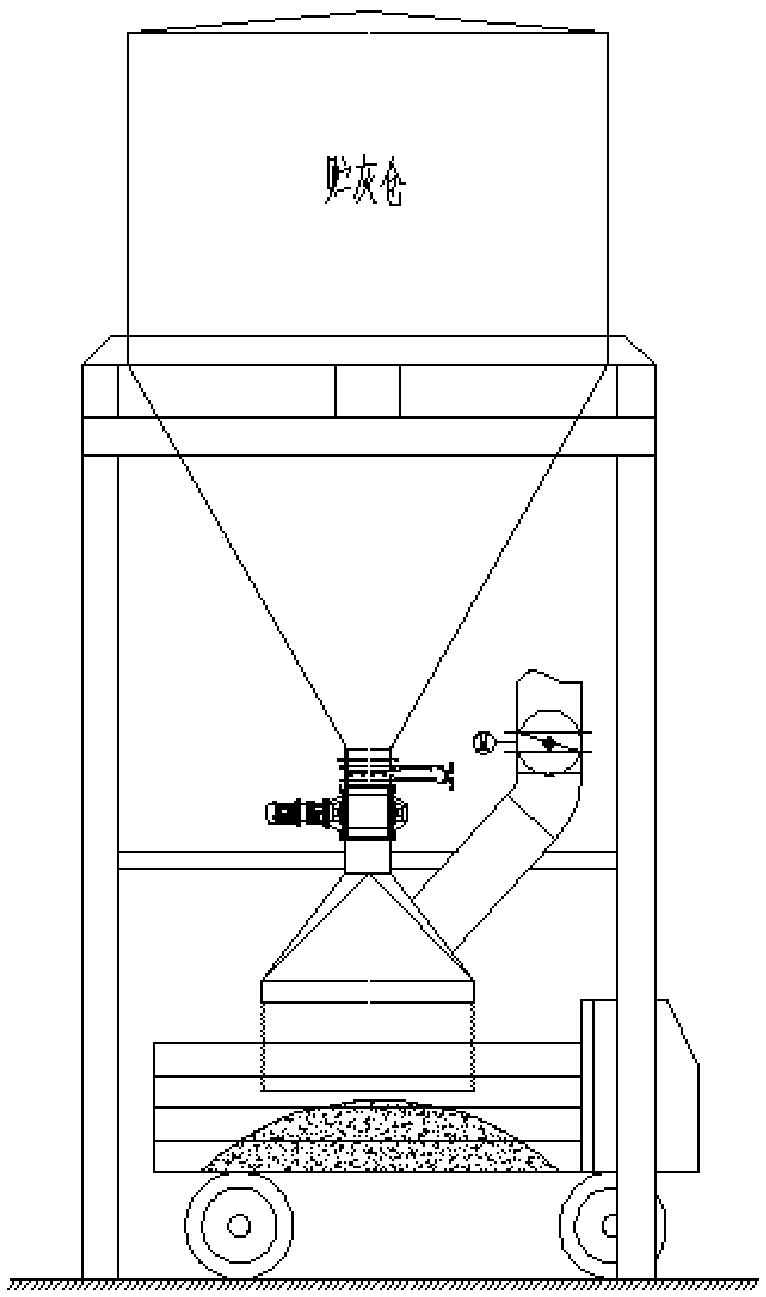

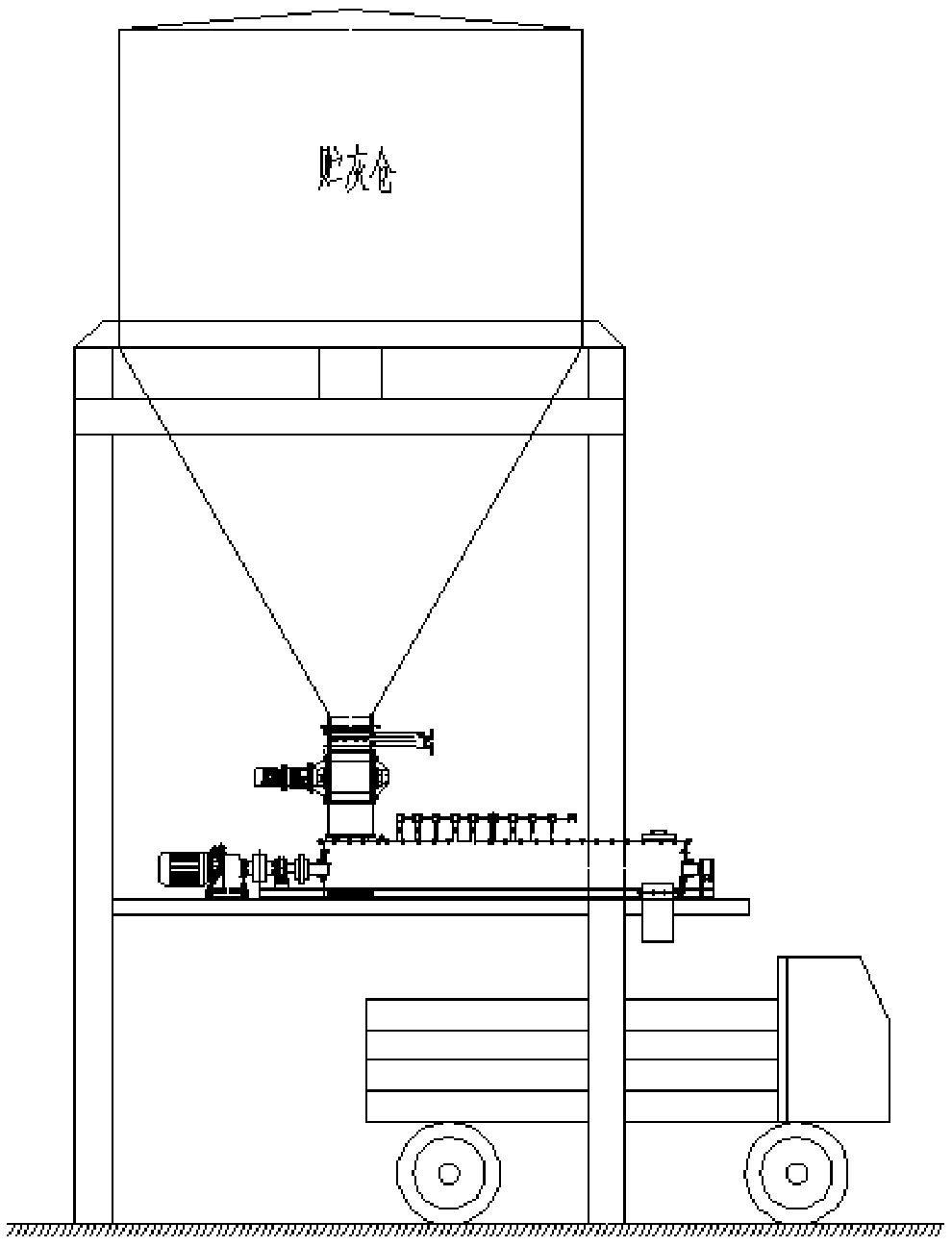

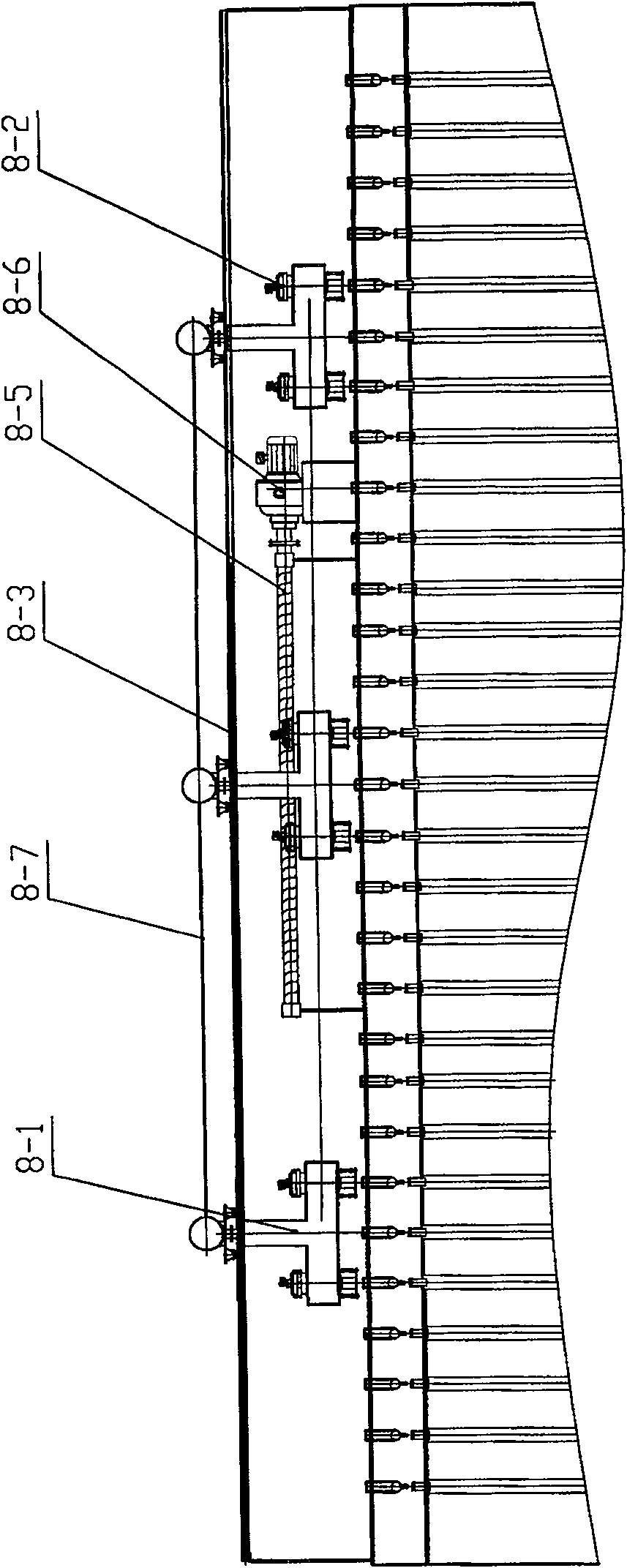

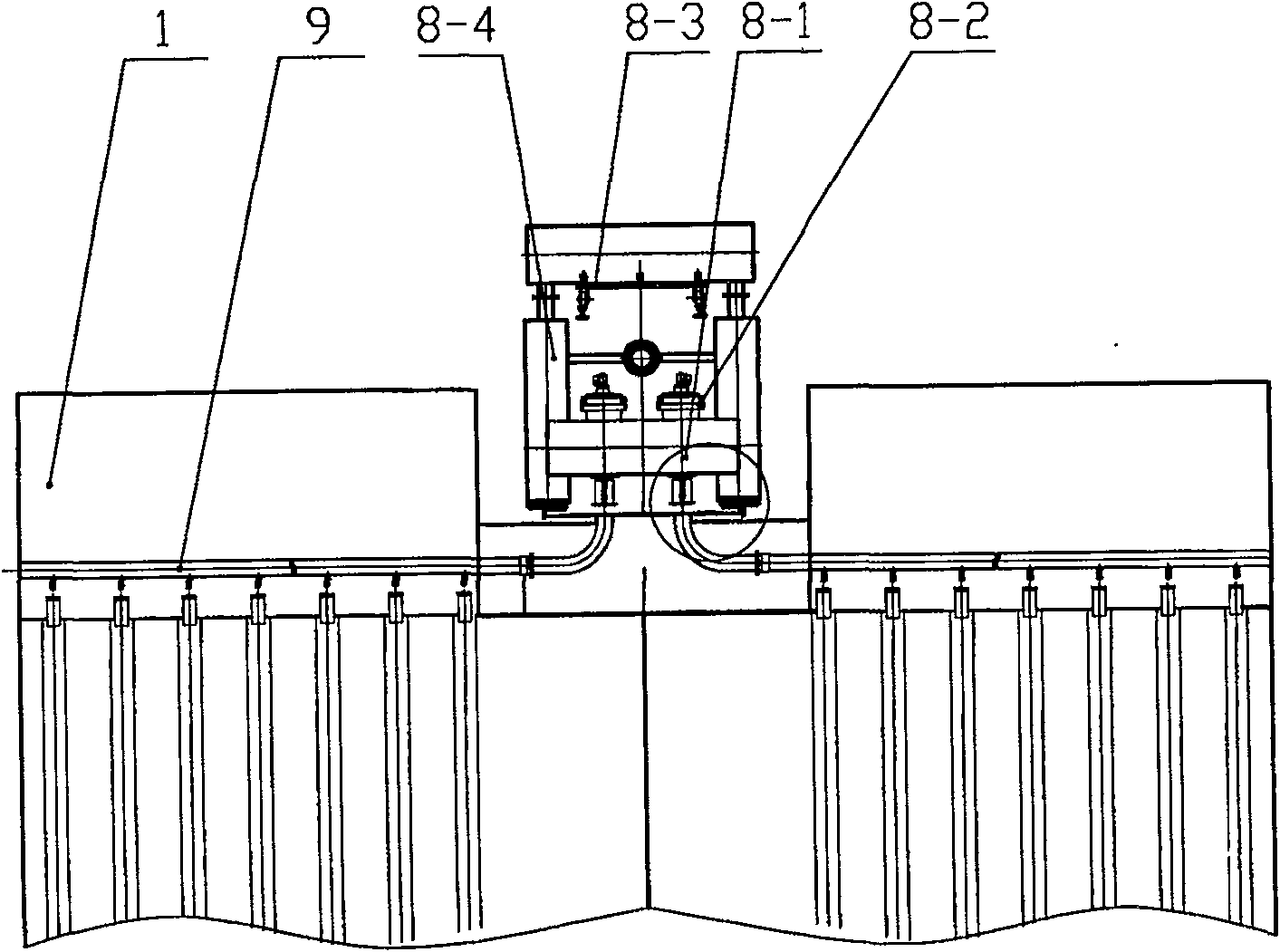

Long-distance pneumatic conveying direct loading-shipping system for bulk materials

ActiveCN102642726AAchieve the purpose of separationAvoid it happening againLoading/unloadingThermodynamicsLow speed

The invention relates to a long-distance pneumatic conveying direct loading-shipping system for bulk materials, which relates to a loading-unloading device for vehicles and ships, and belongs to the technical field of mechanical equipment. The structure of the long-distance pneumatic conveying direct loading-shipping system for bulk materials comprises a stander, a filling head and a large-sized cloth-bag dust collector as well as a pneumatic conveying device, wherein the filling head fills materials into a compartment of a vehicle or a ship, the large-sized bag-cloth dust collector is used for separating the gas which is discharged from the filling head and is mixed with the materials from the gas which is discharged from the compartment of the vehicle or the ship and is mixed with the materials, and the pneumatic conveying device is used for conveying the materials into the filling head. Due to the adoption of the loading-shipping system, the problems of flying dust and low loading-shipping efficiency caused by adopting the existing conveying loading-shipping system when in pneumatic conveying loading and shipping can be solved. Before the gas enters a discharging pipe, the gas flow is separated from the materials, the gas flow is thoroughly exhausted or the dust is further separated from the gas flow, and the materials enter the discharging pipe and the compartment at a low speed, so that a great amount of natural or secondary flying dust can be avoided; and meanwhile, little flying dust produced inside the compartment can be further collected and removed, and the conveying efficiency is remarkably improved.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

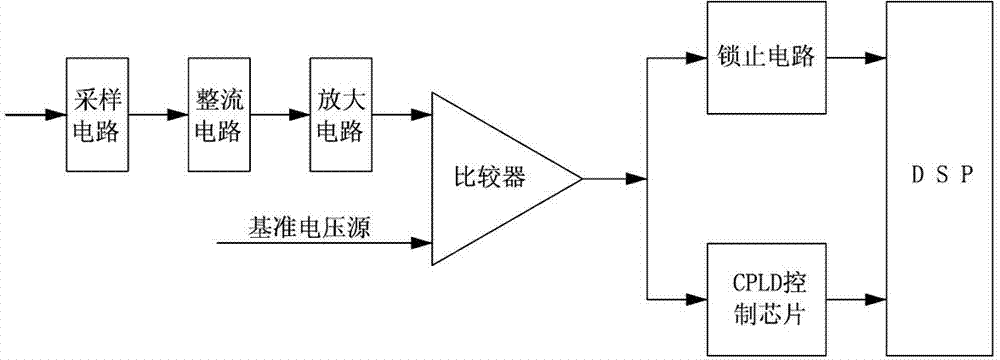

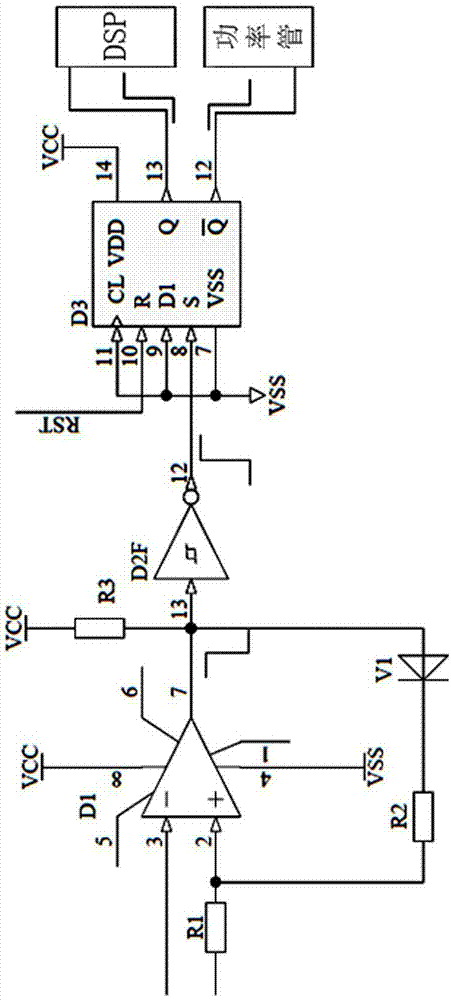

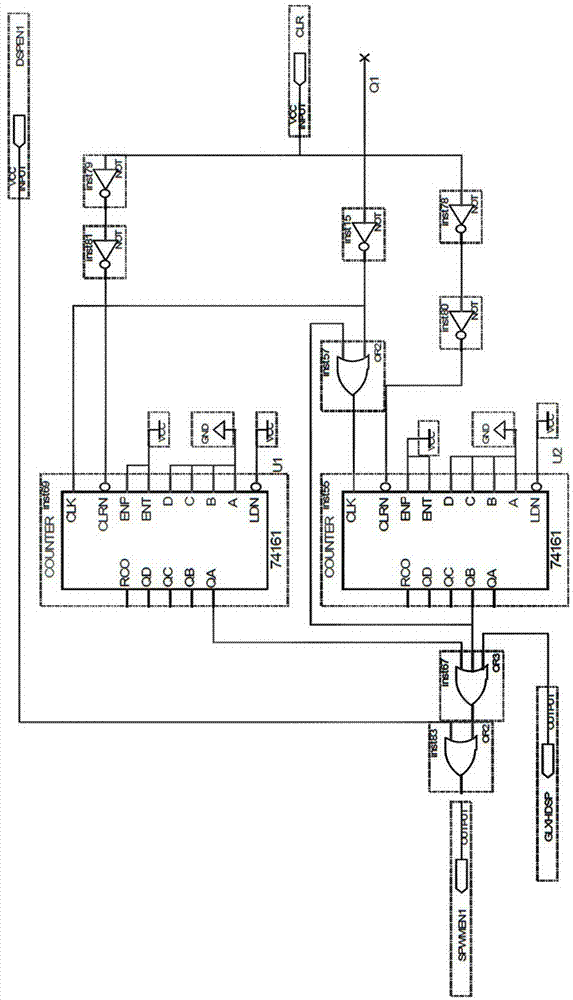

Multi-energy level spark detection system with locking function

ActiveCN104505809AImprove dust removal efficiencyImprove energy savingEmergency protective circuit arrangementsControl systemComplex programmable logic device

The invention discloses a multi-energy level spark detection system with a locking function and aims to solve the technical problems that when an electrostatic dust collector causes electric spark discharge, as a high-voltage power supply cannot be timely cut off, a power module and a power pipe are damaged. The multi-energy level spark detection system comprises a sampling circuit, a conditioning circuit, a comparator, a spark energy level judging circuit and a locking circuit which is used for locking output of the high-voltage power supply, wherein the spark energy level judging circuit comprises a CPLD (complex programmable logic device) control chip; a dithering elimination circuit, a delay circuit and a spark detection control circuit are integrated in the CPLD control chip. According to the multi-energy level spark detection system, the power pipe can be reliably locked to drive an enable signal, and a power supply of an overcurrent load can be instantaneously cut off, so that safe and stable operation of the high-voltage power supply is guaranteed; the dithering elimination circuit, the delay circuit and the spark detection control circuit are integrated in the CPLD control chip, so that the integrity is high, the flexibility of a control system is improved, and debugging and equipment upgrading are facilitated.

Owner:GUODIAN NANJING AUTOMATION

High-efficiency purification electrostatic dust collector

PendingCN108568347AReduce secondary dustSimple structureElectrode constructionsElectrodes cleaningHigh humidityBaghouse

The invention relates to a high-efficiency purification electrostatic dust collector, aiming at solving the problem that the dust removal efficiency is reduced, caused by reverse corona and secondarydust rising. The high-efficiency purification electrostatic dust collector comprises a gas inlet, a gas outlet, a dust collection plate, a discharging wire and an ash bucket, wherein the dust collection plate is provided with an ash cleaning device; ash cleaning boxes with a special design are adopted and are used for squeezing dust swept by an ash cleaning brush at the top of the box body, so that the secondary dust rising is avoided; two ash cleaning boxes form one group, and form a loop through a rope; when one ash cleaning box is ascended, the other ash cleaning box is descended to clean ash. The ash cleaning brush is designed to keep vertical with the dust collection plate in an ash cleaning process; when the ash cleaning brush is ascended to be reset, a brush head is folded, so thatthe service life is prolonged. According to the dust collector provided by the invention, the disadvantages of a conventional electrostatic dust collector that the specific resistance is high, ultrafine dust and high-viscosity dust are difficult to collect and clean, the secondary dust rising is easy to cause and the like are overcome, and the defects of a bag dust collector that the equipment resistance is great, the operation cost is high, the working amount of daily maintenance is great, high-temperature and high-humidity flue gas is difficult to treat and the like are also made up; the high-efficiency purification electrostatic dust collector is simple in structure, high in ash cleaning efficiency, low in cost and easy to maintain.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Flat plate type dust collector

InactiveCN103934104AIncrease contact areaImprove dust collection efficiencyElectrostatic separation detailsEngineeringDust collector

The invention discloses a flat plate type dust collector. The flat plate type dust collector comprises a shell, wherein one end of the shell is provided with an air inlet, and the other end of the shell is provided with an air outlet; the air inlet and the air outlet are coaxial, and the shell is internally provided with main and subsidiary dust collecting units which are mutually perpendicular; the subsidiary dust collecting unit is horizontally arranged in the shell, and the front end of the subsidiary dust collecting unit is connected with the upper part of the shell through a front separation baffle which is perpendicular to the subsidiary dust collecting unit; the rear end of the subsidiary dust collecting unit is connected with the main dust collecting unit through a rear separation baffle, and axes of the air inlet and the air outlet of the shell are perpendicular to a windward side of the main dust collecting unit; the main and subsidiary dust collecting units both comprise dust collecting pole plates and discharge electrodes arranged outside the dust collecting pole plates, the discharge electrodes are perpendicularly uniformly provided with discharge electrode burrs, and the dust collecting pole plates are composed of dust collecting poles arranged in a clamping groove frame. The flat plate type dust collector provided by the invention has the beneficial effects that the dust collecting effect is good, a dust cleaning device is combined, the service life of each dust collecting pole plate is prolonged, and dust collecting effects of the dust collecting pole plates are guaranteed.

Owner:任利萍

Electric precipitator

InactiveCN104785370AIncrease driving speedImprove adsorption capacityElectrode carrying meansExternal electric electrostatic seperatorAirflowCathode

The invention relates to an electric precipitator. The electric precipitator comprises a housing, an air inlet box, an exhaust box, an insulation box and ash hoppers, wherein the housing is fixed by a housing vertical beam and a housing cross beam; the air inlet box and the exhaust box are arranged at the two ends of the housing; the insulation box and the ash hoppers are arranged on the upper and lower sides on the outer side of the housing respectively; an anode hanging device is arranged in the housing; a flow guiding plate and a flow distribution plate perpendicular to the airflow direction are arranged in the air inlet box; a cathode hanging device is fixed at the upper end of the anode hanging device; the anode hanging device is connected with an anode frame; the anode frame is connected with an anode rapping device; the cathode hanging device is connected with a cathode frame; the cathode frame is connected with a cathode rapping device. Compared with the prior art, the electric precipitator solves the problems that the conventional electric precipitators are low in dust removal efficiency, poor in dust removal effect, slow in dust migration velocity, and much in blowing dust.

Owner:斯诺堡(北京)节能环保设备有限公司

Preparation method of natural and environment-friendly dust suppressant

ActiveCN107057644AHigh strengthTo achieve the effect of dust suppressionOther chemical processesCross-link(Hydroxyethyl)methacrylate

The invention belongs to the technical field of flying dust management of roads and in particular relates to a preparation method of a natural and environment-friendly dust suppressant. The preparation method comprises the following steps: firstly, mixing bagasse powder with de-ionized water and sodium hexadecyl benzene sulfonate; carrying out microwave treatment to obtain a bagasse mixed solution; then regulating the pH (Potential of Hydrogen), adding carob gum and sodium carboxymethyl starch in sequence and reacting to obtain a reactant; mixing bagasse juice and sodium alginate and heating; adding N,N-dimethylacrylamide, hydroxyethyl methacrylate and a cross-linking agent; after cooling, adding the reactant; stirring and then regulating the pH; mixing with an ammonium persulfate solution and stirring and reacting to obtain the low-temperature-resisting natural and environment-friendly dust suppressant; the low-temperature-resisting natural and environment-friendly dust suppressant provided by the invention has a low-temperature-resisting property, can be freely sprayed under a low-temperature condition and is not frozen; after the low-temperature-resisting natural and environment-friendly dust suppressant is sprayed, a shell layer with certain thickness and strength is formed on the surface of a material; the shell layer is not broken by frosting and cracked under a low-temperature environment, does not cause ash, corrosion and secondary pollution and can be biologically degraded.

Owner:内蒙古睿鸿鑫环保科技有限公司

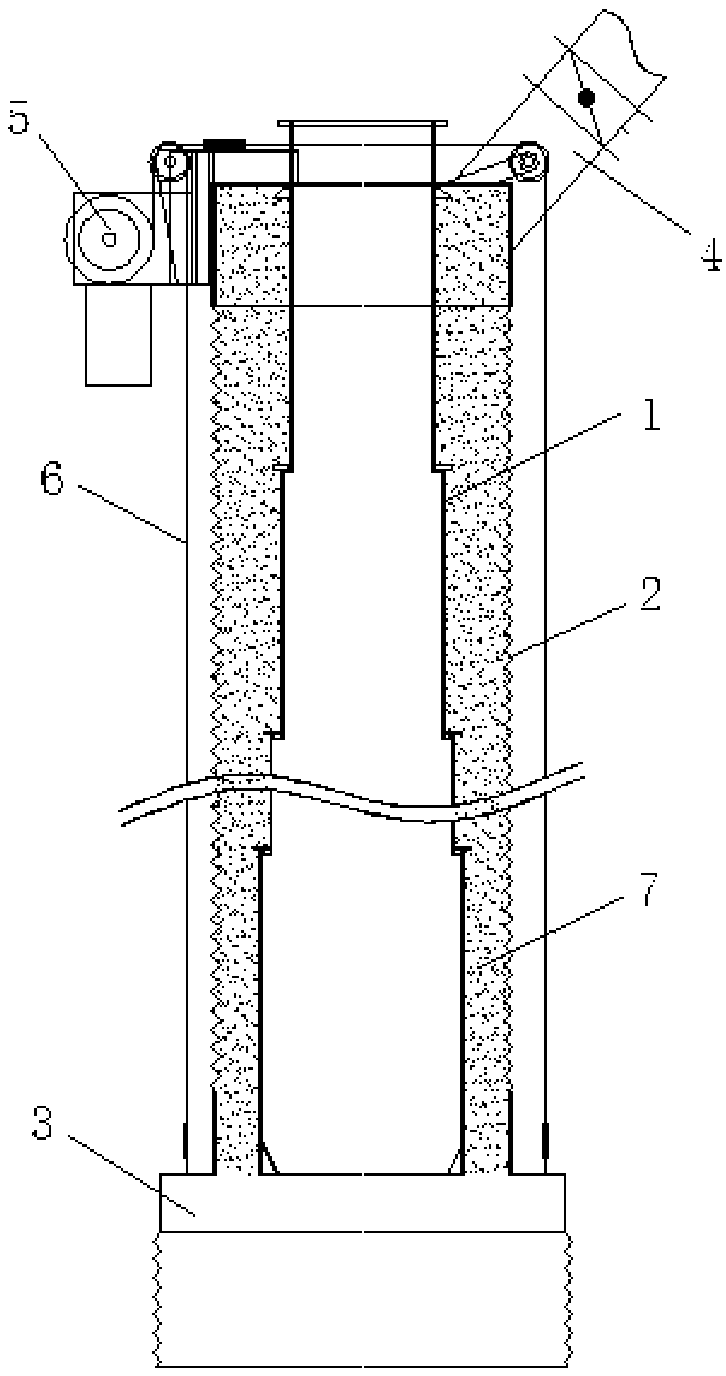

Dust discharging and collecting integrated device

InactiveCN109552905AReduce energy consumptionNo pollution in the processDirt cleaningLoading/unloadingArchitectural engineeringEnergy consumption

The invention discloses a dust discharging and collecting integrated device in the field of dust removing equipment. The dust discharging and collecting integrated device comprises a telescopic innersleeve, a telescopic outer sleeve and a dust hood, an unloading inlet is formed in the upper end of the telescopic inner sleeve, the lower end of the telescopic inner sleeve is connected with the dusthood, the telescopic outer sleeve is arranged outside the telescopic inner sleeve in a covering mode, the upper end of the telescopic outer sleeve is connected with the telescopic inner sleeve in a sealed mode, and the lower end of the telescopic outer sleeve is communicated with the dust hood, a vent pipe is arranged at the upper end of the telescopic outer sleeve pipe and is connected to a dustremoval pipe network or is pressed and returned by a dust removal fan to return to a dust bin. The dust discharging and collecting integrated device has the advantages that the telescopic inner sleeve and the telescopic outer sleeve are arranged, the distance between the dust hood and the carriage can be adjusted during unloading, secondary flying dust can be reduced, the dust catching channel isformed through the telescopic outer sleeve, so that secondary flying dust is further reduced, the storage bin is small in energy consumption, no dust is generated, the influence of wind force is avoided, the environment pollution of the ash discharging post is avoided.

Owner:PANGZHIHUA PANGANG GROUP DESIGN & RES INST

Energy-saving environment-friendly road dust removing device

InactiveCN113398692AAvoid going back againReduce secondary dustUsing liquid separation agentWater flowEnvironmental engineering

The invention relates to the technical field of road dust removal, and discloses an energy-saving environment-friendly road dust removing device. The device comprises an upper cavity, wherein a dust removal cavity is fixedly installed at the bottom of the upper cavity, a threaded rod is movably installed in the upper cavity, and the threaded rod can rotate along the axis of the upper cavity. According to the invention, the upper cavity is divided into an air cavity and a water cavity through a partition plate; a wind cup is driven to rotate by a flow speed change driven by flowing of automobiles, and the rotating wind cup can drive a piston plate to move, so air pressure in the upper cavity is changed, and finally, the dust removal cavity sucks outside air with dust; on the other hand, water flow forms water mist under the action of a water outlet pipe and a water outlet, and the water mist is combined with the dust, so the dust has a certain weight, and the dust and the water are deposited at the bottom of the dust removal cavity; and during cleaning, due to the fact that the dust is wet, secondary dust raising caused during dust cleaning is effectively reduced, the dust is prevented from returning to the air again, and dust removal efficiency is improved.

Owner:段婷

Gliding blowing bag-type dust remover for large-sized cement kiln

ActiveCN100574848CReduce in quantityReduce manufacturing costDispersed particle filtrationEngineeringCement kiln

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com