Preparation method of efficient dedusting module

A high-efficiency, metal module technology, applied in the direction of electrostatic effect separation, solid separation, external electrostatic separator, etc., can solve the problems of indoor air humidification, difficult processing, large HEPA pressure drop, etc., to reduce secondary dust, remove Great effect with adjustable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

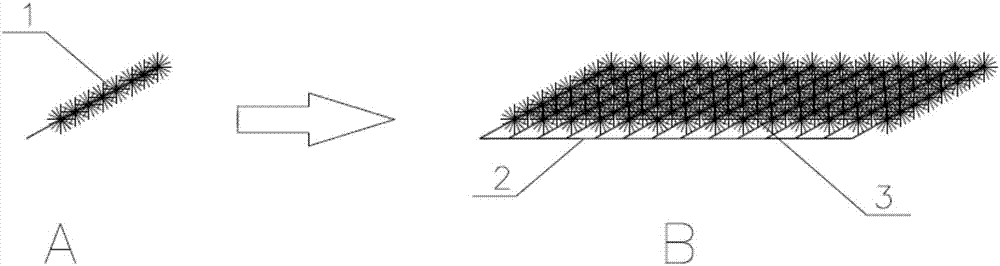

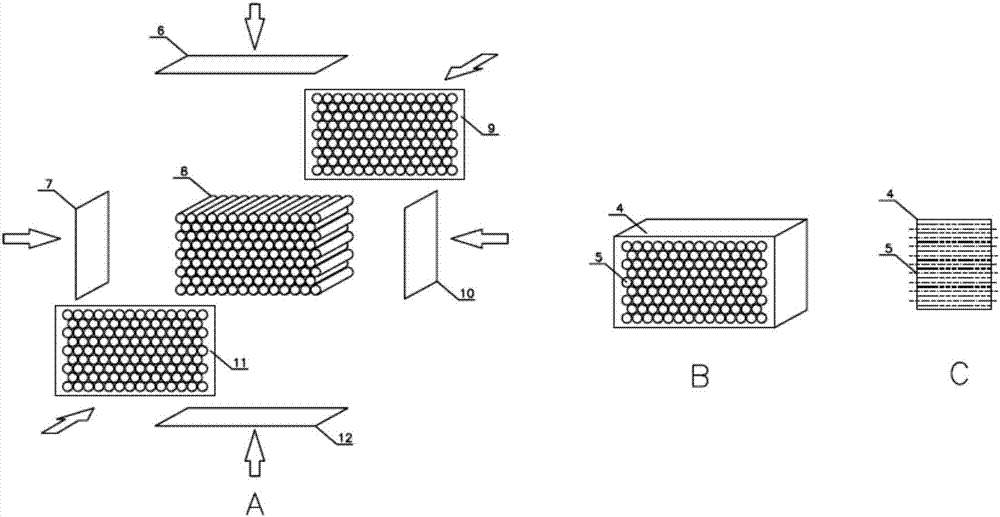

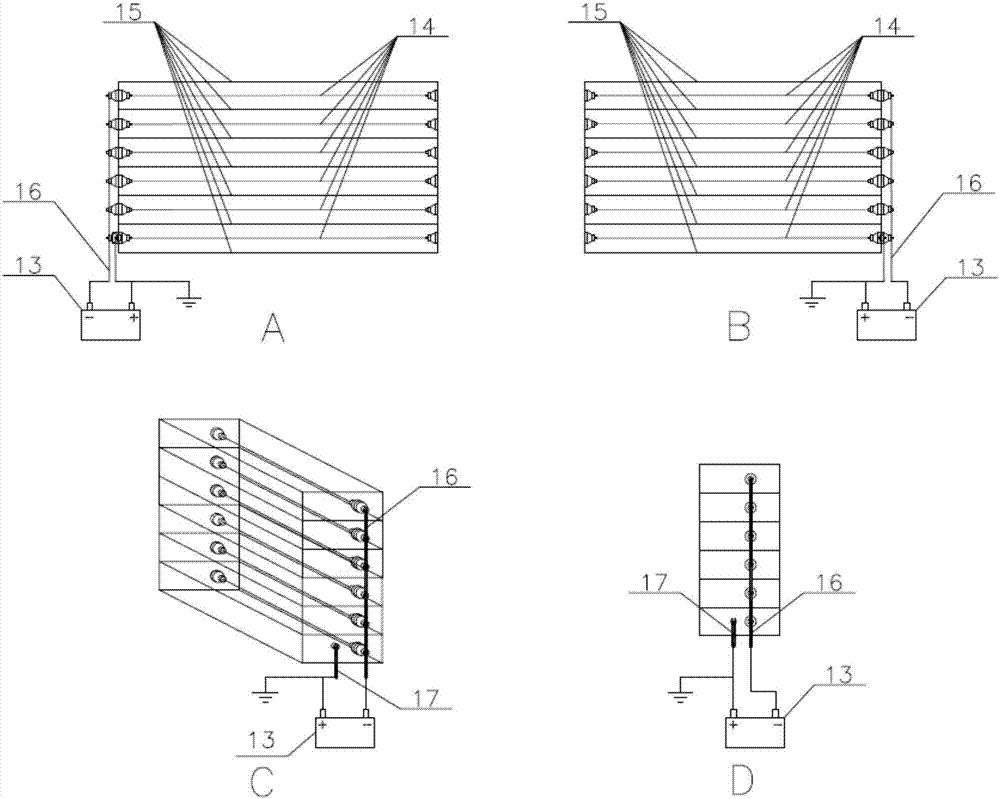

Embodiment 1

[0022] Prepare a charging module with a flow channel size of 30cm×20cm, its pole spacing is 3cm, 10 round wires with a diameter of 0.1mm and a length of 20cm are used as corona wires, and the width of the dust collecting plate in the airflow direction is 3cm, the corona electrode is loaded with a positive voltage of 6000V, the dust collection plate is grounded, and a stainless steel charging module with a size of 30cm×20cm×10cm is connected. The airflow channel is a cylindrical channel with a length of 10cm and a hole diameter of 10mm. The distance between the centers of the three holes is 15mm, and the centers of every three adjacent holes are arranged in an equilateral triangle. The number of holes is 293. Take 293 twisted wire brushes with an outer diameter of 11mm. The bristles are made of polyethylene wire and the length of the hair is 10cm. The two twisted wires in the middle of each brush are copper wires, which are inserted into the holes of the stainless steel charging...

Embodiment 2

[0024] Prepare a charging module with a flow channel size of 20cm×20cm, its pole spacing is 2cm, use 10 star-shaped wires with a diameter of 1mm and a length of 20cm as corona wires, and the width of the dust collecting plate in the airflow direction is 3cm, the corona electrode is loaded with 2000V negative voltage, the dust collection plate is grounded, and a carbon steel charging module with a size of 20cm×20cm×5cm is connected. The airflow channel is a cylindrical hole with a length of 5cm and a hole diameter of 20mm. The distance between the center of the circle is 24mm, and the center of each three adjacent holes is arranged in an equilateral triangle, the number of holes is 68, and 68 twisted wire brushes are taken, the outer diameter is 32mm, the bristle material is polypropylene wire, and the length of the hair bit is 5cm, the two twisted wires in the middle of each brush are aluminum wires, inserted into the holes of the carbon steel charging module, one brush is inse...

Embodiment 3

[0026] Prepare a charging module with flow channel size of 10cm×10cm, its pole spacing is 5cm, use 2 helical wires with a diameter of 0.5mm and a length of 10cm as corona wires, and the width of the dust collecting plate in the airflow direction is 4cm, the corona electrode is loaded with 20kV positive voltage, the dust collection plate is grounded, and a copper charging module with a size of 10cm×10cm×5cm is connected. The airflow channel is a cylindrical hole with a length of 5cm and a hole diameter of 15mm. The center of every three adjacent holes is arranged in an equilateral triangle. The number of holes is 27. Take a twisted wire brush with an outer diameter of 20mm. The bristle material is pig bristle, and the length of the hair is 5cm. The twisted wire is stainless steel wire, which is inserted into the hole of the copper charging module, and a brush is inserted in each hole. The outer wall is grounded, and a layer of paraffin oil is loaded on the bristles of the brush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com