Electric precipitator

An electrostatic precipitator and anode technology, which is applied in the field of gas purification technology devices, can solve the problems of improving the dust removal efficiency without equipment, increasing the difficulty of equipment manufacturing, and increasing the manufacturing cost of the equipment, so as to achieve enhanced deformation resistance, improved rapping effect, and increased The effect of rapping intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

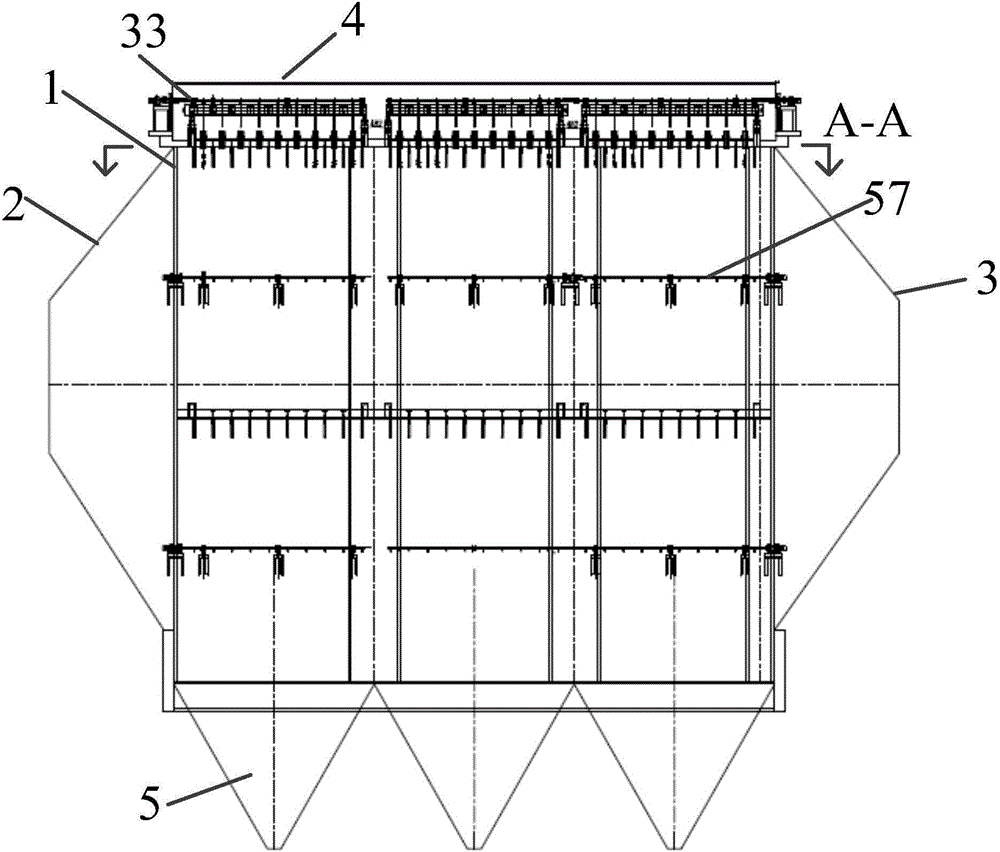

[0089] Such as figure 1 As shown, an electrostatic precipitator includes: a housing (1), and the two ends of the housing (1) fixed by the housing vertical beam (50) and the housing beam (49) are respectively provided with air intake boxes ( 2) and an exhaust box (3), an incubator (4) and an ash hopper (5) respectively arranged on the upper and lower sides of the outer side of the housing (1); the housing (1) is provided with a plurality of dedusting stages (64 ),Such as Figure 28 As shown, the air intake box (2) is provided with a deflector (38) and an air distribution plate (41) perpendicular to the airflow direction,

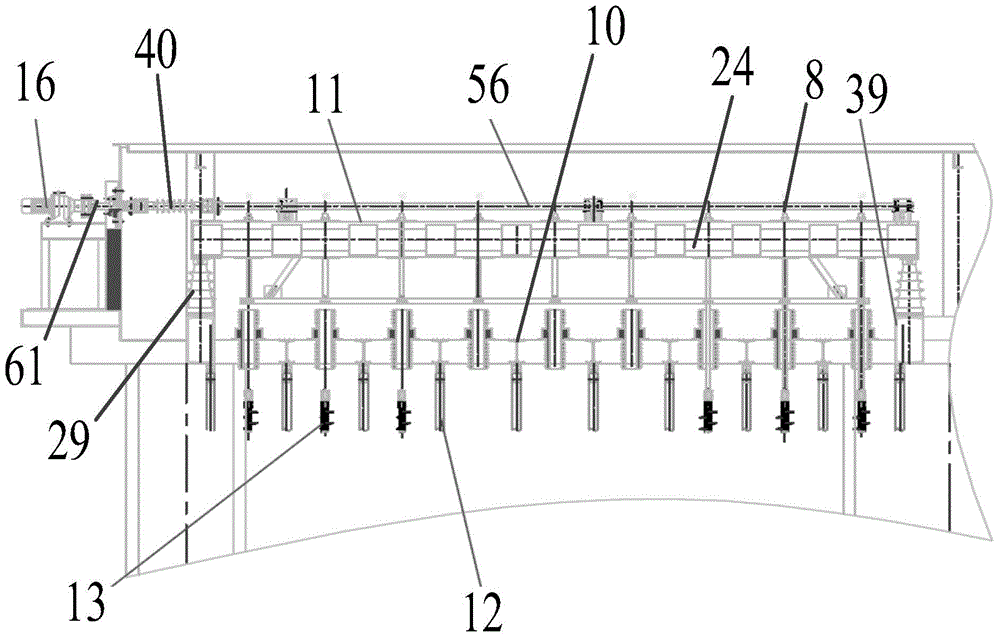

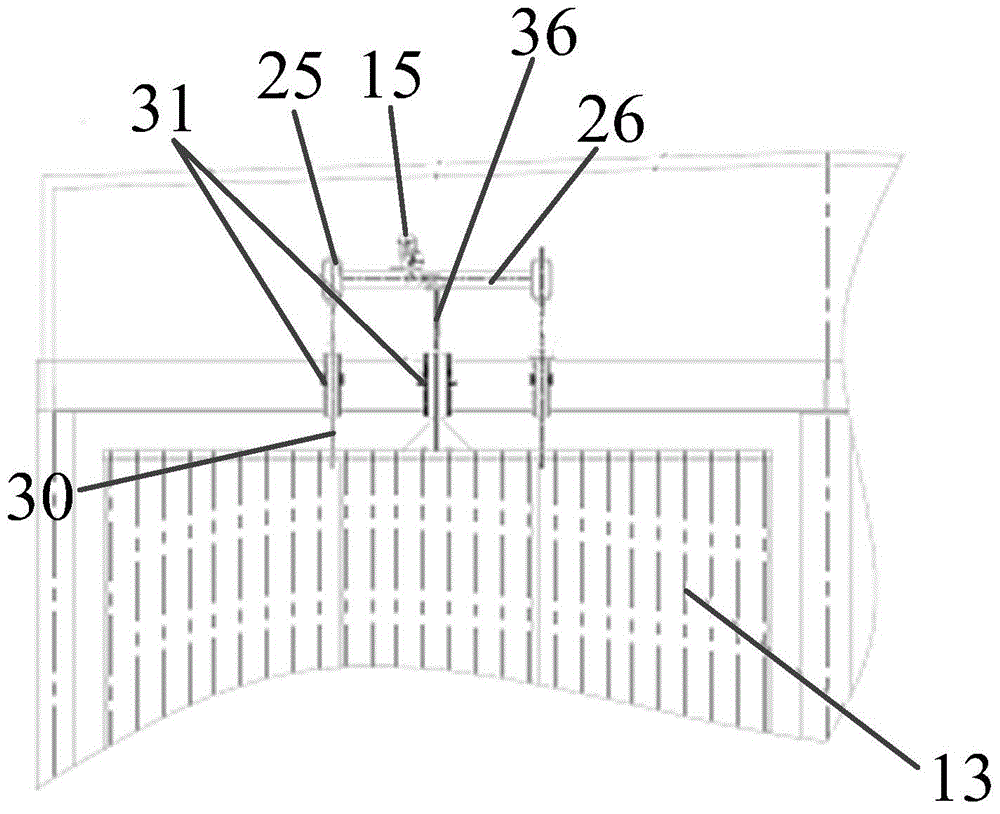

[0090] Such as Figure 30 and Figure 31 As shown, the dust removal stage (64) is multi-row, and each of the dust removal stages (64) is provided with one or more sets of anode suspension (10) and cathode suspension (11);

[0091] Such as figure 2 As shown, the upper end of the anode suspension (10) is fixed with a cathode suspension (11);

[0092] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com