All-terrain adaptive wheel track and application thereof

An adaptive, all-terrain technology, applied in the direction of wheels, tracked vehicles, motor vehicles, etc., can solve the problems of inability to realize all-terrain and all-road conditions application, no all-terrain wheel shoes, and inability to freely switch, so as to improve passability and improve Driving speed and traction improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

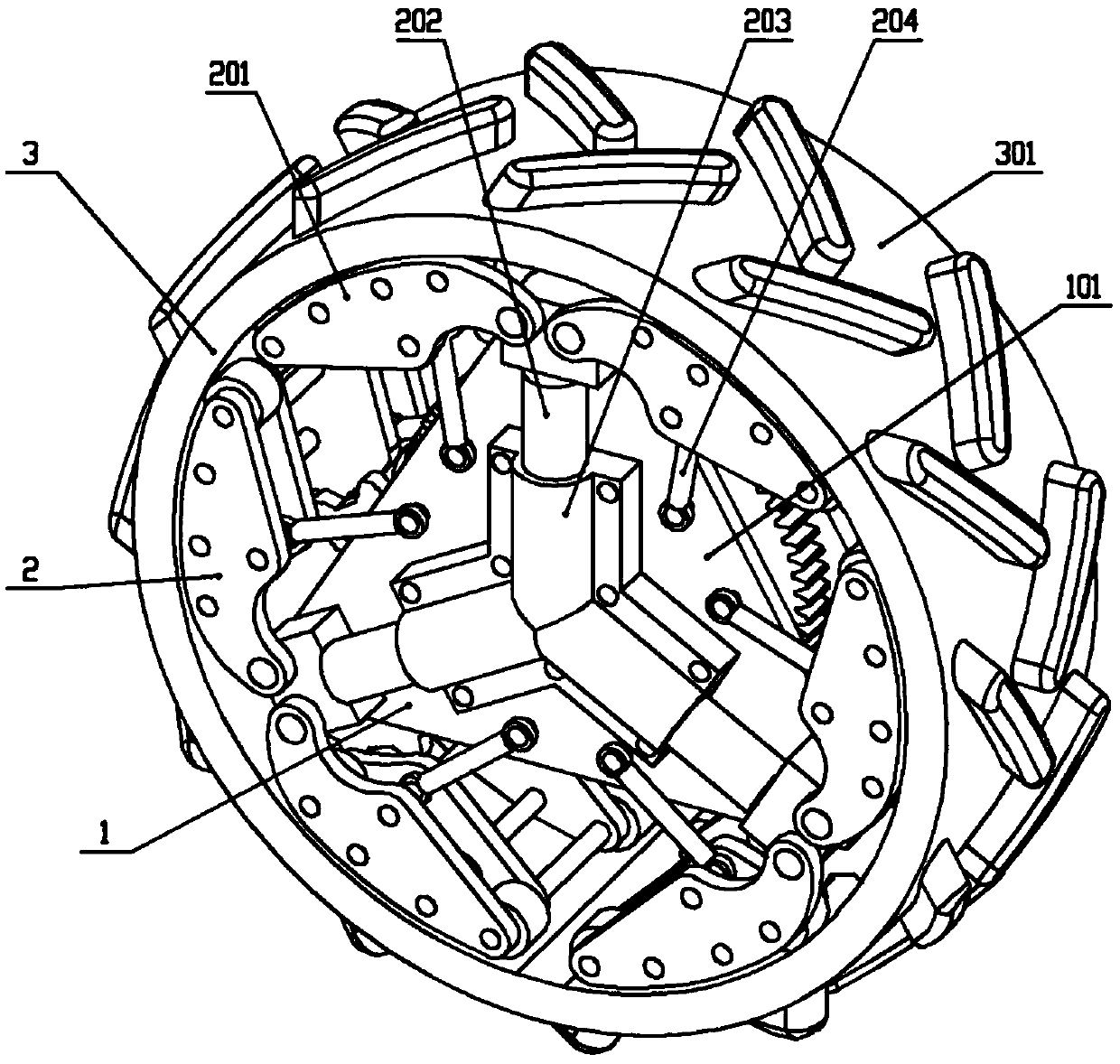

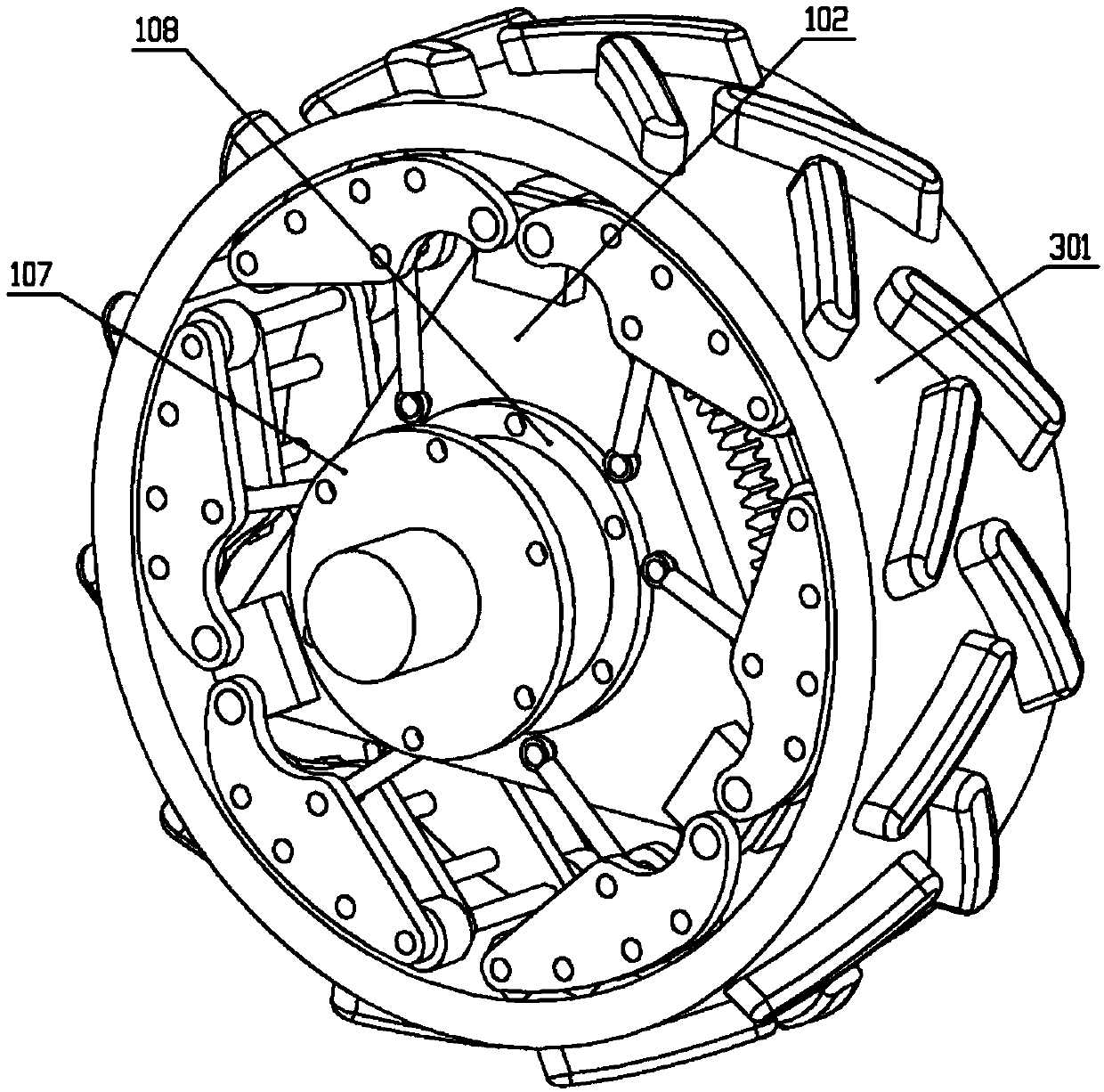

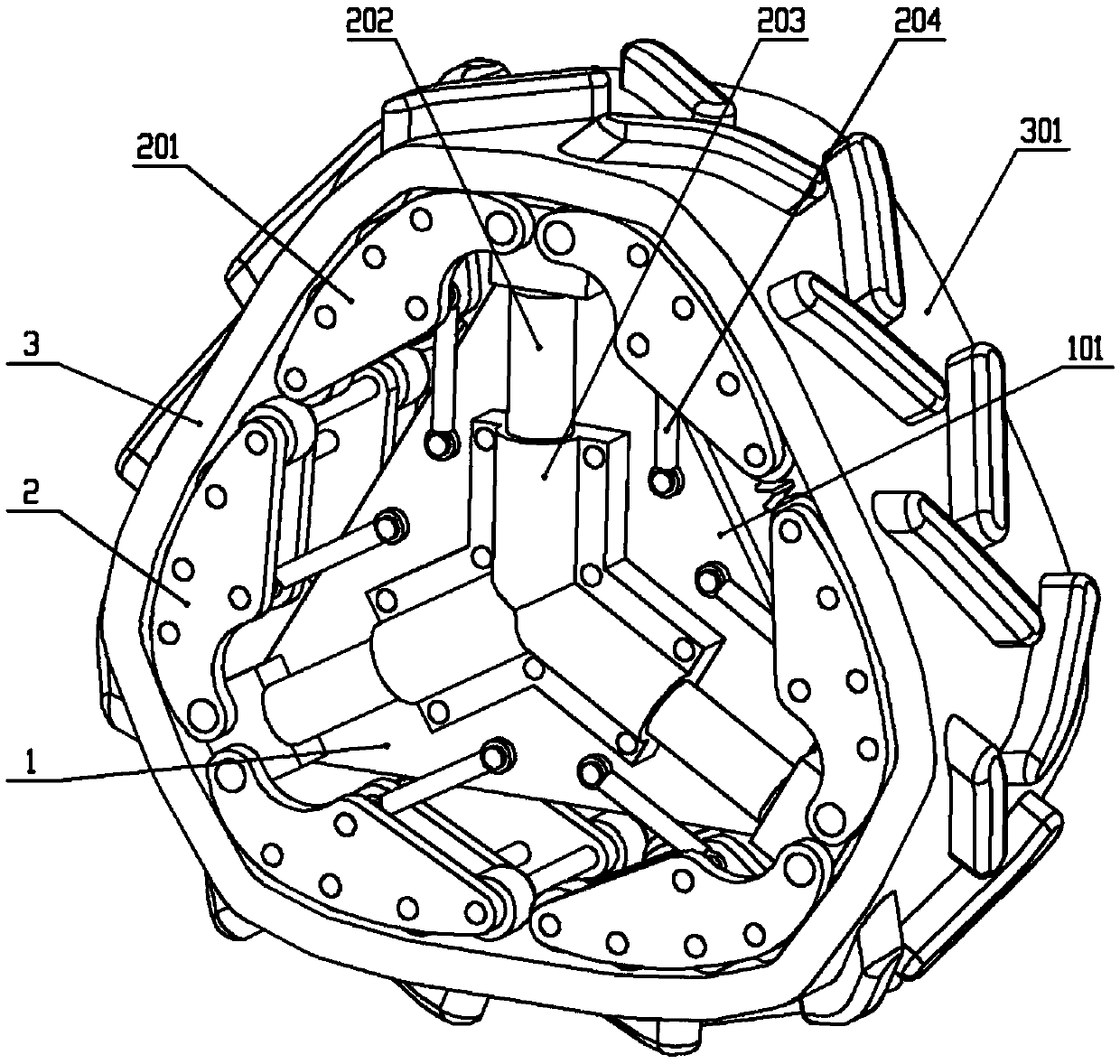

[0037] Such as Figure 1 to Figure 7 As shown, this embodiment provides an all-terrain adaptive wheel shoe, which mainly includes three parts: a planetary gear reduction mechanism 1, a movable combined hub mechanism 2 and a rubber crawler transmission mechanism 3;

[0038] The planetary gear reduction mechanism 1 is connected to the movable combined hub mechanism 2 through the telescopic device and the support rod 204, and the movable combined hub mechanism 2 changes its external shape through the operation of the telescopic device;

[0039] The rubber crawler transmission mechanism 3 is connected with the movable combined hub mechanism 2, and when the external shape of the movable combined hub mechanism 2 changes, the conversion between the wheel form and the crawler form of the rubber crawler transmission mechanism 3 is realized.

[0040] Specifically, the planetary gear reduction mechanism 1 includes a front planet carrier 101, a rear planet carrier 102, a drive shaft 103, ...

Embodiment 2

[0047] An all-terrain self-adaptive wheel shoe, the structure of which is as described in Embodiment 1, the difference lies in that the telescopic device adopts a cylinder. According to the different requirements of the vehicle, different telescopic devices can be selected to meet the personalized configuration.

Embodiment 3

[0049] An all-terrain self-adaptive wheel shoe, the structure of which is as described in Embodiment 1, the difference lies in that the telescopic device adopts an electric cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com