Embedded type electric bag compound dust remover

An embedded electric bag and dust collector technology, which is applied in the direction of combination device, electrostatic effect separation, chemical instruments and methods, etc., can solve the problems of shortened service life of filter bag, short filter bag cleaning cycle, low space utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

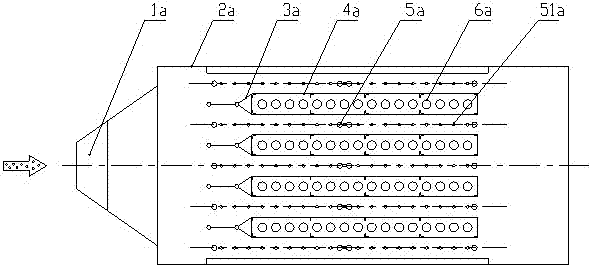

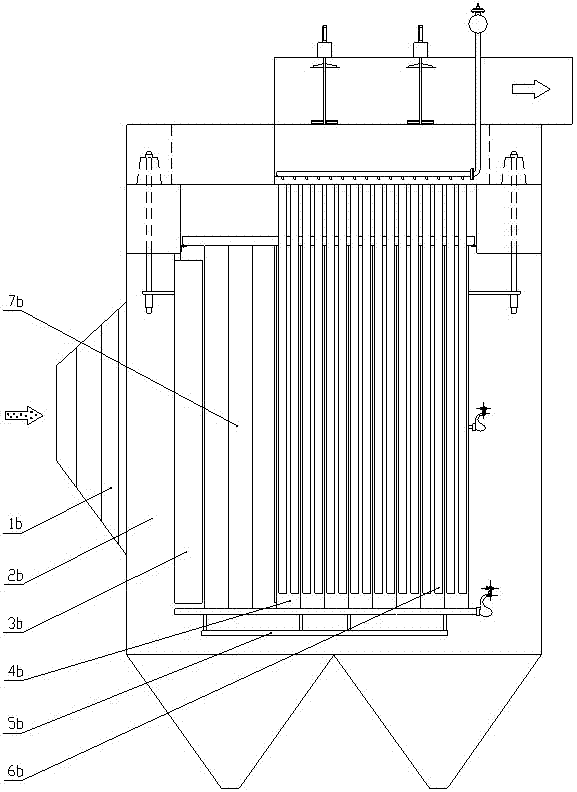

[0042] Such as Figure 4 to Figure 7 As shown, an embedded electric bag composite dust collector provided by the present invention includes a housing 2 and a front-stage electric field dust removal area and an embedded electric bag composite dust removal area that are sequentially arranged in the housing 2 from front to back; The first-stage electric field dust removal area is equipped with a high-frequency high-voltage power supply (not shown), a set of pre-stage dust collector rapping device and a set of pre-stage dust collector rapping device; the pre-stage electric field dust removal area includes 16 The front stage dust collection plate 7 and fifteen pieces are provided with the front stage corona pole frame 8 of the front stage corona wire 81, so that the front stage dust collection plate 7 can collect dust on both sides, thereby significantly reducing the embedded electric current. The dust concentration of the inlet flue gas in the bag composite dust removal area.

[...

no. 2 example

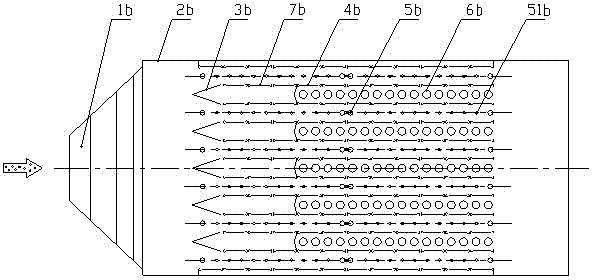

[0058] Further, directly below each row of filter bags 6 in the first embodiment, an auxiliary corona electrode frame 26 with fourteen auxiliary corona wires 261 is provided, so that the lower part of each row of dust collecting orifice plates 4 The two sides are respectively provided with a rear-stage corona pole frame 5 and an auxiliary corona pole frame 26 parallel to each other, so that the bottom of these dust collecting orifice plates 4 can be used for double-sided dust collection, thereby further reducing the For the dust concentration of the inlet flue gas in the filter bag dust removal area, please refer to Figure 8 and Figure 9 and then prolonging the cleaning cycle of the filter bag a little bit can further improve the dust removal efficiency of the dust collector, prolong the service life of the filter bag, save the energy consumption of dust cleaning and reduce the operating cost of the dust collector.

[0059] Such as Figure 8 and Figure 9 As shown, one si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com