Flat plate type dust collector

A dust collector, a flat-plate technology, applied in chemical instruments and methods, solid separation, electrostatic separation, etc., can solve the problems of high filter bag replacement costs, high water consumption, pollution, etc., improve dust removal and purification efficiency, and increase contact area , Accelerate the effect of dust collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment, the present invention is further described:

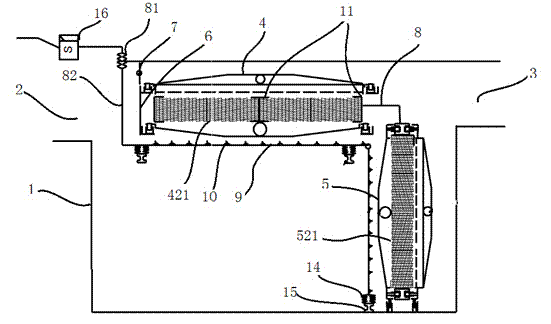

[0030] The present invention discloses a flat type dust collector, such as figure 1 As shown, it includes a casing 1, one end of the casing 1 is an air inlet 2, the other end of the casing 1 is provided with an air outlet 3, and the air inlet 2 and the air outlet 3 are coaxial.

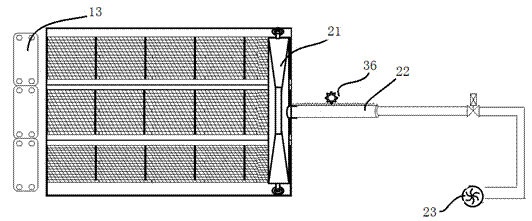

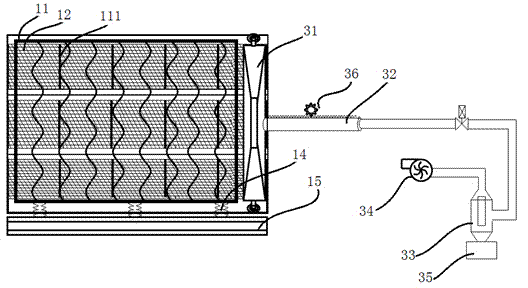

[0031] The housing 1 is provided with main and auxiliary dust collection units that are perpendicular to each other; the auxiliary dust collection unit 4 is arranged horizontally in the housing, and the front end of the auxiliary dust collection unit 4 A bypass baffle 7 is also arranged between the partition 6 and the upper part of the casing 1 . The bypass baffle 7 is provided with a rotating shaft in the middle, and can rotate 90° around the rotating shaft. The rotating shaft is arranged above the auxiliary dust collecting unit 4, and the two ends are respectively fixed on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com