Long-distance pneumatic conveying direct loading-shipping system for bulk materials

A technology for pneumatic conveying and bulk materials, which is applied in the field of mechanical equipment, can solve the problems of flying dust and low efficiency of loading ships, and achieve the effect of ensuring separation efficiency, avoiding a large amount of dust, and reducing secondary dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

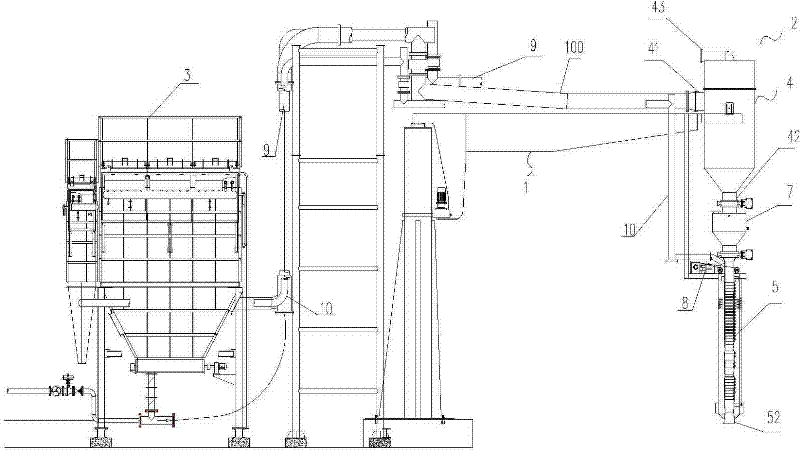

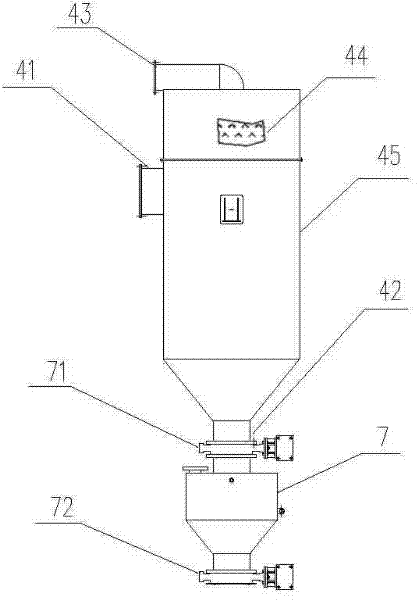

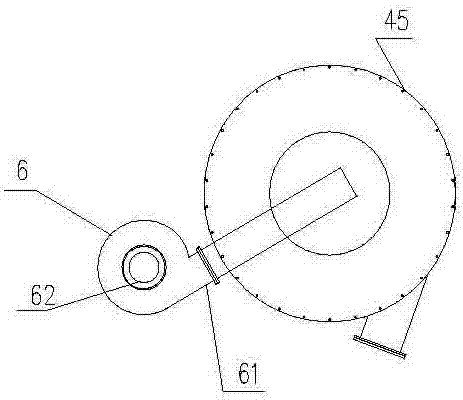

[0038] The applicant used the technology of the present invention to design a long-distance pneumatic conveying direct loading system for fly ash for a power plant in Zhejiang, with a loading distance of 850m, an output of 65t / h, and a conveying gas volume of about 60m 3 / min, due to the long gas transmission distance and the high velocity of the air flow, a large-scale bag filter is installed on the shore in this embodiment, and a fully automatic drive system is used to realize shipment, and a cyclone separator is installed to enhance the dust removal effect, and a ship position tracking system is set Realize precise control. Specifically, the structure is as follows:

[0039] A long-distance pneumatic conveying system for bulk materials directly loaded onto ships, such as figure 1 As shown, it includes a frame 1, fixed on the frame 1, a filling head 2 for filling materials in the vehicle cabin, and a gas mixed with materials discharged from the filling head 2 and The large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com