Super-hydrophobic oleophilic sponge material and preparing method and oil-water separation application thereof

A super-hydrophobic and sponge technology, applied in the direction of liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of poor repeatability, low separation efficiency, low mechanical strength, etc., and achieve cost reduction, low surface energy of sponge, and low price cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

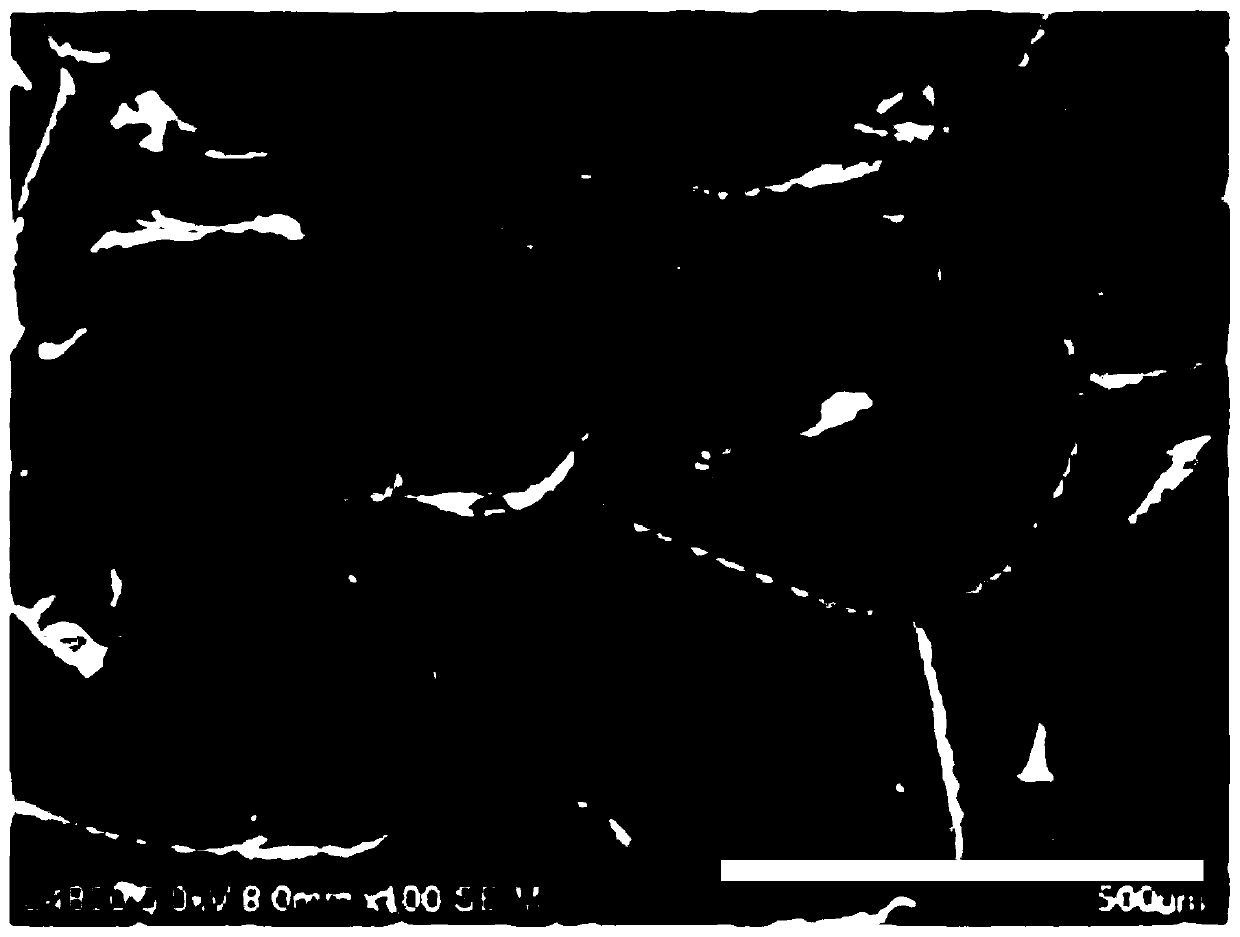

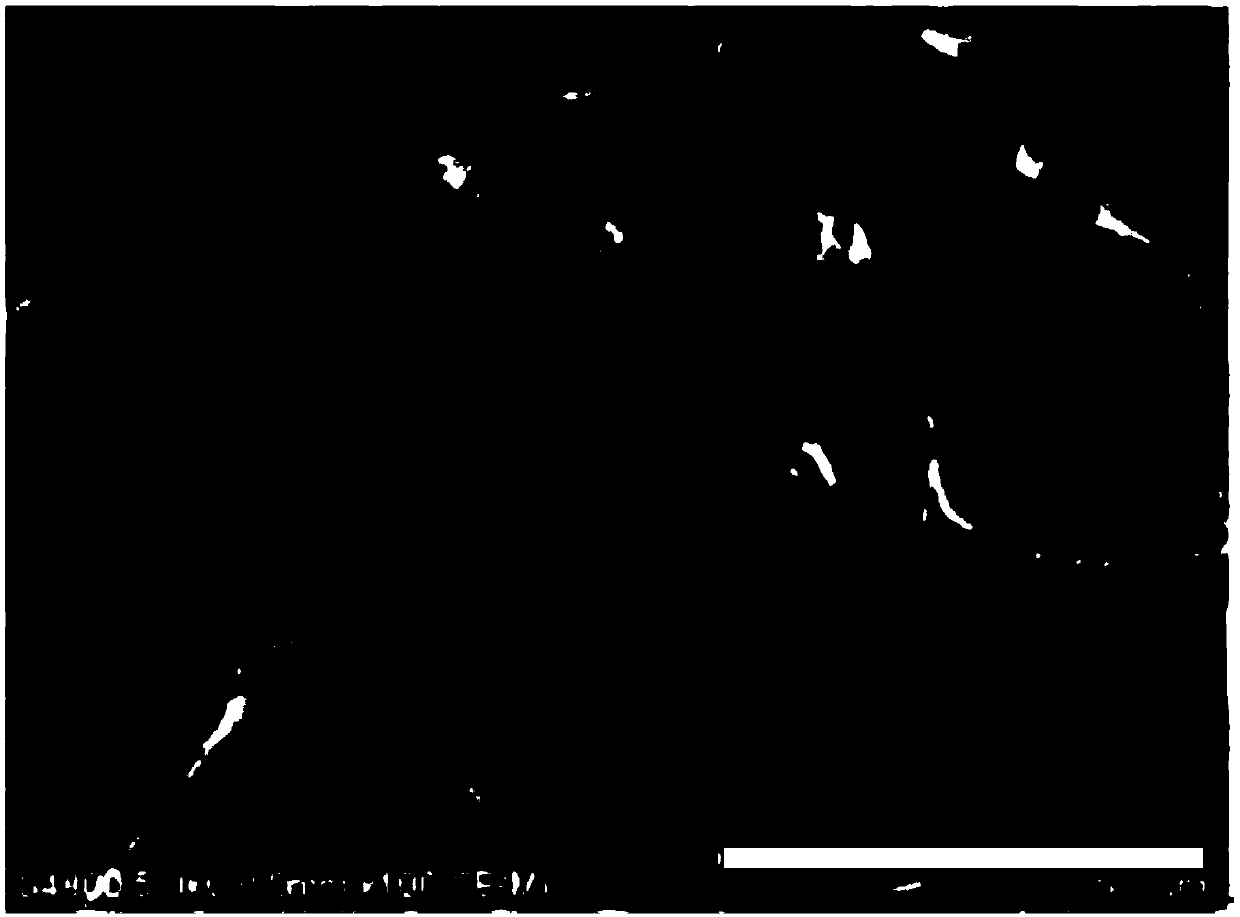

Image

Examples

Embodiment 1

[0049] A preparation method of a superhydrophobic lipophilic sponge material, comprising the steps of:

[0050] (1) Pretreatment of the sponge: 60ppi polyurethane sponges were respectively subjected to ultrasonic vibration cleaning for 0.5h in ethanol and deionized water to remove impurities and obtain pretreated sponges;

[0051] (2) Sponge roughening treatment: soak the pretreated sponge in step (1) in the mixed aqueous solution of chromium trioxide and concentrated sulfuric acid, and carry out surface roughening treatment, wherein, by mass ratio, chromium trioxide: thick The ratio of sulfuric acid is 1:1, the mass concentration of solute in the roughening solution is 50g / L, and the immersion time in the roughening solution is 100s. Take out the sponge, wash it repeatedly with a large amount of deionized water until the filtrate becomes transparent and clear, and dry it in vacuum at 60°C for 24 hours to obtain a sponge containing active groups;

[0052] (3) Hydrophobic modi...

Embodiment 2

[0056] A preparation method of a superhydrophobic lipophilic sponge material, comprising the steps of:

[0057] (1) Pretreatment of the sponge: 100ppi melamine sponges were respectively subjected to ultrasonic shock cleaning in ethanol and deionized water for 2 hours to remove impurities and obtain pretreated sponges;

[0058] (2) Sponge roughening treatment: soak the pretreated sponge in step (1) in the mixed aqueous solution of chromium trioxide and concentrated sulfuric acid, and carry out surface roughening treatment, wherein, by mass ratio, chromium trioxide: thick The ratio of sulfuric acid is 1:1, the mass concentration of solute in the roughening solution is 100g / L, and the soaking time in the roughening solution is 100s. Take out the sponge, wash it repeatedly with a large amount of deionized water until the filtrate becomes transparent and clear, and dry it in vacuum at 70°C for 48 hours to obtain a sponge containing active groups;

[0059] (3) Hydrophobic modificat...

Embodiment 3

[0063] A preparation method and application of a superhydrophobic lipophilic sponge material, comprising the steps of:

[0064] (1) Pretreatment of the sponge: 40ppi polyurethane sponges were respectively subjected to ultrasonic vibration cleaning for 1 hour in ethanol and deionized water to remove impurities and obtain pretreated sponges;

[0065] (2) Sponge roughening treatment: soak the pretreated sponge in step (1) in the mixed aqueous solution of chromium trioxide and concentrated sulfuric acid, and carry out surface roughening treatment, wherein, by mass ratio, chromium trioxide: thick The ratio of sulfuric acid is 1:2, the mass concentration of solute in the roughening solution is 20g / L, and the immersion time in the roughening solution is 60s. Take out the sponge, wash it repeatedly with a large amount of deionized water until the filtrate becomes transparent and clear, and dry it in vacuum at 70°C for 24 hours to obtain a sponge containing active groups;

[0066] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnification | aaaaa | aaaaa |

| Magnification | aaaaa | aaaaa |

| Magnification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com