Preparation method of novel anodic oxidation aluminium template and nano array

A technology of anodizing aluminum oxide and aluminum oxide template, which is applied in the field of electrochemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

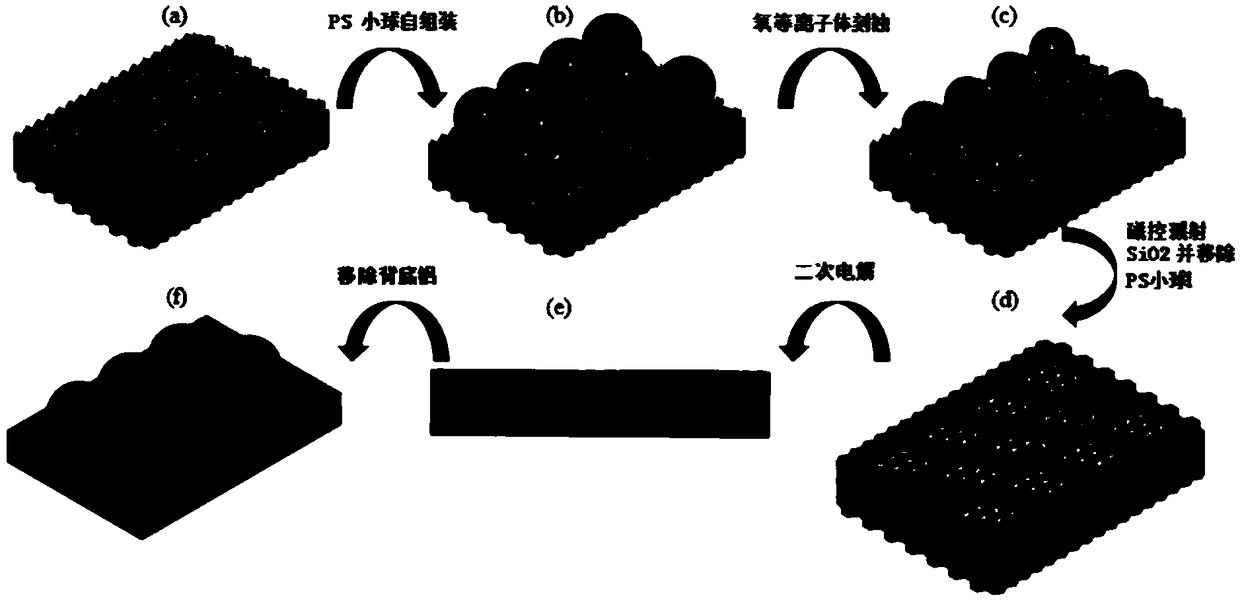

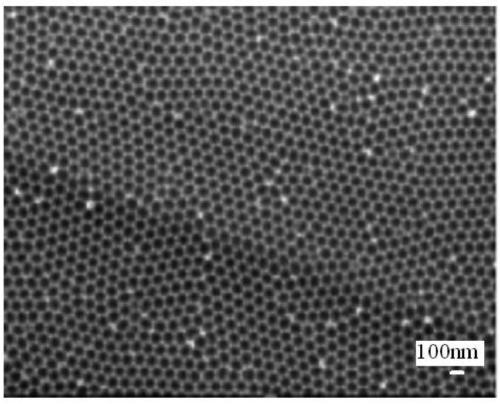

[0030] The preparation method of the anodized aluminum template provided by the present invention includes: performing an electrolytic treatment on the polished aluminum sheet; removing the aluminum oxide layer produced by the first electrolysis; preparing polystyrene pellets on the surface of the aluminum substrate; etching the polystyrene Ethylene pellets; deposit a silicon dioxide film on the etched aluminum substrate to remove polystyrene pellets; perform secondary electrolytic treatment on the aluminum substrate to obtain an alumina template, and perform hole expansion on the alumina template.

[0031] 1. Perform an electrolytic treatment on the polished aluminum sheet:

[0032] The selected polished aluminum sheet is mechanically polished and chemically polished in advance, and then subjected to constant voltage DC electrolysis, the electrolyte is 0.3M oxalic acid solution, the working electrode is polished aluminum sheet, the counter electrode is platinum sheet, and the ...

Embodiment 1

[0063] 1. Perform an electrolytic treatment on the polished aluminum sheet:

[0064] The selected polished aluminum sheet is mechanically polished and chemically polished in advance, and then subjected to constant voltage DC electrolysis, the electrolyte is 0.3M oxalic acid solution, the working electrode is polished aluminum sheet, the counter electrode is platinum sheet, and the electrolyte is The temperature was controlled at 7°C, the voltage was 40V, and the electrolysis time was 7h. After electrolysis, the template was rinsed with deionized water to remove residual oxalic acid on the surface, and then dried with a nitrogen gas gun. At this time, a 10 micron thick aluminum oxide layer will be formed on the surface of the polished aluminum sheet.

[0065] 2. Remove the primary oxide layer produced by primary electrolysis:

[0066] The template was immersed in a mixed acid of 6wt% chromic acid and 1.8wt% phosphoric acid at a temperature of 60°C for 8 hours to obtain an alu...

Embodiment 2

[0078] Steps 1-3 are the same as in Example 1.

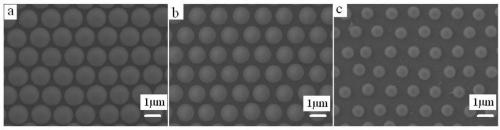

[0079] 4. Etching polystyrene pellets:

[0080] When using an oxygen plasma cleaner to process polystyrene pellets, the experimental conditions are: the power is 40W, the frequency is 20khz, and the oxygen flow rate is 2sccm. It takes 90 min to etch the polystyrene sphere to 1.3 μm. image 3 b is the SEM image of the polystyrene ball etched to 1.3 μm.

[0081] 5. Inversion of the hexagonal arrangement structure:

[0082] A 250nm silicon dioxide film was magnetron sputtered on the etched template at an experimental speed of 0.5A / s. The polystyrene balls were then glued off with scotch tape, and finally a layer of silicon dioxide film with a hexagonal microporous structure was deposited on the surface of the aluminum substrate.

[0083] 6. Perform secondary electrolytic treatment on the template:

[0084] The aluminum substrate deposited with porous silica arrays was subjected to secondary constant voltage direct current elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Channel diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com