Preparation method of high-temperature-resistant high-humidity-resistant binder for packaging

A packaging and adhesive technology, applied in the directions of non-polymer adhesive additives, adhesives, adhesive types, etc., can solve the problem that the high temperature and high humidity performance cannot meet the application requirements of retort food packaging, and the curing temperature of the adhesive High temperature and poor flexibility, etc., to achieve the effect of maintaining heat resistance, increasing high temperature and high humidity resistance, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

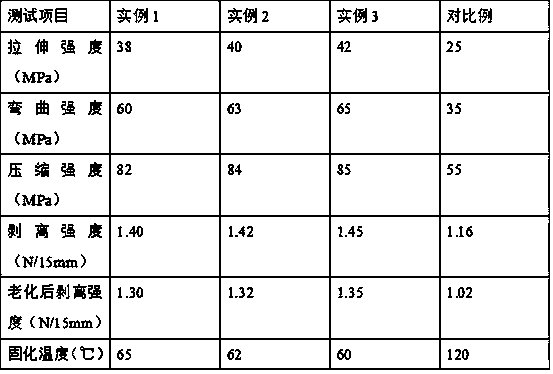

Examples

example 1

[0027]In a four-necked flask with a stirrer and a reflux condenser, add 50 mL of soybean oil, 10 mL of formic acid, 20 mL of hydrogen peroxide with a mass fraction of 20% and 30 mL of a sulfuric acid solution with a mass fraction of 75%, start the stirrer, and set the temperature at 200r / min Stir at a constant speed, heat up to 90°C, and keep warm for 2.0 hours to obtain a reaction product. Move the reaction product into a separatory funnel, wash with water until the washing liquid is neutral, discard the water phase, and obtain epoxidized soybean oil, which is set aside; take 80g Asbestos fiber and 220g mass fraction are that 3% acetic acid solution is put in the there-necked flask, leave standstill 10min, then add 20g maleic anhydride in the there-necked flask, and the three-necked flask is placed in the water-bath pot, control water-bath temperature to be 70 ℃, with Stir at a speed of 200r / min for 30min; after stirring, add N,N-dimethylformamide and epoxidized soybean oil in...

example 2

[0029] In a four-necked flask with a stirrer and a reflux condenser, add 55 mL of soybean oil, 11 mL of formic acid, 22 mL of hydrogen peroxide with a mass fraction of 20% and 35 mL of a sulfuric acid solution with a mass fraction of 75%, and start the stirrer at 210r / min Stir at a constant speed, heat up to 92°C, and keep warm for 2.2 hours to obtain a reaction product. Move the reaction product into a separatory funnel, wash with water until the washing liquid is neutral, discard the water phase, and obtain epoxidized soybean oil for later use; take 85g Asbestos fiber and 235g mass fraction are that 3% acetic acid solution is put into there-necked flask, leave standstill 12min, then add 22g maleic anhydride in there-necked flask, and three-necked flask is placed in water-bath, control water-bath temperature to be 75 ℃, with Stir at a speed of 250r / min for 32min; after stirring, add N,N-dimethylformamide and epoxidized soybean oil into the above-mentioned three-necked flask ac...

example 3

[0031] In a four-necked flask with a stirrer and a reflux condenser, add 60 mL of soybean oil, 12 mL of formic acid, 25 mL of hydrogen peroxide with a mass fraction of 20% and 40 mL of a sulfuric acid solution with a mass fraction of 75%, start the stirrer, and set the temperature at 220r / min Stir at a constant speed, heat up to 95°C, and keep the temperature for 2.5 hours to obtain a reaction product. Move the reaction product into a separatory funnel, wash with water until the washing liquid is neutral, discard the water phase, and obtain epoxidized soybean oil, which is set aside; take 90g Asbestos fiber and 250g mass fraction are that 3% acetic acid solution is put into the there-necked flask, leave standstill 15min, then add 25g maleic anhydride in the there-necked flask, and the three-necked flask is placed in the water-bath pot, control water-bath temperature to be 80 ℃, with Stir at a speed of 300r / min for 35min; after stirring, add N,N-dimethylformamide and epoxidized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com